Formula Air BADA-VEX User manual

BADA-VEX

ATEX non-return valves

Maintenance manual (EN)

V1.2-2023

Maintenance manual | BADA-VEX ATEX non-return valves

www.formula-air.com

2

Table of content

1. Introduction ..................................................................................................................................................... 4

2. Preamble......................................................................................................................................................... 4

3. Safety information............................................................................................................................................ 4

4. Standards and certificates............................................................................................................................... 5

4.1. BADA-VEX range is according to following standards :........................................................................... 5

4.2. Manufactured according to quality standards : ....................................................................................... 5

4.3. Conformity of complementary standard :................................................................................................. 5

5. Working features ............................................................................................................................................. 5

5.1. BADA-VEX range: DN 160 to DN800 (DN 6” to DN 32”)....................................................................... 5

5.2. Working airflow: Under-pressure airflow (pull flow) ................................................................................. 5

5.3. BADA-VEX installation features (Tab-1) : ................................................................................................ 6

6. BADA-VEX working ......................................................................................................................................... 6

6.1. Airflow rules : .......................................................................................................................................... 6

6.2. Explosion risk direction : .......................................................................................................................... 7

6.3. BADA-VEX working modes: .................................................................................................................... 8

6.4. Setting of working mode :........................................................................................................................ 9

6.4.1. Floating flap mode : ....................................................................................................................... 9

6.4.2. Flap kept open mode by mechanic system :.................................................................................. 10

6.4.3. Flap position indicator, when it’s opened : ................................................................................... 12

6.4.4. Flap position in idle position (only for floating flap mode) :............................................................ 12

6.4.5. Flap indicator in waiting position :................................................................................................ 13

6.4.6. Flap locked in closed position :..................................................................................................... 13

6.4.7. Indicator position with flap locked closed :................................................................................... 14

7. Installing the BADA-VEX................................................................................................................................ 14

7.1. Rules to install the BADA-VEX : ............................................................................................................. 14

8. Overall dimensions (The list of models is not exhaustive) ................................................................................ 19

8.1. BADA-VEX range in metric « DN » (TAB-4) ............................................................................................ 19

8.2. BADA-VEX range in imperial « DN » (TAB-5) ......................................................................................... 20

9. Flap locking sensor (in closed position)........................................................................................................... 20

9.1. Inductive sensor Ø12 non-ATEX zone (DN≤350 - DN≤14") : ................................................................. 21

9.2. Optional : inductive sensor Ø12 for ATEX zone - II 2 D (DN≤350 - DN≤14") :............................... 21

9.3. Inductive sensor Ø18 non-ATEX zone (DN≥400 - DN≥16") : ................................................................. 22

9.4. Optional : inductive sensor Ø18 for ATEX zone - II 2 D (DN≥400 - DN≥16"): ................................ 22

10. Dust build-up sensor.................................................................................................................................. 22

10.1. Capacitive sensor Ø12 for ATEX zone - II 1 D:.............................................................................. 24

11. ATEX marking............................................................................................................................................ 25

11.1. Certification features :........................................................................................................................... 25

11.2. Scope of the standards present on product marking :............................................................................ 25

11.3. Marking example : ................................................................................................................................ 25

12. Aeraulic pressure loss ................................................................................................................................ 26

Maintenance manual | BADA-VEX ATEX non-return valves

www.formula-air.com

3

12.1. Pressure loss graphs.............................................................................................................................. 26

12.2. Pressure loss values (in mm H2O /inch Wg) measured at 20 m/s (4000 ft/min) (TAB-8). ........................ 27

13. Maintenance operations and periodic inspections..................................................................................... 28

13.1. Standard requirements :........................................................................................................................ 28

13.2. Periodic inspection operations : ............................................................................................................ 28

13.3. Check all following points (TAB-9):........................................................................................................ 29

13.4. Procedure in case of an explosion :....................................................................................................... 29

14. Dismantling and recycling ......................................................................................................................... 30

15. Maintenance log ....................................................................................................................................... 31

Contacts................................................................................................................................................................. 32

Maintenance manual | BADA-VEX ATEX non-return valves

www.formula-air.com

4

1. Introduction

This manual cannot be reproduced, even partially, without prior written consent by Formula Air Group. Every step of

the ATEX non-return valve range has been deeply analyzed by Formula Air Group in the expected area during the

design, construction, and user manual creation. However, it is understood that nothing can replace the experience,

training and good sense of those professionals who work with the device.

