Foseco MDS-100 Manual

ຩಓԖϦљ

F O S E C O C O R P .

NO. 118-10, YUNG HO RD., TA-YA,

TACHUNG CITY, TAIWAN, 428-77

TEL:04-2568-5609 FAX:04-2568-5480

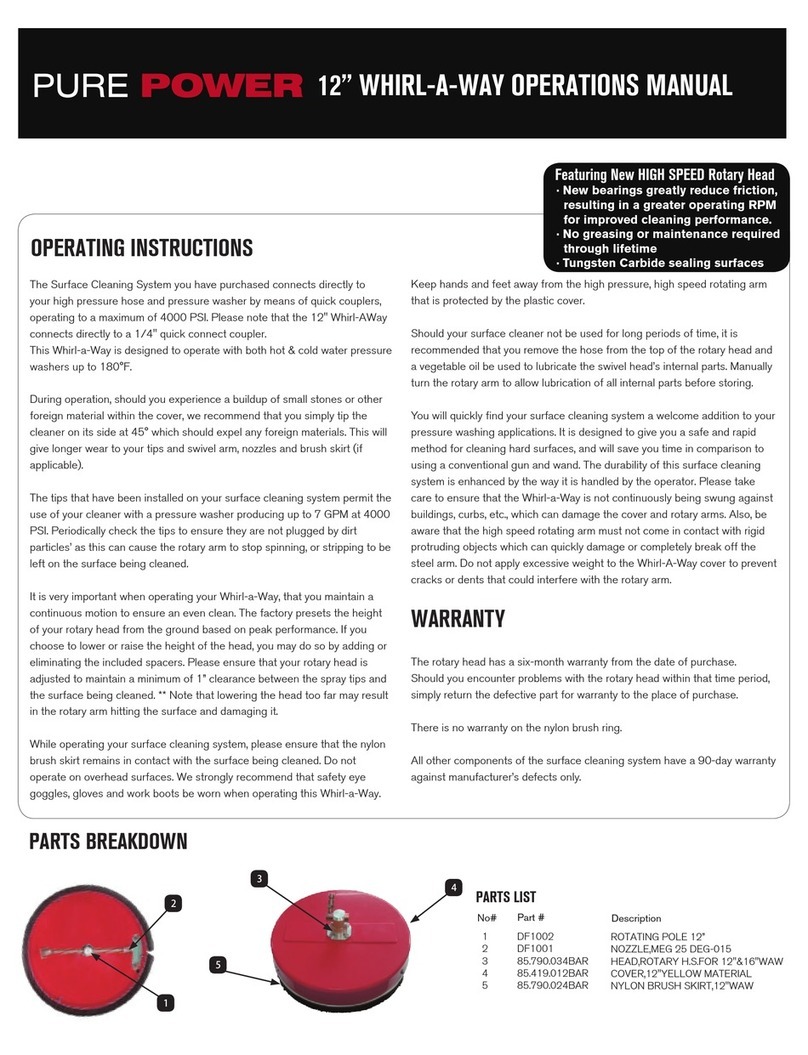

MDS-100

DRY ICE BLASTING

CLEANER

FOSECO CORP.

貿紳有限公司 FOSECO CORP.

No. 118-10, Yung Ho Rd., Ta Ya, TEL: +886 4 2568 5609

Taichung, Taiwan 428-77 FAX:+886 4 2568 5480

I

Operation & Maintenance Handbook www.dryice.com.tw W01-002-01(E)

DRYICE BLASTING CLEANER

OPERATION & MAINTENANCE HANDBOOK

This product –Dry Ice Blasting Cleaner, manufactured by FOSECO company, has

been through rigorous quality examination before shipment, the buyer (user) to use this

product, should indeed read to the "Operation Manual”and this handbook, in order to

ensure the product quality and maintain the use of the normal life of the product.

FOR YOUR SAFETY MUST FOLLOW

Please read the “OPERATION MANUAL”provided by the Company before using this

product and operate correctly.

If the label information is ignored, the level of the harm and damage occurs when use is

shown as following explanation:

WARNING

The content of this field is marked "assumes the possibility

of death or injury."

CAUTION

The content of this field is marked "the possibility of injury

and only damage on articles."

Content of "Warning or

Caution”.

“Prohibited Items”NOT

allowed.

MUST follow the

“Instructions”.

FIGURES

貿紳有限公司 FOSECO CORP.

No. 118-10, Yung Ho Rd., Ta Ya, TEL: +886 4 2568 5609

Taichung, Taiwan 428-77 FAX:+886 4 2568 5480

II

Operation & Maintenance Handbook www.dryice.com.tw W01-002-01(E)

Due to we are not able to control the way and the environment of user's operation, we

cannot guarantee the life of this product; only able to require the user to operate this product

in accordance with the following recommendations.

