The etching device is mounted completely by Gie-Tec. Only the glass heater

and the thermometer has to plug in the holes at the top of the tank.

Place the etching device into the catch basin. Place the device on a horizontal,

stable and acid-proof table.

The working area should be ventilatable and well illuminated!

1. Start-up

1.1 Placement

ACHTUNG! GEFAHR!

1.3 Handling of the board holder

For adjust different board sizes, loosen the

screws of the board holder below the handle

strip (8).

In case of single-side boards, you can

double the holding capacity by clambing the

boards back-to-back.

If you do not tighten the screws, you can shift the strips easily

without need a tool.

For larger boards, remove the middle strip.

8

1.4 Etching bath

For etching, we recommend only our sodium persulfate. This etching mediums

is odorless, clear, and pollutes the device only insignificantly.

Further sodium persulfate has the positive feature to get blue if solution is

saturated.

It achives etching times of 6-8 minutes at 40-45°C. The etching speed is

between 4 to 7µm/min with a copper reception of approx.: 30g/l.

- Fill the cuvette with water ( about 4 liter)

- Add the etching granulate (1000g Sodium persulfate) slowly and stir in the

water.

Preparing the etching solution:

The etching device is not suitable for ferrous chloride as an

etchant!

In case of using other etching chemicals, we can not take over any

guarantee for the function of the device since these chemicals may

disolve the glue of the glass cuvette and let damage the cuvette.

l

l

l

l

l

l

l

l

l

l

l

Etching station 1 can be used for etching

printed circuit boards and metal foils of

various sizes.

Any other use of the device is not

permitted.

The device is designed for power

supply AC 230V (50- 60Hz) and may

used only in perfect technical

condition.

Using the etching device it is not

allowed by children and people which

are not instructed.

The basis of the etching device (table,

work bench) is supposed to be

horizontally, stable, resistant to

chemicals and easy to clean.

The area in which the devices are used

should be well illuminated and

ventilatable.

Not required tools, devices or

components are to be kept away from

the working area.

Eating, drinking and smoking are

strictly prohibited!

Keep devices and chemicals out of the

range of children and foods.

Store not required chemicals in the

original container in a dry place.

Assembly and using of the device has

to be done only according the

declaration of conformity.

Carry corresponding protective

clothing (acid and alkal-proof

protection gloves, protective goggles,

overall or apron) when applying the

bath or when working with the device.

The device must not exposed to high

humidity, strong vibrations or

explosive gas.

Keep this manual careful. Personnal

working at this equipment has to be

instructed about the dangers.

If you don´t provide this manual, loss

of property or risk of injury may

happen.

Pay attention to the disposal remarks

for waste materials.

Never pour water on the etching

granulate! First fill the cuvettes with

water and after add granulate, then

mix the liquid.

5

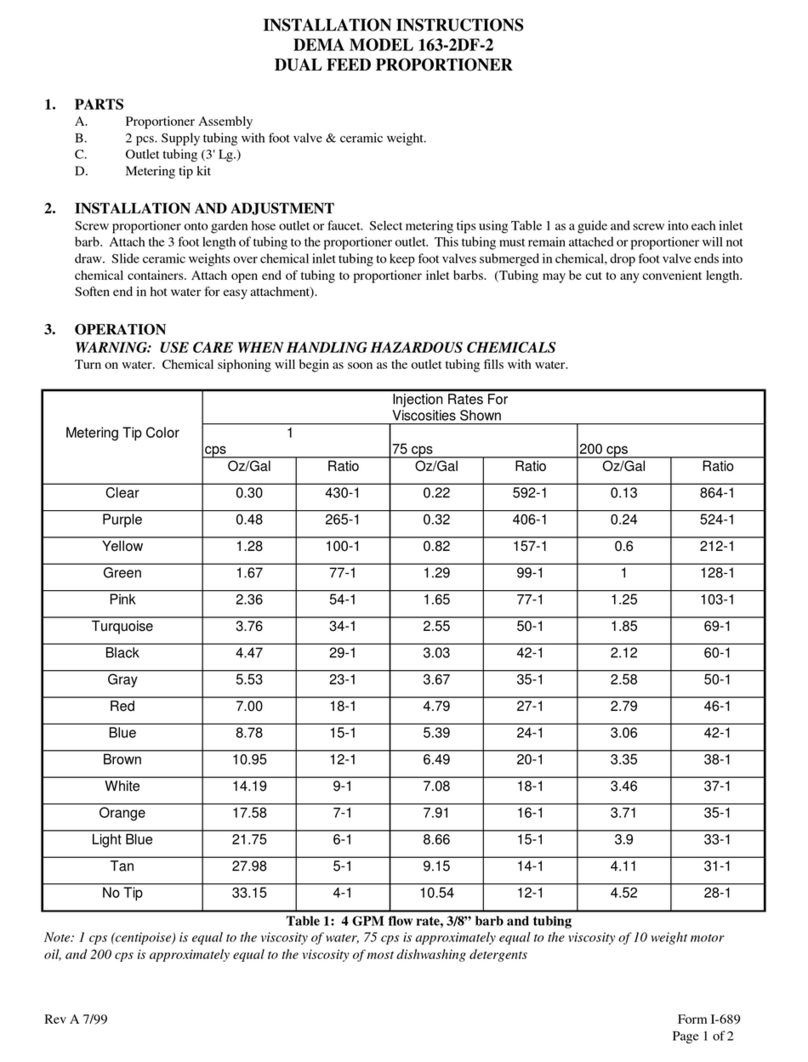

4PVC trip tray

5Glass heater, 150W

6Duaphragm pump

7drain cock

1Developer fluid tank

2Tank for rinsing water

3Etching fluid tank

8PVB holder

9Thermometer

47

8

6

3

7

1

2

Reserve technical changes

ll

FORTEX Limited Lincoln, LN69AP Unit16 Freeman Road United Kingdom

www.fortex.co.uk