FORMTEK Lockformer TDC-Notcher User manual

More Productive Metal Forming Solutions

VER. TDC-Notcher -CE 03-2006 PAGE 1

TDC-Notcher

TDC Hydraulic Notcher

OPERATOR’S MANUAL

INSTRUCTIONS AND PARTS DIAGRAM

More Productive Metal Forming Solutions

VER. TDC-Notcher -CE 03-2006 PAGE 2

WARNING

THIS EQUIPMENT IS DESIGNED TO BE OPERATED WITH ALL

COVERS SECURED IN PLACE. OPERATION WITHOUT THESE

SAFEGUARDS MAY RESULT IN CONDITIONS WHICH ARE

HAZARDOUS TO THE OPERATOR AND OBSERVERS.

SAFETY GUIDELINES

Before operating the machine, study and follow the safety precautions in this

section. These precautions are intended to prevent injury to you and your fellow

workers. They cannot, however, cover all possible situations. Therefore,

EXERCISE EXTREME CAUTION and use COMMON SENSE before performing any

procedure or operation.

Safety Precautions BEFORE Starting The Machine(s)

Only one person should control the machine(s). Never allow anyone to operate the controls

while you are operating or working on this equipment. In addition to disconnecting power

always use lock outs and tagouts to prevent accidental start-up when performing

maintenance procedures. Keep your hands away from internal workings of the machinery

when starting, running or stopping. Keep your work area clean. Remove all scrap, oil spills,

rags, tools and other loose items that could cause you to slip, trip and fall. When cleaning the

machine or any of its components, do not use toxic or flammable substances. Do not perform

any cleaning while the equipment is running. Never override or disable any safety switch or

safety interlock. If so equipped, make sure that hydraulic and pneumatic pressures are at

specified levels before operating this equipment.

Do not operate the Hydraulic Notcher unless all covers and guards are in place.

Be sure that this Instruction Manual is kept near the machine so the operator can refer to it

when necessary. Keep this equipment properly maintained. Always turn off power to the

machine(s) at the main disconnect before performing any maintenance or adjustments so

accidental start-up or electrocution cannot occur.

Safety Precautions WHILE Operating The Machine(s)

Never leave the work area while the equipment is in operation. Never leave the machine

unattended while it is under power or in operation. Always be alert while operating

machinery. Be alert for loose, worn or broken parts. Do not attempt to operate any machinery

with such parts present or if the machinery is making unusual noises or actions. Avoid skin

contact, prolonged breathing, or eye exposure to any stock lubrication fluid being

used. Be aware of the locations of the Power Off or Emergency Stop button in case of an

emergency.

Be sure all guards and covers are in place.

Continually observe the rollforming process and related equipment. If any unusual condition

develops, immediately stop and inspect the machine. Protect yourself ! Wear safety glasses.

Do not wear loose clothing, neckties, or jewelry. If long sleeves must be worn, avoid loose

cuffs and buttons. Tie back and contain long hair. Never adjust any roll feature or perform

work near the rolls, gears or power take off while they are running.

More Productive Metal Forming Solutions

VER. TDC-Notcher -CE 03-2006 PAGE 3

General

-If any pneumatic or hydraulic feature is used, close the main hydraulic lock out valve

,disconnect the main supply pressure and bleed the lines to prevent cycling on retained

pressure before servicing. Always shut off the power at the main disconnect switch before

entering the electrical control box.

-Do not use compressed air to clean the machines. Air pressure may drive dirt and small

chips into the machine(s) bearing surfaces or cause bodily injury.

