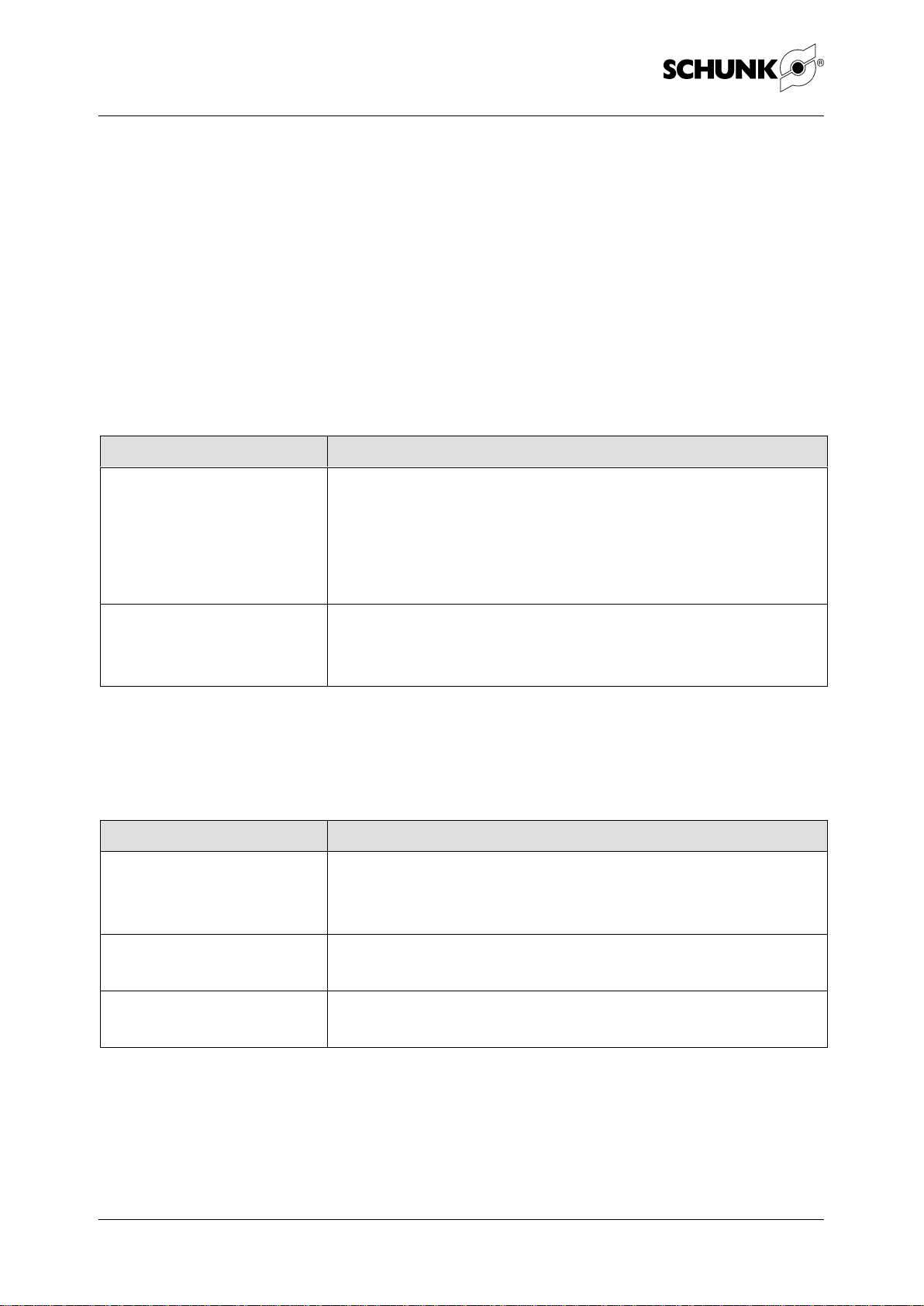

Table of contents

01/RGG/2009-02-09/SW 3

Table of contents

1 About this manual.................................................................................................4

1.1 Purpose/validity..........................................................................................4

1.2 Target groups.............................................................................................4

1.3 Applicable documents..............................................................................s4

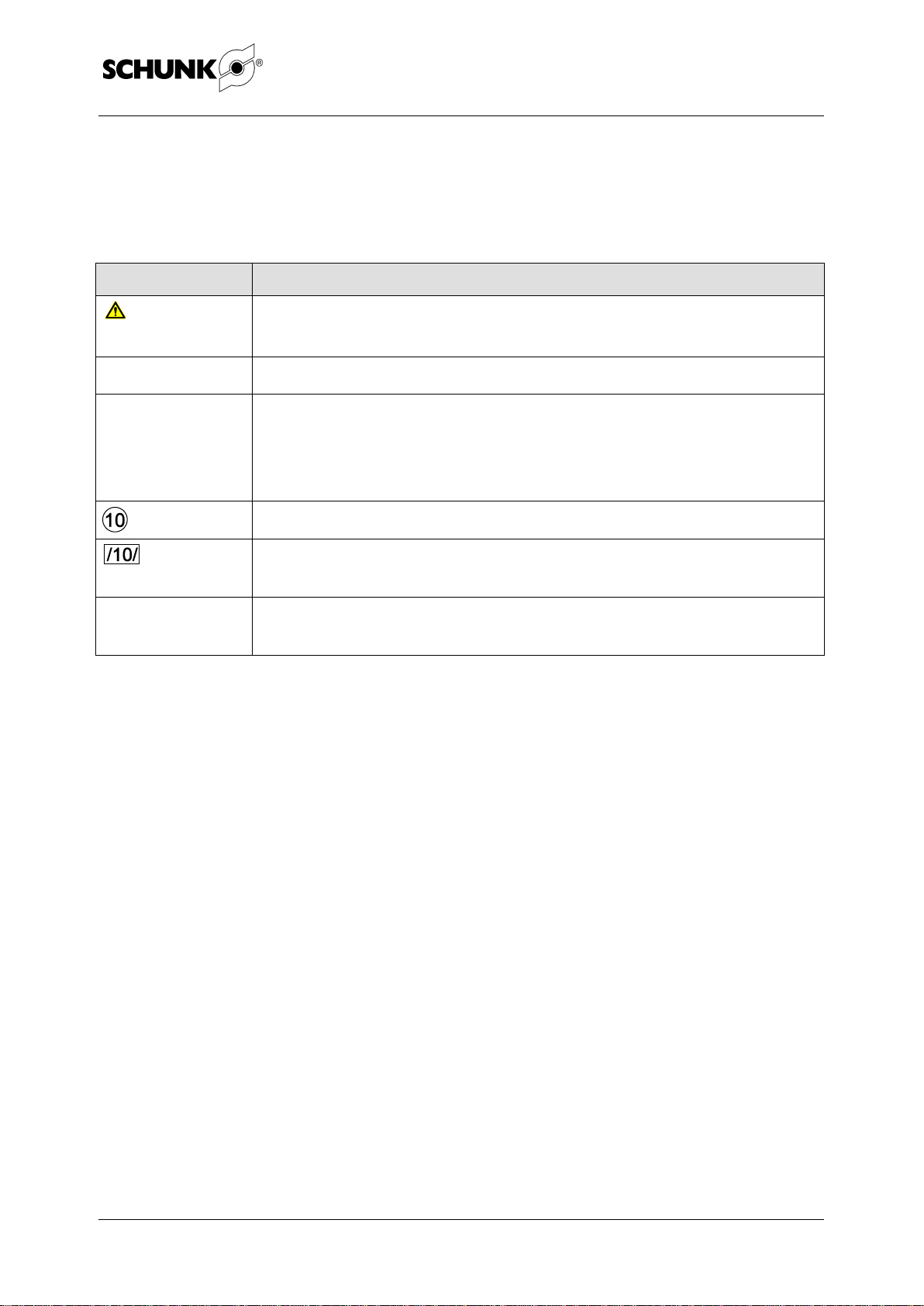

1.4 Symbols in this manual ..............................................................................5

2 Basic safety notes ................................................................................................6

2.1 Intended use ..............................................................................................6

2.2 Environmental and operating conditions ....................................................6

2.3 Controlled production.................................................................................6

2.3.1 Protective equipment.....................................................................7

2.3.2 Constructional changes, attachments, or modifications.................7

2.4 Personnel qualification...............................................................................7

2.5 Safety-conscious working...........................................................................7

2.6 Notes on particular risks.............................................................................7

3 Warranty................................................................................................................8