Ignoring the cautions and warning from the present user manual, using improperly parts or the whole device supplied,

using unauthorized spare parts, manipulating the device by non-qualified personnel, violation of any safety norm

regarding design, construction and use expected by the supplier, exempt Formula Air Group from all responsibility in

case of damages to people or properties.

Formula Air Group does not take any responsibility for the non-observance of the user about the preventive safety

measures presented in this user manual.

Failure to comply with the requirements of the user manual or incorrect use of the ATEX non-return valve during

operation can lead to the damage of the ATEX non-return valve and improper functioning of the ATEX non-return

valve itself. This will result in termination of the warranty on the item and will release the manufacturer from any liability.

Certification

The BADA-VEX non-return valve range is conform to ATEX norms EN16447 & EN15089.

Warranty : Refer to the general sales condition in regards to the device’s warranty.

Attention !

All drawings and references contained within this user manual are non-contractual and are subject to change without

prior notice at the discretion of the Formula Air Group and its partners.

Copyright © Formula Air.

2. Preamble

Before proceeding to the installation of the valve, please read carefully the following instructions.

Warning :

All instructions contained within this manual have to be fully understood and absolutely followed in

order to guarantee the proper functioning of the BADA-VEX ATEX non-return valve. If you have any

questions, especially in specific applications, please contact FORMULA AIR.

3. Safety information

The BADA-VEX is a protection device for dust ATEX zone (EX II D). The facility manager has to implement the European

regulation 1999/92CE. To be sure that this device is correctly used, the authorized workers have to be trained on the

warning signs and safety rules to ensure the safety of people and facilities.

Non-return valve safety rules according to the standards EN 16447. The explosion isolation non-return valves

have not to be used to protect installations with the following substances, nor a mixture containing some of

these substances:

a) Gas, steams or hybrid mixing

b) Unstable chemical substances

c) Explosive substances

d) Pyrotechnic substances

It is mandatory to respect the pipe length between the protected vessel and the BADA-VEX according to

minimum (Lmin) and maximum length (Lmax) to assure the BADA-VEX isolation in case of explosion.

The vessel(s) connected to the BADA-VEX must be protected :

− Either by an explosion venting device (vent panel, flameless)

− Or a suppression system

BADA-VEX is designed to isolate a vessel with a pressure resistance of ≤0.5 bar (Pred). In case the vessel

has a higher resistance, the explosion discharge device has to be defined with maximum reduced pressure in

it of (Pred) ≤0.5 bar. The pipes before and after the BADA-VEX need to resist to 2 bar (like the BADA-VEX).

Maintenance manual | BADA-VEX ATEX non-return valves

www.formula-air.com

5

Don’t use the BADA-VEX to support the pipes upstream or/and downstream. It should not be subjected to

strong vibration to keep its isolation integrity in case of explosion.

Assure the electrical continuity of the installation (earthing) by connecting the BADA-VEX with earth wires to

both pipes.

4. Standards and certificates

4.1. BADA-VEX range is according to following standards :

• 2014/34/UE ATEX regulation

• EN 16447 : 2014 Explosion isolation flap valves

• EN 15089 : 2009 Explosion isolation systems

• EN 1127-1 :2019 Explosion prevention and protection - Part 1

• EN 14460 : 2018 Explosion resistant equipment

4.2. Manufactured according to quality standards :

• 0080 N° of notified body in charge of checking (INERIS)

