foris TwinFresh Expert RA1-50 V.3 User manual

TwinFresh Expert RA1-50 V.3

TwinFresh Expert RA1-50 C1 V.3

TwinFresh Expert RM1-50 V.3

Single-room reversible energy recovery ventilator

USER’S MANUAL

2

TwinFresh Expert RA/M1-50 (C1) V.3

Safety requirements..................................................................................................................................................................... 2

Purpose................................................................................................................................................................................................ 4

Delivery set........................................................................................................................................................................................ 4

Designation key.............................................................................................................................................................................. 4

Technical data.................................................................................................................................................................................. 5

Design and operating principle ........................................................................................................................................... 6

Mounting and set-up.................................................................................................................................................................. 8

Connection to power mains .................................................................................................................................................. 12

Technical maintenance.............................................................................................................................................................. 17

Troubleshooting............................................................................................................................................................................. 19

Storage and transportation regulations.......................................................................................................................... 19

Manufacturer’s warranty........................................................................................................................................................... 20

Certificate of acceptance.......................................................................................................................................................... 23

Seller information.......................................................................................................................................................................... 23

Installation certificate.................................................................................................................................................................. 23

Warranty card................................................................................................................................................................................... 23

This user’s manual is a main operating document intended for technical, maintenance, and operating staff.

The manual contains information about purpose, technical details, operating principle, design, and installation of the

TwinFresh Expert RA/M1-50 (C1) V.3 unit and all its modifications.

Technical and maintenance staff must have theoretical and practical training in the field of ventilation systems and should be able to

work in accordance with workplace safety rules as well as construction norms and standards applicable in the territory of the country.

CONTENTS

All user’s manual requirements as well as the provisions of all the applicable local and national

construction, electrical, and technical norms and standards must be observed when installing

and operating the unit.

Disconnect the unit from the power supply prior to any connection, servicing, maintenance, and

repair operations.

Only qualied electricians with a work permit for electrical units up to 1000 V are

allowed for installation. The present user’s manual should be carefully read before

beginning works.

Check the unit for any visible damage of the impeller, the casing, and the grille before starting

installation. The casing internals must be free of any foreign objects that can damage the

impeller blades.

While mounting the unit, avoid compression of the casing! Deformation of the casing may result

in motor jam and excessive noise.

Misuse of the unit and any unauthorised modifications are not allowed.

Do not expose the unit to adverse atmospheric agents (rain, sun, etc.).

Transported air must not contain any dust or other solid impurities, sticky substances, or fibrous

materials.

Do not use the unit in a hazardous or explosive environment containing spirits, gasoline,

insecticides, etc.

SAFETY REQUIREMENTS

3

Do not close or block the intake or extract vents in order to ensure the efficient air flow.

Do not sit on the unit and do not put objects on it.

The information in this user’s manual was correct at the time of the document’s preparation.

The Company reserves the right to modify the technical characteristics, design, or configuration

of its products at any time in order to incorporate the latest technological developments.

Never touch the unit with wet or damp hands.

Never touch the unit when barefoot.

THE PRODUCT MUST BE DISPOSED SEPARATELY AT THE END OF ITS SERVICE LIFE.

DO NOT DISPOSE THE UNIT AS UNSORTED DOMESTIC WASTE.

This unit is not intended for use by persons (including children) with reduced physical, sensory

or mental capabilities, or lack of experience and knowledge, unless they have been given

supervision or instruction concerning use of the unit by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the unit.

Connection to the mains must be made through a disconnecting device, which is integrated

into the fixed wiring system in accordance with the wiring rules for design of electrical units,

and has a contact separation in all poles that allows for full disconnection under overvoltage

category III conditions.

If the supply cord is damaged, it must be replaced by the manufacturer, its service agent, or

similarly qualified persons in order to avoid a safety hazard.

Ensure that the unit is switched off from the supply mains before removing the guard.

Precautions must be taken to avoid the back-flow of gases into the room from the open flue of

gas or other fuel-burning appliances.

4

TwinFresh Expert RA/M1-50 (C1) V.3

PURPOSE

The ventilator is designed to ensure continuous mechanical air exchange in flats, cottages, hotels, cafés and other domestic and public

premises. The ventilator is equipped with a regenerator that enables supply of fresh filtered air heated by means of extract air heat energy

recovery.

The ventilator is designed for installation on external walls.

The unit is rated for continuous operation.

Name TwinFresh Expert RA/M1-50 (C1) V.3

Indoor assembly unit of the ventilator 1 pc.

Air duct 1 pc.

Sound-absorbing material 1 pc.

Fan assembly 1 pc.

Heat exchanger assembly 1 pc.

Outer ventilation hood 1 pc.

Remote control 1 pc.

Cardboard mounting plate 1 pc.

Mounting kit 2 packages

Foam wedges 1 kit

User’s manual 1 pc.

Mounting hood installation instruction 1 pc.

Packing box 1 pc.

TwinFresh Expert R A 1 -50 C1 L-14 V.3

Unit version

Ventilation hood model

Air duct length

_ – 500 mm

L – 700 mm

L035 – 350 mm

L10 – 1000 mm

Regenerator modication

_ – standard regenerator 150 mm long

C1 – shortened regenerator 100 mm long

Rated air ow [m/h]

Front panel modication

1 – flat front panel

Automation availability

A – controls and control unit are included in the delivery set

M – model without shutters, with manual airflow blocking

Air duct cross section

R – round

Ventilator series

Expert – series of reversible ventilators with unidirectional air flow

DELIVERY SET

DESIGNATION KEY

5

The temperature in the room where the indoor unit of the ventilator is installed must be in the range from +1 ˚C to +40 ˚C with relative

air humidity up to 80 % (no condensation buildup).

