Fonrich FR-DCMG-MMPS User manual

User Manual

Version 1.1

DC System Monitor:FR-DCMG-MMPS

丰郅(上海)新能源科技有限公司

Fonrich (Shanghai) New Energy Technology Co., Ltd.

Add: 1st Floor, Building 5, No.999 Jiangyue Road, Minhang District,Shanghai

Web: www.fonrich.com

Tel: +86 21 61679671

Email: sales@fonrich.com

1

Table of Contents

Documentation statement....................................................................................................................................1

Product description...........................................................................................................................................2

The main function.......................................................................................................................................2

Optional module..........................................................................................................................................3

Terminal description ...................................................................................................................................4

(Optional) PLC expansion module terminal description..............................................................................5

Ground connection and RS485 communication shielded wire....................................................................6

Wiring diagram of monitoring module.............................................................................................................7

(Optional)PLC system network wiring diagram ..............................................................................................8

System diagram..........................................................................................................................................8

Network diagram.........................................................................................................................................9

Networking diagram of the gateway in the inverter.....................................................................................9

Networking diagram of the gateway in the junction box..............................................................................9

PLC wiring in combiner box and inverter..................................................................................................10

UI introduction .................................................................................................................................................11

Key operation ...........................................................................................................................................11

Boot interface ...........................................................................................................................................11

Current interface.......................................................................................................................................11

PLC status interface .................................................................................................................................12

Initial interface display ..............................................................................................................................12

Detailed data interface of channel current and power generation.............................................................12

Parameter settings....................................................................................................................................13

Trip self-test setting interface....................................................................................................................14

Current calibration setting interface..........................................................................................................15

System information display interface........................................................................................................15

Alarm status display interface...................................................................................................................16

DC arc fault alarm interface......................................................................................................................16

Fault alarm clear interface........................................................................................................................16

Alarm information management.....................................................................................................................17

Items that can generate alarms can be set...............................................................................................17

Items that can be tripped by setting..........................................................................................................17

Alarm conditions.......................................................................................................................................17

Alarm message.........................................................................................................................................18

Arc Alarm Strategy....................................................................................................................................18

MODBUS Protocol definition ..........................................................................................................................19

2

Communication format configuration ..............................................................................................19

Data frame format description (refer to Modbus RTU standard)......................................................19

Function code description...............................................................................................................19

Register description........................................................................................................................20

Register description in bit units (function code 02)..........................................................................20

Register description in word unit (function code 03 04 06)..............................................................30

PLC register: ....................................................................................................................................................37

Function code 03......................................................................................................................................37

Function code 06......................................................................................................................................42

The data of PLC node 1 is as follows, the data of other nodes are similar: .............................................43

Appendix ..........................................................................................................................................................45

FAQ..........................................................................................................................................................45

Document revision record.........................................................................................................................46

Contact us ................................................................................................................................................46

1

Documentation statement

This manual is applicable to the products with the models of FR-DCMG-MMPS. The software version

is the monitoring module of version A088 and above; this document also contains the description of

the optional product PLC.

2

Product description

FR-DCMG DC monitor products are mainly used in DC power transmission and distribution, such as

photovoltaic combiner boxes, DC cabinets, telecommunications equipment rooms and

communication base stations. It communicates with host computer through RS485 or power line

carrier(PLC). Its main function is to monitor the current of each branch in the DC system, the bus

voltage, the temperature of the cabinet, the status of the lightning arrester and the status of the DC

breaker. It can realize automatic alarm for abnormal conditions and real-time detection of the

presence of harmful arcs in the DC circuit. Once there is a harmful arc, it will immediately send an

alarm signal to directly drive the trip unit and cut off the faulty circuit, thereby effectively preventing

safety risks such as fire caused by arc.

The main function

•

Monitoring function: Real-time monitoring of the generation current, voltage, temperature of

the combiner box, lightning arrester status, DC circuit breaker status, and DC arc fault status

of each photovoltaic string in the combiner box, and communicate with the host computer

through RS485 or PLC.

•

Display content: For the detected voltage, current, temperature, switching state, power

generation and other data, the FR-DCMG-MMPS can display a histogram interface through

the LCD to read the current and other data more intuitively.

•

Alarm function: It can be configured to open or close the alarm and shunt release functions

according to the actual needs of the site (by default, only the arc alarm and trip functions are

enabled). When an alarm occurs, an alarm message will pop up on the interface.

•

Current calibration: identify zero drift and improve the accuracy of current identification.

(Default off)

•

Trip mode switching: The default o +, o- voltage is 0v, and the voltage output is 24v when

tripped. It can also be set to the opposite application.

•

Power line carrier communication module: through the power line carrier expansion module

DC-DCMG-PLCx, to achieve communication of up to 24 nodes

•

Compatibility:Program compatible model FR-DCMG-MMPD products

3

Optional module

Type

Model

Description

Optional: expansion

module

(PLC communication)

