Fornelli PGA 45 FIERO WH User manual

HOBS

GAS HOB

PGA 45

FIERO

FIERO BL

FIERO WH

COMPANY SPECIALIZING IN BUILT-IN OVENS

AND HOBS

EN

User’s Manual

Installation and operation instructionsInstallation and operation instructions

HOBS

Dear Customer!

Thank you for purchasing a “FORNELLI” product. We hope, this appliance will meet your

expectations and be a reliable assistant of yours in your kitchen. For correct and safe operation

of the appliance, please carefully read all the chapters in the present manual. Keep your ma-

nual for the entire service life of the product you have purchased.

Reading the first part of the manual, you will learn some important conditions of safe operation

of the appliance. To keep your appliance in good condition for a long time, we oer you a lot

of helpful advices and hints on the product care and cleaning. In the manual you can also find

some hints on energy saving.

On the last pages of the manual you can find recommendations which will help you eliminate

minor failures, if any, during use of your appliance.

Your new appliance is made of high-quality materials and fully conforms to any standard of the

European Economic Community.

The manufacturer reserves the right to make changes to the product design to improve its per-

formance. Our household appliances are subject to continual improvement, the performance

is enhanced, and their design is updated. Therefore, drawings and symbols in the manual may

dier from those used for a model you have purchased.

Enjoy your meal!

The manufacturer reserves the right to make changes to the product design in order

to improve its performance.

The appliance has been manufactured in line with European standards and is CE, TUV,

ISO 9001 and EAC certified

The manufacturing date is in the serial number of the product. The serial number is on the internal label.

Serial number explanation: SPG/201408C/0001-50

This example: the appliance was manufactured in August 2014.

SPG / 201408C / 0001 - 50

code year month order number

in the batch

number of this

specification

in the batch

manufacturing

Installation and operation instructions Installation and operation instructions

HOBS

1

Installation and operation instructions

CONTENTS

SAFETY STATEMENTS AND HINTS

Prior to connecting a new appliance ...............................................2

Safety statements.................................................................2

Disposal recommendations........................................................5

Scope of supply ..................................................................5

Technical data of gas hob .........................................................6

YOUR NEW GAS HOB

Gas hob control ..................................................................8

Electrically-ignited gas burners ....................................................8

Choosing a gas burner for food preparation .......................................10

Use of dishware support grids ....................................................10

INSTALLATION OF GAS HOB

Installation areas.................................................................11

Attaching the hob to the tabletop .................................................12

Connection to a gas supply system ...............................................13

Connection to the mains .........................................................14

Setting to various types of gases .................................................15

Adjustment of air supply to gas burners ...........................................15

Minimum flame adjustment ......................................................15

CLEANING AND CARE

Enameled parts .................................................................16

Hobs made of stainless steel .....................................................16

Dishware support grids ..........................................................16

Gas burners .....................................................................16

PERIODIC MAINTENANCE AND REPAIRS

Troubleshooting .................................................................18

Installation and operation instructions

HOBS

2

PRIOR TO CONNECTING

A NEW APPLIANCE

Upon removal of package, make sure that the

appliance and the power cable are not da-

maged. If any damages, please contact your

sales agency prior to connection to the mains

and gas supply system.

Please bear in mind that making any changes,

or trying to make changes to the technical

data of the present appliance is risk bearing.

Do not disassemble the hob; do not touch any

parts inside it.

Whenever necessary, feel free to contact the

Technical Support.

Prior to connection, make sure that your gas

hob is designed for operation with the type of

gas (G20: main pipeline gas; G30/G31: lique-

fied gas) being supplied to the appliance. If

the present requirements are not met, for

safety reasons and in order to ensure comp-

liance with local oicial regulations, contact

an oicial authorized expert who will install

the hob and redesign it for another type of

gas.

Information on the type of gas your hob is de-

signed for can be found on the rear side of its

built-in part, close to the gas supply connec-

tion point.

Using the gas hob for food preparation mig-

ht lead to a higher temperature and moisture

content in the premises, where it is installed.

This makes it important to install the hob,

where required ventilation can be provided.

Intensive or prolonged use of the appliance

may require some extra airing or a more

eective ventilation system (for instance, you

may have to open the windows or increase

the kitchen hood ventilation rate).

It is not advisable to install the hob in a strong

draught, because it can blow out gas burner

flames.