If the conditions of use of the ventilator are outside the specified limits, turn off the ventilator. Provide fresh air with open windows.

The temperature of the transported air should be in the range from -20 ˚C to +40 ˚C.

The unit is rated as a class II electric appliance.

Ingress protection rating against access to hazardous parts and water ingress is IP24.

The ventilator design is constantly being improved, thus some models may be slightly different from those described in this manual.

Technical specifications of the particular model are indicated on the unit casing.

The air duct length depends on the unit model, refer to the Designation Key.

* For the TwinFresh Expert RA1-50 C1 V.3 model, this value is 270 mm.

The supplied ventilation hood model depends on the ventilator model.

The overall dimensions of the outer ventilation hood, the required outside protrusion length of the air duct A and the mounting sequence

of the hood are stated in its mounting instruction.

The overall dimensions of the front panel are stated below

OVERALL DIMENSIONS OF THE INDOOR UNIT [MM]

68

235

285

207

85

137

138

TECHNICAL DATA

A

370 mm*

Air duct length

Wall thickness

Outer ventilation

hood

Indoor unit

Regenerator unit

Fan unit

Sound absorbing

material

Layout of the ventilator units inside the wall

6

TwinFresh Expert RA/M1-50 (C1) V.3

The ventilator consists of an indoor unit with a decorative front panel, a fan unit, a regenerator unit, an air duct with a sound absorbing

layer and an outer ventilation hood.

The fan and regenerator units consist of two filters that ensure rough air filtration and prevent ingress of dust and foreign objects into

the regenerator and the fan.

The indoor unit of the TwinFresh Expert RA1-50 V.3 and TwinFresh Expert RA1-50 C1 V.3 models is equipped with shutters that close

when the ventilator is turned off and prevent the backflow of air, thereby preventing drafts.

The outer ventilation hood is used to prevent direct ingress of water and other objects to the ventilator.

Outer ventilation hood

Prevents ingress of water and foreign objects into the ventilator.

Each ventilator model has a matching ventilation hood model.

Regenerator unit

Provides heat recovery.

Fan unit

Creates air flow.

Air duct

Plastic air duct.

Sound-absorbing material

A layer of sound-absorbing material for attenuation

of noise generated during the ventilator operation.

Fine lter holder*

Provides the required distance between the fan and

the heat exchanger to improve the heat recovery efficiency.

Back part of the indoor unit

The assembly unit includes a control board and basic control units located on the

side of the indoor unit.

The design enables to shut off the air duct in case of an extended downtime of the

ventilator.

Front part of the indoor unit with a face panel

Press down on the front panel to close the air duct tightly. To open the air duct, pull the

front panel towards you using the grooves in the top and bottom of the panel.

Fulfils the decorative function.

VENTILATOR DESIGN

DESIGN AND OPERATING PRINCIPLE

Technical specifications of the particular model are indicated on the unit casing.

*The TwinFresh Expert RA1-50 C1 V.3 model is not equipped with a fine filter holder.

7

Ventilator operation modes

Ventilation: the ventilator runs either in the air exhaust or air supply mode at a set speed.

In this mode some of the ventilators in the network run in the air supply mode and the other ones in air exhaust mode, depending on

the position of the DIP switch No. 2 (See section DIP switch positions).

Boost: the ventilator goes to the maximum speed without changing the operation mode.

Regeneration: the ventilator runs in two cycles, 70 seconds each, with heat and humidity regeneration.

• Cycle I. Warm stale air is extracted from the room and flows through the ceramic regenerator, which gradually absorbs heat and

humidity. In 70 seconds, as the ceramic regenerator gets warmed, the ventilator is switched to supply mode.

• Cycle II. Fresh intake air from outside flows through the ceramic regenerator, absorbs accumulated moisture and is heated up to

the room temperature. In 70 seconds, as the ceramic regenerator gets cooled down, the ventilator is switched to air extraction

mode and the cycle is renewed. If two ventilators are installed, they operate with opposite rotation directions in this mode. While

one ventilator supplies air, the other one extracts it.

The shutters are closed The shutters are open

Operating principle of the louver shutters of the TwinFresh Expert RA1-50 V.3 and TwinFresh Expert RA1-50 C1 V.3

The indoor unit of these models is equipped with automatic shutters.

During the ventilator operation the automatic shutters are open and let the air flow freely through the ventilator.

The automatic shutters are closed for 2 minutes at the ventilator shut down.

WARNING! In case of supplying power to the ventilator when the frontal part of the indoor unit is removed, no power is supplied to the

actuator and its rod is not lifted to avoid damage.

After installing the front part of the indoor unit into place, the louver actuator will start operating normally.

8

TwinFresh Expert RA/M1-50 (C1) V.3

READ THE USER'S MANUAL BEFORE INSTALLING THE UNIT.

DO NOT BLOCK THE AIR DUCT OF THE INSTALLED VENTILATOR WITH DUST

ACCUMULATING MATERIALS, SUCH AS CURTAINS, CLOTH SHUTTERS, ETC.

