FoodLogistik SHREDDR-classic 140 User manual

05/09/23 ShreddR®- classic 140

OPERATION AND MAINTENANCE MANUAL

This Operation and Maintenance Manual is valid for the following machine:

Manufacturer: FOODLOGISTIK

Fleischereimaschinen GmbH

Warliner Str. 8

17034 Neubrandenburg

PF 400 115

17022 Neubrandenburg

Germany

Phone: 0395/ 77 99 0

Telefax: 0395/ 77 99 220

Internet: www.foodlogistik.de

Version date: January 2023

All rights reserved. No part of this document may be reproduced in any form (print, photocopy,

microfilm, or other procedures) or stored in an electronic retrieval system, reproduced, and / or

distributed without the prior written consent of the manufacturer.

We reserve the rights to make changes, due to technical advancement and further

development, of the machine as described in this manual.

Printed in Germany

© FOODLOGISTIK Fleischereimaschinen GmbH 2010

- classic 140

ShreddR®- classic 140 05/09/23

05/09/23 ShreddR®- classic 140 II

To the customer,

This is the operation and maintenance user guide for the ShreddR - classic 140. This

guide includes instructions for safe and successful operation of this ShreddR - classic

140. Attention to the specific guidelines in this manual will help extend the life

expectancy of this machine, eliminate the need for unnecessary repairs and reduce

the risk of potential on site hazards.

The general safety and accident prevention regulations from all local and

professional associations must be abided by at all times. It is essential to comply with

all safety requirements before bringing the machine into operation. This machine may

only be used in accordance to the regulations specified in this document. To ensure

proper handling, only qualified personnel may operate this ShreddR - classic 140.

When ShreddR - classic 140 requires maintenance, only original manufacturer parts

will uphold the warranty guarantee. Foodlogistik reserves the right to cancel the

warranty policy when negligent and or improperly executed repairs are made.

Foodlogistik assumes no liability for damages and or operational errors due to failure

to comply with all stated guidelines set forth in this Instruction Manual.

Any and all technical and safety work place regulations must be in compliance prior

to operation along with:

-accident prevention regulations expressed in this manual,

-operating regulations valid in the country of operation.

Should you need further assistance regarding this machine, please contact our

Table of contents Page

REGISTER OF ILLUSTRATIONS ..............................................................................4

REGISTER OF TABLES.............................................................................................5

1SAFETY........................................................................................................2

1.1 SYMBOLS AND MEANINGS .................................................................................2

1.2 SAFETY REGULATIONS .....................................................................................3

1.2.1 General safety regulations..................................................................................................... 3

1.2.2 Safety regulations for maintenance and repairs .................................................................... 4

1.2.3 Safety regulations for operation of ShreddR - classic 140 .................................................... 4

2TECHNICAL DATA ......................................................................................5

2.1 GENERAL PARAMETERS....................................................................................5

2.2 ELECTRICAL PARAMETERS................................................................................7

3MACHINE DESCRIPTION............................................................................8

05/09/23 ShreddR®- classic 140 2

3.1 RANGE OF APPLICATIONS .................................................................................8

3.2 MACHINE ASSEMBLY ........................................................................................8

3.2.1 Machine overview .................................................................................................................. 8

3.2.2 Cutting tools and accessories.............................................................................................. 10

3.2.2.1 Cutting set ............................................................................................................................................................10

3.2.3 Construction of electrical components................................................................................. 12

4DELIVERY, INSTALLATION AND SET UP ...............................................13

4.1 TRANSPORT..................................................................................................13

4.2 INSTALLATION................................................................................................13

4.3 SET-UP.........................................................................................................13

5OPERATIONS ............................................................................................14

5.1 OPERATING THE MACHINE ..............................................................................14

5.1.1 Overview of the control knobs.............................................................................................. 14

5.1.2 Daily safety checks .............................................................................................................. 15

5.1.2.1 Preparations.........................................................................................................................................................15

5.1.2.2 Functions tests......................................................................................................................................................16

5.1.3 Avoidance of operating-errors for machine protection......................................................... 16

5.1.4 General operational sequence............................................................................................. 17

5.2 DEACTIVATING ..............................................................................................18

5.2.1 Switching Off the machine................................................................................................... 18

5.2.2 Emergency shut off.............................................................................................................. 18

5.2.3 Taking out of operation ........................................................................................................ 18

6CLEANING AND SANITIZING ...................................................................19

6.1 GENERAL RULES............................................................................................19

6.2 DAILY CLEANING............................................................................................19

6.2.1 Removal of the cutting set and functioning parts................................................................. 19

6.2.2 Cleaning and sanitizing........................................................................................................ 24

