Formula Air BADA000018 User manual

BADA ATEX Non-Return Valve

Maintenance Manual

1

Contents

1.

PRODUCT DESCRIPTION .................................................................................................................. 2

1.1

How it works............................................................................................................................ 3

1.2

Overall dimensions.................................................................................................................. 5

1.3

Technical datasheet................................................................................................................. 6

1.3.1

Push flow situation .......................................................................................................... 6

1.3.2

Pull flow situation............................................................................................................ 6

1.3.3

Special conditions for safe use ........................................................................................ 6

2

INSTALLATION ................................................................................................................................. 8

2.1

Valve installation direction...................................................................................................... 8

2.2

Connecting the non‐return valve ............................................................................................ 9

2.3

Precautions for a proper use................................................................................................... 9

3

INSTALLATION ............................................................................................................................... 10

3.1

Maintenance.......................................................................................................................... 10

3.1.1

Cleaning and checking the inside of the non‐return valve............................................ 11

4

ATEX CERTIFICATION ..................................................................................................................... 12

4.1

Potentially explosive atmosphere ......................................................................................... 12

4.1.1

Dangerous areas classification ...................................................................................... 12

4.1.2

Dangerous areas classification ...................................................................................... 13

4.2

ATEX code description........................................................................................................... 13

4.3

Production identification....................................................................................................... 14

5

USEFUL INFO RELATED TO THIS MANUAL..................................................................................... 15

6

DISMANTLING AND RECYCLING .................................................................................................... 16

7

CONTACTS ..................................................................................................................................... 17

2

1.

PRODUCT DESCRIPTION

The non‐return valves are ATEX certificated protective systems which prevent a dust explosion

propagation through the ductwork into other areas. The non‐return valve cannot isolate a dust

explosion when it propagates through the normal air flow direction.

The non‐return valves are not designed to prevent the transmission of fire or burning powder

transported by the normal process flow.

The non‐return valves are built in 3 mm thick 16mo3 steel, powder coated RAL 5010 and the flap

of HB400 (Hardox).

Formula Air Non‐return valves fulfill all relevant requirement to be used safely in an explosion

hazardous environment. To accomplish this, several instructions are described in this manual and shall

be following prior to and during operation.

The following harmonized standards have been applied:

EN‐ISO80079‐36:2016 Explosive atmospheres – Part 36: Non‐electrical equipment for

explosive atmospheres – Basic method and requirement

EN 16447:2014 Explosion isolation flap valves

Figure: 1 shows a non‐return valve.

Figure: 1 Non‐Return Valve

3

1.1 How it works

During the normal process, the non‐return valve’s flap remains opened due to the airflow

(Figure: 2). At deadlock, the valve closes due to the flap’s own weight.

Figure: 2 Non‐Return Valve in open airflow configuration

When an explosion takes place, the ATEX certified non‐return valve blocks the expansion of the

explosion due to the front spreading pressure along the ductwork (Figure: 3).

Figure: 3 Non‐Return Valve in closed configuration

After an explosion and due to pressure oscillations, the valve could re‐open. To avoid the re‐

opening, a safety lock system keeps the valve closed long enough to avoid the propagation of

flames during the explosion event, as can be seen in Figure: 4. The locking system consists of a

spring metal that allows it to bend easily. Therefore, if the flap closes the arm hits the locking

system and the top of the locking system will give in. This way, the flap gets locked beneath the

top plate of the locking system. Once the explosion is completely over, the lock must be

4

in

in

ato

fl

unblocked manually. Before unblocking the valve flap, the complete valve should be checked after

an explosion has occurred for possible damage which could hinder the proper functioning.

Note that the inner flap can also lock itself due to reverse current cleaning of the filter. If this is

the case, the installation distance and reverse flow pressure should be checked to reduce the

effect on the non‐return valve.

Figure: 4 Locking system inside the Non‐Return Valve Figure: 5 Illustration how the indicator works

When the dicator is

this position the flap

inside the non‐return

valve is open

When the indic r is in

this position the ap inside

the non‐return valve is

closed and has to be

unlocked manually

5

1.2 Overall dimensions

Figure: 6 Overall dimensions

Type

Ø d

(mm)

A

(mm)

B

(mm)

C

(mm)

E

(mm)

F

(mm)

S

(mm)

Mass

(kg)