WARRANTY

Our warranty on the products we manufacture is limited to repair or replacement without charge, of

any part found to be defective in materials or workmanship. This warranty is for a period of one

year (unless otherwise specified) from the date of shipment from our factory, for all mechanical

features of the machine except purchased components that carry the warranty of the original

manufacturer. This warranty is conditioned on proper installation, maintenance and use of the

equipment. The warranty will be void if the equipment is subjected to misuse or abused or if used

beyond the standards in this manual, including material dimensions and gauge. Warranty parts and

components will be shipped freight collect from FORMTEK. If the defective part has not been

returned to FORMTEK within 15 working days after receiving the replacement part, your company

will be responsible for the cost of replacement. The warranty provided in this clause is in lieu of all

other warranties, express or implied, arising by law or otherwise, including the implied warranties

of merchantability and fitness for a particular purpose which are hereby disclaimed by FORMTEK

and excluded from this agreement. This warranty shall not be modified for any reason. In no event

shall FORMTEK be liable for consequential or incidental damages, including the cost of assembly

or disassembly, lost production or personal injury. The information in this document has been

reviewed and is believed to be complete and accurate. No responsibility is assumed for minor

inaccuracies or content not addressed in this manual. Furthermore, FORMTEK reserves the right to

make changes to any products herein, at any time, to improve reliability, function, or design.

FORMTEK does not assume any liabilities arising out of any use of any product described herein,

nor does it convey any license under its trade secrets or

patent rights nor the rights of others.

CAUTION!

NEVER OPERATE THIS EQUIPMENT UNLESS

ALL COVERS AND GUARDS ARE IN PLACE.

To provide clarity to points in question the illustrations and photos appearing

in this manual are shown with covers and guards removed.

Common sense and extreme care must be used at all times during the operation and maintenance of this

equipment. It is important that ALL personnel who will operate, maintain, or supervise the use of this

equipment, read and understand the sections of this manual concerning SAFETY and the OPERATION of

the equipment. The equipment described in this manual was designed and manufactured for a specific

function. It should not be used for any other purpose or outside of the design specifications as this may

result in damage to the equipment and/or injury to the operator. Modifications or additions to this equipment

should not be made. Any such modifications or additions will void the warranty and may subject the

operater to injury. Replacement and maintenance parts must be purchased from FORMTEK or the

component original equipment manufacturer. Use of other parts may result in unsafe operation or failure of

the machinery. If there is a question to the suitability of a part, proper personnel FORMTEK should be

consulted.

In general, every piece of equipment must be treated with extreme care. While operating or

maintaining this equipment, each individual must be aware of their own safety as well as the safety

of all bystanders.

More Productive Metal Forming Solutions

VER. TDC-Notcher -CE 03-2006 PAGE 4

SAFETY FIRST

SAFETY SIGN-OFF SHEET

I verify that I have read and understand the safety and operation sections

for this equipment:

It is the employer’s responsibility to instruct all persons who may come in contact with this equipment

on the safe operation and maintenance of this equipment. If a language barrier or other restriction

limits understanding, this manual can be read to the individual with appropriate follow up questions to

verify understanding. Have each individual sign below only after demonstrating their understanding of

the safety practices described in this manual.

NAME DATE NAME DATE

SAFETY GUIDELINES

Do not wear loose clothing, neckties, improper gloves, or jewelry while operating this machine. If

long sleeves must be worn, avoid loose cuffs or buttons, Tie back or contain long hair. Wear

proper gloves to prevent lacerations caused by sharp edges of stock as it travels through the

forming operation. Never operate this equipment unless all covers and guards are properly

installed. Be alert for loose, worn, or broken parts. Never operate this equipment unless it is in

good working condition. As the stock enters the notching dies a pinch point is created.

Keep hands clear of area and all pinch points!

Always disconnect the main power supply power and install lock outs using a lockout / tagout

procedure when making adjustments or repairs. When transporting, take into consideration that

the machine is top heavy and may suddenly tip over. The machine is designed for fixed

installations and are not intended for portability.

You are NOT ready to operate this equipment if you have not read and understood all of the

safety information in this manual.

! WARNING:

Remember that the information contained in this manual is only a portion of an adequate

training program. It must be coupled with specific instructions for your application along

with full information of national and local safety regulations that may apply.

IMPORTANT

The information contained herein is to be use as a general guide only. For further

safey information obtain and read the latest ANSI bulletins

CONTACT: American National Standards Institute

11 West 42nd Street

New York, New York 10036

SOUND PRESSURE INFORMATION (noise levels)

The Lockformer TDC-Notcher described in this manual has been tested for noise DB levels.

At normal operating distance the machine should be no more then 85DB.

