Formula Air RVA1-NX-06 User manual

User manual | RVA Rotary valves

www.formula-air. com

1

RVA Rotary valves

Maintenance manual (EN)

User manual | RVA Rotary valves

www.formula-air. com

2

Content

1. Introduction .................................................................................................................................................... 3

2. Product description......................................................................................................................................... 3

2.1 How it works ........................................................................................................................................... 4

2.1.1 Rotary valve body................................................................................................................................... 4

2.1.2 Rotor ...................................................................................................................................................... 4

2.1.3 Motor and Gearbox................................................................................................................................ 4

2.2 Overall dimensions.................................................................................................................................. 5

2.3 Technical datasheet ............................................................................................................................... 5

2.4 Electrical connection............................................................................................................................... 6

2.5 Precautions for proper use ...................................................................................................................... 6

2.6 Gearbox & Motor.................................................................................................................................... 6

3. Maintenance .................................................................................................................................................. 6

3.1 Periodic maintenance ............................................................................................................................. 6

3.2 Overhaul................................................................................................................................................. 6

3.3 Motor, gearbox & bearings..................................................................................................................... 6

3.3.1. Bearing Maintenance ............................................................................................................................ 6

3.3.2. Greasing interval ................................................................................................................................... 7

3.4 Replacing spare parts............................................................................................................................. 7

3.4.1 Rubber wear out.................................................................................................................................... 7

3.4.2 Replacing the rubber blades.................................................................................................................. 7

3.5 Noise level.............................................................................................................................................. 8

4. Components and spare parts.......................................................................................................................... 8

5. Rotation detector (optional)............................................................................................................................ 9

5.1 Placing the rotation detector ................................................................................................................. 9

5.2 Connecting the detector ...................................................................................................................... 11

6. Troubleshooting ............................................................................................................................................. 11

7. Dismantling and recycling.............................................................................................................................. 12

8. Maintenance log............................................................................................................................................ 13

User manual | RVA Rotary valves

www.formula-air. com

3

1. Introduction

This manual cannot be reproduced, even partially, without prior written consent by Formula Air Group. Every step of

the rotary valve all along its life cycle has been deeply analyzed by Formula Air Group in the expected area during

the design, construction, and manual creation. However, it is understood that nothing can replace the experience,

training and good sense of those professionals who work with the device.

Ignoring the cautions and warning from the present manual, using improperly parts or the whole device supplied, using

unauthorized spare parts, manipulating the device by non-qualified personnel, violation of any safety norm regarding

design, construction and use expected by the supplier, exempt Formula Air Group from all responsibility in case of

damages to people or properties.

Formula Air Group does not take any responsibility for the non-observance of the user about the preventive safety

measures presented in this manual.

The use implies compliance and knowledge of the Machine Directive 2006/42/EU.

Failure to comply with the requirements of the operating manual or incorrect use of the rotary valve during operation

can lead to the damage of the rotary valve and the loss of the proper function performed by the rotary valve itself.

This will result in termination of the warranty on the item and will release the manufacturer from any liability.

Warranty

Regarding to the device’s warranty, see the Sales General Conditions with your local Sales Office.

Attention

Before proceeding with the installation of the rotary valve, ensure that the markings on the product are compatible

with the rating of the site of use. Failure to comply with this prescription can cause serious injury to persons including

death and/or serious damage to property.

NOTE: All drawings and references contained within this manual are non-contractual and are subject to change

without prior notice at the discretion of the Formula Air Group and its partners.

Copyright © Formula Air.

The rotary valves are not designed to prevent the transmission of fire or burning powder transported by the normal

process flow.

The rotary valves are built in 3 mm thick steel, powder coated RAL 5010 and neoprene rubber.

2. Product description

Formula Air rotary valves fulfil all relevant requirement to be used under filters or cyclones. To accomplish this, several

instructions are described in this manual and shall be following prior to and during operation.