BADA000018

204

470

510

590

137

52

3

45

BADA000019

254

520

555

620

137

52

3

52

BADA000020

304

570

610

640

137

52

3

60

BADA000021

354

620

660

670

137

52

3

70

BADA000022

404

670

710

735

157

52

3

83

BADA000023

454

720

760

785

157

52

3

94

BADA000024

504

770

810

835

157

52

3

106

BADA000025

554

820

860

885

157

52

3

118

BADA000026

604

870

910

935

157

52

3

130

BADA000010

653

985

1021

+/‐ 1090

247

71

3

169

BADA000011

703

1035

1072

+/‐ 1120

247

71

3

185

BADA000012

753

1085

1127

+/‐ 1150

247

71

3

199

BADA000013

803

1152

1213

+/‐ 1220

277

71

3

229

BADA000014

853

1202

1263

+/‐ 1340

277

71

3

241

BADA000015

903

1252

1313

+/‐ 1340

277

71

3

268

BADA000016

953

1302

1363

+/‐ 1340

277

71

3

281

BADA000017

1003

1352

1413

+/‐ 1340

277

71

3

294

6

1.3 Technical datasheet

1.3.1

Push flow situation

Considering the normal process flow direction, the situation where the fan is located upstream of

the explosion source (Figure: 7).

1.3.2

Pull flow situation

Figure: 7 Push flow situation

Considering the normal process flow direction, the situation where the fan is located downstream

of the explosion source (Figure: 8).

Figure: 8 Pull flow situation

1.3.3

Special conditions for safe use

Installation:

−

Installation, operation, maintenance and repair in areas with danger of explosions may only

be carried out by qualified personnel;

−

Ensure that no tools, nuts and bolts or assembly parts remain in the machine during assembly

or maintenance;

−

Selection and installation of the electrical parts within hazardous areas shall be fulfilled

according the EN60079‐14 and the installation instructions of the specificequipment;

−

No potential difference between all metal parts within the non‐return valve, or between

non ‐ return valve and earth may exist. Therefor earthing resistance between all metal parts

and earth shall be measured before operation and shall be maximum 1 MΩbetween

7

individual items and to earth and the connected process structure. An earthing resistance

higher than 10Ωmay indicate bad earth connections;

−

An earth connection is provided externally on both sides and a lid of the valve. The external

earth connections shall be used to bond other process parts with a equipotential bonding

conductor of at least 4 mm2;

−

The valve should only be exposed to organic or non‐metallic dust;

−

Ambient temperature range: from ‐20oC to +60oC;

−

Parameters of the dust: organic non‐metal dust, Kst,max=200 bar.m.s‐1, MIE=13mJ, MIT=430oC.

−

DN 200 – 400: Pull and Push, stright pipes or 2x90obend is allowed between the protected

vessel and the flap;

−

DN 450 – 1000: Pull flow situation, straight pipes between the protected vessel and the flap

and venting on the protective vessel only non‐reclosing vent devices. (this excludes e.g.

suppression and venting with reclosing vent devices);

−

The maximal speed flow is 25 m.s‐1;

−

The maximum dust concentration in the ducting is witout the limit;

−

The product has to be installed so that the propagating brush discharges on the extrenal

surface of the device are avoided:

−

The electrical devices installed together with the back pressure flap must have th etype of

protection corresponding with the defined explosive zone;

−

Flap position is horizontal.

Parameters dependent on the size of the flap:

Parameters of flap (unit):

Sizes DN (mm):

200

250 ‐ 400

450 ‐ 600

650 ‐ 1000

p

red, max

(bar)

0,50

0,50

pmax (bar) design pressure ‐ EN 14460

1

1

0,8

0,70

minimal vessel volume (m3)

0,46

0,96

6

6

minimal installation distance (m)

2,2

3,1

4

4

maximal installation distance (m)

7,2

7,2

7,2

7

maximum allowable opening angle of the blade

to the vertical

60o 60o 60o 50o

inclination of flap valve

horizontal

maximal speed flow (m.s‐1)

25

max. dust concentration in duct where device

will be installed

Without limits

8

2

INSTALLATION

CAUTION! The non‐return valve installation, connection, start‐up and maintenance has

to be performed in absence of potentially explosive atmosphere through the process

interruption.

CAUTION! The installation, connection, start‐up and maintenance of the non‐return valves have to

be performed by qualified personnel. Use the right equipment and costumes, and do not work alone.

2.1 Valve installation direction

For a right installation, the air flow direction in normal working conditions has to be the same as

indicated by the arrows on Figure: 9.

Figure: 9 Installation direction regarding to the Air flow

The non‐return valve needs to be installed horizontally. The inspection panel must always be set

upwards, see Figure: 10.

