Formula Air RS-EXL User manual

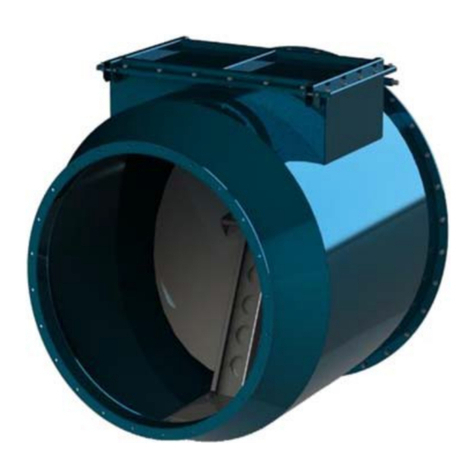

RS-EXL – Ex rotary valve

Maintenance manual

1

Table of contents

1.Introduction.…………..…………………………………………………………………………………..……….…..2

2.Declarationofconformity…………………………....…………………………………………..……………..3

3.Typeofcertificate…………………………....………………………………………..…………………………...4

4.Usage&functionaldescription…………………………....………………..………………………………..6

5.Warning&Safetyinstructions…………………………....……………..………………….………………..8

6.Delivery/Mounting/Storage…………………………………………..………………………………………8

7.Mounting………………………………………………………………………..…………………………….………….9

8.Operation/Maintenance………………………………………………..……………………………………….9

9.Troubleshooting……………………………………………………………..………………………….…………….11

10.Spareparts……………………………………………………………………..………………………..…………….12

11.Disassemblyandrecycling….……………………………………………………………………………………13

12.Contacts…..…………….……….….……………………………………….……..……………………….…….…….14

2

1. INTRODUCTION

WearepleasedthatyouhavechosenanExrotaryvalvethathasbeenthoroughlytested,

andonlymaterialsandcomponentsfromrecognizedsuppliersareused.Inordertoobtain

optimaluseofthepropertiesoftheExrotaryvalveitispresumedthattheuserreadsthis

manualthoroughly.

AnExrotaryvalve(RS‐EXL)istypeapprovedfordustexplosionclassSt1.

AlwaysreadthismanualthoroughlybeforecommissioningofanExrotaryvalve.Pleasepay

specialattentiontothesectionconcerningmaintenance,ascorrectmaintenanceoftheEx

rotaryvalveisaprerequisitefortrouble‐freeoperation.Furthermore,itisaprerequisitethat

themanualiscompliedwithinordertokeepthewarrantyontheExrotaryvalve.

ThismanualmustbekeptthroughoutthelifeoftheExrotaryvalve.Inconnectionwith

reorderingofthemanual,theordernumberonthetypeplatemustbestated.

Youarewelcometocontactusforfurtherinformationandcomments.

Pleasenotethatmounting,operationandmaintenanceofanExrotaryvalveonlymustbe

carriedoutbyskilledpersonnel.

3

2. ECDECLARATIONOFCONFORMITY

Manufacturer:

Moldow A/S

Jørge Hansens Vej 1

D

K-6670 Holsted

Hereby states that EX rotary valve type:

RS-EXL

is in compliance with the following provisions:

EC directive on machinery 2006/42/EC of 17th May 2006 with specific reference

to exhibit I

of the directive concerning important safety and health requirements in

connection with

construction and manufacture of machines.

EMC-directive 2014/30/EU of 26th February 2014 on the harmonisation of the

laws of the

Member States relating to electromagnetic compatibility.

ATEX-directive 2014/34/EU of 26th February 2014 on the harmonisation of the

laws of the

Member States relating to equipment and protective systems intended

for use in potentially

explosive atmospheres.

Furthermore declare that the following harmonized standards have been used:

EN ISO 12100:2011 General principles for design - Risk assessment and risk

reduction

EN 1127-1:2011 Explosive atmosphere – basic concepts and Methodology

EN 15089:2009 - Explosion isolation systems

EN 60204-1:2006 Electrical equipment of machines

The rotary valve is constructed in accordance to the ATEX-directive Group II

category 1

intended for use at zone 20 (II 1/- D).