AS IT PREVENTS AIR CIRCULATION IN THE ROOM.

1. Prepare a round core hole in the outer wall. The hole size is shown in the figure below.

While preparing core holes it is recommended to make preparations for layout of the power cable and other required cables.

A

AA-A

ø 180

min 300

min 300

min 300

2. Install the air duct in the wall and fix it with mounting foam. The air duct end must protrude for the distance that enables installation

of the outer ventilation hood (see the User’s manual for the outer ventilation hood).

A

min 3 mm

Fill the gaps between

the wall and the hole

with a mounting foam.

Mounting wedge

Install the air duct in the wall in such a way so it protrudes

from the wall surface for maximum 3 mm or is flush with

the wall.

Install the air duct with the minimum slope 3 mm

downwards.

On the outer wall side the air duct end must protrude to a

distance that enables installation of the outer ventilation

hood. The distance A is stated in the installation

instruction for the ventilation hood.

MOUNTING AND SETUP

9

3. Stick the delivered cardboard master plate on the indoor wall using a mounting tape. The large opening in the master plate must be

axially aligned with the air duct. For aligning the master plate with respect to the horizon line it is recommended to use a builder’s level.

Then mark the fastening holes for installation of the supplied dowels and drill the holes to a required depth.

Route the power cable from the wall outside through the specially marked opening on the master plate.

Ø 5

85

207

Ø 160

87,5 138

103,5

137

Ø 23

4 holes

4. Unlatch and detach the front part of the indoor unit from its back part.

5. Fix the back part of the indoor unit on the wall with the screws supplied with the mounting kit of the ventilator.

Remove the two retaining screws from the left transparent cover to enable access to the terminals.

The thermal actuator rod

must be in lower position

when installing the front

panel of the

TwinFresh Expert RA unit.

10

TwinFresh Expert RA/M1-50 (C1) V.3

6. Route the power cable as figured below and connect the ventilator to power mains in compliance with the external wiring diagram.

Fix the power cable and the signal cables with cable clamps. After completion of the electrical connection re-install the transparent

cover in site.

Cable clamp

7. Install the fan unit and the regenerator unit into the air duct as figured below. Then fix the wire with the retaining clip and connect

the connector to the circuit board.

Insert the sound-absorbing material into the air duct. Roll the layer of the sound absorbing material to match the air duct diameter.

Insert the sound absorbing roll against stop. Cut off the excess part of the sound-absorbing material. Insert the ready sound absorbing

roll into the air duct.

Insert the wires under the

retaining clip and connect the

connector to the circuit board.

If the wall thickness is less than that in the layout of the blocks inside the wall from the Technical Data section, you can unfasten the fine

filter holder and assemble the ventilator without it and without sound-absorbing material, as shown in the figure below.

A

307 mm*

Air duct length

Wall thickness

Outer ventilation

hood

Indoor unit Heat recovery unit

Fan unit

Layout of the ventilator units inside the wall

with a minimum wall thickness

*For the TwinFresh Expert RA1-50 C1 V.3 model, this value is 270 mm.

With this type of installation, the recovery efficiency may decrease and the emission of street noise into the room may increase.

This will also increase the noise level of the ventilator itself.

11

8. Install the front part of the indoor unit.

10. Install the outer ventilation hood. For this, see the user’s manual for the hood.

12

TwinFresh Expert RA/M1-50 (C1) V.3

POWER OFF THE POWER SUPPLY PRIOR TO ANY OPERATIONS WITH THE UNIT.

THE UNIT MUST BE CONNECTED TO POWER SUPPLY BY A QUALIFIED ELECTRICIAN.

THE RATED ELECTRICAL PARAMETERS OF THE UNIT ARE GIVEN ON THE

MANUFACTURER’S LABEL.

The ventilator is rated for connection to single-phase AC 100-240 V 50/60 Hz power mains.

Connect the ventilator to power mains through an automatic circuit breaker with magnetic trip integrated into the home wiring

system. The tripping current of the circuit breaker is selected based on the electrical characteristics shown on the label of the fan

casing.

For electric installations use insulated, durable conductors (cables, wires) with the minimum cross section of 0.5 up to 0.75 mm for

a power cable and 0.25 mm for signal cables. The cable cross-section is given for reference only. The actual conductor cross-section

selection must be based on its type, maximum permissible heating, insulation, length and installation method. Use copper wires for all

the electric connections!