• INERIS 23ATEX0012X N° of EU type examination certificate

4.3. Conformity of complementary standard :

• NFPA 69 : 2019 Explosion Prevention Systems

5. Working features

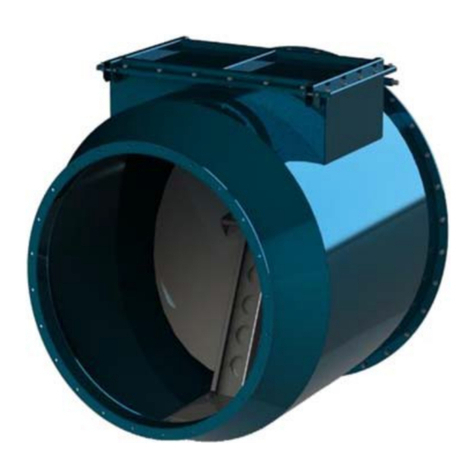

BADA-VEX is an ATEX protective device equipped with a mobile flap which will close under explosion overpressure

and will lock in closed position to avoid the flame to propagate through the ducting to another part of the facility

(suction inlet, filter…).

BADA-VEX is certified for PUSH and PULL flow installations.

BADA-VEX seal the pipe to stop explosion from spreading, either if the explosion come from in opposite direction of

the air + dust flow (example: see picture 1, page 5: “position ”) or if the explosion come from the direction of the

clean airflow (example: see picture 2, page 5: “position ”). In this second case, you need to use the non-return valve

with the flap locked in open position.

Working limits of the BADA-VEX range are defined to ensure the safety of workers, equipment and the

installation. Upholding these limits are the responsibility of the Management exploiting the premises.

5.1. BADA-VEX range: DN 160 to DN800 (DN 6” to DN 32”)

5.2. Working airflow: Under-pressure airflow (pull flow)

Over-pressure airflow (push flow)

• Bends are allowed upstream and downstream of the BADA-VEX, no quantity limit or position restrictions,

• The BADA-VEX can be installed in vertical position (Pictures 15 + 16)

Kst,max ≤250 bar.m/s

Pred,max * ≤ 0.5 bar Airflow speed Clean air side : ≤ 30 m/s

Loaded air side : ≤ 45 m/s

Kst,min No limit BADA-VEX

resistance 2.0 bar Placement Air & dust ducting

Clean air ducting

Pmax 10 bars ATEX marking II D Airflow range Under-pressure : Pull flow

Over-pressure : Push flow

MIE ≥ 10 mJ ATEX inside Zone 20 (II 1 D) Over-pressure

limit 500 mbar max

MIT ≥ 400°C Dust type** All dust types Under-pressure

limit - 800 mbar max

MESG 1.7 mm Dust

concentration No limit Qty.of bends No limit

* Vessel (potential explosion source)

** Organic dust, synthetic dust or metal dust according to the limits defined above.

A

D

Maintenance manual | BADA-VEX ATEX non-return valves

www.formula-air.com

6

Working temperature

Standard : flap gasket in EPDM -30°C to +70°C / -22°F to 158°F

Option : flap gasket in SILICONE -10°C to +180°C*** / 14°F to 356°F***

***Caution: With standard sensor, the working temperature is limited to 70°C / 158°F. Option is available up to

150°C/302°F only for locking sensor.

5.3. BADA-VEX installation features (Tab-1) :

DN Vmin Lmin Lmin +2m Lmax

Ø160 (6") 0,70 m³ 4,0 m 6,0 m 17 m

Ø160 (6") 1,35 m³3,0 m 5,0 m 17 m

Ø180 (7") 0,70 m³4,0 m 6,0 m 17 m

Ø180 (7") 1,35 m³3,0 m 5,0 m 17 m

Ø200 (8") 1,35 m³4,6 m 6,6 m 17 m

Ø250 (10") 1,35 m³4,0 m 6,0 m 17 m

Ø300 (12") 2,90 m³4,6 m 6,6 m 17 m

Ø350 (14") 2,90 m³4,2 m 6,2 m 17 m

Ø400 (16") 4,50 m³5,2 m 7,2 m 17 m

Ø450 (18") 4,50 m³4,7 m 6,7 m 17 m

Ø500 (20") 6,05 m³5,8 m 7,8 m 17 m

Ø550 (22") 6,05 m³5,5 m 7,5 m 17 m

Ø600 (24") 7,65 m³7,2 m 9,2 m 17 m

Ø650 (26") 7,65 m³6,7 m 8,7 m 17 m

Ø700 (28") 7,65 m³6,4 m 8,4 m 17 m

Ø750 (30") 10,00 m³7,3 m 9,3 m 17 m

Ø800 (32") 10,00 m³6,9 m 8,9 m 17 m

Vmin : Min vessel volume being protected by BADA-VEX isolation valve.