The technical dossier is kept with notified body: FTZU

Director

Holsted, the 03-12-2014

EC declaration of conformity

K. Preben Hansen

4

3. TYPEOFCERTIFICATE

5

6

4. USAGE&FUNCTIONNALDESCRIPTION

AnEx‐rotaryvalveisconstructedforfollowinguse:

Safetycomponentforisolationofexplosionsonaplant

Non‐compressedunloadingofmaterials

TheExrotaryvalveisfunctionallybuiltupofthefollowingmainelements:

Rotorcasing

Rotor

Driveset(motor,gearandcoupling)

4.1. Rotorcasing

Therotorcasingismadeofsheetsteel.Inletandoutletareprovidedwithflangeconnection.

Theendplatepositionedatthedrivesetcanbedismountedinawaythatprovidesaccessto

therotor.Therotorcasingisexternallycoatedwithprimerandfinishpaint.

4.2. Rotor

Therotorisbuiltupofarotorshaftmountedwith8setsofbladeretainersinhotgalvanized

plate.Sealingbladesindurablematerialaremountedinthebladeretainers.

4.3. Driveset

Therotorisdrivenbyanelectricmotor.Theconnectionbetweenrotorandelectricmotoris

establishedbycouplingandgear.

4.4. Protectivesystem

7

Theexplosionresistantrotaryvalves(RS‐EXL)havebeentestedasexplosionblockingdevices

industexplosivehazardouscontainersand/orequipment(zone20internally)forflammable

dusttypes(Kstmax).Theexplosionpressureimpactstrengthandbreak‐throughresistanceof

theExrotaryvalveshavebeendemonstratedwithcoaldustuntilthemaximumreduced

explosionpressurepred,maxasflamebreak‐ throughorsparkbreak‐throughdidnottake

place.

Break‐throughandflamebreak‐throughresistanceinandagainstthetransportdirectionhave

beensecured.

Thesealinglistsmustensureimpermeabilitybetweenrotorandcasing.

Userhastoaddsuchequipmentthatupondetectionofanexplosiontherotaryvalvewillstop

automaticallyandinstantaneously.

4.5. Technicaldata

NetweightMax.110kg

RotatingspeedRS‐3Max.38rpm

RotatingspeedRS‐7,5/9Max.18rpm

4.6. Transport

Thetypeoftransport,time,packagingandtemperaturehastobetakenintoconsideration,

byselectingasafemethodoftransport.

4.7. Lifting

Incaseoflifting,useonlyapprovedliftingequipment.Donotstay

underoverhangingloads–DANGERZONE!!!

IMPORTANT:

Theliftingequipmentmustbeapprovedforthecurrentload.

Makesurethatliftingandloweringoccurasslowlyaspossible.Shock,vibrationandfallmay

causeimbalanceandinjury.

4.8. Failure

Anyelectricalfailuremustberectifiedbyauthorizedpersonnelonly.Anymechanicalfailure

mustberectifiedbyauthorizedpersonnelonly.

4.9. Cleaning

Thepowersupplytotheunitmustbedisconnectedsafelyandsecuredagainstreconnection

beforecleaning.

8

5. WARNING&SAFETYINSTRUCTIONS

WARNING‐WARNING‐WARNING!!!

THEPOWERSUPPLYTOTHEPLANTMUSTBEDISCONNECTED

PROPERLYANDSECUREDAGAINSTRECONNECTINGBEFOREANY

KINDOFMAINTENANCEMUSTBECOMMENCED!

TheExrotaryvalveisasafetycomponentforwhichreasonthiswarningsignisplacedonit:

Unintendedusemaycausesqueezing/crushingofhandsandfingers.

Rotatingshaft

Ifthemotorisconnectedelectrically,therotorwithrubberbladesmaybeabletorotate,and

thehandsmaygetsqueezed.Consequently,themotormustnotbeconnecteduntiltherotary

valvehasbeeninstalledunderthefilterandtheductforconveyingthewastehasbeen

installed.

Ifthemotoristobeinstalledinconnectionwithasilo,thecyclonemustbemountedonthe

rotaryvalveandthevalveboltedontothesilobeforeconnectingthemotor.

6. DELIVERY/MARKINGS/STORAGE

6.1. Delivery

Ondelivery,theExrotaryvalveisequippedwithmotorandgear,whichareselectedby

Moldow.

6.2. Marking

Therotaryvalveismarkedaccordingtocurrentrequirements.Thetypeplatestatesamong

otherstype,ordernumberandyearofmanufacture.

9

6.3. Storage

Untilmountingiscommenced,anExrotaryvalvemustbestoredunderconditionsthatprevent

rusting,corrosion,decompositionanddeformations,oranotherkindofstorage,whichcanlead

toriskofmalfunction.