FR-DCMG-PLCD

power line carrier(PLC) expansion module for

1000V and below systems, needs to be used

with FR-DCMG-MMPL

FR-DCMG-PLCU

For 1500V and below systems

4

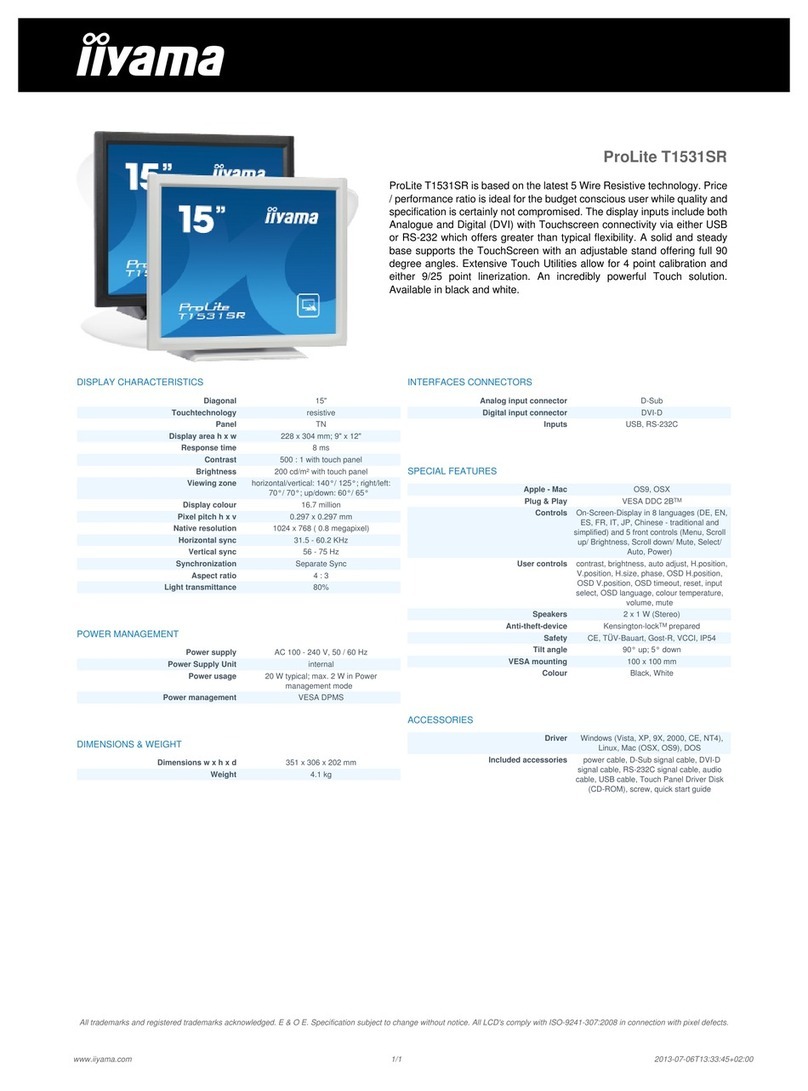

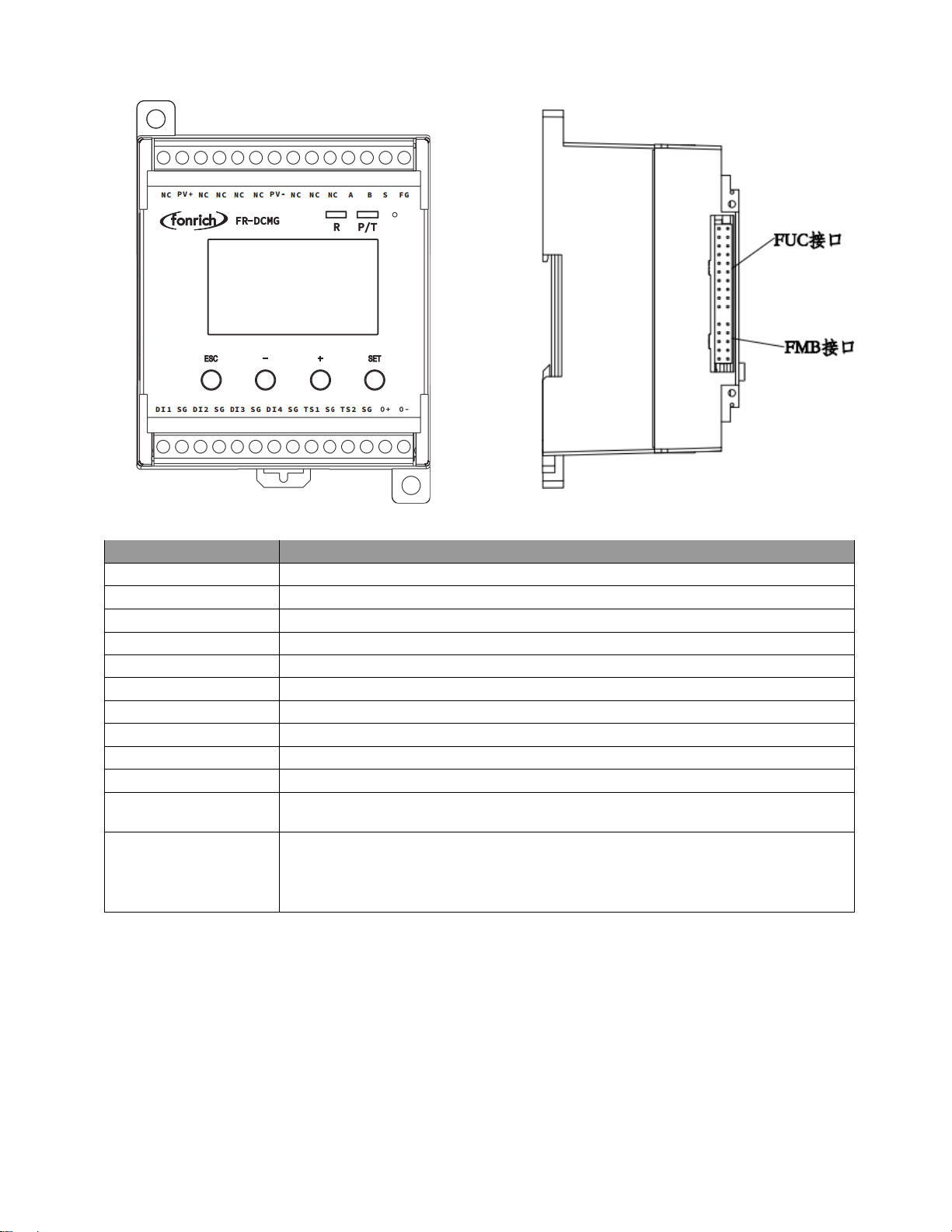

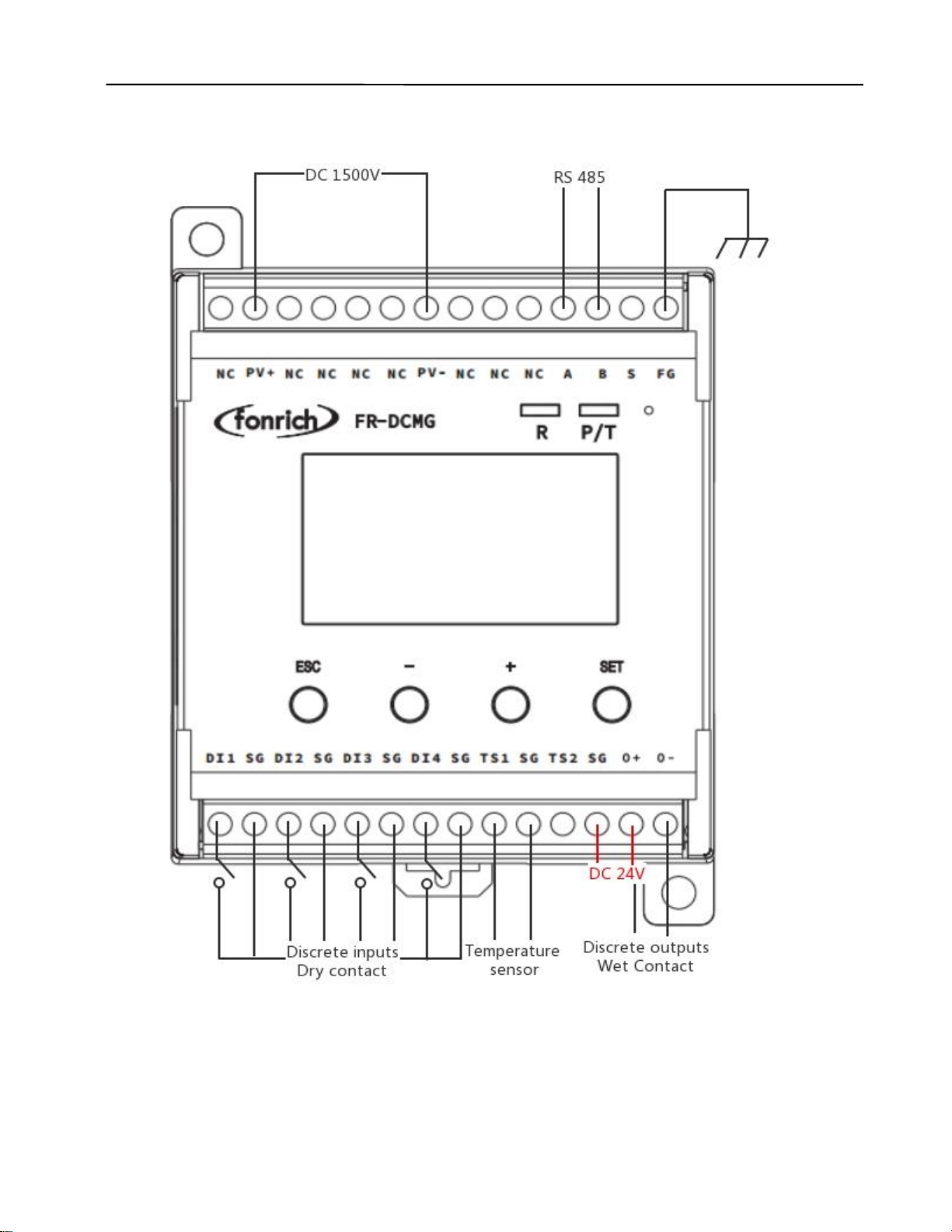

Terminal Definition

Symbol

Meaning

PV+ . PV-

PV DC bus power supply terminal

NC

Not connecion

S

Not connecion

A.B

RS485 Communication terminal

FG

Fixed Ground terminal

TS1.TS2

Externally connected temperature sensor terminals

SG

Temperature sensor and digital input ground terminal

DI1.DI2.DI3.DI4

4 digital input terminals

0+.0-

Connecting the shunt release

FUC

Can connect modules with FUC interface

FMB

Modules with an FMB interface can be connected, such as the FR-

DCMG-AS4A DC Arc Detector.