4 Scope of delivery..................................................................................................8

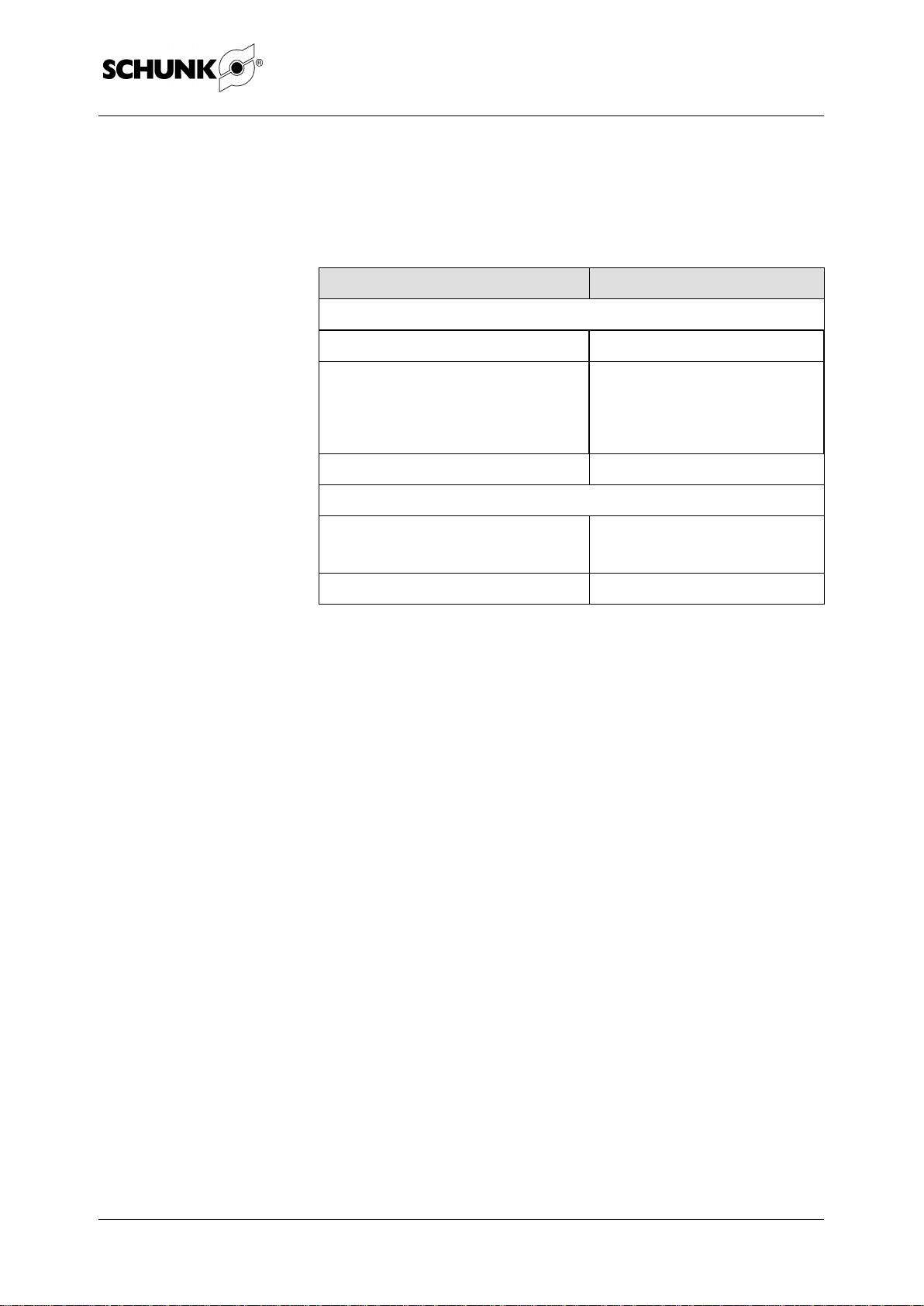

5 Technical Data ......................................................................................................9

6 Assembly and initial commissioning................................................................10

6.1 Mechanical connection.............................................................................10

6.2 Assembly example...................................................................................11

6.2.1 Toolholder TENDO......................................................................11

6.2.2 Toolholder WELDON...................................................................12