7. MOUNTING

AnExrotaryvalvemustnotbestarteduntilithasbeenmechanicallyconnectedonboth

sides.

TheExrotaryvalvemustbesealedonbothsidesoftheholeseriesandboltedinthe

predrilledholeswithM8bolts.

Important:Alwayswearthesafetyequipmentrequired.

7.1. Electricalconnection

Electricalconnectionmustonlybecarriedoutbyacertifiedelectrician.

Inrelationtoelectricalconnection,therotatingdirection

oftherotaryvalvemustbechecked.Therotating

directionisindicatedbythearrowonthecoupling

housing.

Theelectricalconnectionmustbecarriedoutinaccordancewith

currentnationalregulation.

7.2. Electrostaticbond

ElectrostaticbondingofanExrotaryvalvemustbecarriedout

beforecommissioning

8. OPERATION/MAINTENANCE

IfthereisanydoubtwhetheranExrotaryvalveoranyimportantparts

hereofisintactuntilnextoverhaul,replacementmustalwaysbe

carriedout.

Important:Alwayswearthesafetyequipmentrequired.

Thenationalsafetyrulesinforcemustbeobserved.

8.1. Periodicmaintenance

InorderfortheExtypeapprovaltobeguaranteedbythemanufacturer,maintenancemust

becarriedoutbythemanufactureroradistributorappointedbythemanufacturer.

Maintenancemustalwaysbeincompliancewiththedirectionsinthemanual.

10

8.2. Overhaul

Inorderforthemanufacturer’sguaranteeforexplosion‐safeguardtoapply,thecustomer

musthaveregularmaintenancecarriedoutbythemanufactureroradistributorappointed

bythemanufacturer.

Inorderfordistributorstobeapprovedtocarryoutmaintenanceforthemanufacturer,they

mustbetrainedbythemanufacturer.

Thefollowingmustbechecked:Sealingblades,bearings,coupling,gearandmotor.

Note!!!Sealingbladesandsealingringmustbeimpermeable!

Overhaulmustminimumtakeplaceevery6monthsoraccordingtothisschedule:

MaterialO

p

eration hours annuall

y

No. o

f

timesannuall

y

Softwood1600 2

Hardwood1600 3

Softwood3200 4

Hardwood3200 6

Softwood4800 6

Hardwood4800 8

8.3. Motor,gear&bearings

Maintenanceaccordingtotheattachedsupplierdocumentation.

8.4. Rotor

Ifthesealinglamellasarenotimpermeable,theymustbereplaced.Visualinspectionis

carriedout.

8.5. Noise

Thenoiseratioofthecomponentinourscopeofsupplyinconnectedconditionandwithout

mediaisbelow70dB(A)measuredatadistanceof1meterfromthecomponent.

Noisefromtransportedmediaisnotincluded.

Important:

Ahighernoiselevelmayoccurdependingonlocalconditions,likeamachinewhich

isconnectedwithothermachines.Inthiscaseseparatemeasurementsmayberequired.

Ifthetotalnoiselevelintheareaexceeds85dB(A),hearingprotectionmustbeused.

11

9. TROUBLESHOOTING

FailurePossiblecausesProposedsolutions

Rotaryvalve

switchesoff

thermally

- Foreignbodygotstuck

- Rotorfrozen

- Gearmotordefective

- Rotordefective

- Motorprotectionsetincorrectly

- Fusedefective

- Bigvoltagedropinpowersupply

- Removeforeignbody

- Thawontheoutsidewithhot

airorwater

- Replacethegearmotor

- Replacetherotor

- Adjustthemotorprotection

- Replacethefuse

- Replacethecablestoalarger

square

Rotaryvalveis

notrunning

- Workingswitchisoff

- Motorprotectionswitchedof

thermally

- Conditionsofoperationarenot

metinthecontrolsystem

- Fusedefective

- Stoptheinstallation,switchon

theworkingswitch

- See”Rotaryvalveswitchesoff

thermally”

- Investigatewhyconditionsare

notmet

- Replacethefuse

Rotaryvalve

makes

“screaming”

sound

- Foreignbodygotstuck

- Rotor/rotorhousingdefective

- Removeforeignbody

- Replacedefectivepart

Thematerialwill

notpassthevalve

without

accumulation

- Volumeofmaterialpertimeunitin

periodslargerthanplanned

- Airflowoppositethroughthe

valvepreventspropermaterial

flow

- Settlingvelocityofmaterialless

thanexpected

- Thematerialaccumulatesin

lumpswhichcannotpass

- Thematerialisnotremovedfast

enoughattheoutletofthevalve

- Reducethevolumeofmaterial

feed,e.g.atchainfilter.