6.2.3 Fitting of the cutting set and functioning parts according to cleaning.................................. 27

7MAINTENANCE AND INSPECTIONS........................................................29

7.1 GENERAL GUIDELINES....................................................................................29

7.2 INSPECTIONS-AND MAINTENANCE PLAN...........................................................29

7.3 GRINDING THE KNIVES....................................................................................30

7.4 MAINTENANCE OF THE ELECTRICAL EQUIPMENT................................................30

7.5 SYSTEM MALFUNCTIONS ................................................................................31

7.5.1 General Guidelines .............................................................................................................. 31

7.5.2 Troubleshooting ................................................................................................................... 32

REGISTER OF ILLUSTRATIONS

05/09/23 ShreddR®- classic 140 3

8FINAL DECOMMISSIONING AND DISPOSAL..........................................33

05/09/23 ShreddR®- classic 140 4

REGISTER OF ILLUSTRATIONS Page

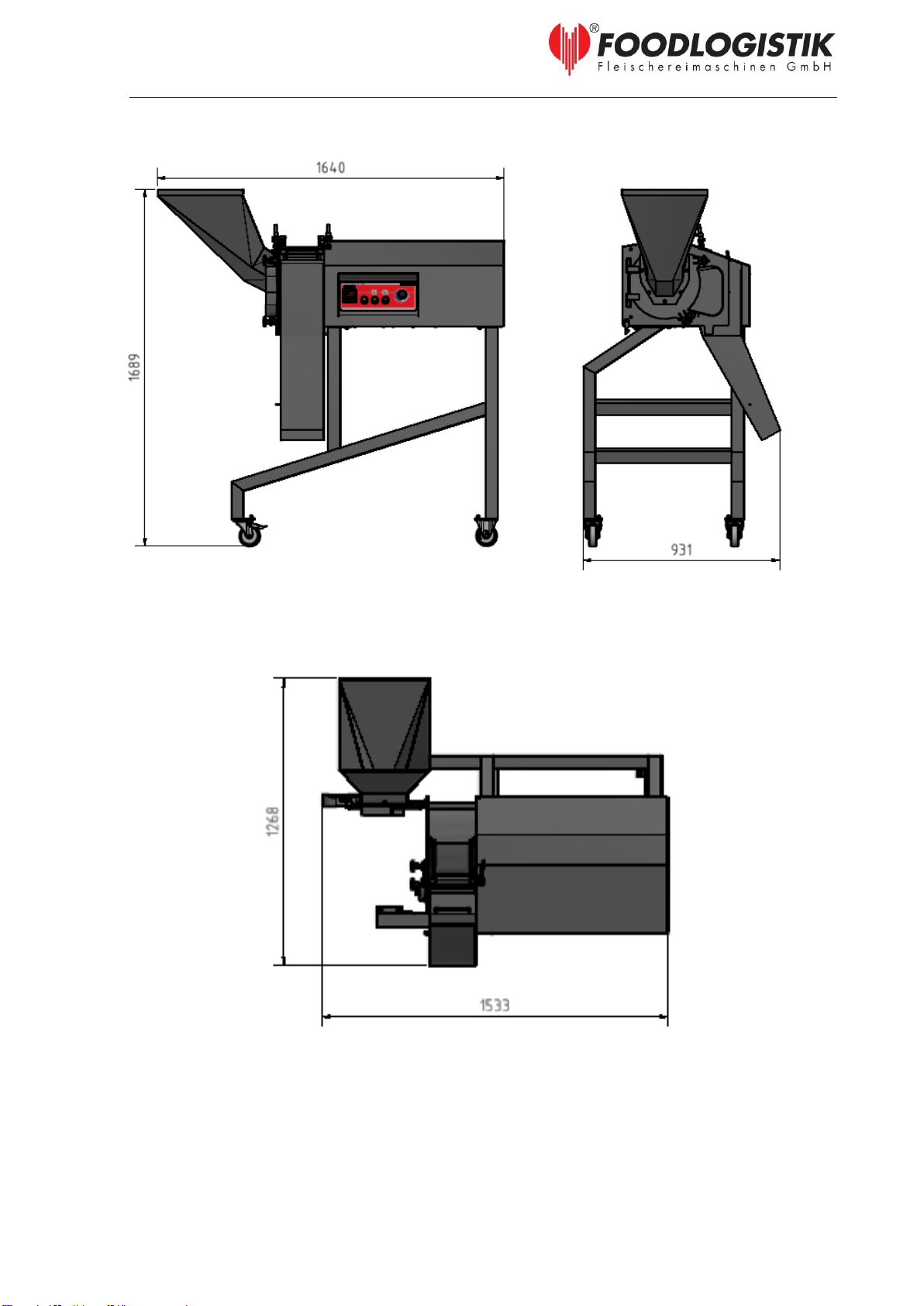

Illustration 1: Machine dimensions ..............................................................................6