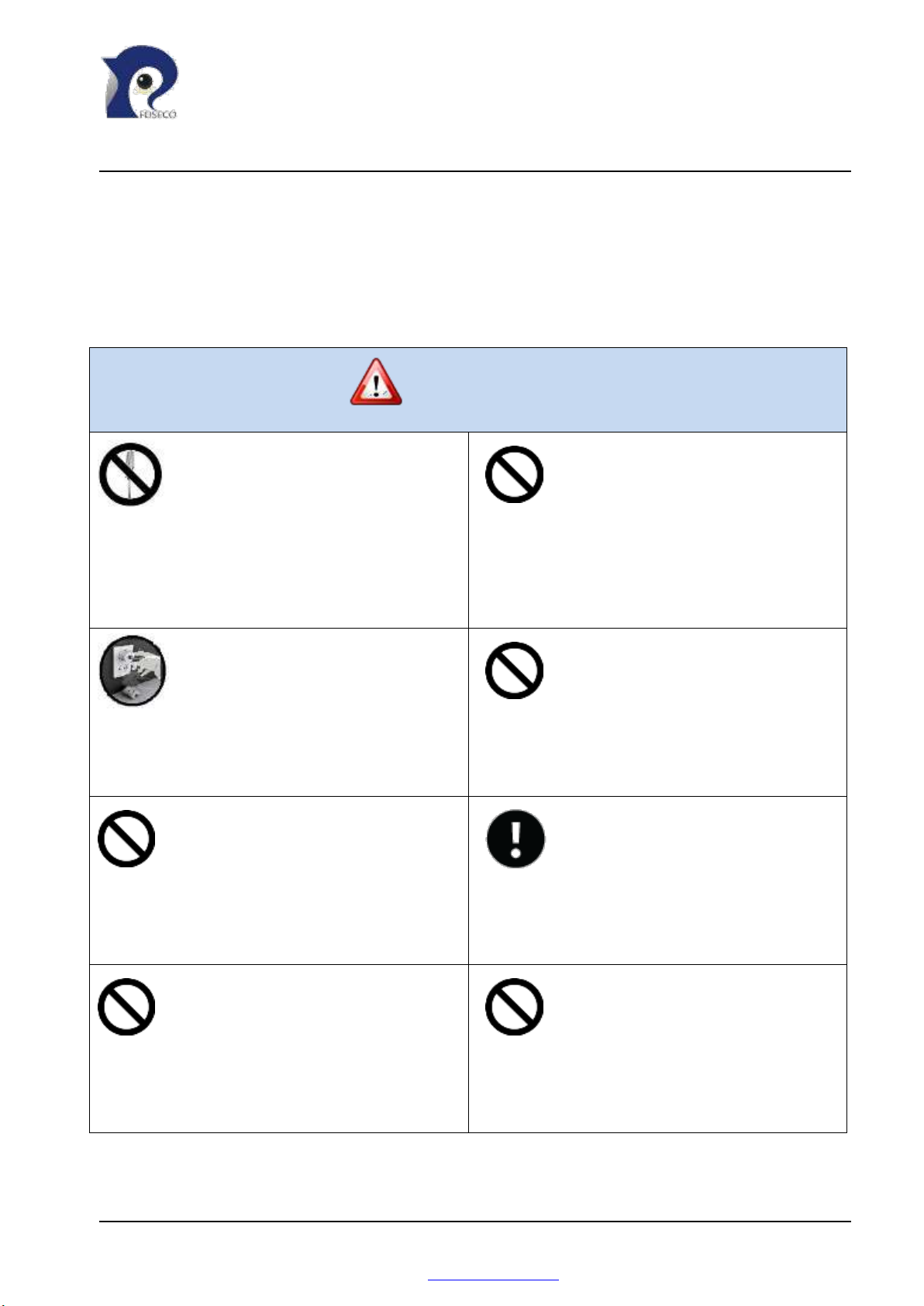

WARNING

NO remodel. Do not let the

disqualified person to operate

or service the machine.

Electric Shock or Injury.

Contact agent for repair.

Do NOT make the wire

damaged or broken,

processing, excessive

bending, pulling, twisting, or

place heavy objects on it.

The damaged wire will lead to

fire, or electric shock.

When maintenance, be sure

to plug the wire uprooted,

moreover, do NOT pull the

plug with wet hands.

Electric Shock or Injury.

Do NOT use the unspecified

voltage.

Electric Shock, fire or Injury.

While wire or plug socket is in

damage, do NOT use it.

Electric shock or short will lead

to injury or fire.

The dust on power plug

should be clean periodically。

Dust accumulation on plug will

cause a fire by poor insulation

due to moisture

Do NOT use this machine for

unspecified use.

Please follow the SOP, shall

not use for other purposes, in

order to avoid mechanical

damage or danger.

Do NOT install the machine

in a unstable place.

Easily to fall and cause a

danger of injury and damage

the product by earthquake or

outside force.

貿紳有限公司 FOSECO CORP.

No. 118-10, Yung Ho Rd., Ta Ya, TEL: +886 4 2568 5609

Taichung, Taiwan 428-77 FAX:+886 4 2568 5480

III

Operation & Maintenance Handbook www.dryice.com.tw W01-002-01(E)

CAUTIONS & CLEANING TIPS

CAUTION

Note the appearance of accessories.

Check the air and blasting hoses if

damaged, bended, or broken.

Check the power wire if damaged.

Do NOT plug in or out with wet hands.

To avoid danger from electric shock.

Do not use the stacked dry ice. (for

MDS-100 series, and MDS-520 use)

Use the whole dry ice block in size of

12x12x25cm or 25x25x25cm.

To cause the cutters blocked by stacked

dry ice.

Do NOT put foreign objects on the top

cover or dry ice chamber of this

machine.

The main causes of injuries or machine

shot down.

Do NOT try to touch the inner parts of

dry ice blasting machine in operations.

To avoid a danger of injury.

Do NOT forget while turn off this blasting

cleaner:

Take out the remaining dry ice.

Pull off the power wire from socket to avoid

a fire.

CLEANING TIPS

1.Check the air pressure and adjust to the best appropriate blasting pressure.

2.Timely adjust the blasting flow to avoid the unnecessary consumption of dry ice.

3.Aim the blasting gun at the object to be cleaned. The proper distance from

nozzle to the object is 4~10cm.

貿紳有限公司 FOSECO CORP.

No. 118-10, Yung Ho Rd., Ta Ya, TEL: +886 4 2568 5609

Taichung, Taiwan 428-77 FAX:+886 4 2568 5480

IV

Operation & Maintenance Handbook www.dryice.com.tw W01-002-01(E)

How to Troubleshoot

CONDITIONS

CHECK ITEMS

TROUBLESHOOTING

Completely unable to

operate

Check the power wire is well

plugged in, the power indicator

is light on.

Make sure the power switch is

turn “ON”.

The power source is operated.

Check if the dry ice chamber

door is closed. If not, the Error

Indicator light is on.

Check if the power fuse or

switch at workshop is operated.

Well connect the power

wire.

Press the power switch

“ON”.

Make sure the dry ice

chamber door is certainly

closed.

Re-start the operation by

steps after the power

source at worksite is

repaired.

Abnormal/error in dry

ice blasting flow

Check if the dry ice remaining in

the chamber room.