YEAR OF MANUFACTURE

More Productive Metal Forming Solutions

VER. TDC-Notcher -CE 03-2006 PAGE 5

INSTALLATION/SPECIFACATIONS

INTENDED PURPOSE of the TDC-NOTCHER

The intended purpose of the TDC-Notcher is to notch (punch threw) the edges of steel sheet metal. The

notched profile is specific for TDC and TDF style duct work.

INSTALLATION

PRELIMINARY: After uncrating, locate unit, with or without base skid, to area of operation. Unbind

foot switch cord and cylinder hoses.

Provide a clean, flat, well lighted installation site. Level the machine and anchor it to the floor.

Inspect all hoses and hydraulic components for oil leakage. Remove any packing or other debris

that may have accumulated during shipping. Fill the reservoir with oil per the information below.

OIL: READ THIS BEFORE ATTEMPTING TO OPERATE THE MACHINE!

Hydraulic oil is not shipped with the machine. The reservoir must be filled before starting the

machine. The oil used in the reservoir is;

Hydraulic oil -- N46 or N68 oil or the equivalent of;

RANDO AW HYDR-46 HYDRAULIC OIL (TEXACO),AW-68 HYDRAULIC OIL (AMACO)

DTE #26 MOBILE

Volume - 10-12 US Gallons, (40-50 liters). Fill to mid level of tank site glass.

Do not operate the machine if signs of oil leakage appear.!

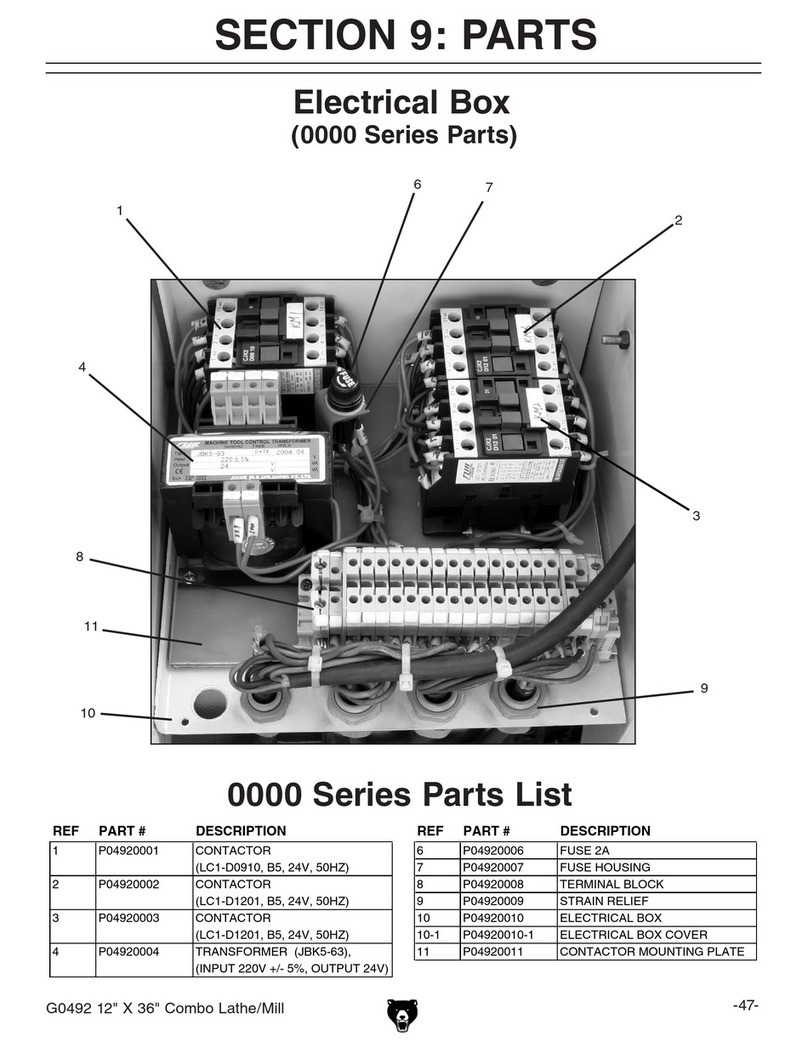

ELECTRICALS

Remove manual starter box cover and wire unit as per diagram illustrated on inside of cover.