Note that besides the rotary valve, the complete installation needs to comply to :

2006/42/EU – Machine Directive

2014/35/EU – Low Voltage Equipment Directive

2014/30/EU – Electromagnetic Compatibility and Repealing Directive (EMC)

2014/68/EU – Pressure Equipment Directive

User manual | RVA Rotary valves

www.formula-air. com

4

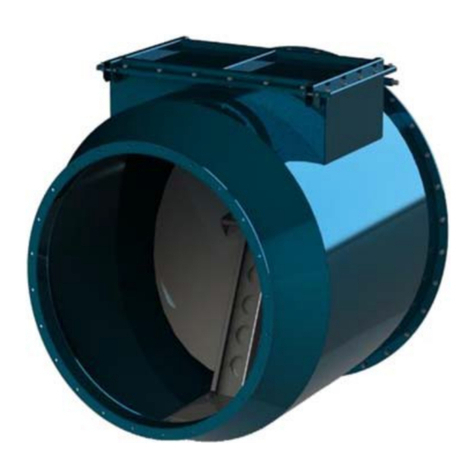

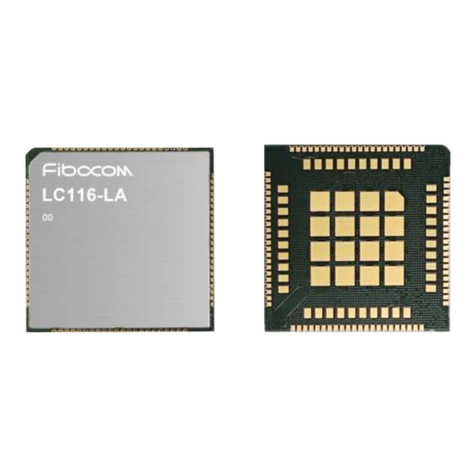

Figure 1. Formula Air rotary valve

2.1 How it works

The rotary valve is functionally built up of the following main components :

1. Rotary valve body

2. Rotor with rubber blades

3. Drive set (motor and gearbox)

Figure 2. Structural design

2.1.1 Rotary valve body

The rotary valve body is made of sheet steel. Inlet and outlet are foreseen with flange connection. The end plate

positioned at the drive set can be dismounted in a way that provides access to the rotor. The rotary valve body is

powder coated.

2.1.2 Rotor

The rotor is built up of a rotor shaft mounted with 6 sets of chambers. Neoprene rubber blades are mounted in the

blade retainers in the chambers.

2.1.3 Motor and Gearbox

The rotor is driven by an electric motor. The connection between rotor and electric motor is established by a gearbox.

User manual | RVA Rotary valves

www.formula-air. com

5

2.2 Overall dimensions

Type

A

(mm)

B

(mm)

C

(mm)

D

(mm)

E

(mm)

F

(mm)

G

(mm)

Mass

(kg)

RVA1-NX-06

250

316

150 (1x150)

68

286

418

782

48

RVA2-NX-06

500

566

450 (3x150)

43

536

494

1108

74

RVA3-NX-06

750

816

600 (4x150)

93

786

494

1359

91

RVA4-NX-06

1000

1066

900 (6x150)

68

1036

494

1609

107

RVA5-NX-06

1500

1566

1350 (9x150)

93

1536

494

2109

141

2.3 Technical datasheet

Installation, operation, maintenance, and repair may only be carried out by qualified personnel.

Ensure that no tools or foreign objects remain in the machine during assembly or maintenance.

Selection and installation of the electrical parts shall be fulfilled according the EN60079-14 and the installation

instructions of the specific equipment.

The airtightness of the rubber blade has to be controlled regularly according to the instructions in this user manual.

CAUTION!

The installation, connection, start-up and maintenance of the rotary valves have to be performed by qualified

personnel. Use the appropriate equipment and clothing, apply the necessary safety measures and do not work alone.

The rotary valve must not be started until it has been mechanically connected on both sides to other ducting

components by means of the built-in flanges.

The rotary valve must be sealed on both sides of the hole series and bolted in the predrilled holes.

It is mandatory to make sure that the whole installation is stopped and cannot be started-up again before everything

is connected and assembled.

User manual | RVA Rotary valves

www.formula-air. com

6

2.4 Electrical connection

Electrical connection must only be carried out by a certified electrician. When making the electrical

connection, check that the rotary valve rotor is turning in the correct direction. The rotation direction

is indicated by an arrow on the rotation disk cover.