O+、SG

DC 24V power supply terminal, bidirectional power supply, external

output current maximum 100mA, but it is not recommended to use the

module for external power supply, which will affect the internal

temperature rise of the module

5

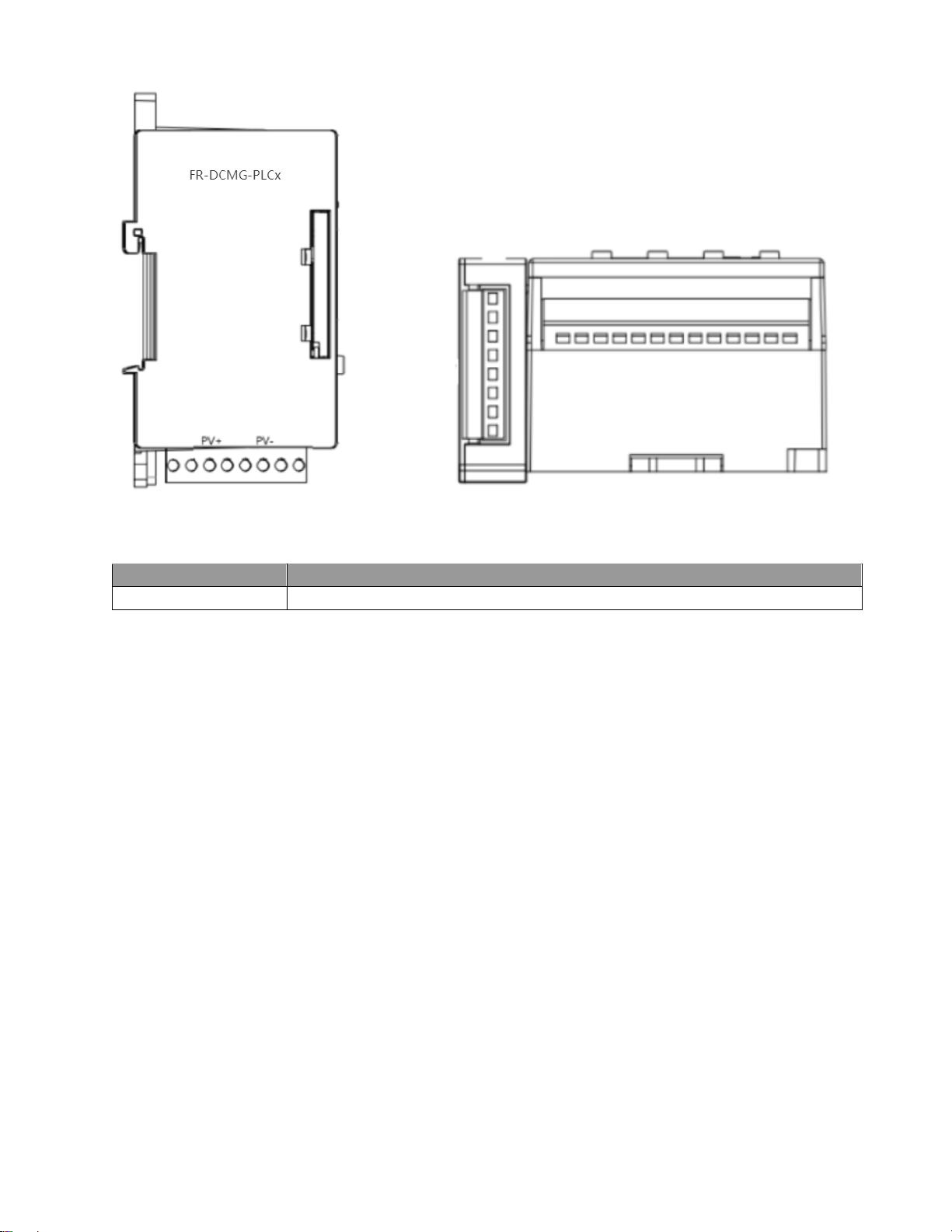

(Optional) PLC expansion module terminal description

Symbol

Meaning

PLCx PV+ . PV-

PLCx expansion module DC power terminal

6

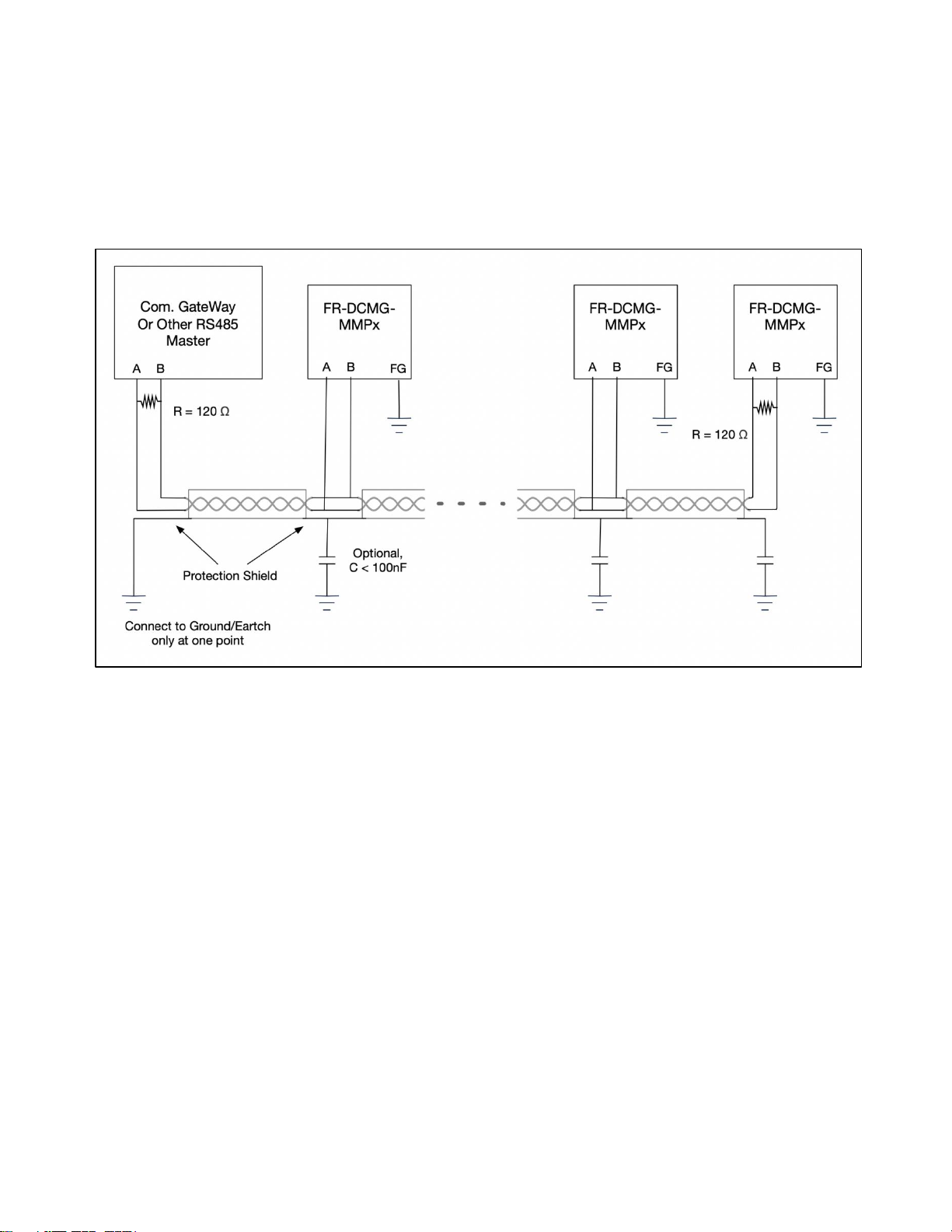

Ground connection and RS485 communication shielded wire

The FG terminal of the FR-DCMG must be grounded, otherwise communication will interfere and the

reliability of the device will decrease. The grounding wire should be grounded nearby. The grounding

wire should be no more than 15cm from the “FG” terminal to the bottom of the combiner box. It is

recommended to be within 10cm. The shorter the better, the thicker the better. The bottom of the

combiner box should be connected to the ground. The main control unit module is fixed on a

standard guide rail with a width of 3.5 cm.