SAFETY STATEMENTS

The user shall become informed of safe hand-

ling regulations with regard to gas- and elect-

rically-operated household appliances.

These are only qualified professionals who

are permitted to mount and connect the app-

liance to the mains and gas supply system,

in compliance with the instructions and a

connection diagram. The appliance shall be

connected to a reliable grounding system to

conform to the valid norms of electrical safety.

Prior to any intervention, please make sure

that the appliance is DISCONNECTED from

the mains.

The manufacturer disclaims all liabilities for

damage to humans and property, if the app-

liance is not or improperly connected to a

grounding system.

These are only adults who are allowed to use

the hob. Take care to ensure that children do

not touch the control console and do not play

with the appliance.

External elements of the appliance have open

flames and heat up to high temperatures.

They remain hot even for some period of time

upon switching o. Do not allow children to

come close to the appliance until it comple-

tely cools down.

When using a socket which is in close vicinity

Attention!

To avoid breakdown of the appliance, keep

in unpacked at a room temperature within 2

hours at least prior to switching on in cold

months.

SAFETY STATEMENTS AND HINTS

Installation and operation instructions Installation and operation instructions

HOBS

3

to the appliance, make sure that power cab-

les of electrical appliances being used do not

touch those areas on the hob that may beco-

me heated and are laid far enough from hot

surfaces of the appliance. The power cables

shall be attached to the kitchen table and not

touch hot parts of the hob.

At regular intervals (but twice a year at least)

check the technical condition of the power

supply cable and flexible gas supply hose (if

this hose is used for gas supplies). Should

you happen to find any defects (cracks, mel-

ting or hardening of materials), contact your

service center immediately. To avoid hazards

of any kind, let your service provider replace

the cable, or a professional of similar quali-

fication.

This gas hob is only designed for food prepa-

ration. It shall never be used for heating pre-

mises or drying laundry above it.

When overheated, fats and sunflower oil

become inflammable. Preparing your food

with use of fats or sunflower oil (for instance,

frying potatoes in frying oil), do not leave the

appliance unattended.

KEEP IN MIND!

Never use water to extinguish inflamed

fats or sunflower oil! Tightly cap the dis-

hware with inflamed oil or fat, or cover

it with a material which would prevent

access of oxygen to flames.

Keep the appliance clean. Food residues may

cause fire.

Upon each use make sure that the position

of any switch on the control console of hob

(and, as may be required, on that of the gas

supply) is OFF or CLOSED.

In the event of breakdown disconnect the

hob from the mains and gas supply system.

Do not operate the faulty appliance for it

may be dangerous. Do not try to repair the

equipment yourself. Repairs performed by

non-qualified persons may result in damage

to the appliance and injuries. The first thing

to do is to refer to the user’s manual.

Should you fail to have found information

required, feel free to contact the nearest

service center. The appliance may only be

repaired by experts of an authorized service

center.

Demand the use of branded spare parts only!

When connecting the hob to a liquefied gas

supply system, arrange and operate gas bot-

tles in line with the Fire Safety Regulations

(in Russia they are named “PPB 01-03 P.111”).

ATTENTION!

IT IS EXPRESSLY PROHIBITED TO CAR-

RY OUT A LEAKAGE TEST USING MA-

TCHES OR OPEN FLAMES!

ATTENTION!

Upon occurrence of gas odor, turn o the

gas delivery cock (shut o the gas bottle

valve). Upon that, turn o any cock at the

hob. Open the windows, do not take any

action which may result in occurrence of

sparks or fire before gas escape is comp-

letely eliminated: do not strike matches,

do not smoke, do not switch on / o the

lighting and electrical appliances.

If you are unable to detect and elimina-

te gas escape, immediately call the gas

emergency service.

Installation and operation instructions

HOBS

4

RECOMMENDATIONS

ON DISPOSAL

Any material used for manufacture of the gas

hob is environmentally sound and recyclable.

Observe the Environment Protection Rules,

use appropriate methods of separate waste

collection.

Used appliances or those which have beco-

me unfit for further use are considered as

useless waste. Various materials used for

manufacture of your appliance may be sub-

ject to disposal.

You may become informed of disposal op-

tions, contacting your sales agency or local

authority.

Prior to disposing the appliance for scrap,

please bear in mind that in children’s hands

its further use may result in an accident.