Normal electrics 220 volt, 60 cycle, 3 phase with overload protection in starter box. Motor

furnished-5 H.P. x 1800 RPM.

Standard electrical motor: 5 HP ( 3.75KW) 220/460V.

Provide a grounded 220/460V power supply at the point of operation. If a 380V motor is ordered,

install the power supply in compliance with the local and national electric codes. For further

information contact a certified electrician or the proper Formtek/Lockformer personnel.

IMPORTANT: When starting unit check to see whether motor and pump rotation conforms to

direction of arrows on motor and pump body. CAUTION: Jog unit until proper rotation is achieved.

Severe damage to pump will result if run backward to rotation shown.

CAPACITY

Maximum capacity is 1.5mm (16 ga.) mild steel (metal) and galvanized steel.

NOTCHER CONFIGUATIONS

The standard notcher machines are normally configured with either 3 heads or 5 heads.

The 3 head configuration includes notch heads for; 1 (one) female seam corner (left side), 1 (one)

male seam corner (right side) and 1 (one) slot notch die. The 3 head notcher can produce L-

section ductwork. Add 2 Vee notch heads for the 5 head machine to produce wrap uct.

The 5 head notcher can produce L section and Wrap-Duct

Both the 3 head and the 5 head can produce 4 sided (4 piece duct)

More Productive Metal Forming Solutions

VER. TDC-Notcher -CE 03-2006 PAGE 6

OPERATING INSTRUCTIONS

∆DISCONNECT POWER BEFORE ATTEMPTING TO MAKE ANY ADJUSTMENTS

ON THE MACHINE.

Install power lock outs to prevent accidental start-up while working on the machine!

The TDC NOTCHER has a Safety Lock-Out valve which is to be CLOSED (OFF) when

ever the machine is serviced or adjusted. The Valve is in the off position in FIG 1

Fig. 1

BASIC OPERATION

IMPORTANT: When starting the unit check to see whether motor and pump rotation conforms to

direction of arrows on motor and pump body. CAUTION: Jog unit until proper rotation is achieved.

damage to pump will result if run backward to rotation arrow.

CYLINDER SHUT OFF VALVES: Each individual cylinder has a valve connected to the hydraulic

hose. This valve can be turned on or off to activate or deactivate a particular notch head as

required.

OPERATION:Loosen left hand notching head and slide to zero mark on Back Scale, clamp into

position. Move VEE NOTCHING heads to required spacing by locating left side of heads to

required measurement from zero on scale.

EXAMPLE: 4”inch x 12”inch DUCT in L duct (2 piece rectangular construction)

PROCEDURE:

(1) Left forming head set at zero. NOTE: seam depth of notch required for Pittsburgh Lock (Small

Pittsburgh) is 1”inch (25mm). Large Pittsburgh is 1 3/8”inch (35mm) ( see section below

ADJUSTING THE NOTCH DEPTH)

(2) Move first VEE NOTCHING head to 4”inch on the tape and secure.

(3) Move right hand notching head to required notch depth of 1/4”inch for right angle flange (small

Pittsburgh).

(4) Place proper width of material onto gauge support table and square duct to gauge pins.

{Material width is 17-1/4”inch for 4”inch x12”inch L-duct using Small Pittsburgh Lock and 1/4”inch

(6mm) 90 o Flange}

(5)Activate notching heads by depressing foot switch until notching is completed. Release foot

switch and remove completely notched duct sheet.

More Productive Metal Forming Solutions

VER. TDC-Notcher -CE 03-2006 PAGE 7

ΔCAUTION: Release foot switch immediately after cutting is completed. If foot

switch is kept depressed oil pressure will be at maximum setting of relief valve

and will cause unnecessary heating of oil and possible damage to pump.

Notching heads will notch the equivalent of 16 ga. Material (.062),

NOTE: Notching heads not required can be quickly deactivated by closing the

valve at the notch head. This makes heads not required inoperative.

ADJUSTING THE NOTCH DEPTH

The notch depth can be adjusted by moving the gauge pin blocks or moving the pin to the next

hole.