Lmax : Max installation distance between the vessel and the BADA-VEX.

Lmin : Min installation distance between the vessel and BADA-VEX, for floating flap with straight horizontal pipe,

no bends.

Lmin + 2 m : Min installation distance between the vessel and BADA-VEX in at least one of following cases :

− Flap locked open by its spring system,

− Pipe with bend between isolated vessel and BADA-VEX, flap in horizontal position ±10° (see picture

18),

− Pipe with bend between isolated vessel and BADA-VEX, flap in vertical position, observe following rules :

Min installing distance = Lmin+2m, if vertical pipe from bend to BADA-VEX > 5 x Øpipe,

Or

Min installing distance = Lmin+2m +5 x Ø, if vertical pipe from bend to BADA-VEX = 5 x Øpipe.

Installation of BADA-VEX in vertical position must be with vertical pipe of min 5 x Øpipe between bend and

BADA-VEX (see picture 16).

6. BADA-VEX working

6.1. Airflow rules :

BADA-VEX is certified to work with under-pressure airflow (Pull flow) or over-pressure airflow (Push flow).

BADA-VEX can be installed in position A and B (picture 1) on the LOADED air side or in position D and E (picture

2) on the CLEAN air side. In position D and E the BADA-VEX needs to be locked open with the mechanical

system.

The working direction of airflow (Push flow or Pull flow) has no influence on the min installation distance.

The working position D and E are advised to inject back the clean air inside the workplace. It’s recommended to

not use the position C (picture 3) and F (picture 4).

Maintenance manual | BADA-VEX ATEX non-return valves

www.formula-air.com

7

6.2. Explosion risk direction :

BADA-VEX installation must observe the direction of the "EXPLOSION RISK" arrow. In fact, this arrow

indicates the direction of explosion flame which has to be stopped by the BADA-VEX, not the normal

working airflow.

Loaded airflow

Clean airflow

Angular position

indicator of flap

Installation direction

Standard working

airflow

DE

A

B

Maintenance manual | BADA-VEX ATEX non-return valves

www.formula-air.com

8

6.3. BADA-VEX working modes:

BADA-VEX can function following 2 modes: either with floating flap (picture 5) or flap kept open (picture 6).

According to the chosen mode, you have to observe the installation distance Lmin and Lmax. These values have

to be checked following the chosen mode as well as the volume of vessel with potential explosion risk (see Tab-

1 page 4).

Floating flap mode, the flap is opened by the working airflow. When the fan stops, the flap closes itself by its

weight without locking (wait to open).

Kept open flap mode, flap is kept open by strip spring system in max opened position. In this mode, the BADA-

VEX can be installed on the clean air side. The kept open flap position can support air speeds up to 30 m/s (6000

ft/min) without closing. It also can be installed in loaded air to reduce the pressure drop especially with low

airflow speeds.

We advise using BADA-VEX in floating flap mode when it’s installed in loaded airflows (working flow in opposition

direction of explosion). However, BADA-VEX has to be used in keep opened flap mode when it’s installed on the

clean air side (explosion flame in same direction than working flow) according to direction of explosion risk.

Only the overpressure of an explosion is capable of activating the locking system of the valve.

Clean airflow

Picture 5

Picture 6

Mode with floating flap

without spring system(s)

Mode with flap kept open

Arm blocked by spring

system

Loaded airflow

Loaded airflow

A

B

D

E

A

B

Maintenance manual | BADA-VEX ATEX non-return valves

www.formula-air.com

9

6.4. Setting of working mode :

The BADA-VEX is delivered from the factory in the ‘Locked Open’ position. If you want to use the BADA-

VEX with a ‘Floating Flap’ remove the external protection cover and take the following measures :

Be sure that the installation is switched off before operating on the BADA-VEX and remove the protect

cover.