Take care to make it as safe as possible. Cut

the power cable o and make the appliance

completely inoperable.

Make sure to carefully follow the instructions

in the present manual.

STORAGE

Keep the appliance in a dry place, away from

sources of high temperatures and sunlig-

ht. During storage, avoid rapid temperature

changes. Storage of an unpackaged product

is not permitted.

TRANSPORTATION

During the transport of the package, it must

be avoided from falling or other mechanical

influences.

SCOPE OF SUPPLY

Your gas hob is classified as a built-in app-

liance.

The manufacturer’s plate to indicate the

model of the hob is on the rear panel of its

built-in part, where another plate is located

to indicate the type of gas your appliance is

designed for (G20, G30/G31).

The scope of supply includes as follows:

1 Gas hob – 1 piece;

2 Connecting piece to be used for various

gas supply sources – 1 piece;

3 Additional bottled gas nozzles – 3 pieces;

4 Clamp to be attached to a piece of kitchen

furniture, including a set of screws –

4 pieces;

5 Sealing gasket – 1 piece;

6 Cast-iron grill – 3 pieces;

7 User’s manual.

Installation and operation instructions Installation and operation instructions

HOBS

5

The present equipment meets the EEC standards as follows:

• 90/396/EEC — gas-fired equipment;

• 73/23/EEC — low voltage equipment;

• 89/336/EEC — EMC;

• 93/68/EEC — general standards;

• 89/109/EEC — food contact materials or subjects.

Electrical ignition system supply voltage: 220–240 V~, 50–60 Hz

Protection Rating: 1.

Net weight, kg: 10,2.

TECHNICAL DATA

Dimensions of the Hob and the Opening for Building-in of the Hob

Dimensions, mm Height Width Depth

(length)

Visible part 8 450 510

Built-in part 58 426 485

Niche 35–45* 430 490

* With a width of the tabletop less than 35 mm, use an additional space plate (not included).

Power of gas burners: max. 6,55 kW

Parameter Power

Gas burner type max./min.

kW

Small 1,0/0,35

Middle sized 1,75/0,65

WOK 3,8/1,9

Installation and operation instructions

HOBS

6

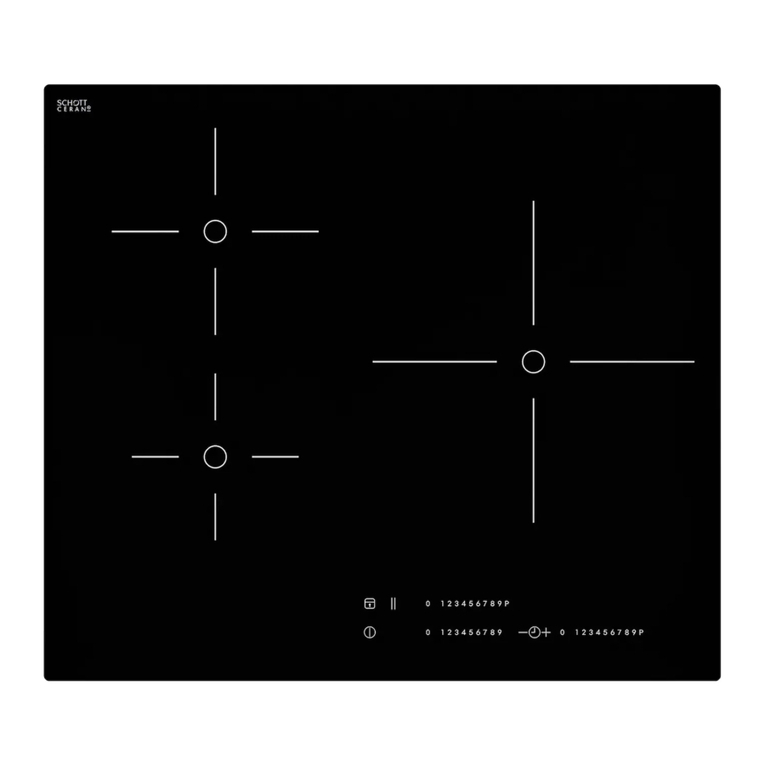

MODEL PGA 45 FIERO

General view of this modification is presented in Figure 1, where the specific components

are designated with position numbers as follows:

1. Gas hob surface

2. WOK gas burner

3. Middle-sized gas burner

4. Small gas burner

5. Dishware support grid

6. Gas burner control knobs .

Fig. 1

YOUR NEW GAS HOB

Installation and operation instructions Installation and operation instructions

HOBS

7

Gas flow to burners (gas burner capacity) is

regulated by means of knobs (Figure 2). The

knobs, in turn, are controlled by cocks.