1. Move the pin to the next hole. Moving the pin over should allow for either SMALL

PITTSBURGH or LARGE PITTSBURGH Notches.

2. Fine tuning the notch depth can be accomplished by loosening the screws that hold the blocks

and sliding the blocks in the desired direction to either add notch depth or subtract notch depth.

The gauge pin blocks are slotted for this purpose.

TDC NOTCH DEPTH - 2 7/16”inch (62mm)

TDF NOTCH DEPTH - 2/9/16inch (65mm)

More Productive Metal Forming Solutions

VER. TDC-Notcher -CE 03-2006 PAGE 8

MAINTENANCE

∆DISCONNECT POWER BEFORE ATTEMPTING TO MAKE ANY ADJUSTMENTS

ON THE MACHINE.

Install power lock outs to prevent accidental start-up while working on the machine!

For proper maintenance of the hydraulic system, the oil should be kept clean and free of dirt or

other foreign matter. The system should be changed after approximately one year’s operation.

This is accomplished by removing drain plug at bottom of reservoir. Replace and fill with clean

filtered oil. A ruler inserted to bottom of reservoir will indicate 7” when proper oil level is reached.

Volume - 10-12 US Gallons, (40-50 liters). Fill to middle of level site on the back of

machine.

DIE CARE AND MAINTENANCE: Punch and dies are manufactured of high carbon high chrome

tool steel for maximum cutting service. When die cutting surfaces become worn it will be

necessary to resharpen.

NOTE: When punch and dies are to be sharpened in the field, grind flat top surface of die

and lower cutting surface of punch. You will note punch has rake angle. This rake

angle must be maintained.

A LIGHT OIL SHOULD BE APPLIED OCCASIONALLY TO CUTTING SURFACE OF PUNCH

AND DIE TO PROLONG DIE LIFE.

NOTE: A slight clearance, not to exceed 0.003”inch( 0.7mm), should be set betwee punch

and die on SLOT-NOTCH by placing a 0.003”inch (0.7mm) to 0.0025” (6.5mm) spacer shim

on both sides of cutting edge of dies.

. For CORNER NOTCH punch and dies, the clearance should be 0.005” (1.3mm).

Setting the clearances is accomplished by adjusting the gibs in the back of the notcher

head.

OIL PRESSURE

During the operation of the machine while the foot switch is depressed and the notchers

have stopped in the down position,the oil pressure should attain a maximum pressure of

1700-1800PSI (12BAR)

OIL: The oil used in the reservoir is a

commercial hydraulic

N46 or N68 oil.

RANDO AW HYDR-46 HYDRAULIC OIL

(TEXACO),AW-68 HYDRAULIC OIL (AMACO)

DTE #26 MOBILE

More Productive Metal Forming Solutions

VER. TDC-Notcher -CE 03-2006 PAGE 9

TDC-Notcher PARTS

More Productive Metal Forming Solutions

VER. TDC-Notcher -CE 03-2006 PAGE 10

More Productive Metal Forming Solutions

VER. TDC-Notcher -CE 03-2006 PAGE 11

More Productive Metal Forming Solutions

VER. TDC-Notcher -CE 03-2006 PAGE 12

More Productive Metal Forming Solutions

VER. TDC-Notcher -CE 03-2006 PAGE 13

More Productive Metal Forming Solutions

VER. TDC-Notcher -CE 03-2006 PAGE 14

More Productive Metal Forming Solutions

VER. TDC-Notcher -CE 03-2006 PAGE 15

Due to continuous improvements, FORMTEK reserves the right to modify the product

design and specifications contained herein without notice. Please contact your

Lockformer sales representative for the most current specification information.

Use, publication, or sale of any images or content without the expressed

written consent of FORMTEK is strictly prohibited.

Visit Our Web Site at:

www.lockformer.com

or www.formtekinc.com

USA

Formtek Inc, 182 Northwest Industrial Cr.

Bridgeton, MO 630441

China

Formtek Machinery (Beijing) Co., Ltd. Beiqijia High-Tech Industrial Park,

Changping, Beijing 102209

Table of contents