Figure: 10 Installation direction

Air Flow

9

2.2 Connecting the non‐return valve

For the best isolation effectiveness, the non‐return valve needs to be installed in proximity of the

risk zone which it is wanted to be isolated.

Step 1: Connect the inlet and outlet to the duct system with the correct fasteners.

Step 2: Make sure that the indicator is in the correct position (Figure: 11).

Figure: 11 Indicator Position

2.3 Precautions for a proper use

CAUTION!

−

It is strictly forbidden to open the inspection panel while the installation is running;

−

During maintenance keep the system disconnected and all the electrical equipment turned

off;

−

The valve should not be placed in an environment that could create a vibration in the

non ‐ return valve;

−

After the event of an explosion, do not unblock or manipulate the non‐return valve until the

explosion is completely extinguished. Check if the non‐return valve and its parts are working

properly. Clean the valve. Replace any parts that are damaged!

Make sure the indicator is inthis position

When the indicator is in this position, the

Valve is blocked, and it will block the airflow

10

CAUTION!

Be aware of hot particles remaining inside the valve, even if the explosion is over.

While opening the inspection panel, parts can fall off from the inside, damaging the

operator or goods.

−

Every time there is a potentially explosive atmosphere danger, special safety steps must be

taken, as the following:

Tools or operations which can produce sparks, which can cause gas

ignition, or flammable vapors, are not allowed to be used in any procedure that takes

place in any area classified as explosion risk.

Avoid dust removal by blowing while cleaning.

The use of free flames near the explosion risk area is strictly forbidden.

3

INSTALLATION

CAUTION! The non‐return valve installation, connection, start‐up and maintenance

must be performed in absence of potentially explosive atmosphere through the

process interruption.

CAUTION! The installation, connection, start‐up and maintenance of the non‐return

valves must be performed by qualified personnel. Use the right equipment, clothing and individual

protection devices according to the situation, and do not work alone.

CAUTION! Any modifications done by the user on the non‐return valve are prohibited!!

3.1 Maintenance

Replacement parts must be purchased from original manufacturer to guarantee explosion

protection.

CAUTION! Internal parts of the non‐return valve shall be inspected 2 monthly for signs of

wear. Especially the EPDM valve seal shall be intact and in place. If EPDM valve seal is worn or not

fitted correctly, the seal must be replaced to guarantee explosion safe operation.

Clean and check the performance of the non‐return valve regularly. It is strictly forbidden to open

the inspection panel while the air flow is running through the duct.

During maintenance keep the system disconnected and all the electrical equipment turned off.

11

3.1.1

Cleaning and checking the inside of the non‐return valve

Step 1: Open the inspection panel as shown in Figure: 12.

Figure: 12 opening inspection panel

Step 2: Clean the inside of the valve and check the condition of every part.

Step 3: Close the inspection as shown in Figure: 13. If necessary, renew the sealing tape to make

sure it remains airtight.

Figure: 13 closing inspection panel

12

4

ATEX CERTIFICATION

EXPLOSIVE ATMOSPHERE DANGER

This symbol indicates information concerning the directive ATEX 2014/34/EU.

Every information attended by this symbol must be executed by highly qualified personnel,

competent in safety environments regarding to places characterized by the presence of potentially

explosive atmospheres.

4.1 Potentially explosive atmosphere

An explosive atmosphere for the purpose of Directive 2014/34/EU is defined as a mixture with air,

under atmospheric condition, of flammable substances in the form of gases, vapors, mists or dusts in

which, after ignition has occurred, combustion spreads to the entire unburned mixture.

A potentially explosive atmosphere is an atmosphere which could become explosive due to local

and operational conditions.

4.1.1

Dangerous areas classification

In carrying out the obligations laid down in Directive 99/92/EC, hazardous places are classified in

terms of zones on the basis of the frequency and duration of the occurrence of an explosive

atmosphere.

Zone 0: A place in which an explosive atmosphere consisting of a mixture with air of flammable

substances in the form of gas, vapor or mist is present continuously or for long periods for frequently.

Zone 1: A place in which an explosive atmosphere consisting of a mixture with air of flammable

substances in the form of gas, vapor or mist is likely to occur in normal operation occasionally.

Zone 2: A place in which an explosive atmosphere consisting of a mixture with air of flammable

substances in the form of gas, vapor or mist is not likely to occur in normal operation but, if it does

occur, will persist for a short period only.