Symbols “Max. flame” , “Min. flame” and

“Flame OFF” are on the hob, close to cont-

rol knobs. Close to the symbol “Max. flame”

there is the “Ignition sparks” symbol which

means that the appliance is equipped with an

automated system of electrical ignition.

Attention! Any operating position of a

control knob shall be selected between

“Max. flame” and “Min. flame” . Bet-

ween these positions one can smoothly

adjust continuous and stable supply of

gas to gas burners of the hob. In no cir-

cumstances select an operating positi-

on between “Max. flame” and “Flame

OFF” .

For a more convenient flame control ignite gas

prior to putting the dishware onto the grid.

Any model described herein is equipped with

electrically-ignited gas burners, but some mo-

dels have, in addition to that, a gas escape pre-

vention system (alternatively, it is called “gas

control”). Figure 3 presents a general view of a

disassembled gas burner. Its main components

as follows can be highlighted:

Fig. 2

1. Gas burner cap

2. Flame spreader

3. Igniter

4. Thermoelement of “gas control”.

Let us consider specifics of gas ignition in

both cases.

Fig. 3

GAS HOB CONTROL

Installation and operation instructions

HOBS

8

ELECTRICALLY-IGNITED

GAS BURNERS

These gas burners do not have Position 4, as

shown in Figure 3.

To ignite a gas burner, press the

selected gas burner control knob,

turn it counterclockwise to the positi-

on of the symbol “Max. flame” that

corresponds to maximum gas supply.

Do not try to turn the knob without

pressing it for this may result in damage

to the gas valve.

To ensure stable gas inflammation, press

and hold the control knob within 3 seconds

approximately. The inflammation process is

attended by typical clicks caused by electric

discharges within the igniters (Pos. 3, Figure

3). Upon gas inflammation, select any posi-

tion of the control knob between symbols

“Max. flame” and “Min. flame” to have a

flame of desired intensity. If you have failed to

ignite the gas burner, try it again proceeding

in the same way.

If the igniter is contaminated, electrical igni-

tion may not function properly. Therefore, it

is highly recommended to keep the hob as

clean as possible. Use a small brush to clean

the igniter, as it may be required. Please bear

in mind that it is not at all necessary to apply

much force for cleaning. If, for some reason

or other, electric power is not supplied or

is cut o, you can ignite the gas burner the

old-fashioned way – just lighting and setting

a match. For that, press the control knob of

the selected gas burner, turn it countercloc-

kwise up to the position “Max. flame” .

To turn o gas supply, rotate the control knob

to the right, up to the position “Flame OFF”

(See Figure 2).

ATTENTION! Electrical ignition process

shall not last longer than 15 sec.

If you have failed to ignite the gas burner

after this time, or the flame has acciden-

tally extinguished, wait a minute prior to

trying again.

If you have failed to ignite the gas burner

upon several attempts, please check the

position of the gas burner cap (Pos. 1, Fi-

gure 3) and flame spreader (Pos. 2, Figure

3).

Pay attention to the following:

If the gas pressure of the gas supply network

of your location is above the standard one, it

will be easier to ignite the gas burner with a

lesser volume of gas to be supplied. In this

connection we recommend you to ignite the

gas burner prior to putting the dishware onto

the hob. We also recommend you to select

the control knob position between “Max. fla-

me” and “Min. flame” or bring it to the

“Min. flame” position.

Installation and operation instructions Installation and operation instructions

HOBS

9

HOW TO CHOOSE A GAS BURNER

FOR FOOD PREPARATION

Symbols printed close to the control knobs

(to the left and above) of the gas burners (Fi-

gure 2) show which knob regulates a specific

gas burner.

The gas burner controlled by a specific knob

is marked with a darkened section.

To ensure decreased gas consumption and

higher eiciency of gas burners, use flat dis-

hware the size of which corresponds to that

of gas burners. Flame intensity and sizes of

dishware shall be chosen in such a way that

the flame does not reach the side walls of the

dishware. Table 1 presents recommended

use of gas burners depending upon the dis-

hware sizes.