Check if the dry ice block is

broken.

Check if the blasting hose (blue)

is connected well on two ends

between cleaner and nozzle.

Check if the air hose (black) is

well connected on two ends

between the cleaner and air

compressor.

Make sure the air pressure is

keeping greater than 4kg/cm2.

Check if the air hose and

blasting hose are damaged,

broken or bended.

Check if the great gear is still

well running.

Replace a new dry ice

block when dry ice is used

off or broken.

Well connected both

blasting hose and air

hose.

Make sure the air

compressor at workshop is

running well.

Replace a new blasting

hose or air hose while they

are broken or damaged.

Others

Check the dry ice crimped inside

the cleaner.

Take out the remaining dry

ice, and spray air on the

crimped area by air

compressor until the dry

ice is gasified.

貿紳有限公司 FOSECO CORP.

No. 118-10, Yung Ho Rd., Ta Ya, TEL: +886 4 2568 5609

Taichung, Taiwan 428-77 FAX:+886 4 2568 5480

V

Operation & Maintenance Handbook www.dryice.com.tw W01-002-01(E)

OTHER RECOMMENDATION

WORKSHOP ENVIRONMENT LIMIT

1.The operation (cleaning) area must be provided with sufficient lighting, with a minimum

illumination above 300LUX, for carrying out the cleanliness check in much easier way.

2.If the noise over to 80dB (A) during cleaning process, please wear ear protectors.

3.The machine must be operated in well-ventilated circumstances.

MACHINE SCRAP and WASTE

This machine do not need special disposal for manufacturing materials, for the treatment

of scrap and waste to this machine, please be treated in accordance with the

requirements of local government.

IF THE MALFUNCTION IS STILL EXISTED, PLEASE

CONTACT US.

PLEASE SEE “OPERATION MANUAL”FOR PART

NAME & OPERATION DETAILS.

貿紳有限公司 FOSECO CORP.

No. 118-10, Yung Ho Rd., Ta Ya, TEL: +886 4 2568 5609

Taichung, Taiwan 428-77 FAX:+886 4 2568 5480

VI

Operation & Maintenance Handbook www.dryice.com.tw W01-002-01(E)

RECOMMEND MAINTENANCE PERIOD

Daily

No.

Check Item

Visual

Operate

1.

The machine wheels are running well. Check the

dusts or contaminations on wheels.

2.

Check the blasting hose; no damaged or

bended.

3.

Check the air hose; no damaged or bended.

4.

Check the power wire; no damaged.

Weekly

No.

Check Item

Visual

Operate

1.

Check the automatic drainage system on filter of

air compressor.

2.

Lubricate the Cylinder and the FRL system.

3.

Airing the ball valve near cutter plate

Monthly

No.

Check Item

Visual

Operate

1.

Lubricate the driving chain of motor

2.

Sharpen the dry ice cutters

ຩಓԖϦљ

F O S E C O C O R P .

NO. 118-10, YUNG HO RD., TA-YA,

TACHUNG CITY, TAIWAN, 428-77

TEL:04-2568-5609 FAX:04-2568-5480

[ ]

MDS-100

DRY ICE BLASTING

CLEANER OPERATION MANUAL

FOSECO CORP.