Illustration 2: Space requirement of the machine ........................................................6

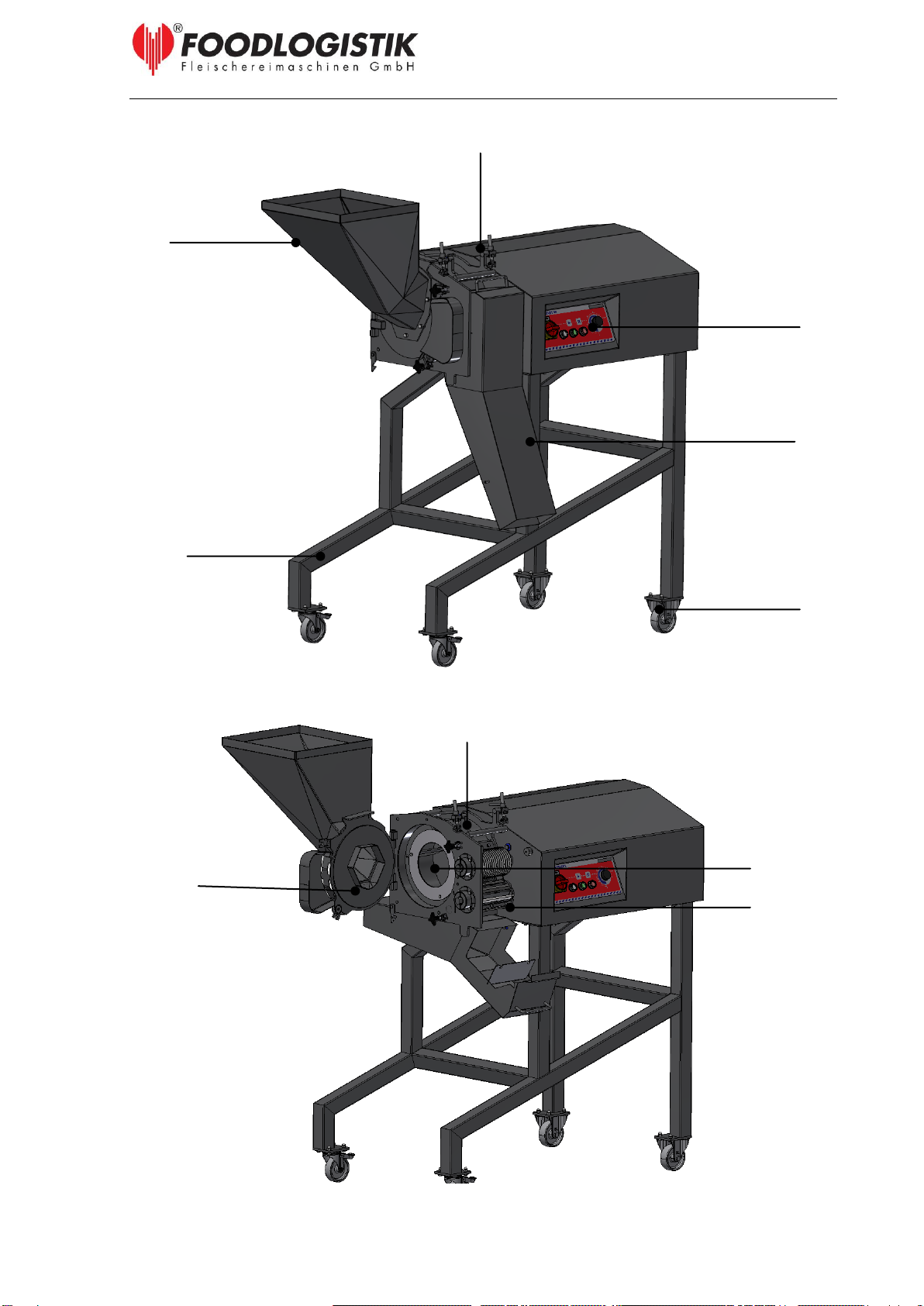

Illustration 3: Machine overview (1).............................................................................9

Illustration 4: Machine overview (2).............................................................................9

Illustration 5: Cutting set 10x10x10 mm ....................................................................10

Illustration 6: Machine safety switch..........................................................................12

Illustration 7: Control knobs.......................................................................................14

Illustration 8: Open the cutting area...........................................................................20