Use the dishware with covers – this would

significantly reduce the cooking time.

Upon boiling, reduce the flame intensity so

that it can be enough to keep the food boiling

and you do not have to move or take o the

cover.

USE OF SUPPORT GRIDS

The support grids are designed to ensure ho-

rizontal and stable position of dishware abo-

ve the gas burners, for more convenient and

safer operation of hobs. Every time you use

your hob, make sure that the support grids

are stable. Always check proper positioning

of rubber end pieces beneath, take care to

ensure they are not damaged.

Table 1

Gas burner Minimum dishware

diameter

Maximum dishware

diameter

Small-sized 60 mm or less 140 mm

Middle-sized 160 mm 200 mm

Large 200 mm 240 mm

Installation and operation instructions

HOBS

10

GAS HOB

INSTALLATION

ATTENTION! These are only qualified

professionals who are permitted to

install hob.

The appliance shall be installed in line with

valid norms and regulations.

The hob for building-in the appliance shall

resist temperatures of up to 100ºC.

Any works shall be performed with the app-

liances disconnected from the mains and gas

supply system.

Removal of combustion by-products

and installation area

The appliance shall be installed and used in

a suitable environment and in line with valid

and relevant norms and regulations.

The installer shall observe the laws applied

to ventilation and removal of combustion

by-products.

Please keep in mind that a volume of air

required for gas combustion is calculated as

follows: 2 m3/ hour / gas burner wattage.

Removal of combustion

by-products

During operation of gas-fired appliances, com-

bustion by-products release which must be

removed by means of ventilation or a kitchen

hood (See Figure 4).

Figure 4 shows components as follows:

A – natural air flow

E – ventilation

C – kitchen hood for removal of combustion

by-products.

Fig. 4

A

E

C

750 mm

Note:

minimum distance between the kitchen

hood and gas hob shall be 750 mm.

Installation area

The gas equipment shall be installed, where

natural air flow is available required for gas

combustion (standards UNI-CIG 7129 and

7131). At that, one shall observe all the norms

and regulations that apply to installation of

household gas-fired appliances in a country,

where they are purchased and used.

The gas hob may be built-in into any piece

of kitchen furniture able to resist high tem-

peratures. The size of a recess in the surface

of that furniture piece (tabletop), as well as

minimum distances between the rear part

and surfaces adjoining aside, are shown in

Figure 5. Figure 6 presents a method to at-

tach the hob to the tabletop.

Installation and operation instructions Installation and operation instructions

HOBS

11

Please keep in mind:

To ensure suicient air circulation above the

gas ob, it is required to keep a minimum dis-

tance of 10 mm to any drawer, any partition

wall, or any oven that may be located beneath

the hob.

Should the as hob be installed combined with

an oven, you have to follow the guidelines of

the oven manufacturer which is to ensure

required ventilation as shown in Figure 7. At

that, gaps “C” and “E” shall make 30 mm at

least.

Any way, if you are going to use a gas-fired

oven, both parts of the equipment shall be

connected to the mains and gas pipeline

separately.

Gas hob attachment

to the tabletop

Cut out a recess in your tabletop on the ba-

sis of dimensions shown in Figure 5.

Wood fibres used for manufacture of table-

tops can quickly swell if exposed to mois-

ture. In this connection, a special adhesive

or sealant shall be applied onto the side

surface of the recess cut to protect it from

vapors or moisture condensed on the un-

derside of the tabletop.

Prior to installation of the hob into a recess

prepared (Figure 6), it is necessary to attach

a self-adhesive sealing gasket “C” onto the

lower edge of the hob. The gasket shall be

uniformly attached along the entire perime-

ter, without breaking or overlapping that.

For that, you should remove support grids,

gas burner cap and flame spreaders.

Fig. 6.Fig. 5

510

450

426

120 min

430

55

58

490

485

Installation and operation instructions

HOBS

12

Turn over the hob avoiding not to damage

igniters and thermoelements of “gas cont-

rol”. Attach the sealing gasket “C” along the

entire lower edge of the hob which is to be

recessed.

Place the hob into the recess prepared, it

its center, supporting the hob from below.

Then, press on it to make it stably rest upon

the piece of furniture. Have someone to as-

sist you – in that case the work will be more

convenient and you will not move the sea-

ling gasket.