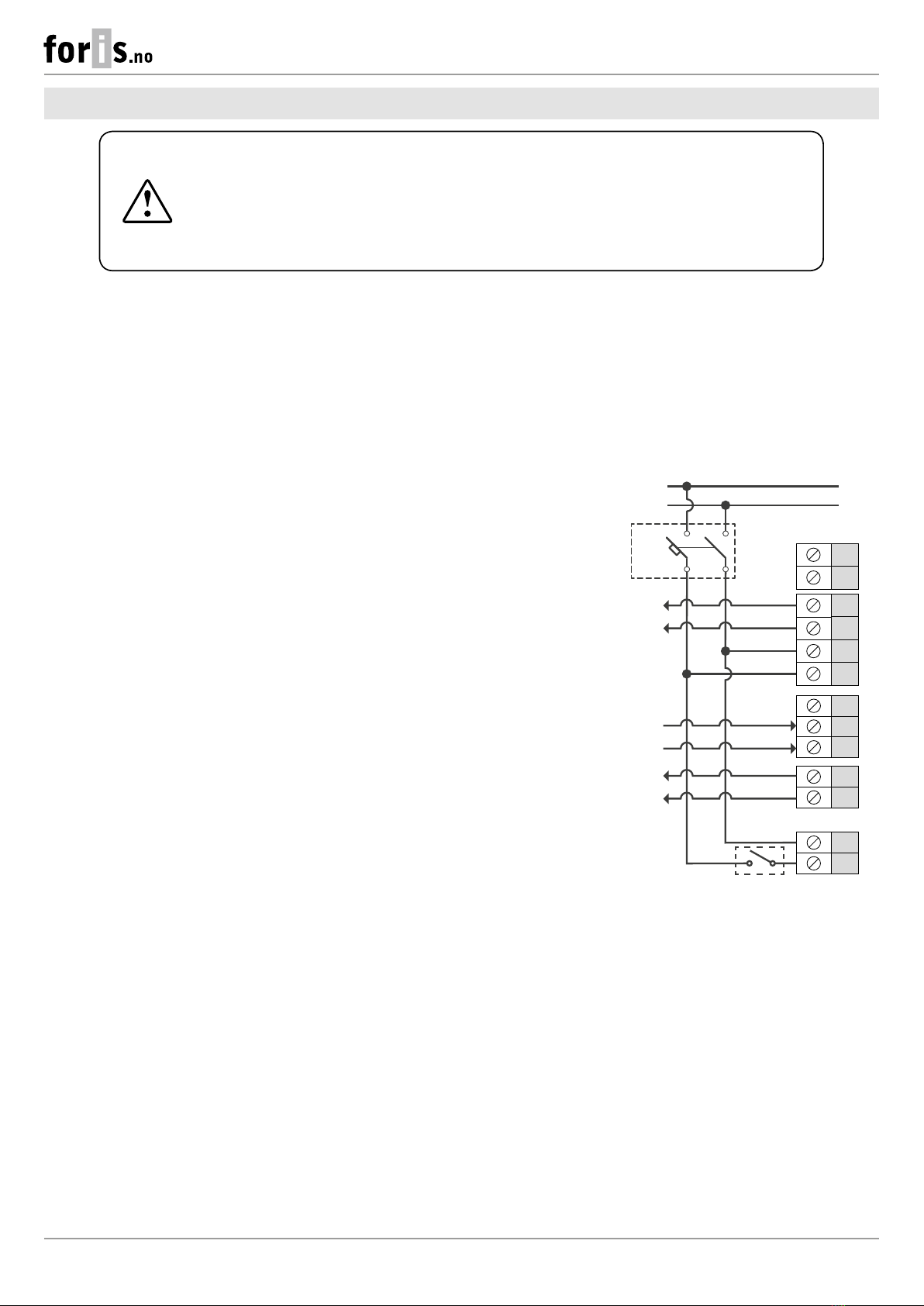

External connections diagram

The ventilator design enables connecting any external controls

with a normally opened contact (NO-contact), such as an external

CO₂ sensor, humidity sensor, relay switch, etc.

When the normally open contact of the external device is closed,

the ventilator goes to a maximum speed.

The ventilators can be connected in series and in parallel with a

central control by the master ventilator.

In case of in series or in parallel connection of several ventilators

power is supplied either from a previous ventilator or from power

mains.

N

L

1a

2a

N

L (~)

N (~)

L

In

Gnd

NO1

NO2

+12V

Gnd

Out

QF*

Control signal output

to the next ventilator

Power

АС 100-240V

50/60 Hz

Power to the

next ventilator

Normally open contact

of the external device

(relay sensor)