Illustration 9: Removal of the cutting sets..................................................................20

Illustration 10: Removal of the cutting drum ..............................................................21

Illustration 11: Removal of the scraper......................................................................21

Illustration 12: Removal of the infeed drum and the bearing bush.............................22

Illustration 13: Removal of the separating knife assembly.........................................23

Illustration 14: The separating knife assembly...........................................................23

Illustration 15: The cutting area.................................................................................27

REGISTER OF TABLES

05/09/23 ShreddR®- classic 140 5

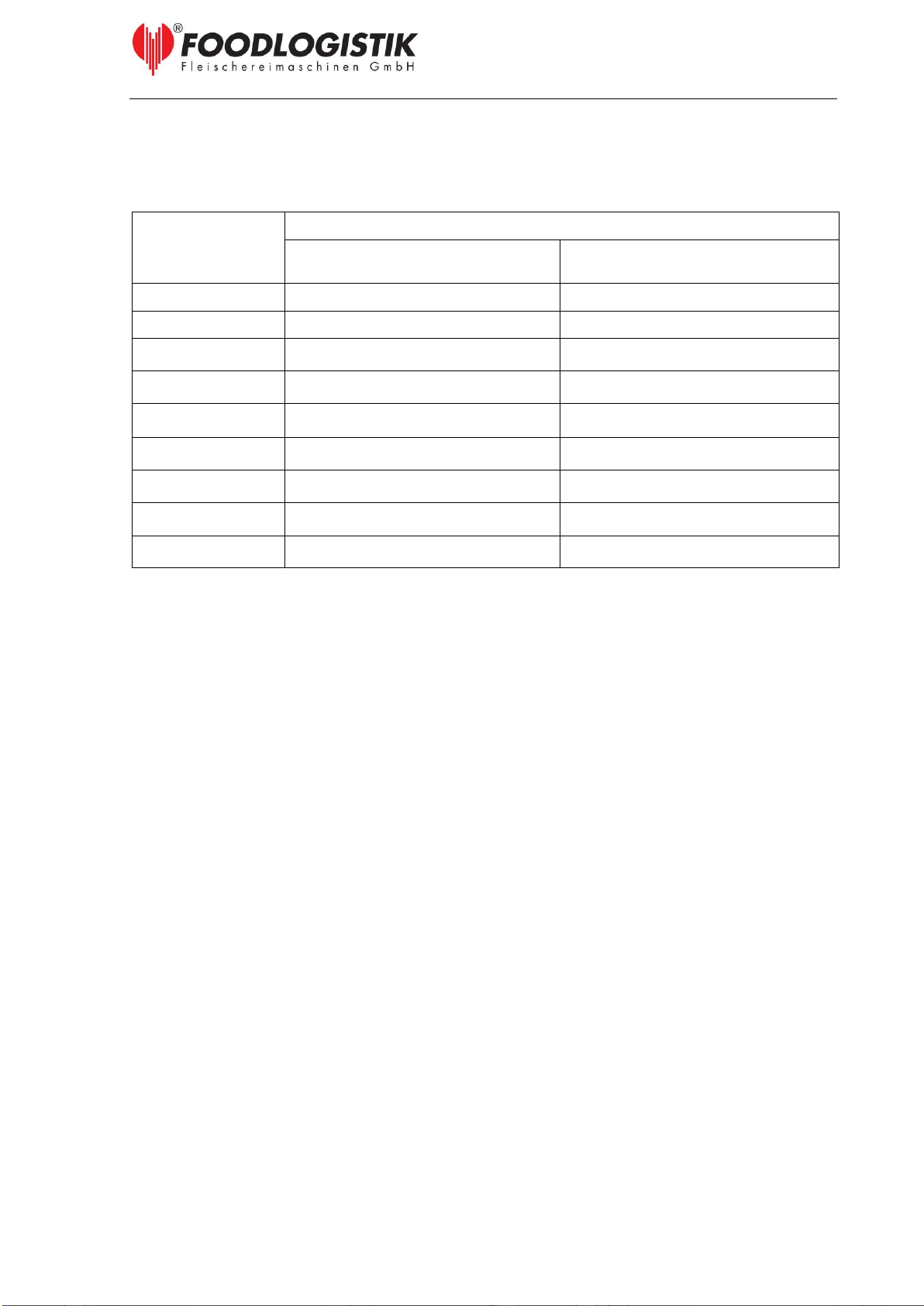

REGISTER OF TABLES Page

Table 1: General parameters.......................................................................................5

Table 2: Electrical parameters.....................................................................................7

Table 3: Cutting set sizes..........................................................................................11

Table 4: Control knobs..............................................................................................15