Zone 20: A place in which an explosive atmosphere in the form of a cloud of combustible dust in air

is present continuously, or for long periods or frequently.

Zone 21: A place in which an explosive atmosphere in the form of a cloud of combustible dust in air

is likely to occur in normal operation occasionally.

Zone 22: A place in which an explosive atmosphere in the form of a cloud of combustible dust in air

is not likely to occur in normal operation but, if it does occur, will persist for a short periodonly.

13

4.1.2

Dangerous areas classification

The ATEX 2014/34/EU Directive classifies the protection system (in this case the non‐return valve)

into 3 categories, with different protection levels, guaranteed to the related protection.

Protection Level

Plant

Dust Category

Very High 1D (zone 20)

High 2D (zone 21)

Normal 3D (zone 22)

4.2 ATEX code description

The non‐return valve is marked according the European Directive 2014/34/EU:

II 1D/2D Ex h IIIB T85OC Da/Db

II D St 1

Ta= ‐20OC to +60OC

In which:

CE : CE‐marking and number of the noticed (monitoring) body (1026) (not for equipment

category 3)

Ex : Explosive protection symbol (ATEX)

II : Equipment group II for use above ground

1

: Equipment category (Category 2)

2

: Equipment category (Category 2)

D : Explosive atmosphere (dust)

Ex : Explosive protection marking

h : Type of protection

IIIB : Equipment group (Electrical apparatus group III, subgroup IIIB (non‐conductive dust),

intended for use in areas where an explosive dust atmosphere is to be expected, other than mines

susceptible to firedamp)

T850: Surface temperature

Da : Equipment Protection Level (EPL Da; equipment with very high protection level)

St 1 : Suitable as explosion isolation flap valve for dust explosion class St 1

Ta : Allowed ambient temperature range

14

4.3 Production identification

The identification of Formula Air Group as manufacturer of the non‐return valve is due to the

conformity with the current legislation by means of the following:

−

Declaration of conformity according to Directive ATEX 2014/34/EU

−

Maintenance manual

−

Marking plate ATEX of outlet explosion device BADA 200‐1000 Figure: 15.

P. Motiekaičio g. 3

2 1 LT‐77104 Šiauliai

Lithuania

Product:

Non‐Return Valve

Type: BADA XXXX FF20‐ATEX

Serial Number:

XXXXXXXXXX

Production year:

20XX

P

Red, max

X.X bar

P

max

X.X bar

V

max

XX m/s

T

amb

‐20°C to +60°C

Minimal vessel volume

X m

3

Inclination of flap valve

Horizontal

Max. dust concentration

Without limits

ATEX certificate:

FTZÚ 18 ATEX 0141X

II D St 1

EN 16447:2014

II 1D/2D Ex h IIIB T850C

Da/Db

Please refer to user manual before installation

Figure: 15 Name label used for every ATEX Non‐Return Valve 200 ‐ 1000

Explanation of the label Figure: 15:

1)

Name and address of the manufacturer

2)

CE marking

3)

Designation of series of type

4)

Serial number

5)

Year of construction

6)

Explosion resis tance pressu re or explosion shock resistance pressure for the flap valve*

7)

Maximal airspeed

8)

Ambient temperature range

9)

The volume of the Non‐Return Valve

10)

Positioning of the Non‐Return Valve

11)

Maximal dust concentration in duct at install location

12)

The certification references

13)

The numbers of standard that are used

14)

For equipment‐group II, G (Gas) and/or D (Dust)**

* Acconding to EN 16447:14.

** Acconding to II ATEX 2014/34/EU minimum info (some other manuals have more info);

3

4

5

6

7

8

9

10

11

12

13

15

5

USEFUL INFO RELATED TO THIS MANUAL

This manual is compiled in accordance with the Directive ATEX 2014/34/EU.

This manual cannot be reproduced, even partially, without prior written consent by Formula Air Group.

Every step of the non‐return valve all along its life cycle has been deeply analyzed by Formula Air

Group in the expected area during the design, construction and manual creation. However, it is

understood that nothing can replace the experience, training and good sense of those professionals

who work with the device.

Ignoring the cautions and warning from the present manual, using improperly parts or the whole

device supplied, using not authorized spare parts, manipulation the device by non‐qualified personnel,

violation of any safety norm regarding design, construction and use expected by the supply, release

Formula Air Group from every responsibility in case of damages to people or properties.

Formula Air Group does not take any responsibility for the non‐observance of the user with regard

to the preventive safety measures presented in this manual.