The electrical connection must be carried out in accordance with current local and national

regulation.

2.5 Precautions for proper use

CAUTION!

It is strictly forbidden to open the rotary valve while the installation is running.

During functioning, the user has to ensure himself that there is no material stacking or material build-up inside the

rotary valve in order to ensure the proper discharge of the material.

During maintenance keep the system disconnected and all the electrical equipment turned off.

Avoid dust removal by blowing while cleaning.

2.6 Gearbox & Motor

For information on the installation of the gearbox and drive motors, see relevant manuals from the original

manufacturers (supplied separately).

Electrical parts shall be maintained according to manufacturer’s instructions and inspected periodically according to

local and national legislation (e.g. EN 60079-17).

IMPORTANT : Always wear the required safety equipment. The national safety rules in force must be observed.

3. Maintenance

3.1 Periodic maintenance

In order for the rotary valve to be guaranteed by the manufacturer, regular maintenance must be carried out by the

installer, manufacturer or a distributor appointed by the manufacturer.

Maintenance must always be carried out according to the instructions in the manual.

3.2 Overhaul

For the manufacturer’s guarantee to apply, the customer must have regular maintenance carried out by the installer,

manufacturer or a distributor appointed by the manufacturer.

For distributors to be approved to carry out maintenance for the manufacturer, they must be trained by the

manufacturer. The following must be checked: rubber blades, rotor, bearings, gearbox and motor.

NOTE : Rubber blades and sealing ring must be impermeable! Monitor wear regularly until service intervals can be

determined. Overhaul must minimum take place every 6 months.

3.3 Motor, gearbox & bearings

3.3.1. Bearing Maintenance

The lifespan of the grease is influenced by many factors. The greasing intervals in our table thus can only be seen as

very rough estimates.

Experience with comparable bearings or ones already used is therefore very important as not all operating conditions

and influential factors that affect the service life of a lubricant – and hence also the bearing – are known or

determinable in many cases.

User manual | RVA Rotary valves

www.formula-air. com

7

3.3.2. Greasing interval

Operating

temperature of

bearing °C

Greasing interval

Environmental conditions

Clean

Dirty

Very dirty

Heavily humid

50

3 years

6 months

3 months

70

1 year

2 months

1 month

100

3 months

2 weeks

1 week

For information on the maintenance of the gearbox and drive motors, see relevant manuals from the original

manufacturers (supplied separately).

3.4 Replacing spare parts

If the rubber blades are not impermeable or worn, they must be replaced. Visual inspection is carried out.

3.4.1 Rubber wear out

Rubber blades are worn out and must be replaced when dimension A and B are below optimal measurements in the

following table (See figure 4).

*

Figure 4. Rubber wear out

3.4.2 Replacing the rubber blades

CAUTION! Before any manipulation to the rotary valve, make sure that the motor is stopped and that all electrical

connections are disconnected.

NOTE : all electrical manipulations should be performed by qualified personnel only.

Step 1 : Unscrew the nuts and bolts holding the rubber blades.

Step 2 : Take the rubber blades out.

RVA size

A (mm)

B (mm)

RVA1

32

10

RVA2

38

10

RVA3

38

10

RVA4

38

10

RVA5

38

10

User manual | RVA Rotary valves

www.formula-air. com

8

Step 3 : Introduce the new rubber blades into the metal vane gap. Make sure that the holes are aligned, and the flap

is in the right direction then bolt them back.

3.5 Noise level

The noise ratio of the component in our scope of supply in connected condition and without media is below 70 dB (A)

measured at 1 meter from the component.

Noise from transported media is not included.

IMPORTANT!

A higher noise level may occur depending on local conditions, transported material and other components connected

to the rotary valve. In this case separate measurements may be required.

If the total noise level in the area exceeds 85 dB (A), hearing protection must be used.