- Morefrequentregeneration

- Shorterstep‐intervalofchain

conveyor

- Replacesealinglamellae

- Adjusttheproductionmachineto

changetheflowofmaterial

- Checkthefunctionofthe

emptyingsystem

12

10. SPAREPARTS

Pos.PartNo.RS‐3PartNo.RS‐7,5PartNo.RS‐9Quan. Description

180106‐073180106‐072680106‐07198Sealingblades

280106‐071880106‐071880106‐07182Sealingring

380106‐073080106‐072580106‐07208bladeretainer

480106‐073380106‐073480106‐07351Shaftcomplete

580105‐009380105‐009380105‐00932Feltplatefordustsealing

680105‐010880105‐010880105‐01082Basefordustsealing0,63mm

780105‐008880105‐008880105‐00882Basefordustsealing2mm

885282‐001685282‐001685282‐00162Flangebearing

985285‐001885285‐001885285‐00182Coupling,half

1085177‐002185177‐002185177‐00212Bushforcoupling

1185285‐001985285‐001985285‐00191Couplingelement

1280106‐042980106‐042980106‐04291Couplinghousing

1385277‐010385277‐004185277‐00411Gear

1485271‐000285271‐004785271‐00471Electricmotor

1580106‐073280106‐072180106‐07101Rotorcasing

1680106‐071380106‐071380106‐07131Endplateforrotorcasing

1780106‐012280106‐009680106‐04481Counterflange

13

11. DISMANTLINGANDRECYCLING

Whendismantlingaunit,besuretokeepinmindthefollowingimportantinformation:

Astheunitisdismantled,setasideallstillfunctioningpartsinordertore‐usethemon

anotherunit.

Youshouldalwaysseparatethedifferentmaterialsdependingontheirtype:iron,rubber,

oils,greases,etc…

Recyclablepartsmustbedisposedofintheappropriatecontainersorbroughttoalocal

recyclingcompany.

Therubbishmustbecollectedinspecialcontainerswithappropriatelabelsanddisposedof

incompliancewiththenationallawsand/orlocallegislationsinforce.

CAUTION!Itisstrictlyforbiddentodisposeoftoxicwastesinmunicipalsewerageanddrain

systems.Thisconcernsalloils,greases,andothertoxicmaterialsinliquidorsolidform.

14

12. CONTACTS

ForsparepartspleasecontactFormulaAirGroup.

FormulaAir

TheNetherlands

Bosscheweg 36

SX 5741 Beek en Donk

The Netherlands

Tel: +31 (0) 492 45 15 45

Fax: +31 (0) 492 45 15 99

view Google Map

FormulaAir

Belgium

Rue des Dizeaux 4

1360 Perwez

Belgium

Tel: +32 (0) 81 23 45 71

Fax: +32 (0) 81 23 45 79

view Google Map

FormulaAir

Baltic

Televizorių G.20

LT-78137 Šiauliai

Lithuania

Tel: +370 41 54 04 82

Fax: +370 41 54 05 50

view Google Map

FormulaAir

France

Zac de la Carrière Doree

BP 105, 59310 Orchies

France

Tel: +33 (0) 320 61 20 40

Fax: +33 (0) 320 61 20 45

view Google Map

FormulaAir

EstAgenceFrance

2, rue Armand Bloch

25200 Montbeliard

France

Tel. +33 (0) 381 91 70 71

Fax +33 (0) 381 31 08 76

info-fr-est@formula-air.com

view Google Map

FormulaAir

FranceAgenceOuest

19a rue Deshoulières

44000 Nantes

France

Tel. +33 (0) 251 89 90 75

Fax +33 (0) 251 89 94 06

view Google Map

FormulaAir

FranceAgenceSud

Chemin de Peyrecave

09600 Regat

France

Tel: +33 561 66 79 70

Fax: +33 567 07 01 09

info-fr-sud@formula-air.com

view Google Map

AirFormula

Russia

Нижний Новгород

Россия

Tel: +7 (499) 609 23 45

Fax: +7 (831) 277 85 38

View Google Map

FormulaAir

Vietnam

# 33, Lot 2, Den Lu 1

Hoang Mai District, Hanoi,

Vietnam

Tel: +84 (4) 38 62 68 01

Fax: +84 (4) 38 62 96 63

www.vinaduct.com

View Google Map

NOTE:Alldrawingsandreferencescontainedwithinthismanualarenon‐contractualand

aresubjecttochangewithoutpriornoticeatthediscretionoftheFormulaAirgroupandits

partners.