Control signal input from

the previous ventilator

CONNECTION TO POWER MAINS

13

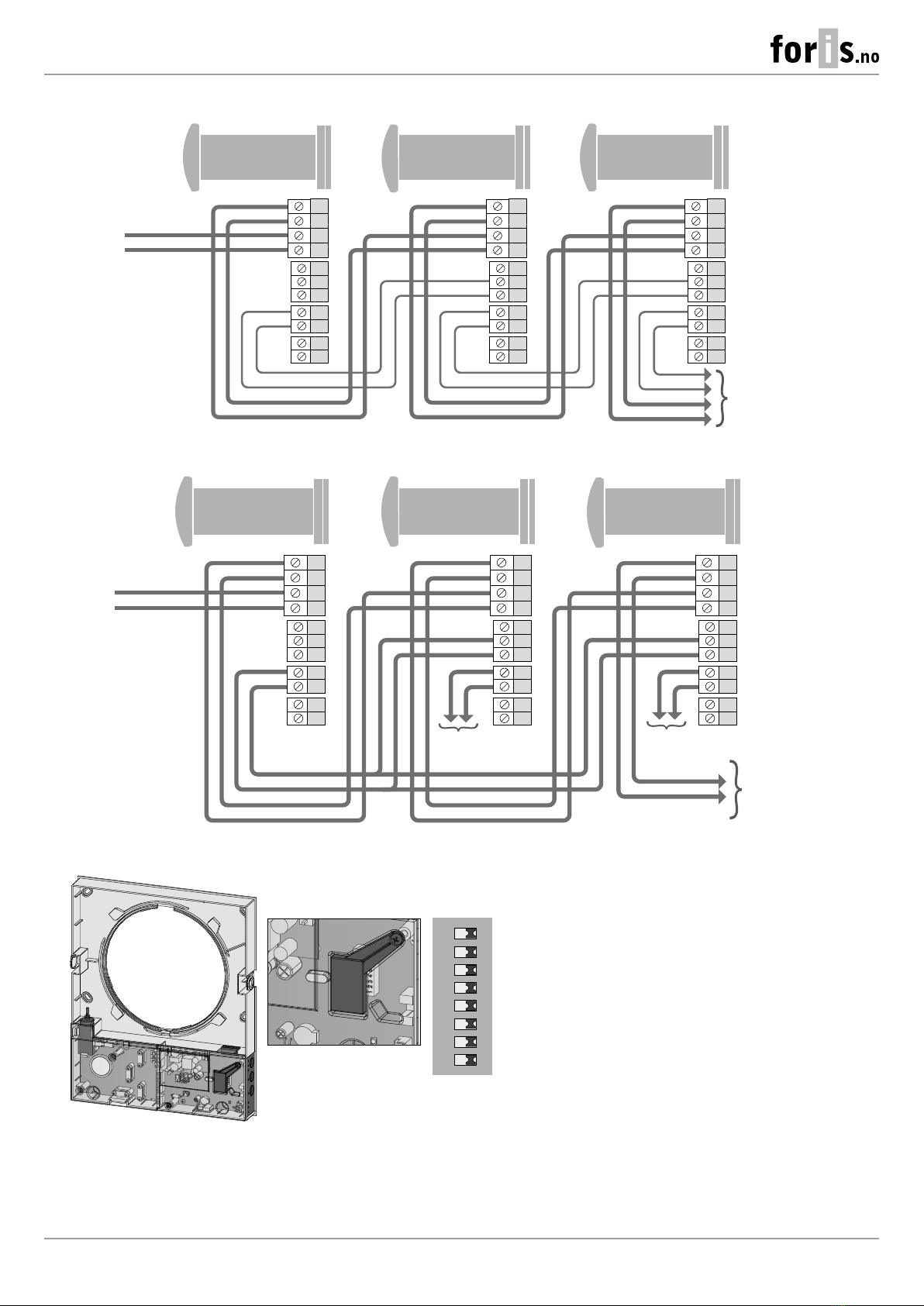

Wiring diagram for in series connection

N

L

N

L

In

Gnd

Gnd

Out

NO1

NO2

+12V

N

L

N

L

In

Gnd

Gnd

Out

NO1

NO2

+12V

N

L

N

L

In

Gnd

Gnd

Out

NO1

NO2

+12V

Master Slave 1 Slave N

N

L

Power input

АС 100-240V 50/60 Hz

to the next

ventilator

Wiring diagram for in parallel connection

Master Slave 1 Slave N

N

L

N

L

In

Gnd

Gnd

Out

NO1

NO2

+12V

N

L

N

L

In

Gnd

Gnd

Out

NO1

NO2

+12V

N

L

N

L

In

Gnd

Gnd

Out

NO1

NO2

+12V

N

L

Power input

АС 100-240 V 50/60 Hz

to the next

ventilator

to the next

ventilator

to the next

ventilator

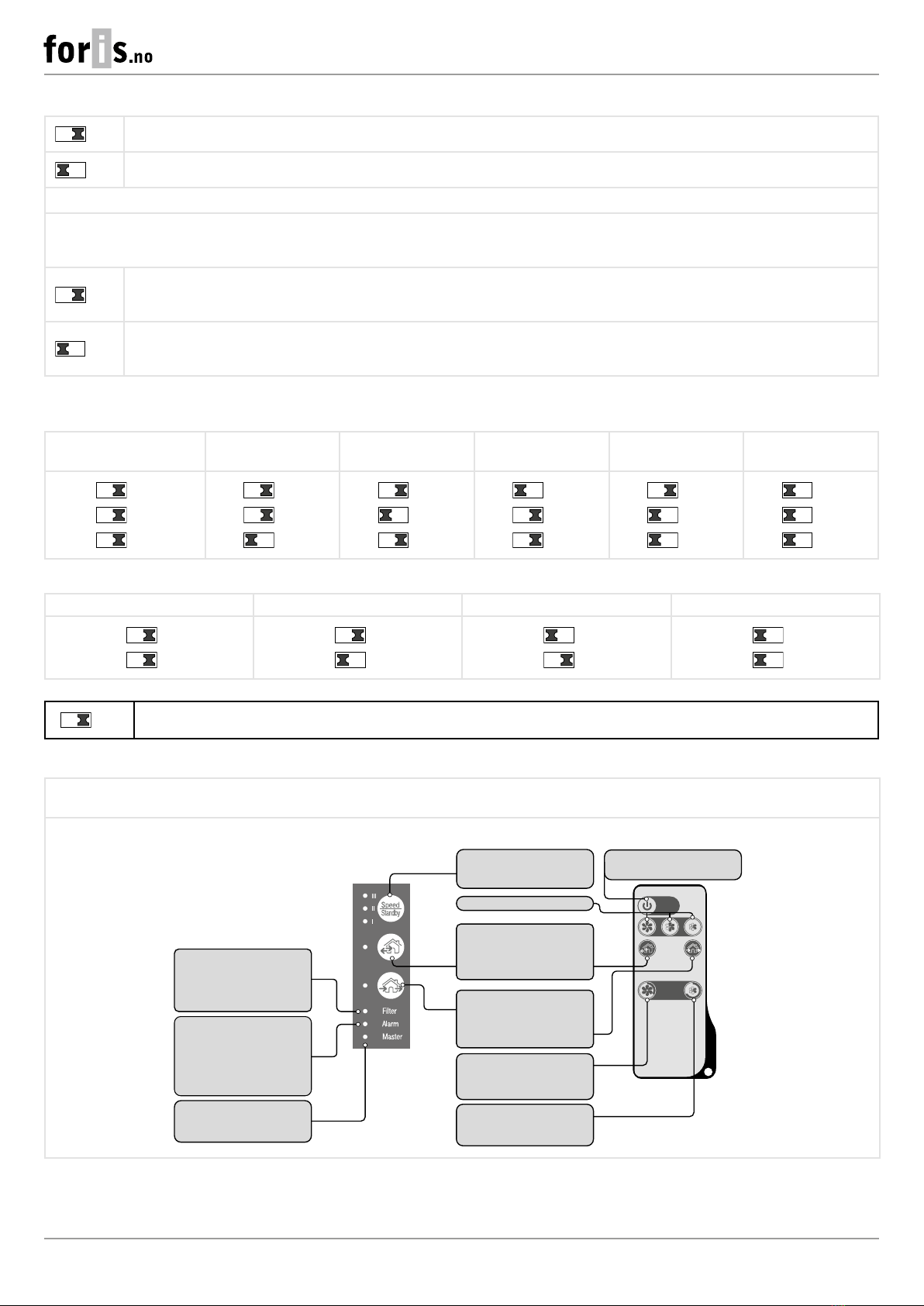

Ventilator setup

ON DIP

12345678

Open the rubber plug

DIP switch

under the plug

Prior to operating the ventilator set it up using the DIP

switch. It is located on the controller circuit board.

To access the DIP switch, take off the front panel of the

indoor unit and uplift the rubber plug that covers the

switch.

14

TwinFresh Expert RA/M1-50 (C1) V.3

Positioning of the DIP switches

1

Turning the ventilator o is allowed. The switch position enables switching the ventilator off with the button on the side control

panel.

1

Turning the ventilator o is not allowed. The switch position disables switching the ventilator off with the button on the side control

panel.

TwinFresh Expert RA/M1-50 V.3

Fan rotation direction. For controlled ventilation it is recommended to install the ventilators pairwise and integrate them in a group using a signal

cable. Set one half of the connected units into supply mode and the other half into extract mode.

2

In the Ventilation mode the ventilator supplies air to the room.

In the Regeneration mode the ventilator starts operating first in the air supply mode.

2

In the Ventilation mode the ventilator extracts the air from the room.

In the Regeneration mode the ventilator starts operating first in the air exhaust mode.

Humidity sensor set value. The humidity sensor measures the extract air humidity. If the extract air humidity is above the set point, the ventilator

switches to Speed III. As humidity drops down to the set point, the ventilator changes to pre-set speed after elapsing of the time set on the turn-on

delay timer.