&217(176

0$&+,1(287/,1(

6$)(7<),*85(6

63(&,),&$7,21

&21752/3$1(/

,16758&7,216

%,//2)0$7(5,$/63$576

%/$67,1**81

&,5&8,7',63/$<

:,5,1*',$*5$0

3$5765(3/$&(0(17

&877(55(3/$&(0(17

352'8&7:$55$17<&(57,),&$7(

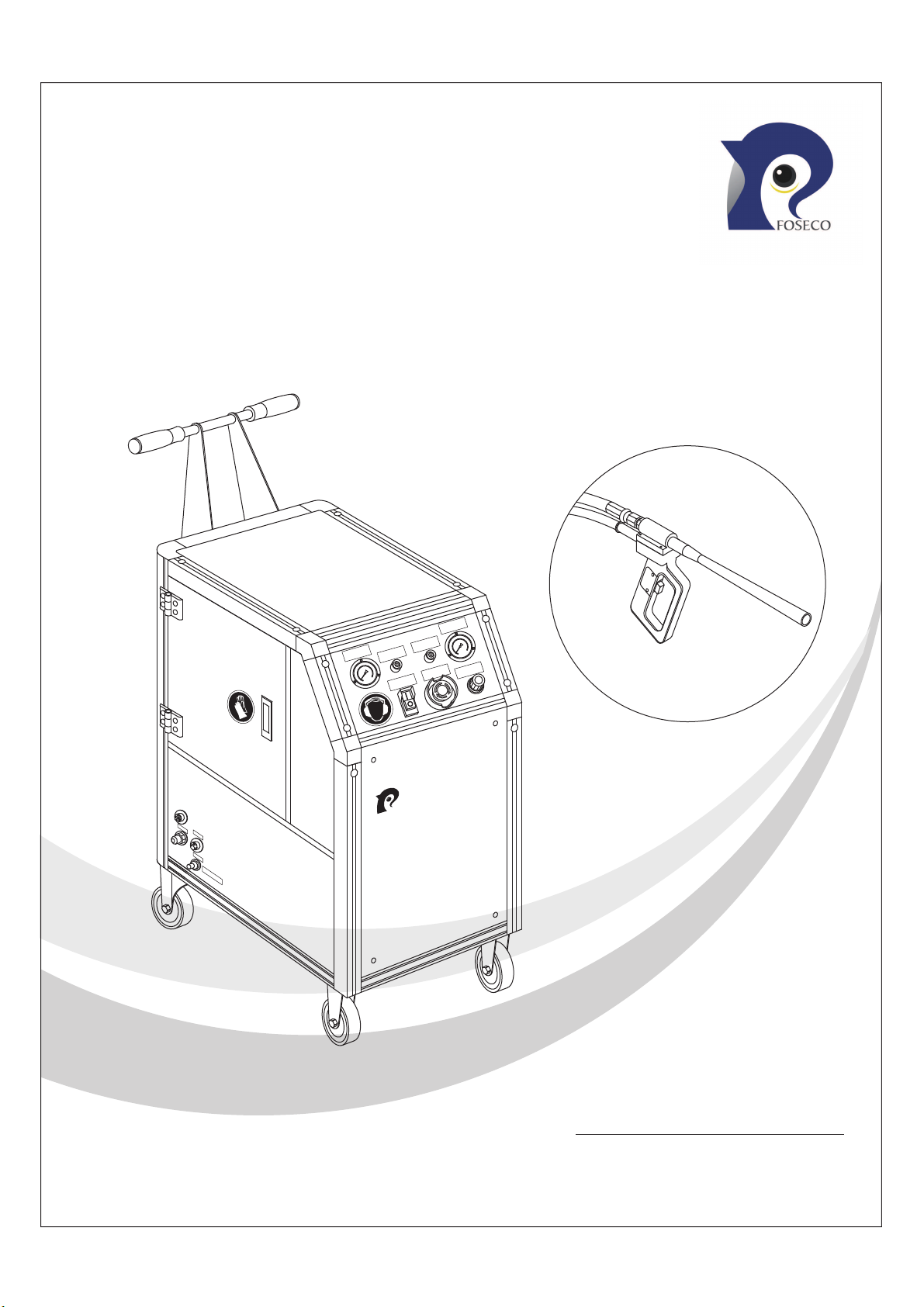

MDS-100

0$&+,1(287/,1(

MDS-100

P.01

FOSECO CORP.

ႝݙཀ/ᙣᏹբ

FMFDUSJD!TIPDL

PQFSBUF!DBSFGVMMZ

EBOHFS

BD!!22 1W !!!2

2

3

4

6

5

!

UPQ!DPWFS

DPOUSPM!QBOFM

GSPOU!QMBUF

NBDIJOF!IBOEMF

FMFDUSJD!DBCJOFU

CBDL!QMBUF

ESZJDF!DIBNCFS!EPPS

CMBTU!XJSF!DPOOFDUPS

QPXFS!DPOOFDUPS

BJS!TPVSDF!DPOOFDUPS

CMBTU!IPTF!DPOOFDUPS

! !

7

8

22

21

:

9

ᐒᏔၮᙯϐ

ሡӃ ௗ Ӧ

ΕӒᓀ

ᇂηѺ໒

ፎނၮᙯ

Hspvoe!nbdijof!up

b!tvjubcmf!hspvoe

cfgpsf!pqfsbujpo/

XBSOJOH

!