Table 5: Functions test..............................................................................................16

Table 6: General work flow........................................................................................17

Table 7: Cleaning plan ..............................................................................................25

Table 8: Inspections- and maintenance plan.............................................................29

SAFETY

05/09/23 ShreddR®- classic 140 2

1 SAFETY

1.1Symbols and meanings

a) Work place safety symbol:

This symbol indicates a warning to personal safety, and or risk

to bodily injury. When this symbol appears follow all

instructions and inform others of any safety guidelines given.

b) Attention:

ATTENTION

This is a system malfunction indication and denotes that

general maintenance may be required. When this symbol

appears refer to instruction and operation guidelines to ensure

that all operating procedures have been properly followed to

reduce the risk of repairs.

c) Information:

This symbol denotes information relating to the economic use of

the ShreddR - classic 140 or technical requirements that the user

must take into special account.

SAFETY

05/09/23 ShreddR®- classic 140 3

1.2Safety regulations

1.2.1 General safety regulations

The ShreddR - classic 140 is operationally compliant and in accordance with the

requirements set forth in the guidelines of the Council of the European Community

for Machinery (2006/42/EG), along with the current German accident prevention

regulations (UVV/VBG).

Incorrect usage of the ShreddR - classic 140 causes dangers. All users of the

ShreddR - classic 140 must strictly adhere to all technical safety instructions and

regulations established in this manual when installing, and operating this machine.

The following German legislation regulations relating to employee and general work

place safety and or their national equivalents, need to be taken into consideration:

- EN 60204-1:2019-06: Safety of machinery –Electrical equipment of machines -

Part 1: General requirement

- EN 50110-1:2014-02: Operation of electrical installations –

Part 1: General requirements;

- 89/391/EEC - Safety and health of workers - Employer-s duty to ensure the safety

and health of workers in all aspects related to work - Employer-s liability

- 2009/104/EC concerning the minimum safety and health requirements for the use of

work equipment by workers at work

- 2014/35/EC relating to electrical equipment designed for use within certain voltage

limits (Low Voltage Directive)

- guidelines of the respective countries of usage

The safety guidelines set forth in this user manual are universally compliant and

should be followed in order to maintain employee safety, eliminate work place injuries

and be in compliance with the environmental protection agency regulations. All

authorized employees must pass regular inspections and attend monthly training to

maintain compliance to operate this machine.

Only authorized employees may operate the ShreddR - classic 140 and must wear

all required safety gear when operating, maintaining or cleaning this machine.

SAFETY

05/09/23 ShreddR®- classic 140 4

1.2.2 Safety regulations for maintenance and repairs

Changes should never be made to any of the protective equipment/installations when

cleaning or carrying out maintenance. During maintenance and repairs of the

ShreddR - classic 140 the power supply and machine must be in the off position. At

all times authorized workers making repairs or maintaining this machine must wear

the proper safety gear (gloves, goggles, rubber-soled shoes). There may be no

alterations to the machines pre-installed safety features. Any pieces removed from

the machine need to be re-installed and tested to ensure proper working order before

the machine may be re-instated to normal working conditions.

This machine should be in proper working order at all times. Any malfunctions need

to be noted and reported to the appropriate managers. Only trained and authorized

mechanics and technicians (electricians and hydraulic specialists) may service and or

repair any part of this machine. Before making repairs ensure that the dicer is in the

off position, meaning the main switch is off and in the locked position. While making

repairs, at no time may any alterations to the machines pre-installed safety features

be made unless otherwise consented by the machine manufacturer.

After any and all servicing and or repairs, trial runs and safety tests must be made to

ensure proper working order of all machine systems and safety features, before it

may return to the work floor (see 5.1.2).

1.2.3 Safety regulations for operation of ShreddR - classic 140

Before the work day begins, the ShreddR - classic 140 must pass inspection of its

safety systems.

At no times are employees allowed to climb into or on the machine by any means.

While the machine is in operation do not stand in the vicinity or under the loading

arm.

Do not place hands, fingers or arms inside the hopper or under the machine door into

the cutting area, while the machine is running.

While the machine is operating it needs to remain under constant supervision to

ensure that any malfunctions that arise are immediately reported and fixed.

In case of an emergency, shut the machine off by pressing the emergency stop

button on the control panel.