Humidity control is

disabled

Set value 40 % Set value 50 % Set value 60 % Set value 70 % Set value 80 %

345

345

345

345

345

345

Delay timer. During activation of the humidity sensor or any other external device the ventilator switches to higher speed. After normalization of the

indoor humidity level or any other air parameters the ventilator will switch to the previous mode after the set time.

Time delay 0 min Time delay 5 min Time delay 15 min Time delay 30 min

6 7

6 7

6 7

6 7

Resetting timer lter

8

To reset the filter timer, turn on the DIP switch for a period of at least 3 seconds and then turn it off.

Ventilator control

The ventilator can be operated with the remote control or the control buttons on the side part of the indoor unit, as figured below.

In case of in series or in parallel connection, the signal from a control unit is received by the first ventilator (Master) only.

Turning

the ventilator on/o

Party mode

Activation of Speed III by timer

(4 hours by default).

Night mode

Activation of Speed I by timer

(8 hours by default).

Speed selection

Speed/Standby

The speed selection sequence is as

follows: I-II-III-Standby

Regeneration mode

In this mode the unit switches

between the supply and the

extraction modes every 70 seconds

with heat recovery. Heat recovery is

performed in this mode.

Ventilation mode

The ventilator operates in the supply

or extraction mode at a set speed.

Remote control

Buttons on the

ventilator casing

Alarm indicator

In case of the motor jam, the Alarm

indicator starts glowing and the

ventilator stops. All the ventilators

connected in series stop

synchronously.

Master indicator

Indicator of the first ventilator in the

group.

Filter indicator

After the set filter replacement

periodicity (90 days) has expired, the

Filter indicator starts glowing. In this

case, clean or replace the filters.

15

Ventilator control with the buttons on the indoor unit

The speed selection sequence is as follows: I-II-III-Standby. All the units integrated in a single network operate according to the speed

settings of the Master unit.

I: permanent indicator glowing indicates operation of the unit at Speed I. The indicator blinks when the first speed timer is activated.

Iand II: permanent glowing of these indicators indicates operation of the unit at Speed II.