6.4.1. Floating flap mode :

To set up the BADA-VEX in mode : floating flap, you have to take off the spring strip(s) to allow the flap to move

freely (picture 7 and 7b).

Caution : the outside arm is part of the moving parts. The weight of this subassembly is high for the BADA-

VEX ≥DN 400 (16"). Be especially careful when handling it, don’t put your hand either in the moving zone nor

in the gasket zone of the flap inside the body.

The arm of the flap is

locked in closed position

by the mechanical

locking system

Cover

D

Picture 7

BADA-VEX floating flap mode DN160 (6")

to DN450 (18")

Remove the following parts :

A) Spring strip

B) Pin

C) Bolt and screw

D) Pin lock

E) Locked open leaf spring

A B

C

Damper arm

E

Maintenance manual | BADA-VEX ATEX non-return valves

www.formula-air.com

10

6.4.2. Flap kept open mode by mechanic system :

The BADA-VEX is delivered from factory in mode: Flap kept open by mechanic locked system. If you have to

change the working mode into floating flap position, to set back the BADA-VEX in flap « locked open position”

mode or to place again the flap in kept open position, you have to take off the protection cover and undertake

the following operations :

1. To set back on mode: flap kept open by mechanic system, you have to put in place the spring strip(s) ref. A

on the bracket(s) ref. E operate in opposite way as described in the pictures 7 or 7b. Then tighten the bolt

to 5 Nm and loosen by a ¼ turn.

2. To place again the flap in kept open position by mechanic system (picture 8 and 8b). Step 1, you have to

turn the spring strip(s) ref. A to outside position in order to raise the arm against the top stop part ref. F.

Step 2, you have to turn back the spring strip(s) under the outside arm and slowly release the arm. Now, you

have to lock the spring strip(s) in position with the pin ref. B and pin lock ref. D.

It’s forbidden to use the BADA-VEX without protection cover.

You have to put the cover back in place with fixing screws after each operation.

Picture 7b

BADA-VEX floating flap mode DN500 (20")

to DN800 (32")

Remove the following parts :

A) 2 spring strips

B) 2 pins

C) 2 bolts and nuts

D) 2 pin locks

E) Locked open leaf springs

Cover

D

C

E

B

Damper arm

A

Maintenance manual | BADA-VEX ATEX non-return valves

www.formula-air.com

11

In function of the BADA-VEX size, 3 models of flap kept open system exist. Number and design of spring strips

are defined in this table (Tab-2):

BADA-VEX

range

Ø160 to Ø350

Ø6" to Ø14"

Ø400 to Ø450

Ø16" to Ø18"

Ø500 to Ø800

Ø20" to Ø32"

Version rep. A Flexible Rigid Rigid

Qty rep. A x1 x1 x2

Drawing

Turn the spring strip(s)

towards the outside ref.

A

Damper arm F A

Picture 8

BADA-VEX flap kept open by mechanic system

1er step: raise the arm against the top stop part

Example of BADA-VEX DN≤500 (20") with double spring strips.

Operation is the same for all other sizes, only difference about spring strip number.

D

Turn back the spring

strip(s) ref. A under the

arm

B

D

B

Picture 8b

2nd step:

lock the blocking system of the damper arm (and the flap)

AAA

A

Maintenance manual | BADA-VEX ATEX non-return valves

www.formula-air.com

12

6.4.3. Flap position indicator, when it’s opened :

Totally open position is visible from outside via angular indicator ref. G (picture 9) independently of the running

mode: flap kept open position from mechanic system or floating flap. When the flap is open, the indicator ref. G

is on the top of the green part.

6.4.4. Flap position in idle position (only for floating flap mode) :

In floating flap mode the BADA-VEX flap is simply opened by airflow generated by the fan. When the fan is

stopped, the flap drops down and the outside arm rests against the locking spring strip ref. H but unlocked by

bottom spring(s) ref. I (picture 10).

Picture 9

G

Green zone is the

angular sector where

the flap can move.

Flap outside arm in

idle position

H

Picture 10

I

Maintenance manual | BADA-VEX ATEX non-return valves

www.formula-air.com

13

6.4.5. Flap indicator in waiting position :

Flap position in waiting is visible from outside by the indicator ref. G placed in limit of green and red zones.