Attach the hob to the tabletop, using clamps

“A” and screws “B” (included).

If the sealing gasket “C” sits properly, it will

provide complete protection against penet-

ration of liquids under the hob. This is par-

ticularly topical for cleaning and care.

Fig. 7.

Connection to a gas supply system

These works can only be performed

by a representative of a state-run gas

service in your location. An act shall

be drawn up to confirm performance of

the works, on the company's letterhead

and in two copies, one for each party.

The appliance shall be connected to a gas

supply system according to valid norms and

regulations of the country, where a hob is

installed by qualified experts. At the end of a

supply pipeline there must be a safety valve

installed.

The appliance was subject to factory accep-

tance tests and set to that type of gas which

is indicated in the manufacturer’s plate. That

plate is on the rear panel of the hob, close to a

connecting gas pipe line. Make sure that gas

being supplied corresponds to that indicated

in the manufacturer’s plate.

If not, follow the instructions from “Setting to

various types of gases”.

To ensure maximum eiciency and minimum

gas consumption, make sure that gas supply

pressure has parameters as follows:

Main pipeline gas: G20 - 2,0 kPa;

Liquefied gas: G30 - 2,8-3,0 kPa,

G31 - 3,7 kPa,

(attention: these values may slightly vary).

Installation and operation instructions Installation and operation instructions

HOBS

13

If gas pressure parameters dier from values

recommended (or pressure is subject to fluc-

tuations), there must be a pressure regulating

device to be installed at the intake pipeline.

Connect the appliance to a local gas supply

system, using a rigid metal pipe and pipe

connections, or a flexible pipe made of stain-

less steel (pipes of both types shall conform

to valid standards). Make sure that flexible

metal pipes do not come into contact with

movable parts. They also must be neither da-

maged nor squeezed.

The outer thread size of the connecting gas

pipe line is ½’’. Avoid any force impact upon

the gas hob when connecting it.

Attention!

Upon completion of installation, it is a

must to check leak tightness of connec-

tions, using soap solution!

DO NOT CHECK LEAK TIGHTNESS OF

CONNECTIONS USING A FLAME!

CONNECTION TO THE MAINS

The present appliance is designed for 220–

240 V, 50 / 60 Hz. It must be connected to

the mains subject to valid norms, regulations

and laws.

The plug and power cable shall conform to

relevant standards and power consumed by

the appliance.

The yellow-green earth wire shall not be in-

terrupted by a breaker switch.

The power cable shall anyway be laid in such

a way so that the temperature at any point of

it does not exceed the ambient one by more

than 50°C.

Attention! Do not use extension cables

to connect to the mains. They can over-

heat and inflame!

Grounding is an obligatory condition!

The manufacturer shall in no circum-

stances be liable for ignoring the inst-

ructions by a user.

If the power cable turns out to be dama-

ged, it is a qualified professional of the

service center who has to replace it.

Is the power cable subject to replacement,

use only those cables providing for the pro-

per operation of the appliance at existing

loads and operating temperatures. The earth

wire (yellow-green) shall be 20 cm longer

than any other one. For this equipment cab-

les are used, the cross-section area of which

makes 3 x 0.75 mm.

Installation and operation instructions

HOBS

14

SETTING TO VARIOUS TYPES

OF GASES

If the type of gas you are going to use diers

from that your gas hob is set to, you will have

to replace gas nozzles. For that, do the fol-

lowing:

• Remove the support grids; take out fla-

me spreaders and gas burner caps.

• Unscrew “J” gas nozzles (Figure 8), using

an Allen wrench, and replace them with

appropriate ones (See Table “Diameters

of gas nozzles, mm”). The value of the di-

ameter is marked in the upper part of the

nozzle and indicated in mm.

• Carefully assemble all the components

of the hob in reversed order.

Reminder: if gas pressure diers from

that in the manufacturer’s plate you will

have to install an appropriate pressure

regulating device according to local stan-

dards of use of gas supply systems.

Adjustment of air flow to gas burners

Not required.

Fig. 8

Minimum flame adjustment

This adjustment is required upon replace-

ment of gas nozzles, or whenever necessary.

The sequence of actions is as follows:

• Ignite the gas burner; turn the control

knob to the position “Min. flame”.

• Take o the control knob.