I, II and III: permanent glowing of these indicators indicates operation of the ventilation unit at Speed III. Blinking of the indicators I, II and

III indicates activation of the timer for Party mode or the turn-off delay timer triggered by any connected external sensors or the integrated

humidity sensor.

Regeneration mode:

TwinFresh Expert RA/M1-50 V.3

The rotation direction of both fans changes to opposite every 70 seconds. Heat recovery is performed in this mode.

Ventilation mode:

TwinFresh Expert RA/M1-50 V.3

The ventilator operates in the supply or extraction mode at a set speed. The air flow direction depends on positioning of the DIP switch

(set to air extract by default).

Filter

Contamination indicator of lters. 90 days (continuous operation) after installation of the cartridge the Filter contamination indicator

starts glowing. In this case, clean or replace the filters (see section Technical maintenance).

During in-series connection the Master ventilator indicator has a steady glow and the indicator of the ventilator requiring filter replacement

blinks. To reset the filter timer of the units, switch the DIP switch no. 8 on for at least 3 seconds and then turn it off.

Alarm

Alarm indicator for emergency shutdown of the unit. Permanent glowing of the Alarm indicator of the Master unit indicates an alarm in

the network of the connected ventilation units. Its blinking indicates shutdown of a specific ventilation unit in the network.

In case of an emergency shutdown of the TwinFresh Expert RA/M1-50 V.3 unit in the network, the defective ventilation unit is marked with

the blinking Alarm indicator. All the connected TwinFresh Expert RA/M1-50 V.3 ventilation units are also stopped.

Master

Master unit indicator. Permanent glowing of the indicator shows the leading unit in the network (Master unit). Indicator blinking indicates

the driven unit (Slave unit) and no connection to the Master unit.

No glowing of the lamp indicator means that this ventilation unit is a Slave ventilation unit and it is connected to a Master unit.

Remote control of the ventilator

Turning the ventilator on/off. The unit may be turned off only if it is enabled by the settings.

Reset of alarm and timer settings.

Ventilator speed selection: Speed III-II-I respectively.

Regeneration mode

In this mode, for the TwinFresh Expert RA/M1-50 V.3 ventilators, the direction of fan rotation changes every 70 seconds.

Heat regeneration is performed in this mode.

Ventilation mode

In this mode, the TwinFresh Expert RA/M1-50 V.3 ventilators supply or extract air at the selected speed. The air flow direction

depends on positioning of the DIP-switch (set to air extract by default).

Timer buttons:

Party mode: 4 hours on the third speed Night ode: 8 hours on the first speed

Upon expiration of the set time period the ventilator reverts to a pre-set speed.

Press any button of the manual speed setting to deactivate the timer.

16

TwinFresh Expert RA/M1-50 (C1) V.3

Air ow cut-o

Press the front panel to close the air duct. The fan turns off automatically. The unit functionality is not changed.

To open the air duct, pull the front panel while holding the special recesses. The fan starts operating according to the actual speed

setting.

Air duct shut-off Air duct

opening

The front panel incorporates an operating LED indicator. During the dark time the indicator light intensity drops down.

17

TECHNICAL MAINTENANCE

Maintenance of the ventilator means regular cleaning of the ventilator surfaces of dust and cleaning and/or replacement of the filters.

After the set filter replacement periodicity (90 days) has expired the Filter indicator starts glowing. Before performing maintenance,

stop the ventilator using the remote control or the buttons on the indoor unit, then disconnect it from power mains using the circuit

breaker. Afterwards, carry out the following steps:

1. Press the latches on the side of the indoor control unit to take off the front part.

Please make sure the shutter actuator rod is in lower position during re-installation of the front panel. If the rod is up, please

wait for about 2 minutes until it goes down.

2. Disconnect the connector from the circuit board. Do not remove the connector by pulling the wires. Use a flat screwdriver to uplift

it if required.

Disconnect the connector

from the circuit board.

Do not pull on

the electric cable! Use a flat screwdriver to

disconnect the connector.

3. Pull the cord to remove the cartridge from the air duct. Clean the filters as often as required, but at least 3 times a year.

When installing the front

panel, the shutter actuator rod

of the TwinFresh Expert RA1

model must be lowered

.

18

TwinFresh Expert RA/M1-50 (C1) V.3

4. Wash the filters and let those dry out completely. Install the dry filters in their place and assemble the unit in the reverse order. Vacuum

cleaning is allowed.

The filter rated service life is 3 years. For new filters contact the Seller.

Some dust may accumulate on the heat exchanger block even in

case of regular maintenance of the filters.

To maintain high heat recovery efficiency, the regenerator should

be cleaned regularly with a vacuum cleaner at least once a year.

To reset the filter timer, before installing the front part of the indoor unit back in place, supply power to the ventilator using the circuit

breaker, then switch on the DIP switch no. 8 for at least 3 seconds and switch it off.

If necessary, the battery in the remote control can be replaced.

After long-term usage of the remote control the battery must be

replaced.

No response of the unit for pressing the remote control buttons

indicates the need to replace the battery.

The battery type is CR2025.

Remove the holder with the battery from the lower part of the

remote control.

Replace the battery and install the holder with a new battery back

to the remote control.

+

CR2025

3V

+

CR2025

3V

19

Possible reasons and troubleshooting

Problem Possible reasons Troubleshooting

When switching on the

ventilator, the fan does not

start.

No power supply.

Make sure the power supply line is connected

correctly, otherwise troubleshoot the connection

error.