(Picture 11).

6.4.6. Flap locked in closed position :

The flap can be closed by explosion overpressure or by air flow > 35 m/s in case of BADA-VEX installed on clean

air pipe, position (picture 2). In this case, at the end of the fall, the outside arm pushes the spring(s) ref. I until

the stop part ref. J, so the locked spring strip ref. H comes and lock the outside arm of BADA-VEX ref. K (picture

12).

To unlock the flap, you have to press on the spring ref. I with the outside arm. So, you can push down on the

locked spring strip ref. H in order to release the moving part.

D

In idle position, the flap is

placed at the beginning of

green zone

Picture 11

Picture 12

KH

Outside arm in

locked position

J

I

Maintenance manual | BADA-VEX ATEX non-return valves

www.formula-air.com

14

6.4.7. Indicator position with flap locked closed :

Flap position when it’s closed locked (flame is stopped) is visible from outside by the indicator ref. G placed in

the red zone (picture 13).

7. Installing the BADA-VEX

Verification required before starting the installation :

The installer has to check before starting the installation that the delivered material hasn’t suffered any distortion.

BADA-VEX installation must be realized by qualified staff, especially regarding safety rules for workers when they can

be in ATEX risk zone following European regulation n°1999/92/CE.

Upstream and downstream ducting must match the BADA-VEX pressure resistance (2 Bar).

7.1. Rules to install the BADA-VEX :

1. Always use lifting eyes ref. L when handling the BADA-VEX (picture 19).

2. Respect the installation distances Lmin, Lmax and also volumes Vmin according to the BADA-VEX size

(pictures 16, 17, 18 and see TAB-1).

3. Attach the BADA-VEX on a support bracket to avoid that the pipes support the device’s weight.

4. To put back the access door ref. P, you must tighten the M10 bolts with torque 20 Nm to avoid leakage

(Picture 19).

5. Place gaskets between the BADA-VEX and the pipe flanges on either side.

6. Respect the tightening torque according to the bolt size of fixing flange (TAB-3).

Screw class ≥ 6.8 Tightening torque

M6 5 Nm

M8 10 Nm

M10 20 Nm

7. Select the BADA-VEX working mode (Floating OR ‘Locked Open’ before installation).

NOTE : BADA-VEX is delivered with the flap in the ‘Locked OPEN’ position.

8. Respect the installation tolerances for HORIZONTAL and VERTICAL positioning (picture 14).

Picture 13 G

In closed locked position, the

flap is placed in the red zone

Maintenance manual | BADA-VEX ATEX non-return valves

www.formula-air.com

15

9. Allowed Orientation of BADA-VEX for horizontal and vertical installations (picture 15).

• The positions A and B according to BADA-VEX installations in horizontal position ±10°.

• The positions C, D, E, F, G and H are according if the BADA-VEX is installed in angled or vertical

positions (greater than ±10°).

Picture 14 Horizontal position Vertical position

A B

E

D

C

H

G

F

Figure 15

→

Position Ato E & Bto C

2 possibilities to work:

- flap in floating position

so, it’s open by airflow.

- flap is kept open by

mechanic system, so it’s

always open.

→

Position Cto D & E to D

Always work with flap

kept open by gravity.

→

Position Ato G & Bto G

Always need to work with

flap kept open by

mechanic system, so it’s

always open (if not

pressure drop is too high).

Maintenance manual | BADA-VEX ATEX non-return valves

www.formula-air.com

16

10. Allowed installation distances from isolated vessel to BADA-VEX :

• Multiple bends are permitted (no quantity limit) in any position, upstream or downstream of the BADA-

VEX. The system is functional with bend on the pipe in upstream or downstream of BADA-VEX. Lmin and

Lmax installation distances must be observed (see TAB1).

• Lmax is 17 m, it includes all pipe elements (especially the bends) and it’s measured on the center of the

ducting.

Lmin : Min distance in floating flap mode on straight horizontal pipe (±10°), without bend (picture 17, see

TAB 1).

Lmin+2m : Min distance between isolated vessel and BADA-VEX in at least one of following cases :

− Flap in Locked Open mode (picture 18, see TAB 1).