The wiring specifications of the communication shielded wire are shown in the figure above:

The wiring of on-site communication lines requires that the communication shield can only be

grounded at a single point, otherwise there will be a risk of lightning surge damage to all equipment

on the entire communication line during a lightning strike;

If you encounter a situation where communication line interference is too large to communicate, you

can refer to the figure above, and insert a high voltage capacitor C <100nF between the shielded

wire of each combiner box and the ground wire, and use this capacitor to filter the shielding layer

interference.

7

Wiring diagram of monitoring module

8

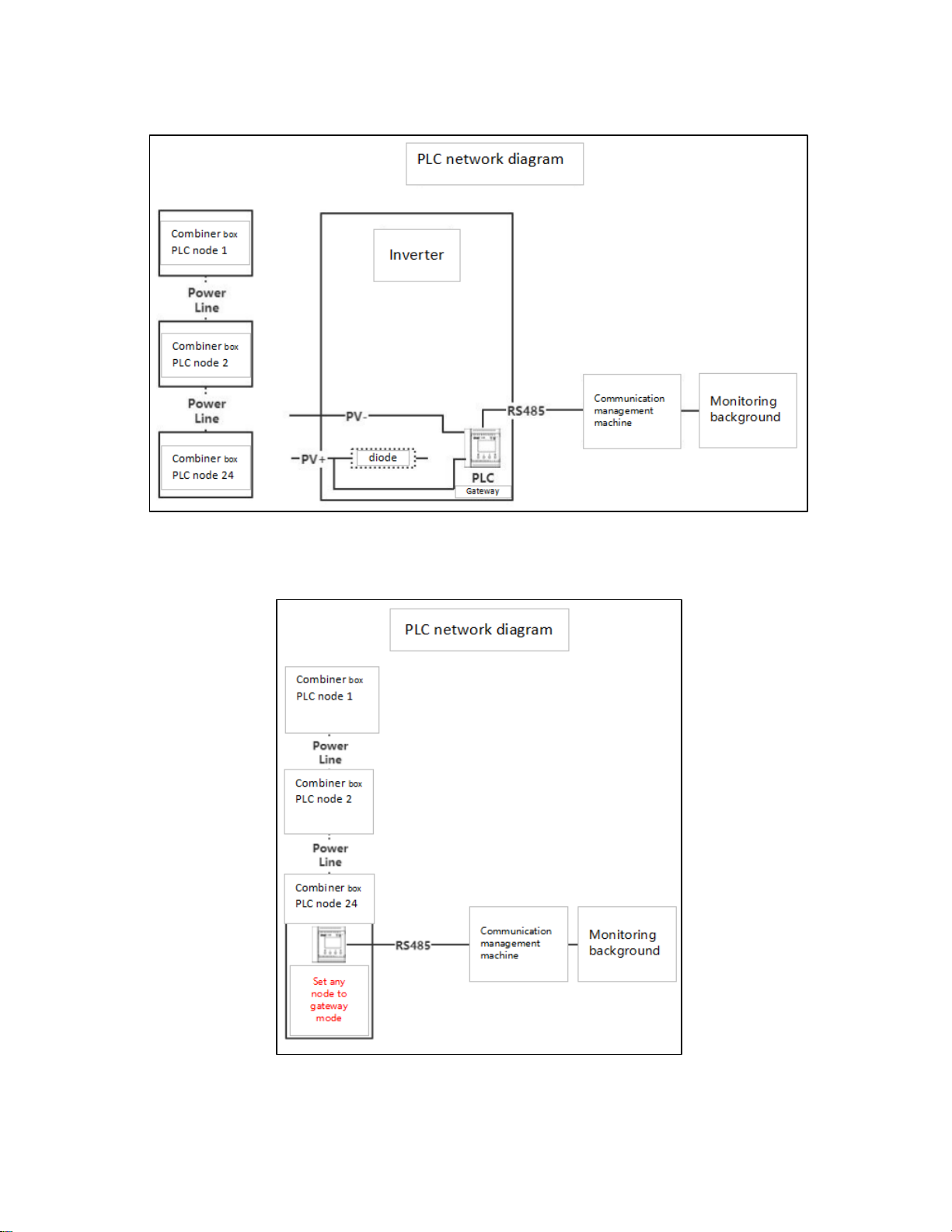

(Optional)PLC system network wiring diagram

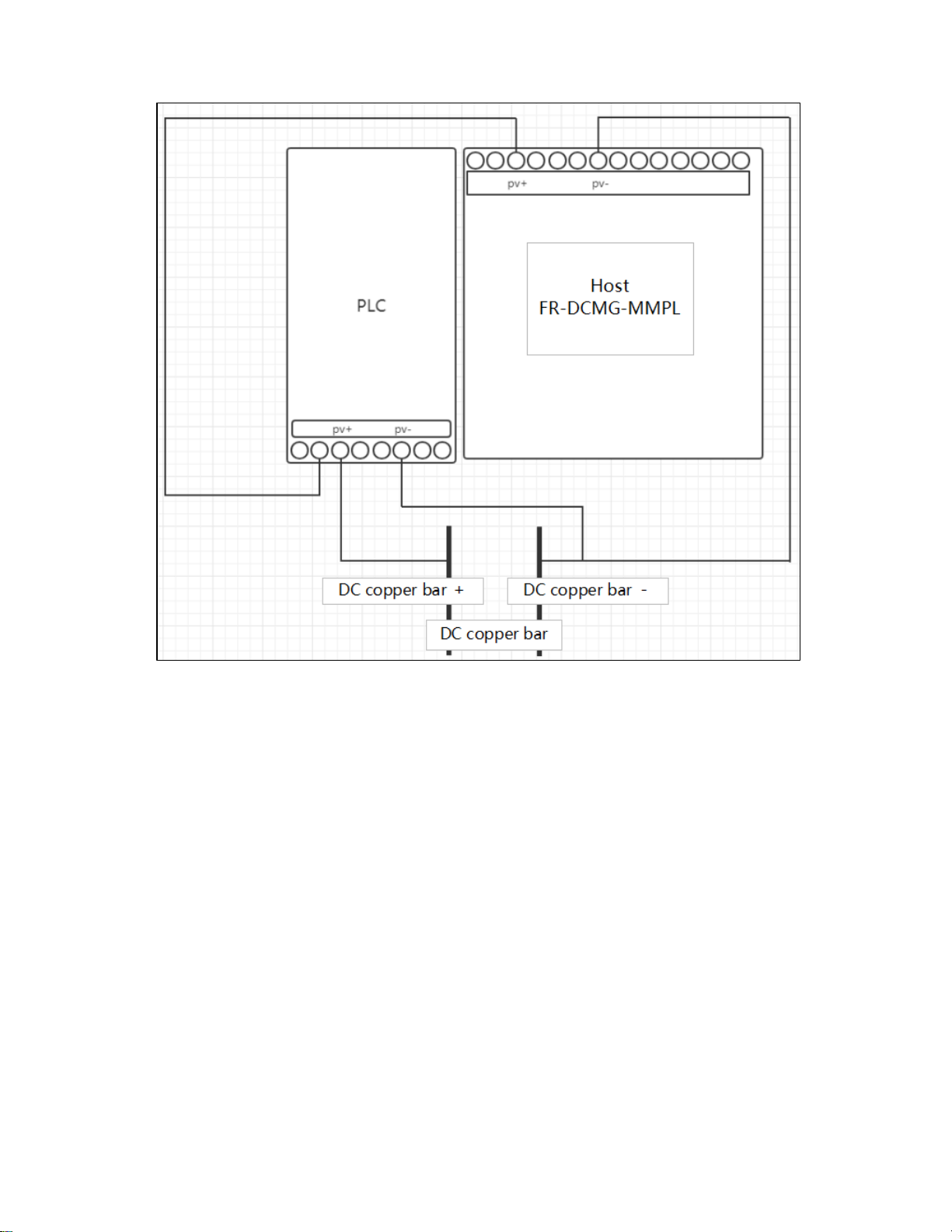

System diagram

9

Network diagram

Networking diagram of the gateway in the inverter

Networking diagram of the gateway in the junction box

10

PLC wiring in combiner box and inverter

11

UI introduction

Key operation

FR-DCMG-MMPS has four keys “ESC”, “-”, “+”, and “SET”.

"ESC" key is used to return to the default interface and cancel parameter setting and View PLC

status;

“SET”key is used to enter the parameter setting mode, select the parameter to be set and complete

the setting of the parameter;

The "+" and "-" keys are used to scroll the screen and adjust parameters;

Press the "+" and "-" keys at the same time to display the software version interface;

Press the "ESC" and "-" keys simultaneously to display the current calibration interface;

Press the “ESC” and “+” keys simultaneously to display the trip self-test interface;

If there is no key operation for 10 seconds, the interface will automatically jump to the default

interface of the current mode, and the brightness will decrease after 5 seconds.

Boot interface

After the device is powered on, the following interface will be displayed:

Current interface