The motor is jammed, the impeller blades are

soiled.

Turn the ventilator off. Troubleshoot the motor jam

and impeller clogging. Clean the blades. Restart the

ventilator.

Circuit breaker tripping during

the ventilation unit start-up.

Overcurrent as a result of short circuit in the

electric line.

Turn the ventilator off.

Contact the Seller for further information.

Low air flow.

Low set fan speed. Set higher speed.

The filters, the fan or the regenerator are clogged. Clean or replace the filter. Clean the fan and the

heat exchanger.

Noise, vibration.

The impeller is clogged. Clean the impeller.

Loose screw connection of the unit casing or the

outer ventilation hood.

Tighten the screws of the ventilator or the outer

ventilation hood.

TROUBLESHOOTING

STORAGE AND TRANSPORTATION REGULATIONS

• Store the unit in the manufacturer’s original packaging box in a dry closed ventilated premise with temperature range

from +5 °C to +40 °C and relative humidity up to 70 %.

• Storage environment must not contain aggressive vapors and chemical mixtures provoking corrosion, insulation, and sealing

deformation.

• Use suitable hoist machinery for handling and storage operations to prevent possible damage to the unit.

• Follow the handling requirements applicable for the particular type of cargo.

• The unit can be carried in the original packaging by any mode of transport provided proper protection against precipitation and

mechanical damage. The unit must be transported only in the working position.

• Avoid sharp blows, scratches, or rough handling during loading and unloading.

• Prior to the initial power-up after transportation at low temperatures, allow the unit to warm up at operating temperature for at least

3-4 hours.

20

TwinFresh Expert RA/M1-50 (C1) V.3

MANUFACTURER’S WARRANTY

The product is in compliance with EU norms and standards on low voltage guidelines and electromagnetic compatibility. We hereby

declare that the product complies with the provisions of Electromagnetic Compatibility (EMC) Directive 2014/30/EU of the European

Parliament and of the Council, Low Voltage Directive (LVD) 2014/35/EU of the European Parliament and of the Council and CE-marking

Council Directive 93/68/EEC. This certificate is issued following test carried out on samples of the product referred to above.

The manufacturer hereby warrants normal operation of the unit for 24 months after the retail sale date provided the user's observance

of the transportation, storage, installation, and operation regulations. Should any malfunctions occur in the course of the unit operation

through the Manufacturer's fault during the guaranteed period of operation, the user is entitled to get all the faults eliminated by the

manufacturer by means of warranty repair at the factory free of charge. The warranty repair includes work specific to elimination of faults

in the unit operation to ensure its intended use by the user within the guaranteed period of operation. The faults are eliminated by means

of replacement or repair of the unit components or a specific part of such unit component.

The warranty repair does not include:

• routine technical maintenance

• unit installation/dismantling

• unit setup

To benefit from warranty repair, the user must provide the unit, the user's manual with the purchase date stamp, and the payment

paperwork certifying the purchase. The unit model must comply with the one stated in the user’s manual. Contact the Seller for warranty

service.

The manufacturer’s warranty does not apply to the following cases:

• User’s failure to submit the unit with the entire delivery package as stated in the user’s manual including submission with missing

component parts previously dismounted by the user.

• Mismatch of the unit model and the brand name with the information stated on the unit packaging and in the user's manual.

• User’s failure to ensure timely technical maintenance of the unit.

• External damage to the unit casing (excluding external modifications as required for installation) and internal components caused

by the user.

• Redesign or engineering changes to the unit.

• Replacement and use of any assemblies, parts and components not approved by the manufacturer.

• Unit misuse.

• Violation of the unit installation regulations by the user.

• Violation of the unit control regulations by the user.

• Unit connection to power mains with a voltage different from the one stated in the user's manual.

• Unit breakdown due to voltage surges in power mains.

• Discretionary repair of the unit by the user.

• Unit repair by any persons without the manufacturer’s authorization.

• Expiration of the unit warranty period.

• Violation of the unit transportation regulations by the user.

• Violation of the unit storage regulations by the user.

• Wrongful actions against the unit committed by third parties.

• Unit breakdown due to circumstances of insuperable force (fire, flood, earthquake, war, hostilities of any kind, blockades).

• Missing seals if provided by the user’s manual.

• Failure to submit the user’s manual with the unit purchase date stamp.

• Missing payment paperwork certifying the unit purchase.

FOLLOWING THE REGULATIONS STIPULATED HEREIN WILL ENSURE A LONG AND

TROUBLEFREE OPERATION OF THE UNIT.

USER’S WARRANTY CLAIMS SHALL BE SUBJECT TO REVIEW ONLY UPON PRESENTATION

OF THE UNIT, THE PAYMENT DOCUMENT AND THE USER’S MANUAL WITH THE

PURCHASE DATE STAMP.

This manual suits for next models

2

Table of contents

Other foris Fan manuals

Popular Fan manuals by other brands

Jaga

Jaga OXRE.015 installation instructions

Ruck Ventilatoren

Ruck Ventilatoren ROTO KOMPAKT Assembly and operating manual

Fantech

Fantech ERV-WI 500 Installation, operation and maintenance manual

Beacon

Beacon LUCCI AIRFUSION HAVANA installation instructions

ACB

ACB Vento BORA instructions

Panasonic

Panasonic FV-24JR2 Installation and operationg instructions