− Pipe with bend between isolated vessel and BADA-VEX, flap in horizontal position ±10° (see

picture 18).

Pipe with elbow between isolated vessel and BADA-VEX, flap in vertical position (over 10°), observe

following rules (pictures 16, TAB 1) :

* Min installing distance = Lmin+2m, if vertical pipe from bend to BADA-VEX > 5 x Ø pipe,

Or

* Min installing distance = Lmin + 2m + 5 x Ø, if vertical pipe from bend to BADA-VEX = 5 x Ø pipe,

* Installation of BADA-VEX in vertical position must be done with vertical pipe of min 5 x Ø pipe

between bend and BADA-VEX.

11. Reminder of installation conditions of BADA-VEX in horizontal position :

Lmin : In floating flap working, on straight horizontal pipe, without bend (picture 17, see TAB 1).

Lmin + 2m : Min distance between isolated vessel and BADA-VEX in at least one of following cases :

- Flap kept open by its spring system (pictures 17, 18, see TAB 1).

- Pipe with bend between isolated vessel and BADA-VEX, flap in horizontal position ±10°

(see picture 18).

X

Picture 16

BADA-VEX in vertical position

3

1

2

Volume

Volume

Volume

<5 xØ pipe

=5 xØ pipe

>5 x Ø pipe (pipe =5xØ includes in Lmin+2m)

Lmin+2m : Min distance from vessel to BADA-VEX

5 x Ø pipe : Min vertical distance before the BADA-VEX

Complementary distance longer than Lmin+ 2m

1

2

3

Maintenance manual | BADA-VEX ATEX non-return valves

www.formula-air.com

17

Top view

Lmin

Lmin + 2m

Side view

Volume Volume

BADA-VEX in horizontal position, straight ducting

BADA-VEX horizontal position,

Flap help open = Lmin + 2m

BADA-VEX horizontal position,

Flotting flap = Lmin

Volume Volume

Side view

Top view

1

2

3

4

B

5

6

1

2

3

4

B

5

6

Vertical ducting

BADA-VEX in horizontal position,

Flap floating or held open,

No limit on bends,

No position restrictions :

.Bends close to BADA-VEX possible,

.Bends between vessel and BADA-VEX,

.Bends after the BADA-VEX.

BADA-VEX in horizontal position, ducting with bends

= Lmin + 2m : min distance from vessel to BADA-VEX (on center),

The safety distance Lmin + 2m must be measured on the center of ducting.

Picture 17

Picture 18

Maintenance manual | BADA-VEX ATEX non-return valves

www.formula-air.com

18

12. The inspection door is fixed during manufactory, after each maintenance operation, be sure to tighten all M10

bolts @ 20 Nm.

: Lifting eyes (x3)

13. Connect both earthing straps ref. M from the BADA-VEX to the pipes on either side, upstream and

downstream (Picture 20). Before starting to use the BADA-VEX, check electric continuity and that the earthing

connection is efficient.

Picture 19

P

O

O

O

20 N.m -16mm

Option :

Inspection window

Picture 20

M

M

Insert gaskets between the

flanges

Maintenance manual | BADA-VEX ATEX non-return valves

www.formula-air.com

19

8. Overall dimensions (The list of models is not exhaustive)

The BADA-VEX is conceived on seven main body bases. The main bodies are indicated with an “x” in the tables TAB-

4 and TAB-5, they are used for one or two other connected pipe diameter sizes.

The possible pipe diameter sizes are indicated in measure unit : metric (TAB-4) or imperial TAB-5).

The BADA-VEX model is indicated according to the pipe size, example DN200.