TECHNICAL DATA

05/09/23 ShreddR®- classic 140 5

2 TECHNICAL DATA

2.1General parameters

Table 1: General parameters

Parameter

ShreddR - classic 140

Performance Rate (contingent upon

application, cutting size, usage of infeed

drum and operating staff)

10mm x 10mm cubes, 2000 kg/h

Length [mm] (Illustration 1)

1640

Width [mm] (Illustration 1)

931

Height [mm] (Illustration 1)

1689

Space Requirement [m²] (Illustration 2)

2,5

Weight [kg]

300

Width of drum [mm]

140

Diameter of drum [mm]

320

Diameter fill opening [mm]

144

Equivalent sound pressure level

80 dB (A)

Employees Needed

1 Person

Construction Method

corrosion resistant stainless steel

construction and aluminum

Goods to be processed

vegetables, fruits

(–3° C to + 60° C, 27° F to + 140° F)

Cutting sizes

3 to 20 mm

Power Sources

electric

Storehouse: Relative Humidity

max. 93 % at 25° C, 77° F

Operating Conditions: Temperature

+5° C to +25° C , 41° F to 77° F

TECHNICAL DATA

05/09/23 ShreddR®- classic 140 6

Illustration 1: Machine dimensions

Illustration 2: Space requirement of the machine

TECHNICAL DATA

05/09/23 ShreddR®- classic 140 7

2.2 Electrical parameters

Table 2: Electrical parameters

Electrical parameters

1PE / 230 V / 50 Hz

Connected load

1,8 kW

Rated current

10 A

Fuse current

16 A

Type of current

PE

Operating frequency

50 Hz

Operating voltage

230 V

Control voltage

24 V DC

Simultaneousness factor

0,9

Operating mode

Permanent operation

Protective system

IPX 5

Ambient temperature

+5 °C to +25 °C

MACHINE DESCRIPTION

05/09/23 ShreddR®- classic 140 8

3 MACHINE DESCRIPTION

3.1Range of applications

The featured application of this dicer is its ability to cut food. The ShreddR - classic

140 has the ability to cut cubes, stripes or slices from vegetable and fruit products.

Use of this machine in ways other than intended is restricted

and at the risk of the user. The manufacturer is not liable for

any damages incurred due to improper use and or neglect.

3.2Machine assembly

3.2.1 Machine overview

The machine overview is pictorially displayed through illustrations and diagrams. The

ShreddR - classic 140 consists of (view Illustration 3 and Illustration 4):

01 –Frame

02 –Control panel

03 –Product outfeed

04 –Adjustment of cutting-size

05 –Hopper

06 –Upper cover for cutting-area

07 –Cutting area with cutting tools

08 –Cutting-area door

09 –Feet

10 –Infeed drum

MACHINE DESCRIPTION

05/09/23 ShreddR®- classic 140 9

Illustration 3: Machine overview (1)

Illustration 4: Machine overview (2)