After the boot interface, the histogram interface will be displayed, as shown below:

①It indicates that the connected Hall has the arc detection function, and the ordinary Hall does not

have this mark;

②The number of online current channels varies according to the number of Halls actually connected;

③Switch input status: DI1, DI2, DI3, DI4 real-time status;

④Real-time temperature;

⑤Real-time voltage;

12

⑥Current histogram; the default display range is -2A ~ 10A, and the display range can be expanded

by setting register 0x0B16;

⑦Histogram partition: because 6 Halls are inserted, 6 partitions

PLC status interface

In the histogram interface, without the PLC expansion module connected, press the ESC key to

display the following interface:

With the PLC expansion module connected, press the ESC key to display the following interface:

Node mode Gate mode

•

SNR is the signal-to-noise ratio of the current PLC line

•

SEND xxx is the number of data packets that have been sent by the current node

•

The figure on the right shows the PLC status information of the node, the rows and columns

of the table, for example

•

The fifth in row 1 shows the node with address 5

•

The first display in row 2 is the node with address 9

•

The second in row 3 shows the node with address 18

•

PLC supports a maximum of 24 nodes, and the address range of these 24 nodes is 1 ~ 24.

•

The communication quality is represented by numbers 0-9 (for example: the data of the node

with address 5 in the above figure can be received, and the communication quality is the best

9)

Initial interface display

The factory default is Modbus mode. When the host computer is connected to the device via RS485

and communicates, the LED lights “R” and “P / T” will flash alternately to indicate normal

communication. When the device is not connected to communication, it restarts by default every 5

minutes, or you can turn off the default restart function, which can be turned off through the 0xF003

register.