8.1. BADA-VEX range in metric « DN » (TAB-4)

Ø BADA-VEX Overall dimensions Flange Duct Mounting support

Ducting

DN Body

LHWXØ ext. Ø axis

mm

qty. ø holes

mm

AHt

axis EFGØ h holes Weight

mm mm mm mm mm mm mm mm mm mm mm Kg

160 x640

386 400 216

215 195 8 10 591 126 282

110 90 12

21

180 612 235 215 8 10 531 136 254 20

200 857 466 490 261 255 235 12 10 857 138 325

160 140 12 35

250 x717 305 285 12 10 671 163 253 33

300 966 575 590 311 355 336 12 10 966 197 373

160 160 12 44

350 x817 415 389 12 12 776 222 302 50

400 1088 705 740 385 465 439 16 12 1089 249 431

180 260 12 81

450 x945 515 489 16 12 893 274 359 77

500 1197 815 840 434 565 540 16 12 1 199 309 441

200 300 12 106

550 x1045 615 590 16 12 996 334 369 104

600 1549

1038 992 508

665 640 16 12 1549 366 588

200 400 12

150

650 1363 715 690 24 12 1364 391 517 150

700 x1207 785 750 24 12 1155 416 446 150

750

1751 1213 1200 602 835 800 24 12 1752 443 514

400 500 12 285

800 x1563 885 850 24 12 1564 468 442 285

Maintenance manual | BADA-VEX ATEX non-return valves

www.formula-air.com

20

8.2. BADA-VEX range in imperial « DN » (TAB-5)

Ø BADA-VEX Overall dimensions Flange Duct Mounting support

Ducting

DN Body

LHWXØ ext. Ø axis

mm

inch

qty. ø holes

mm inch

AHt

axis EFGØ h holes Weight

mm mm mm mm mm mm mm mm mm mm mm Kg

6" x649

386 400 216

209 185,7 7-

5/16 6 7,1 9/32 628 120 291

110

90 12 21

7" 616 238 215,9 8-1/2 6 9,5 3/8 559 133 258 20

8" 857

466 490 261

263 242,9 9-

9/16 6 9,5 3/8 857 138 325

160

140 12

35

10" x717 327 300 11-

13/16 6 11,1 7/16 670 163 253 33

12" 966 575 590 311

384 355,6 14 8 11,1 7/16 965 197 373

160

160 12 50

14" x817 435 406,4 16 8 11,1 7/16 776 222 302 50

16" 1089 705 740 385

486 457,2 18 8 11,1 7/16 1089 249 431

180

260 12 81

18" x945 536 508 20 8 11,1 7/16 893 274 359 77

20" 1199

815 840 434

587 552,5 21-

3/4 12 11,1 7/16 1199 309 441

200

300 12

110

22" x1039 638 603,3 23-

3/4 12 11,1 7/16 981 336 364 110

24" 1541

1038 992 508

689 657,2 25-

7/8 12 11,1 7/16 1538 368 582

200

400 12

178

26" 1353 766 720,7 28-

3/8 16 11,1 7/16 1353 393 512 170

28" x1200 816 771,5 30-

3/8 16 11,1 7/16 1138 419 438 170

30" 1739

1213 1200 602

867 822,3 32-

3/8 16 11,1 7/16 1739 444 508

400

500 12

285

32" x1548 918 873,1 34-

3/8 16 11,1 7/16 1545 470 435 285

9. Flap locking sensor (in closed position)

The BADA-VEX is equipped with an inductive sensor (external) which detects when the flap is locked in closed position

(picture 21). It sends a signal to stop the installation when the sensor detects the target screw (ref. Q) in closed position

(explosion is isolated).

The BADA-VEX is equipped in standard execution with a non-ATEX detector version. Optionally, ATEX sensors are

available for ATEX II2 D (zone 21).

Sensors have different sizes according to BADA-VEX size :

− Inductive sensor Ø12 for BADA-VEX DN≤350 (DN≤14")

− Inductive sensor Ø18 For BADA-VEX DN≥400 (DN≥16")

We advise combining the position sensor to a sound alarm, light alarm or process PLC to have information regarding

the locking closed position of flap following an explosion accident or unusual running.

The sensor works in positive safety running, (NC switch) when the flap is not locked in closed position.

The sensor installations is set in the factory. In case of its replacement, you have to simulate the locked in

closed position of outside arm in order to set the target screw (ref. Q) in front of the sensor in detection

condition. You will have to adjust the length of the target screw (ref. Q) until the sensor status changes

(switches off), then tighten the counter-nut to lock the setting.

Table of contents

Other Formula Air Control Unit manuals