4. Components and spare parts

Figure 8. Exploded view

User manual | RVA Rotary valves

www.formula-air. com

9

Spare parts

Code Description

JCAB000028

Bearing for RVA rotary valve (all models)

JCAB000001

Set of rubber blades (6 pcs) for RVA1

JCAB000002

Set of rubber blades (6 pcs) for RVA2

JCAB000003

Set of rubber blades (6 pcs) for RVA3

JCAB000004

Set of rubber blades (6 pcs) for RVA4

JCAB000005

Set of rubber blades (6 pcs) for RVA5

JCAB000027

Felt seals kit for all RVA rotary valve (2 seal rings)

JEBB000001

Gearbox for motor 0,37kW

JEBB000002

Gearbox for motor 0,55kW

JEAA000005

Motor - IE2 - 0,37kW - 4Pole - 230/400V - 50Hz

JEAA000006

Motor - IE2 - 0,55kW - 4Pole - 230/400V - 50Hz

JCAB000006

Rotor complete with rubber blades RVA1 – NX -06

JCAB000007

Rotor complete with rubber blades RVA2 - NX -06

JCAB000008

Rotor complete with rubber blades RVA3 - NX -06

JCAB000009

Rotor complete with rubber blades RVA4 - NX -06

JCAB000010

Rotor complete with rubber blades RVA5 - NX -06

5. Rotation detector (optional)

The optional rotation detector is a detection system that controls if the rotation disk is turning. In case of rotation

failure, it sends a signal to a control panel.

CAUTION! Before any manipulation to the rotary valve, make sure that the motor is stopped and that all electrical

connections are disconnected.

NOTE : all electrical manipulations should be performed by qualified personnel only.

5.1 Placing the rotation detector

Remove the rotation disk protection cover by untightening the bolts holding it on the rotary valve body.

Position

Description

Position

Description

1

Body

7

Motor and gear

2

Bearing housing

8

Bolt M5 x 10

3

Cover

9

Rotation detector

4

Rotation disc cover

10

Rotor and rubber blades

5

Detector holder

11

Bolts and washers M8

6

Rotation disc

12

Bolts, nuts & washers M8

User manual | RVA Rotary valves

www.formula-air. com

10

DU-6 detector ;

Attach the sensor through the inside of the sensor holder with the bolts and nuts delivered with the sensor.

M18 optical sensor :

Introduce the sensor in the hole on the top of the front of the over and tighten it in place with the nuts supplied with

the detector.

NOTE : make sure that the min/max distance between detector head and disk is respected as mentioned in the

supplier detector guide.

Place the rotation disc cover back in place by tightening the bolts holding it on the ATEX rotary valve body.

User manual | RVA Rotary valves

www.formula-air. com

11

5.2 Connecting the detector

CAUTION! Before any manipulation to the rotary valve, make sure that the motor is stopped and that all electrical

connections are disconnected.

NOTE : all electrical manipulations should be performed by qualified personnel only.

DU-6 connection : M18 optical connection :

6. Troubleshooting

Failure

Possible causes

Proposed solutions

Rotary valve

switches off

thermally

Foreign body got stuck

Rotor frozen

Gear motor defective

Rotor defective

Motor protection set incorrectly

Fuse defective

Big voltage drop in power supply

Remove foreign body

Thaw on the outside with hot air or water

Replace motor, or gearbox

Replace rotor

Adjust the motor protection

Replace fuse

Insure voltage consistency

Rotary valve

is not turning

Working switch is off

Motor protection switched of thermally

Conditions of operation are not met in the control

system

Fuse defective

It might be that something is stuck in the rotary valve

It might be that the motor or gearbox is broken

It might be that the motor or gearbox shaft key is

broken

Stop the installation, switch on the working

switch

See “Rotary valve switches off thermally”