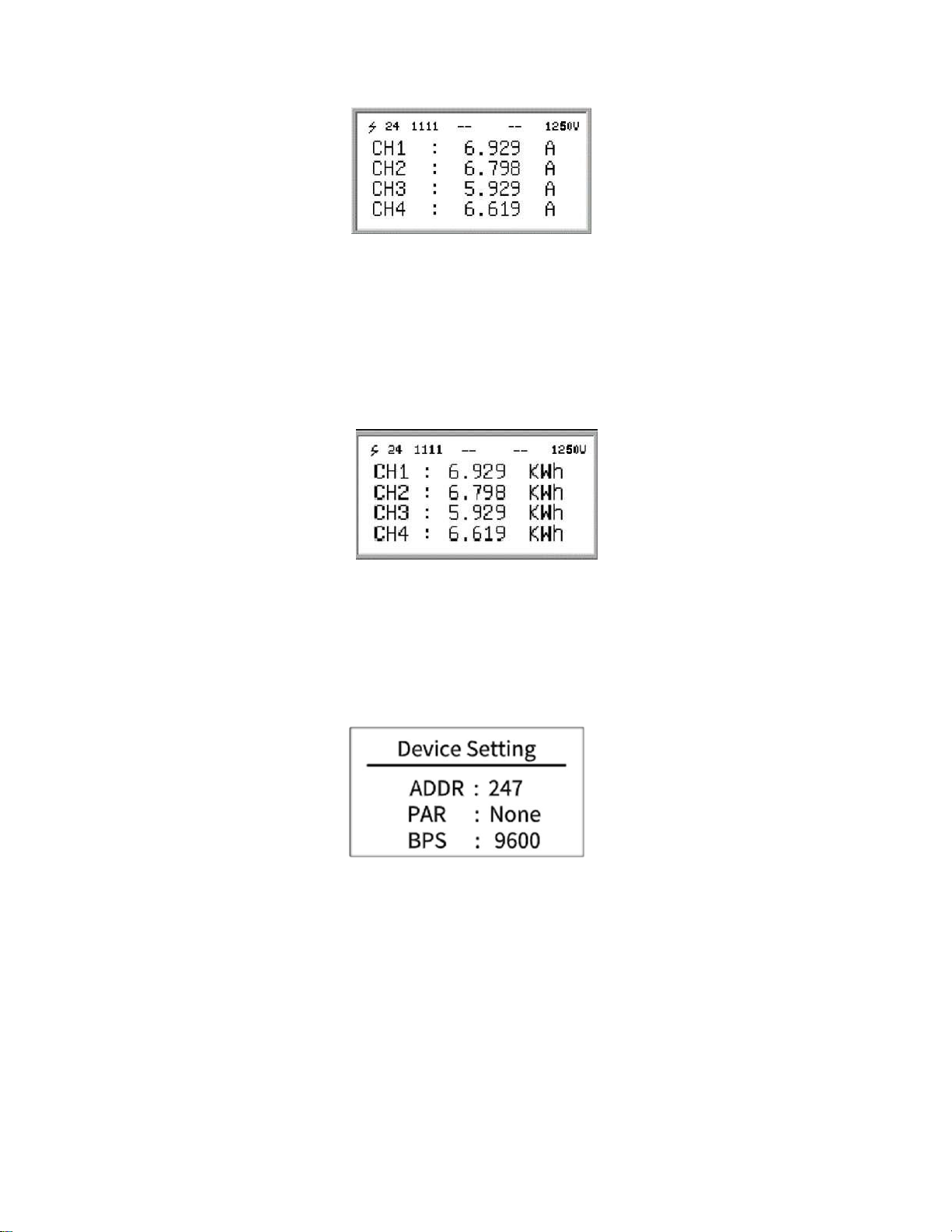

Detailed data interface of channel current and power generation

Under the current interface, press the "+" or "-" key to enter the channel current and power

generation display interface. The current value and cumulative power generation of each channel are

displayed on the screen. When the "+" key is pressed first, the digital value of the current is displayed

13

first, and when the "-" is pressed first, the digital value of the current is displayed first

The value of cumulative power generation. When viewing the values of current and cumulative power

generation, you can scroll through the screen by continuing to press the "+" or "-" key. After the

current display is completed, continue to press the "+" key to start displaying the cumulative power

generation. The figure above shows the current display interface. “CH1:” in the figure indicates that

the current value monitored by channel 1 in real time is “6.929A”, and so on.

The figure below shows the cumulative power generation display interface. "CH1:" in the figure

indicates that the cumulative power generation of channel 1 is "6.929kwh", and so on.

Parameter settings

Press the "SET" key to enter the Modbus parameter setting interface. The

Modbus parameter setting is as shown in the figure below:

•

ADDR: The communication address of the Modbus slave node, the range is 1 ~ 247 (default

is 247).

•

PAR: The data verification method of Modbus communication. The optional parity (None),

odd parity (Odd), even parity (Even), and no parity by default.

•

BPS: Baud rate for Modbus communication. The selectable baud rates are 2400, 4800, 9600

(default), 19200, 38400.