• Insert a small-sized screwdriver with a

flat shrank into the valve core (see Figure

10). In valves equipped with a safety de-

vice of “gas control”, the adjusting screw

may be outside the valve core.

• Unscrew to increase the flame, and

screw in to decrease it. The flame has

been adjusted properly, if the flame is

uniform over the whole circumference

of the gas burner, and its height makes

approximately 3–4 mm.

• With liquefied gas used, the adjusting

screw must be screwed in all the way.

• Make sure that the flame does not ex-

tinguish with rapid changes from “Max.

flame” to “Min. flame” and vice versa.

Installation and operation instructions Installation and operation instructions

HOBS

15

• If the “gas control” safety system fails to

activate with a minimum volume of gas

to be supplied to a gas burner, increase

that volume using the adjusting screw.

• Check whether the adjustment procedu-

re has been carried out in a proper way:

let the gas burner operate for several mi-

nutes. Increase the minimum, if the flame

extinguishes.

CLEANING AND CARE

Before you begin care or cleaning, discon-

nect your hob from the mains and let it cool

down. To keep the hob in good condition, cle-

an it after each use.

Enameled parts

All the enameled parts shall be only cleaned

with a sponge and soapy water, or specially

developed commercially available non-abra-

sives. Do never use steel wools, abrasives or

stain removers for baths or wash sinks.

Prior to installation, dry out the washed parts

or wipe them dry.

Stainless steel surface

Stainless steel may darken due to long-term

contact with water or aggressive cleaning

agents to contain sodium hydroxide or phosp-

horus. Therefore its condition must be focus of

much attention of yours.

To clean a surface made of stainless steel use a

wet cloth and special cleaning agents. Upon rin-

sing, wipe it dry with a piece of chamois-leather

or soft cloth.

For maximum eect we recommend you to use a

special, branded professional agent for stainless

steel care.

Support grids

To clean them, use a sponge, water and soap.

Clean them only when cold. Do not use any

abrasives or cutting tools. The grid size enab-

les to wash them in a dishwasher.

Gas burners

Gas burners consisting of two parts (cap +

flame spreader) can be removed, cleaned

and washed for which appropriate cleaning

agents must be used.

Models with automated ignition systems

have ceramic igniters within an area of gas

burners. Inside these igniters there are metal

electrodes (“E” elements in Figure 9).

Fig. 9

Those models that are equipped with the

“gas control” system” also have thermoele-

ments within an area of gas burners (“T”

elements in Figure 9). These are sensors of

safety valves.

Installation and operation instructions

HOBS

16

To ensure reliable operation of both gas bur-

ners automated ignition and “gas control”

systems, clean the igniter and thermoele-

ment of the hob at regular intervals, procee-

ding with extreme caution.

Attention!

To avoid damage to the electric igni-

tion system, do not use it with the flame

spreaders removed

Upon cleaning and washing the gas burner

elements dry them out and place them

back, carefully and properly.

PERIODICAL MAINTENANCE

AND REPAIRS

It is required, on a time basis, to carry out tests

of the gas pipe line to check its integrity and

eiciency, as well gas pressure regulating de-

vice tests (if installed). Should any failures be

detected, please contact experts and demand

complete replacement of defective or faulty

parts, not just their repairs.

To provide for proper functioning of the gas

hob, you have to regularly lubricate valves to

adjust gas supply to gas burners.

The valves shall be regularly lubricated

by qualified professionals of the gas ser-

vice who are also able to solve problems

related to failures and defects detected.

Before shipping to a customer, the appliance

is subject to factory acceptance tests and set-

tings. These works are fulfilled by experienced

specialists to make the equipment operation

more eective. Repairs or settings that the-

reafter may be required shall be performed

with care and caution.

In this connection we recommend you to

always contact a sales agency where you

have purchased the appliance, or to the ne-

arest service center. State the kind of failure,

equipment model and serial number of the

product. This information can be found in the

manufacturer’s plate.

Installation and operation instructions Installation and operation instructions

HOBS

17

TROUBLESHOOTING

Upon occurrence of any failure, or if the hob goes wrong, read this paragraph before calling

your service center. Probably, you can solve problems encountered yourself.

First, make sure that gas is supplied normally. Check the power. Then, check, if the gas valve

is open or not.

Failure detected Possible causes

The gas burner does not ignite, or

the flame is not uniformly distributed

over its circumference.