Investigate why conditions are not met

Investigate that nothing is stuck in the rotor

Investigate if a part is broken and needs to

be replaced

Rotary valve

makes

“screaming”

noise

Foreign body got stuck

Rotor/rotary valve body is defective

The rotor turns the wrong way

Remove foreign body

Replace defective component

Wire the motor correctly

The material

will not pass

the valve

without

accumulation

Volume of material per rotation is larger than planned

Airflow opposite through the rotary valve presents

proper material flow

Settling velocity of material less than expected

The material accumulates in lumps which cannot pass

The material is not removed fast enough at the outlet of

the rotary valve

Transported material is too big/bulky

Material agglutinates

Reduce the volume of material feed, or

replace rotary valve

More frequent regeneration

Shorter step-interval of chain conveyor

Adjust the production machine to change

the flow of material

Check the proper functioning of the

emptying system

Use the adequate rotary valve

Rotation disk

doesn’t’ turn

but rotor

does

Rotation disk and rotor axle are no longer consolidated Tighten rotation disk on rotor axle

Rotation

detector

doesn’t react

Cable is not connected

Improperly connected cables

Detection distance is too big or too short

Make sure cables are connected

Insure proper cable connection

Verify installation distance

If the problem persist, contact the installer or manufacturer.

NAMUR NAMUR

NPN

User manual | RVA Rotary valves

www.formula-air. com

12

7. Dismantling and recycling

When dismantling a unit, be sure to keep in mind the following important information:

•As the unit is dismantled, set aside all still functioning parts to re-use them on another unit.

•You should always separate the different materials depending on their type: iron, rubber, oils, greases, etc…

•Recyclable parts must be disposed of in the appropriate containers or brought to a local recycling company.

The rubbish must be collected in special containers with appropriate labels and disposed of in compliance with the

national laws and/or local legislations in force.

CAUTION!

It is strictly forbidden to dispose of toxic wastes in municipal sewerage and drain systems. This concerns all oils,

greases, and other toxic materials in liquid or solid form.

User manual | RVA Rotary valves

www.formula-air. com

13

8. Maintenance log

date

description

User manual | RVA Rotary valves

www.formula-air. com

14

Formula Air The Netherlands

Head Office / Production / Sales

Bosscheweg 36

5741 SX Beek en Donk,

The Netherlands

+31 492 45 15 45

info-nl@formula-air.com

Formula Air Germany

Sales

Dr.-Oetker Straße 10

54516 Wittlich

Germany

+49 6571 269860

info-de@formula-air.com

Formula Air France – West

Sales

6, avenue des Lions

44800 Saint-Herblain

France

+33 9 72 15 29 38

contact-ouest@formula-air.com

Formula Air Nordic

Sales

Stortorget 17

211 22 Malmö

Sweden

+46 40 654 06 10

info-scan@formula-air.com

Formula Air Belgium

Logistics / Sales

Rue des Dizeaux 4

1360 Perwez

Belgium

+32 81 23 45 71

info-be@formula-air.com

Formula Air France – North

Sales

Zac de la Carrière Dorée

BP 105, 59310 Orchies

France

+33 9 72 15 29 38

contact-fr@formula-air.com

Formula Air France – South

Sales

Chemin de Peyrecave

09600 Regat

France

+33 9 72 15 29 38

contact-sud@formula-air.com

Formula Air Export

Sales

Rue des Dizeaux 4

1360 Perwez

Belgium

+32 81 23 45 71

info-be@formula-air.com

Formula Air Baltic

Production / Sales

P. Motiekaičio g. 3

LT-77104 Šiauliai

Lithuania

+370 41 54 04 82

info-lt@formula-air.com

Formula Air France – East

Sales

2, rue Armand Bloch

25200 Montbéliard

France

+33 9 72 15 29 38

contact-est@formula-air.com

Formula Air Vietnam

Production / Sales

#33, Lot 2, Den Lu 1

Hoang Mai District, Hanoi

Vietnam

+84 (24) 38 62 68 01

info@vinaduct.com

Contacts

This manual suits for next models

4

Table of contents

Other Formula Air Control Unit manuals

Popular Control Unit manuals by other brands

Quectel

Quectel SC20-CE user guide

ABB

ABB COM600 series 5.0 Cyber security deployment guideline

Xtreme Power Systems

Xtreme Power Systems XtremeLink Installation and usage manual

GCE

GCE Druva VPMA Instructions for use

Sierra Wireless

Sierra Wireless AirPrime AR7594 Hardware integration guide

Unitronics

Unitronics Vision OPLC V100-17-CAN manual