05

09

07

03

08

10

06

04

02

01

MACHINE DESCRIPTION

05/09/23 ShreddR®- classic 140 10

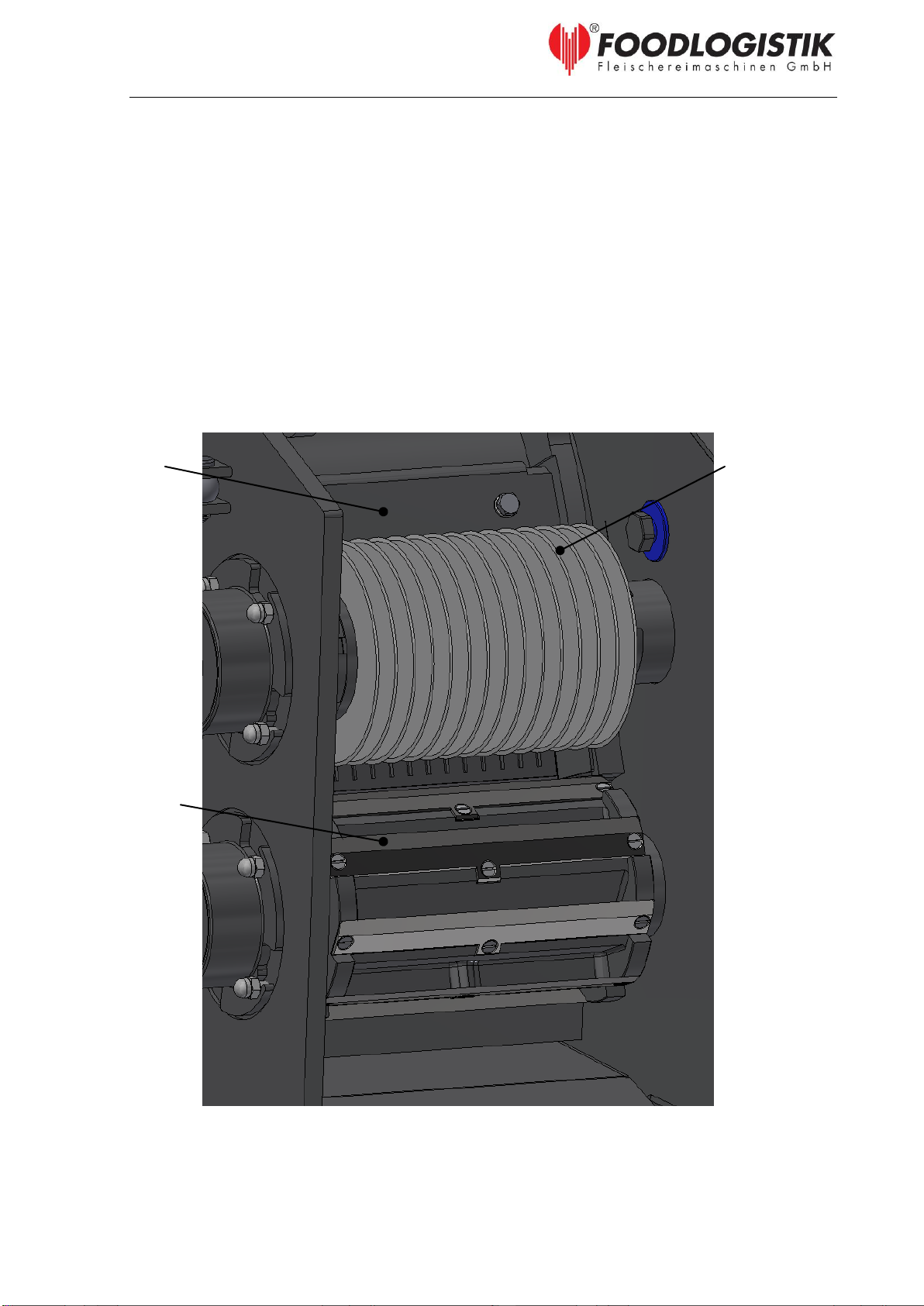

Upper cutting

drum with circular

knives

Lower cutting

drum with cross

cutting knives

Scraper

3.2.2 Cutting tools and accessories

3.2.2.1 Cutting set

The ShreddR - classic 140 can be equipped with optional cutting sets. The cutting set

is depicted in

Illustration 5.

Illustration 5: Cutting set 10x10x10 mm

MACHINE DESCRIPTION

05/09/23 ShreddR®- classic 140 11

FOODLOGISTIK GmbH offers cutting sets in the following sizes:

Table 3: Cutting set sizes

Sizes [mm]