Ȑ2ȑ

Ȑ3ȑ

Ȑ4ȑ

Ȑ5ȑ

Ȑ6ȑ

Ȑ7ȑ

Ȑ8ȑ

Ȑ9ȑ

Ȑ:ȑ

Ȑ21ȑ

Ȑ22ȑ

Ȑ23ȑ

ΕӒᓀ

ᇂηѺ໒

ፎނၮᙯ

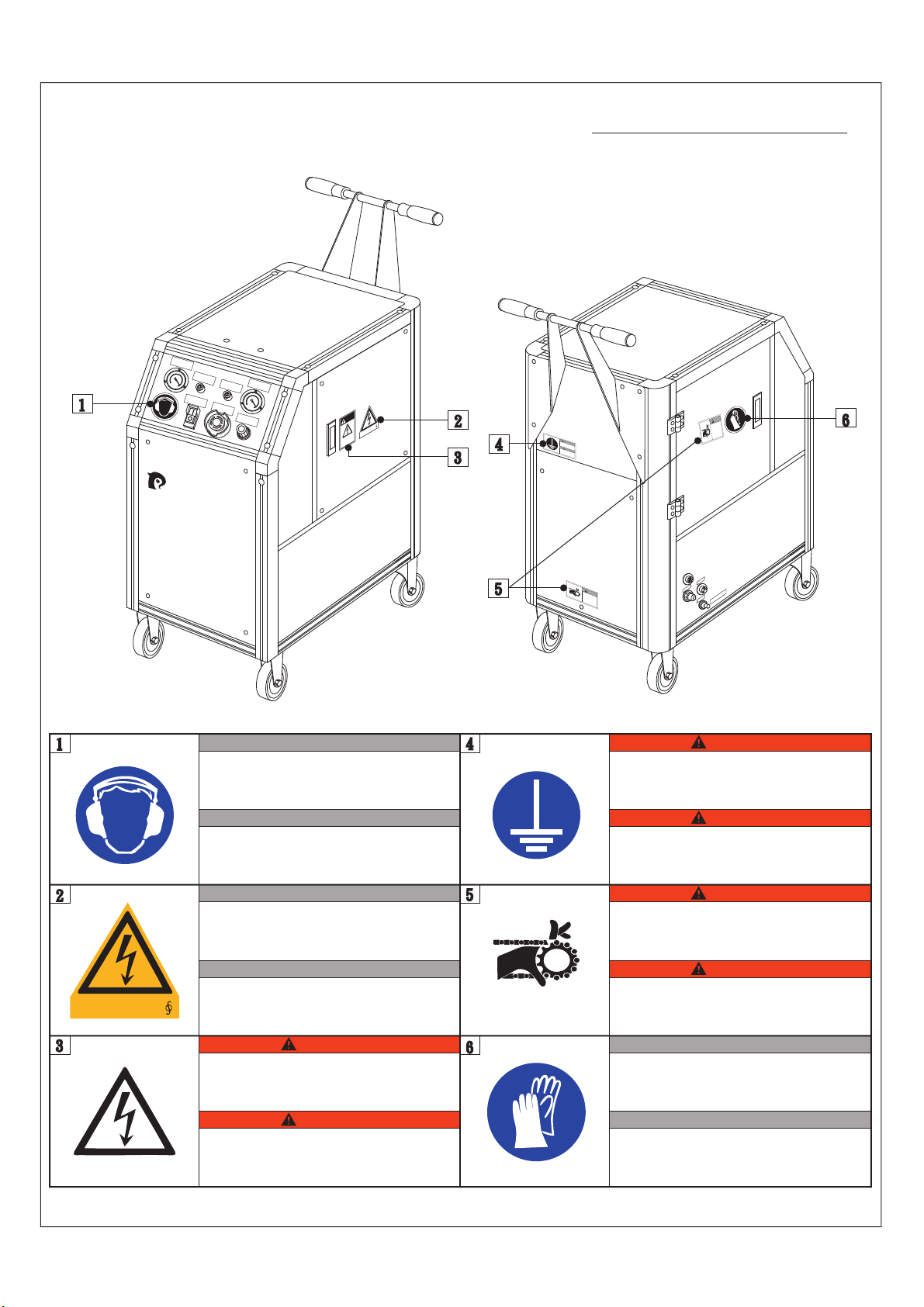

6$)(7<),*85(6

BD!!221W!!!2

ᐒᏔၮᙯϐ

ሡӃௗӦ

XBSOJOH

!

XBSOJOH

!

XBSOJOH

!

ΕӒᓀ

ᇂηѺ໒ፎϮၮᙯ

ႝݙཀ/ᙣᏹբ

Electric Shock

Operate Carefully

MDS-100

P.02

FOSECO CORP.

ႝݙཀ/ᙣᏹբ

FMFDUSJD!TIPDL

PQFSBUF!DBSFGVMMZ

EBOHFS

BD!!2 2 1 W !! !2

2

2

3

3

4

4

5

5

!

7

7

ᐒᏔၮᙯϐ

ሡӃ ௗ Ӧ

ΕӒᓀ

ᇂηѺ໒

ፎނၮᙯ

Hspvoe!nbdijof!up

b!tvjubcmf!hspvoe

cfgpsf!pqfsbujpo/

XBSOJOH

!

6

6

Ground machine to a suitable

ground before operation.

ΕӒᓀ

ᇂηѺ໒

ፎނၮᙯ

ROLLING

KEEP HANDS AWAY

ݙཀႝᓸ

ELECTRICAL

VOLTAGE

EAR PROTECTORS

DURING OPERATION

ᏹբፎٵᔎԸ༞

DRY ICE LOADING

GLOVES NECESSARY

৾ڗଳӇ

୍ѸଛᔎٛএЋ

Spec.

Dryice Storage

Pressure

Consumption rate

Machine Dimension

Power

Air Inlet

Dryice Dimension

Horse Power

Machine Weight

MDS-100

5kg

4~10 kg/cm2;45scfm

10kg~ 30

kg/hr

850 x560 x1040 mm

110v/220v 60hz

1/2”

125 x125 x250 mm

120 W

85 kg

671nn

2151nn

961nn

SPECIFICATION

MDS-100

P.03

1 AIR SUPPLY GAUGE: AIR SUPPLY MUST GREATER THAN 6 kg/cm2.!

!

2 POWER INDICATOR: CHECK POWER ON/OFF.

!

7 POWER SWITCH: POWER ON/OFF.

!

4 AIR SUPPLY ADJUSTOR: INDICATE THE AIR PRESSURE WHILE OPERATING.

5 AIR PRESSURE ADJUSTOR: TO ADJUST THE AIR PRESSURE FOR OPERATION.

6 EMERGENCY STOP: TO STOP THE MACHINE IN EMERGENCY.

3 ERROR INDICATOR: THE DRYICE CHAMBER MUST BE SURELY CLOSED.

CONTROL PANEL

MDS-100

P.04

23

4

6

7

8

5

3/8*,17+(:,5(727+(5(&(37$&/(62.0$.(685(7+(3(32:(5

($57+,1*&211(&7('

&211(&77+($,5+26($1'&+(&.7+($,56833/<*$8*(08676+2:

$7%(7:((1aNJFP

&211(&77+(:,5(727+(0$&+,1(3,16$6:(//$67+(%/8(

%/$67,1*+26(

6(77+('5<,&(%/2&.727+(&+$0%(567$%/<386+7+(%2$5'7,*+7/<

$1')25:$5'/<&/26(727+('5<,&(&877,1*$5($

35(667+(%87721212)%/$67,1**817267$57,)7267237+(135(66

$*$,1

,16758&7,216

MDS-100

P.05

7+(%(67',67$1&(727+(2%-(&7,6

a&0

6

2

3

4

5

FOSECO CORP.

,17(5/2&.$8720$7,&$//<2))

:+,/(7+('225,623(1('

%,//2)0$7(5,$/63$576

MDS-100

Ȑ1ȑ

Ȑ2ȑ

Ȑ3ȑ

Ȑ4ȑ

Ȑ5ȑ

Ȑ6ȑ

Ȑ7ȑ

PNEUMATIC CYLINDER

DAMPER PLATE

DRYICE CHAMBER

CUTTER FIX BASE

CUTTER

CUTTER PLATE

DRYICE GUIDE

CUTTER PLATE SCREWS

COUPLING SHAFT

CUTTER FIX PLATE

GREAT GEAR

SPEED REDUCER

FIX PLATE

DRYICE GATHER GASKET

(UPPER)

DRYICE GENERATOR

BEARINGS

DRYICE GATHER GASKET

(LOWER)