6.3 Commissioning.........................................................................................13

7 Troubleshooting..................................................................................................14

7.1 Is there no air/cooling water coming out of the RGG?..............................14

8 Maintenance and care ........................................................................................14

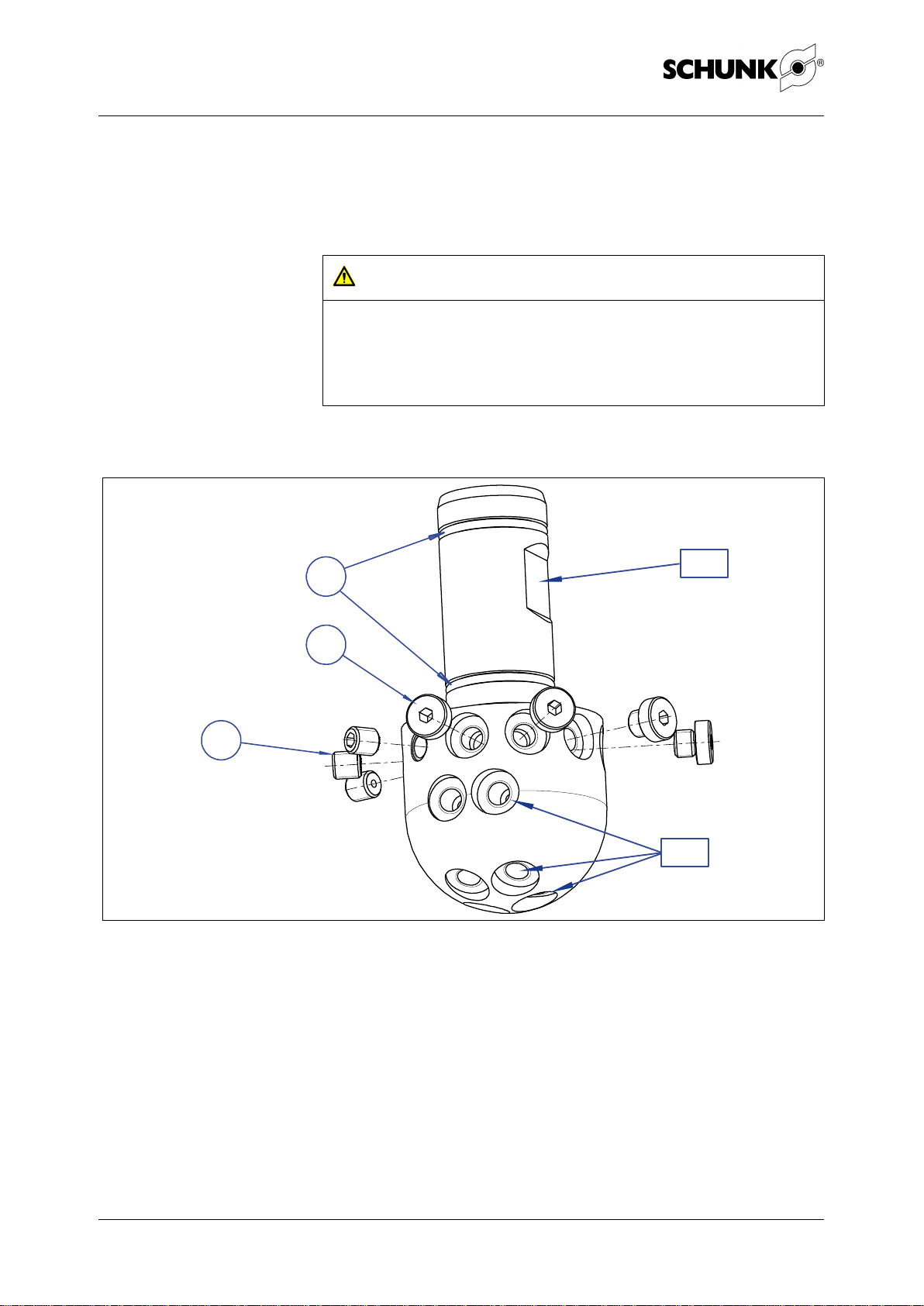

9 Assembly drawing..............................................................................................15

10 Spare parts..........................................................................................................16

11 Contact ................................................................................................................17