This manual suits for next models

3

Table of contents

Other Formula Air Control Unit manuals

Popular Control Unit manuals by other brands

AsahiAV

AsahiAV AV Series Installation, operation and maintenance manual

Avid Technology

Avid Technology Pro Tools SYNC HD Guide

Lefroy Brooks

Lefroy Brooks CW-4050 Installation, operating, & maintenance instructions

Barco

Barco UDX-4K40 installation manual

Contrive

Contrive GsmComfort+ Advanced manual

Lennox

Lennox Harmony III brochure

Siemens

Siemens SIRIUS 3RA1941-1A Original operating instructions

Dectris

Dectris EIGER 2 S 500K-RW Technical specifications

SMC Networks

SMC Networks SY3000 SERIES Operation manual

Overkiz

Overkiz Hattara DIN Rail PSU quick start guide

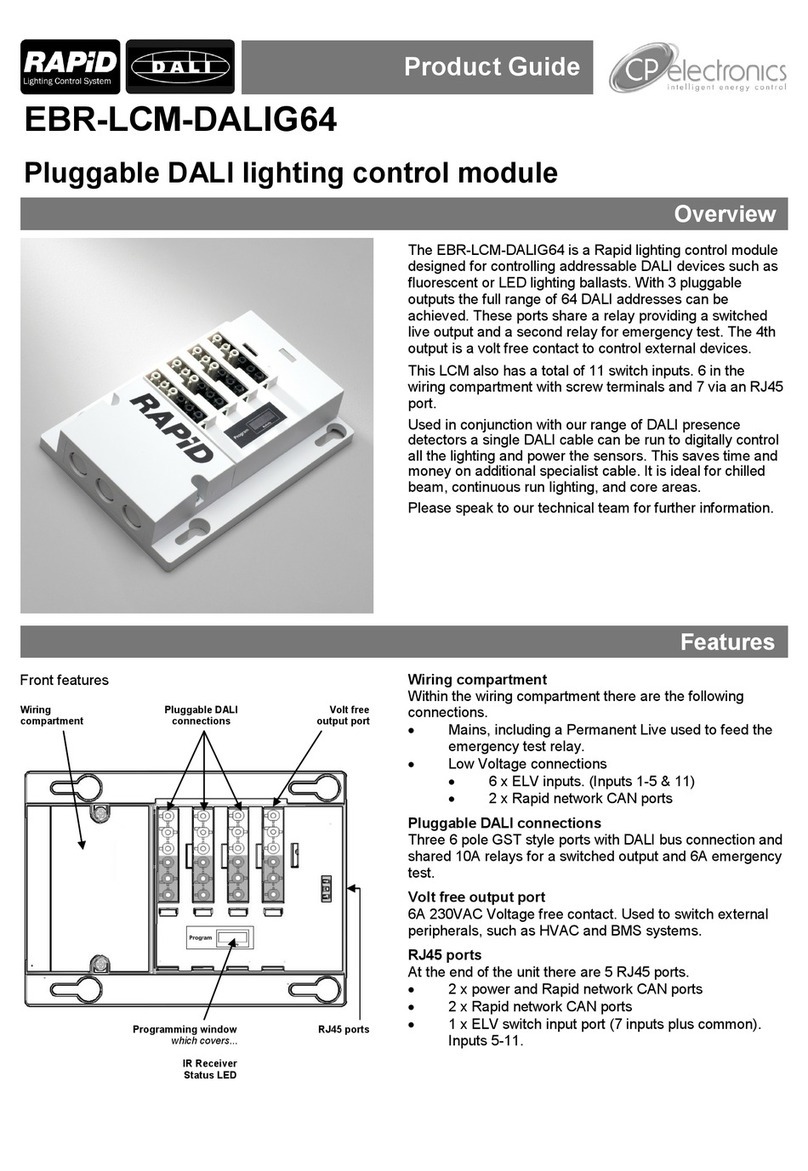

Rapid

Rapid EBR-LCM-DALIG64 Product guide

Lincoln

Lincoln POWER-MASTER III 84981 Owner's/operator's manual