OUTLET HOUSE

FIX PLATE

DRYICE OUTLET

OUTLET BASE

Ȑ8ȑ

Ȑ9ȑ

Ȑ10ȑ

Ȑ11ȑ

Ȑ12ȑ

Ȑ13ȑ

Ȑ14ȑ

Ȑ15ȑ

Ȑ16ȑ

Ȑ17ȑ

Ȑ18ȑ

Ȑ19ȑ

Ȑ20ȑ

Ȑ21ȑ

P.06

1

23

5

6

7

8

10

11

12

13

9

4

14

15

16 17

18

19

21

20

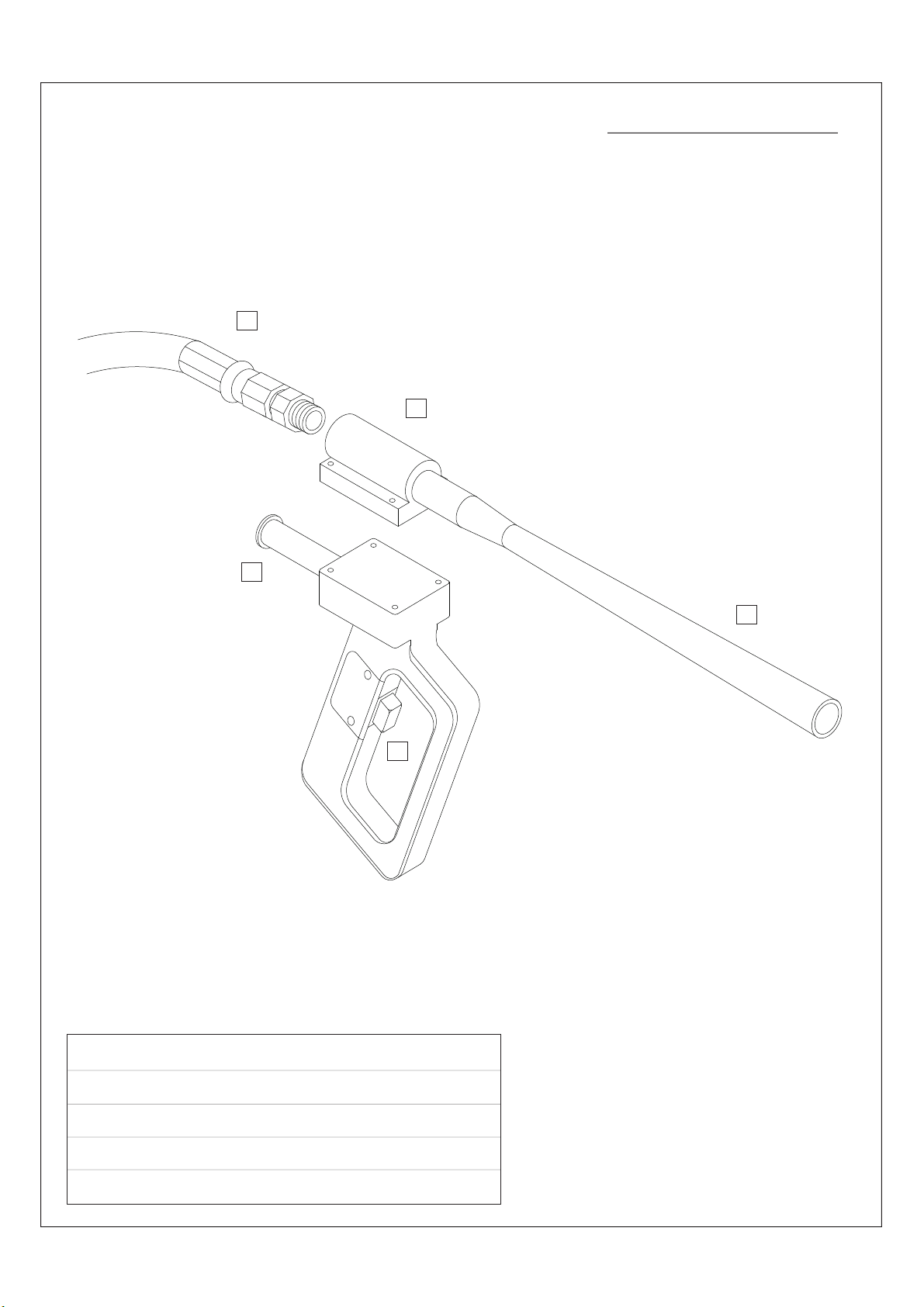

% / $ 6 7 , 1 * * 8 1

MDS-100

Ȑ1ȑ

Ȑ2ȑ

Ȑ3ȑ

Ȑ4ȑ

Ȑ5ȑ

2

3

4

6

5

P.07

BLASTING HOSE

BLASTING SEAT

BLASTING HANDLE

BLASTING APPLICATOR

BLASTING NOZZLE