- clogged openings in the flame spreader

- removable parts have not been properly instal-

led

- the appliance is in a strong draught

The flame extinguishes (models with

“gas control”).

- you do not press the control knob all the time

when turning it

- you do not press and hold the control knob long

enough to make the thermoelement heat

- clogged openings in the flame spreader (on the

thermoelement side)

The gas burner extinguishes with

the control knob in the “Min. flame”

position.

- clogged openings in the flame spreader

- the appliance is in a strong draught

- minimum supply has not been adjusted in

a proper way (See “Minimum flame adjust-

ment”)

Dishware is not stable on the hob. - the dishware bottom is not perfectly flat

- the dishware is not centered relative to the gas

burner

- the support grid is not properly placed

Gas valves rotate heavily or get

stuck.

- gas valves are contaminated

- gas valves are not lubricated

If you did not manage to correct the troub-

le, feel free to contact any service center to

provide maintenance of “FORNELLI” pro-

ducts.

If your appliance is under warranty, provide

information as follows: number of your war-

ranty certificate, failure type, model and se-

rial number of the product in the manufactu-

rer’s plate that is at the bottom of your hob.

If the warranty period has already expired,

the information on the model and failure

description will be suicient.

Avoid services provided by unauthorized

persons.

Installation and operation instructions

HOBS

18

The products are subject to free repair, if used only

for personal, family or other needs, not related to

business activities, or satisfying household requi-

rements in an oice of a company, institution or

enterprise. The use of the products for purposes

diering from above is deemed violation of the

operation regulations.

The warranty certificate confers a right on free

repair of the product within 12 months from the

purchase date. Should you have any questions re-

garding the maintenance service, please contact

the oicial representative of the brand. The con-

tact details are on the web site of our partner kro-

na-steel.com. Within the warranty period defective

parts of the products are subject to free repair or

replacement with new ones. It is the Service Cen-

ter that has to decide whether the defective pro-

ducts shall be repaired or replaced.

The service life of the product is 7 (seven) years.

The service life starts on the purchase date. If it

turns out to be impossible to determine the purc-

hase date, the service life shall start on the manu-

facturing date, encoded in the product serial num-

ber which is on the manufacturer's plate.

The manufacturer’s plate availability is an obliga-

tory condition! Make sure it is available and keep

it for the entire service life of the product. If it is

not available, it may turn out impossible to deter-

mine the product model, manufacturing date. As

a consequence, a request for a free repair may be

declined.

The free repair is only possible with a properly and

duly filled in warranty certificate, sale receipt for

a product purchased, other documents to confirm

the warranty period of the product submitted for

repairs or diagnostics.

When buying a product, make sure the warrant

certificate is duly filled in, contains no corrections

and bears the purchase date, the stamp of a sales

agency and signature of a sales assistant (inclu-

ding a tear-o card), model and the serial number

of the product.

Before you call a Service Center specialist, please

carefully read the operation regulations. If the pro-

duct turns out to be non-defective upon diagnos-

tics performed by the specialist, the Service Cen-

ter reserves the right to demand an ungrounded

call payment from the customer, basing upon the

current price list.

For your safety, these are only licensed and autho-

rized specialists and companies who are permit-

ted to carry out installation and connection of gas

operating equipment.

Please keep receipts and other documents with

regard to installation and connection of your pro-

duct for its entire service life.

Any complaints with regard to quality of the com-

ponents are subject to consideration only upon the

quality inspection (technical condition inspection)

to be conducted by a representative of the autho-

rized Service Center.

Kõik pretensioonid toote kvaliteedi ja detailide

komplektsuse suhtes vaadatakse läbi pärast (teh-

nilise olukorra) kvaliteedikontrolli hoolduskeskuse

autoriseeritud esindaja poolt.

The manufacturer shall not be liable for any dama-

ge to a customer or property of a customer and not

be obliged to perform free repairs on the occur-

rence of any of the following:

– documents are missing to confirm the right for

free repairs;

– repairs have not been performed by authorized

persons, the product design has been chan-

ged, the product intervention is found, conflic-

ting with the operation regulations;

– the operation regulations have been violated,

stated in the product manual;

* Except backlight lamps, unless its replacement procedure is described in the operation manual.

It is only the replacement procedure that is free, not the lamp itself.

Warranty service conditions

This manual suits for next models

2

Table of contents

Other Fornelli Hob manuals