Number of knives

Upper cutting drum with

circular knives

Lower cutting drum with

cross cutting knives

3 x 3

47

30

4 x 4

36

22

5 x 5

29

15

6 x 6

24

13

7 x 7

21

12

10 x10

15

8

12 x 12

13

7

15 x 15

10

6

20 x 20

8

4

MACHINE DESCRIPTION

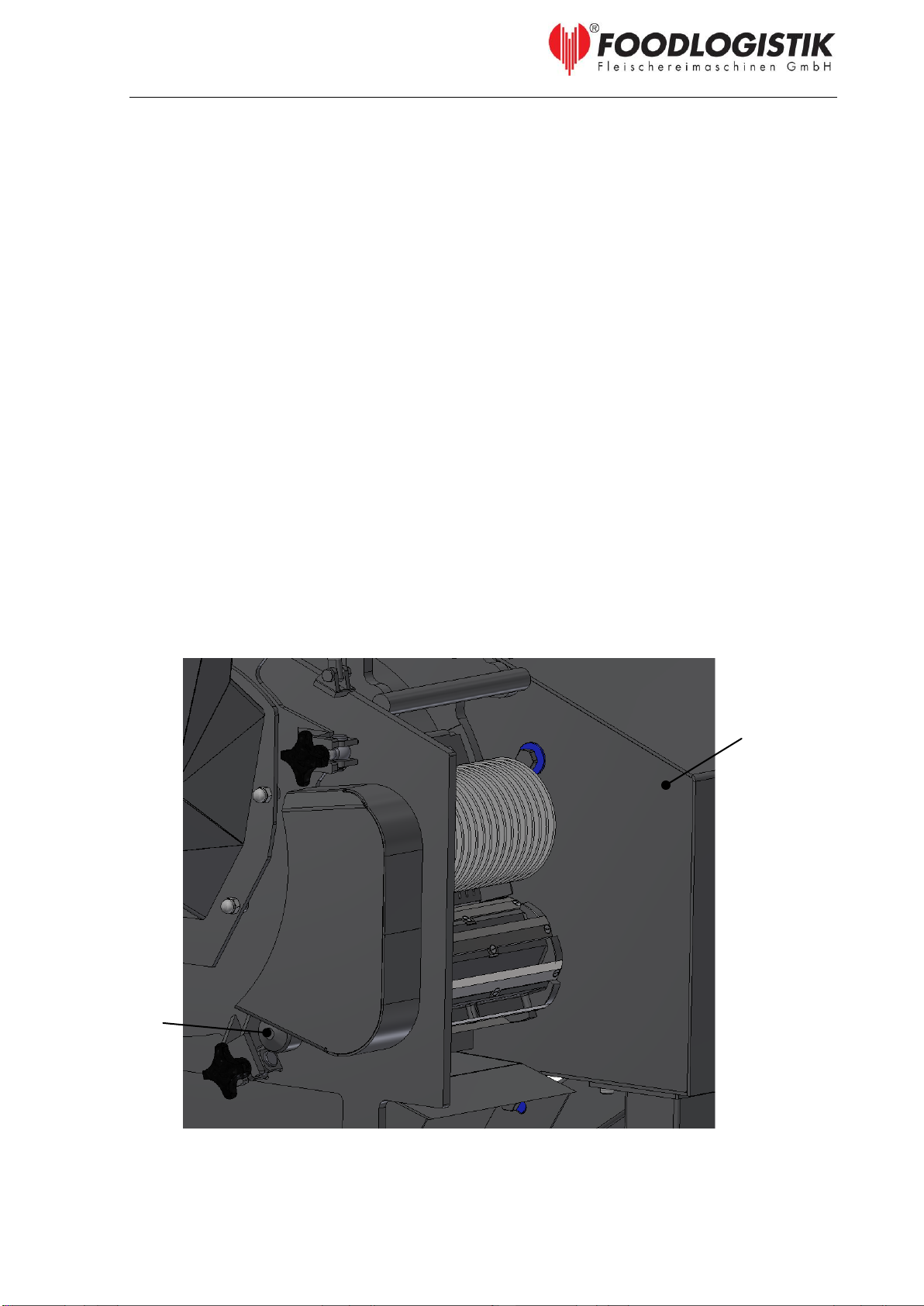

05/09/23 ShreddR®- classic 140 12

Safety switch

B2

Safety switch

B1

(under the sheet

metal)

3.2.3 Construction of electrical components

The electrical equipment of the machine consists of electric box, control panel and

electrical parts inside of the machine frame.

a) Electric box

The electric box is the information processing centre for all machine functions. The

electric box houses all the required control elements for this dicer. All safety and

control switches, transformers, fuses, motor protection switches as well as the

terminal strip can be found in this area.

b) Control panel

The control panel is the main operating station for machine functions. Here the

operator is able to control and observe all machine functions.

c) Machine

Inside the machine frame itself is the main driving unit for the cutting tools, safety

switches and the magnetic switches. The arrangement of the safety switches can be

viewed in Illustration 6.

Illustration 6: Machine safety switch

DELIVERY, INSTALLATION AND SET UP

05/09/23 ShreddR®- classic 140 13

4 DELIVERY, INSTALLATION AND SET UP

Delivery, installation and setup of this machine is to be completed by an authorized

Foodlogistik technician or other authorized specialized personnel / Foodlogistik

associate. Foodlogistik is not liable for damages when delivery, installation and setup

of this machine has been completed by someone other than an authorized

Foodlogistik technician.

4.1Transport

Use a hand forklift when unloading this machine and while transporting to work place

station. The machine is to be transported in the upright position.

While transporting on hand forklift, ensure the machine is

firmly situated in the centre of the forks, so that the machine

does not fall. Take care about the electric power cable of the

machine.

4.2Installation

This dicer is only to be used in upright position, in respect to the

load carrying capacities and horizontal level of the facility (see point

2.1).

Test the machine stability and whether every foot is situated firmly on the work floor,

before putting machine into use. Ensure there is sufficient space for the machine

operator (see point 2.1).

This machine under no circumstance be operated on any type

of height adjusting equipment; by installing supports of any

sort, or by installing upon a platform.

4.3Set-up

First, the door and the product outfeed must be installed in the machine (behold

illustration 3).

The ShreddR - classic 140 comes included with a 5 m long power cord. The owner of

the machine needs to ensure that correct voltage and power supply is provided (see

point 2.2 ).

With every start and restart of this machine, there needs to be systems checks to

ensure proper working order of all machine functions. Check the cutting distance of

the cutting sets. After every adjustment made, there needs to be systems safety

checks to ensure proper working order of machine functions (see point 5.1.2).

Table of contents