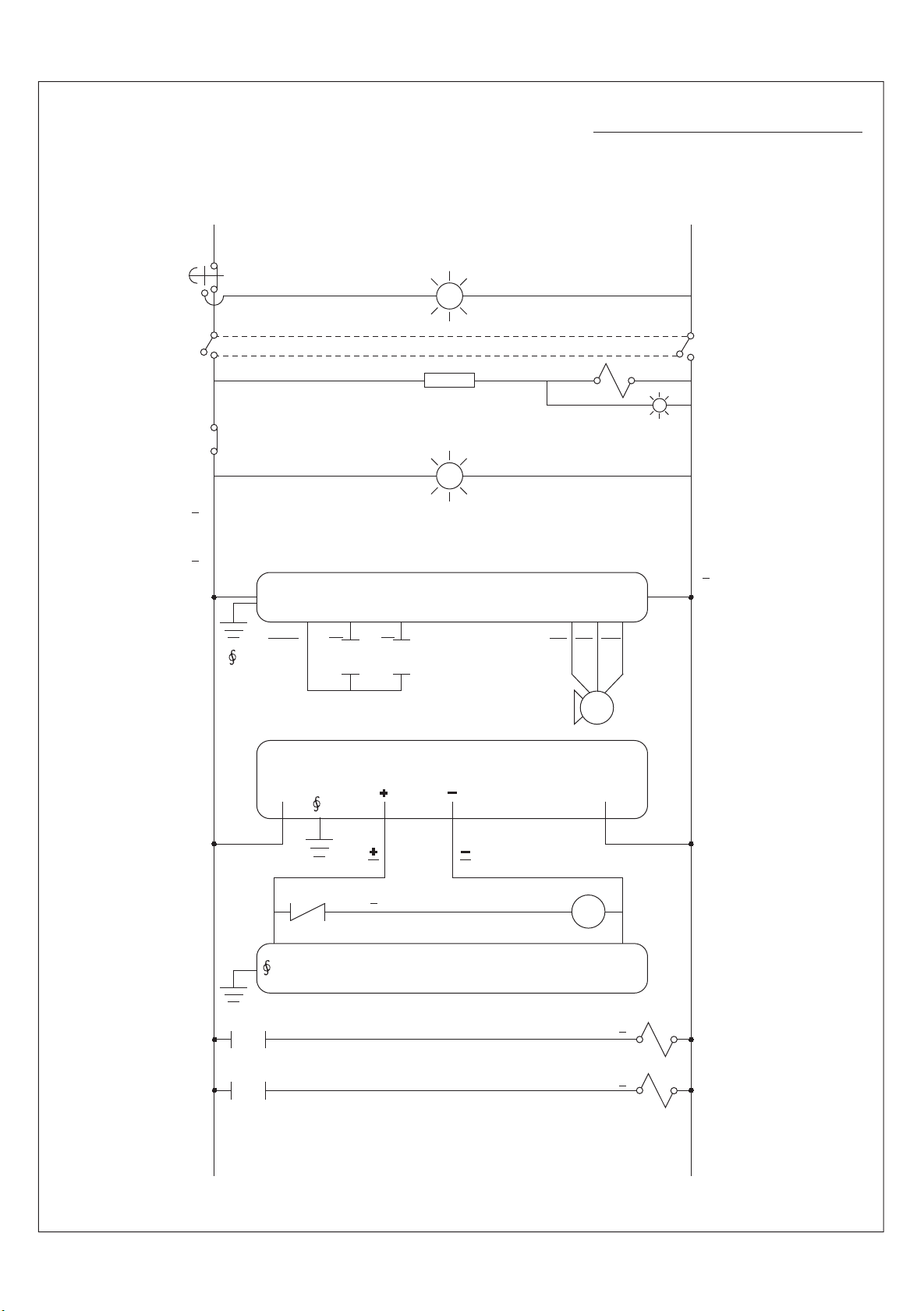

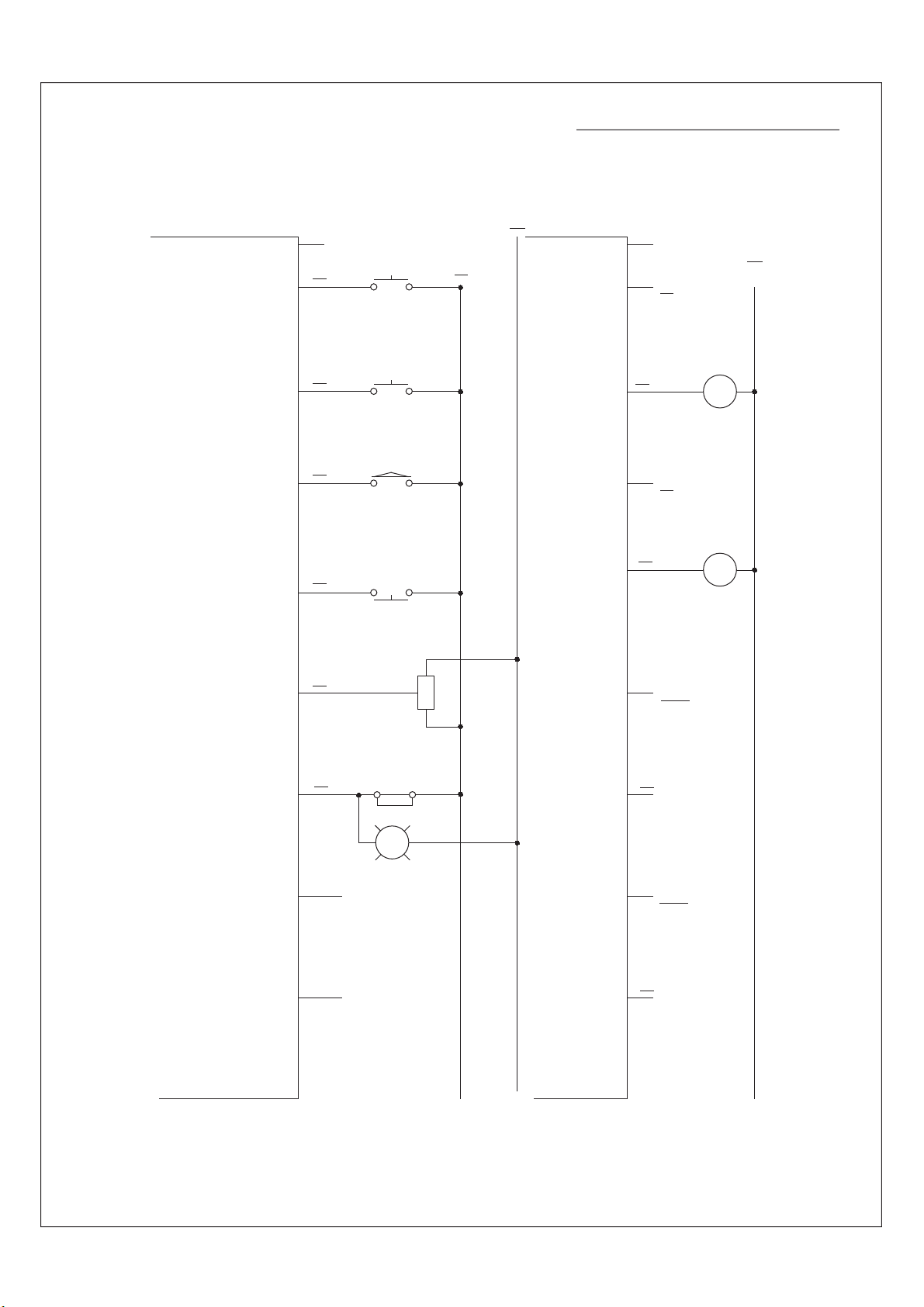

CIRCUIT DISPLAY

MDS-100

PLC

R1

R2

R3

LS1

7

POWER SUPPLY

L + _

+_

N

INV

COM FWD REV

Y0 Y1

23 22COM U1 V1 W1

TM

1

YR1

YR0

YR1

Blow Solenoid

EMO

INTERLOCK

Push Solenoid

2

3

0

1

5

4

白

BLK

U<

P.08

1.2mm

1.2mm

1.2mm

MDS-100

PRESS TO STA RT

SELF-HOLD IN G

PRESS TO STA RT

NO SELF-HOL DI NG

X0

P+

10

SELF HOLDIN G

(PRESS 2SEC )