Warranty:

Regarding to the device’s warranty, see the sales general condition in the contractual center.

NOTE: All drawings and references contained within this manual are non‐contractual and are

subject to change without prior notice at the discretion of the Formula Air Group and its partners.

16

6

DISMANTLING AND RECYCLING

When dismantling a unit, be sure to keep in mind the following important information:

CAUTION! Make sure there is no remaining any explosion potential dust of similar before

dismantling. As the unit is dismantled, set aside all still functioning parts in order to re‐use them on

another unit. You should always separate the different materials depending on their type: steel,

stainless steel, rubber, foams, etc…

Recyclable parts must be disposed in the appropriate containers or brought to a local recycling

company. The rubbish must be collected in special containers with appropriate labels and disposed in

compliance with the nation laws and/or local legislations if force Figure: 14.

CAUTION! It is strictly forbidden to dispose toxic wastes in municipal sewerage and drain

systems. This concerns all oils, greases, and other toxic materials in liquid or solid form.

Figure 14: Recycling the Non‐Return Valve

17

7

CONTACTS

For spare parts please contact Formula Air Group.

Formula Air France Nord

Zac de la Carriere Dorée

BP 105,

59310 Orchies, France

Tel : +33 (0) 320 61 20 40

contact‐nord@formula‐air.com

Formula Air Nordic

Södra Vallviksvägen 12

352 57 Vaxjo,

Sweden

Tel : +46 (0)8 12 41 01 24

info‐scan@formula‐air.com

Formula Air Belgium

Rue des Dizeaux 4

1360 Perwez,

Belgium

Tel: +32 (0) 81 23 45 71

info‐be@formula‐air.com

Formula Air France Est

2, rue Armand Bloch

25200 Montbéliard,

France

Tel : +33 (0) 381 91 70 71

contact‐est@formula‐air.com

Formula Air Russia

Нижний Новгород

Россия

Tel : +7920008 88 75

info‐ru@formula‐air.com

Formula Air Germany

Dr. Oetkerstrasse 10

54516 Wittlich,

Germany

Tel 49 (0) 65 71 26 98 6‐0

info‐de@formula‐air.com

Formula Air France Sud

Chemin de Peyrecave

09600 Regat,

France

Tel : +33 561 66 79 70

contact‐sud@formula‐air.com

Formula Air The Netherlands

Bosscheweg 36

5741 SX Beek en Donk,

The Netherlands

Tel : +31 (0) 45 492 15 45

info‐nl@formula‐air.com

Formula Air Baltic

P. Motiekaicio g. 3

77104, Šiauliai,

Lithuania

Tel: +370 41 54 04 82

info‐lt@formula‐air.com

Formula Air France Ouest

6 Avenue des Lions

44800 Saint Herblain,

France

Tel : +33 (0) 251 89 90 75

contact‐ouest@formula‐air.com

Formula Air Export

Rue des Dizeaux 4

1360 Perwez,

Belgium

Tel : +32 (0) 81 23 45 71

customerservice@formula‐air.com www.formula‐air.com

NOTE : All drawings and references contained within this manual are non-contractual and are subject to

change without prior notice at the discretion of the Formula Air group and its partners.

This manual suits for next models

16

Table of contents

Other Formula Air Control Unit manuals

Popular Control Unit manuals by other brands

Rain Bird

Rain Bird TBOS manual

Vapotherm

Vapotherm Oxygen Assist Module Instructions for use

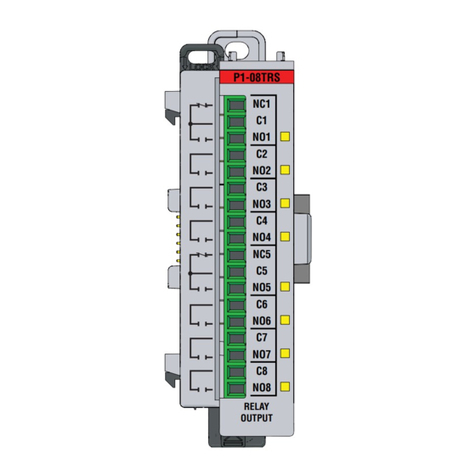

Automationdirect.com

Automationdirect.com Productivity 1000 P1-08TRS manual

BARIX

BARIX IPAM 400 Preliminary Development Specification

ICP DAS USA

ICP DAS USA M-7002 quick start guide

Telit Wireless Solutions

Telit Wireless Solutions SE867-AGPS user guide