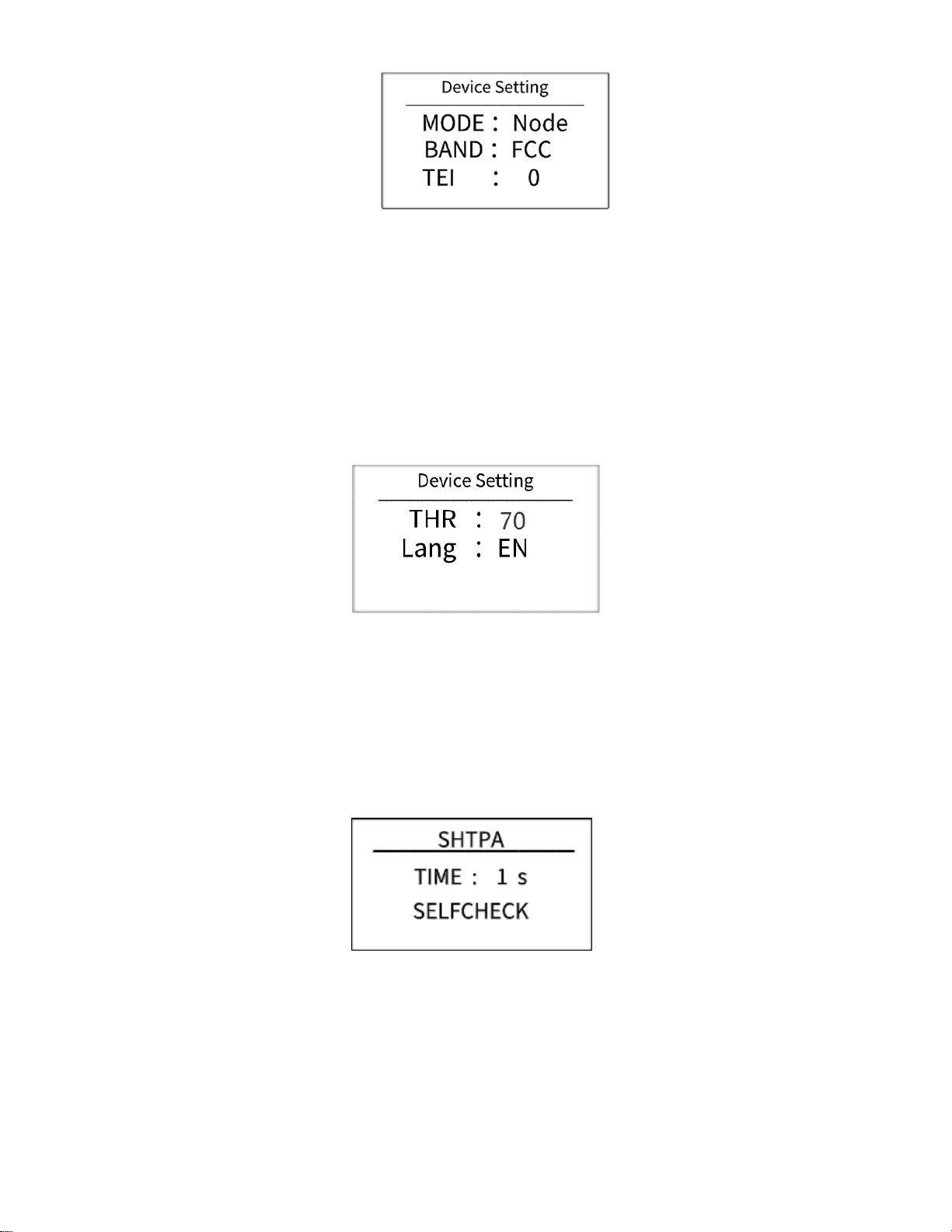

Press the "+" key to select down to the second page of the setting

interface

14

•

MODE: PLC mode (Gate gateway, Node node, node address and Modbus address are the

same, setting range 1-24)

•

BAND: PLC frequency band (currently only supports FCC, please consult technical staff for

other options)

•

TEI: PLC's network identification (the TEI under the same network must be consistent,

otherwise it cannot communicate, the setting range is 0-99)

Press the "+" key to continue the selection down to the third page of the

setting interface:

•

THR:Arc alarm threshold (default: 70)

•

LANG:language settings(default: EN)

Trip self-test setting interface

Press the “ESC” and “+” keys at the same time to enter the shunt trip setting interface.

(Factory default)Release mode (o ±DC voltage is 0v), the interface is as follows:

(Special needs)Relay mode (o ±DC voltage is 24v), the interface is as follows:

15

In the shunt trip setting interface, you can set the enable time (TIME) and trip self-check

(SELFCHECK) of the shunt trip during the arc alarm.

When "*" flashes in the TIME line, press the "SET" key and then press ±to modify the shunt release

time.

When "*" flashes on the SELFCHECK line, press the "SET" key, and the self-check of the shunt

release will be performed automatically.

The specific behavior is that when the time is reached, the shunt release operates, and after the

enabling time has passed, the shunt release is restored.

Current calibration setting interface

Press the "ESC" and "-" keys at the same time to enter the current calibration setting interface, as

shown below:

Note:To use this feature, please contact the company's technical support staff.

System information display interface

In the histogram interface, press the "+" and "-" keys at the same time to enter the software version

number display interface, as shown below:

•

HV:Keep

•

SV:Software version number

•

ST:Keep

16

Alarm status display interface

Alarm messages can be cleared remotely and manually. Manual clearing requires long-pressing the

host's "ESC" key for 2 seconds, remote clearing requires writing "1" to register 0x0079 to clear. If an

arc trip alarm occurs, it must be cleared manually or remotely. Restarting the host will still display the

alarm message.

DC arc fault alarm interface

After the DC arc sensor detects the occurrence of a fault arc, the alarm information interface of the

host is as shown below.

In the figure above: "02" means channel arc fault alarm, and "4" means that the fault arc alarm

channel is 4.

Fault alarm clear interface

The host sends an alarm when it detects a fault, and the user can choose to handle it locally or

remotely. By long-pressing the "ESC" key for about 5 seconds locally, the system jumps out of the

interface as shown below, indicating that the alarm status has been cleared; remote processing

needs to write "1" to 0x0079 to clear, and the interface shown below will be displayed after clearing

successfully.

17

Alarm information management

Items that can generate alarms can be set

Channel arc

Voltage is too high

Voltage is too low

Temperature is too high

Channel reverse current

Total reverse current is too high

Total current is too high

Total current is too low

Channel without current

Low channel current

High channel current

Channel current value undercurrent

Channel current value overcurrent

Lightning Arrester Status (DI1)

circuit breaker status (DI2)

Switch DI3 status

Switch DI4 status

Items that can be tripped by setting

Channel arc

Voltage is too high

Temperature is too high

Channel reverse current

Total reverse current is too high

Total current is too high

Channel without current

Low channel current

High channel current

Channel current value undercurrent

Channel current value overcurrent

Lightning Arrester Status (DI1)

Circuit breaker status (DI2)

Monitor DI3 status

Monitor DI4 status

Alarm conditions

1.

Current reverse, no current, under current, over current, low current, high current, etc.

a. Only when the average value of the channel current is greater than the set

alarm threshold of the current channel, the alarm function of the above current-

related items is activated; otherwise, the alarm status is forcibly cleared to 0.

b. As for whether the alarm needs to be separately met the respective alarm conditions

(above or below the respective alarm threshold).Alarm message

c. Check if the corresponding alarm register is open, closed by default

Other manuals for FR-DCMG-MMPS

1

Table of contents

Other Fonrich Monitor manuals