X1

11

X2

12

X3

13

X4

14

X5

15

N-

OFF DELAY TM1

MATE RI AL D ET EC TI NG

DOOR (OPE N)

RL

BLOW SOLE NO ID

PUSH SOLENO ID

CO M0

P+

Y0

20

CO M1

Y1

21

CO M2

Y2

22

N-

N-

IN V-REV

IN V-FWD

CO M3

Y3

CO M

CO M

23

YR

0

YR

1

P.09

& , 5& 8 , 7 ' , 6 3 / $<

& , 5& 8 , 7 ' , 6 3 / $<

MDS-100

PRESSURE GA UG E

GUIDE VA LVE

BLASTIN G

5~10 kg/cm

1~7 kg/cm

V

V

CYLINDER

4 kg/cm

V

P.10

FILT ER

2302-4L-R

RC 1/2

GFC200

08-F1-P

G1-40015WPP

AR2000

N-P

4V210-08

S

P

R

B

A

4V210-08

S

P

R

B

A

PRESSURE GA UG E

ADJUSTOR

SOLENOI D

PRESSURE GA UG E

SOLENOI D

FRL

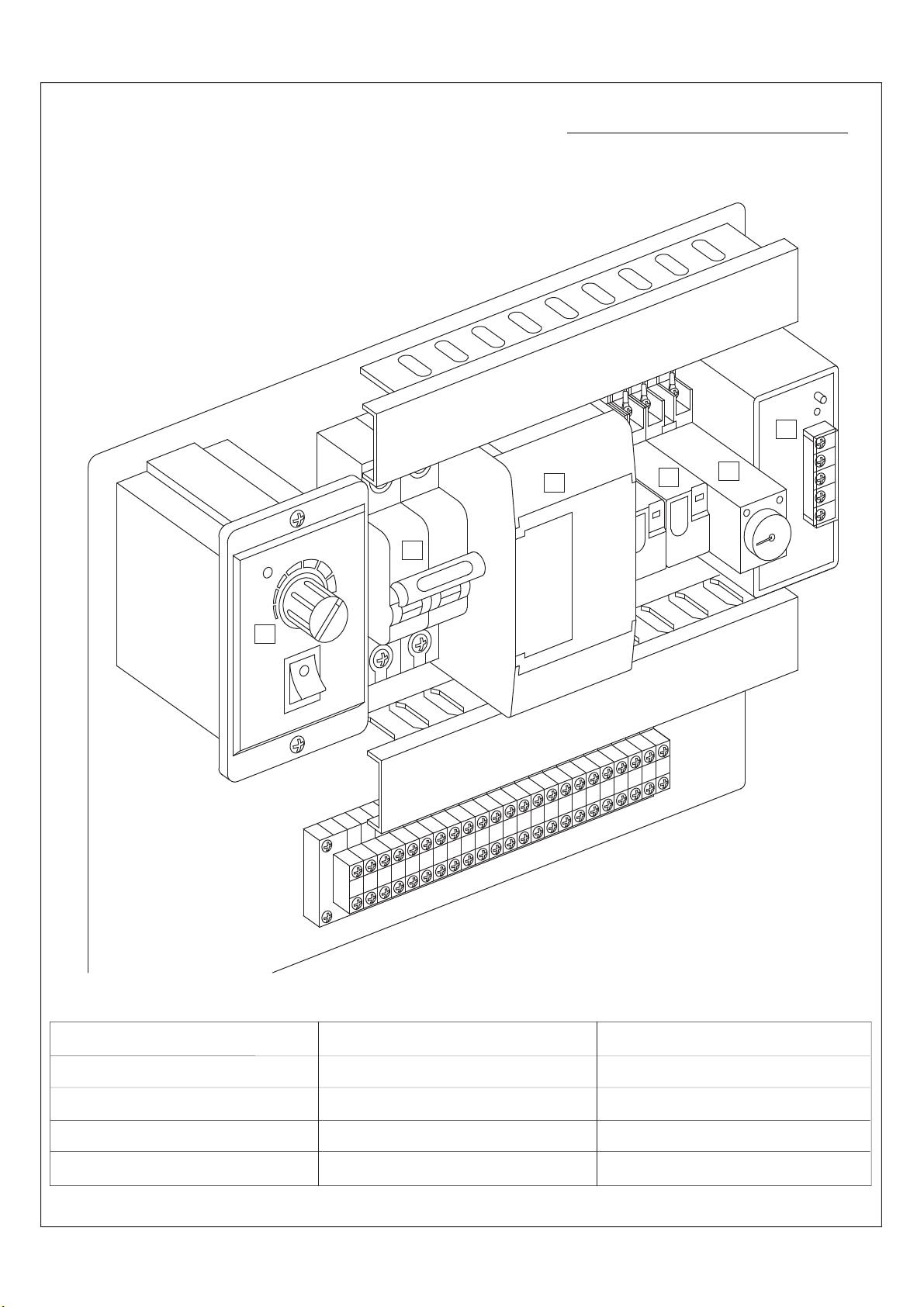

: , 5 , 1 * ' , $* 5 $ 0

MDS-100

P.11

қᆘV2W2X2 41526Q,O.2122 24Q, O. Q,O.

2625

7

Ȑ1ȑMOTOR REGULATOR DC POWER SUPPLY

POWER SWITCH

PLC CONTROLLER

RELAY

TIMER

Ȑ2ȑ

Ȑ3ȑ

Ȑ4ȑ

Ȑ5ȑ

Ȑ8ȑ

Ȑ9ȑ

Ȑ10ȑȐ15ȑ

Ȑ6ȑ

Ȑ7ȑ

Ȑ11ȑ

Ȑ12ȑ

Ȑ13ȑ

Ȑ14ȑ

2

3

456

7