F+D ECO 200 User manual

User ManualUser Manual

Label Printer

ECO 200ECO 200

Revision: January 2003

3073.02.994.90.06

User Manual ECO 200

Introduction

F+D Feinwerk- und Drucktechnik GmbH

Kirchenstraße 38, D-69239 Neckarsteinach

Tel.: 06229 7000, Fax: 06229 70067

E-Mail: [email protected], Internet: http://www.fuddruck.de

3

Contents

1. Introduction .......................................................................................................4

2. Initial Start Up....................................................................................................5

2.1 Preparation of Location......................................................................................................5

2.2 Security Advice..................................................................................................................5

2.3 Unpacking..........................................................................................................................5

2.4 Connection of Mains Cable................................................................................................5

2.5 Insertion of Paper and Transfer Ribbon..............................................................................6

2.6 Printout of a Test Label......................................................................................................7

2.7 Parallel Interface................................................................................................................7

2.8 Serial Interface...................................................................................................................8

2.9 Transporting the Printer .....................................................................................................8

3. Operating ..........................................................................................................9

3.1 Control Panel.....................................................................................................................9

3.1.1 LCD-Display................................................................................................................9

3.1.2 Power- and Error-Display............................................................................................10

3.1.3 Keys...........................................................................................................................10

3.2 Main Menu Mode...............................................................................................................11

3.3 Sub-Menu Mode................................................................................................................11

3.3.1 Menu and Parameters.................................................................................................13

3.3.2 Printer Infos................................................................................................................14

3.3.3 Macro Navigater .........................................................................................................15

3.3.4 Label Data..................................................................................................................16

3.3.5 Print Parameters.........................................................................................................18

3.3.6 Printer Specs..............................................................................................................19

3.3.7 Character / LCD..........................................................................................................21

4. Maintenance......................................................................................................22

4.1 Ribbon- and Paper-Changing.............................................................................................22

4.2 Cleaning of the Thermal Print Head ...................................................................................22

4.3 Cleaning of the Feed Rollers..............................................................................................22

4.4 Changing of Thermal Print Head........................................................................................22

4.5 Update of printer software ECO 200...................................................................................23

5. Hardware Modifications.....................................................................................24

5.1 Thermal Direct Printing ......................................................................................................24

5.2 Transfer Device .................................................................................................................24

5.3 Carrier Foil Rewinding Device............................................................................................24

5.4 Front Rewinder..................................................................................................................24

5.5 Cutting Device ...................................................................................................................24

5.6 Dispensing Device.............................................................................................................24

5.7 External Rewinder / Winder................................................................................................25

6. Service Diagnosis..............................................................................................26

6.1 Improvement of the Printing Quality ...................................................................................26

6.2 Error Correction.................................................................................................................27

6.2.1 Error Level 1...............................................................................................................28

6.2.2 Error Level 2...............................................................................................................28

6.2.3 Error Level 3...............................................................................................................28

7. Accessories, Options.........................................................................................29

8. Technical Data..................................................................................................30

9. Declaration of Conformity..................................................................................31

10. Index .................................................................................................................32

4User Manual ECO 200

Introduction

F+D Feinwerk- und Drucktechnik GmbH

Kirchenstraße 38, D-69239 Neckarsteinach

Tel.: 06229 7000, Fax: 06229 70067

E-Mail: [email protected], Internet: http://www.fuddruck.de

1. Introduction

With the ECO 200 you have purchased a professional label printer.

Developed and produced by F+D Feinwerk- und Drucktechnik GmbH,

the ECO 200 sets new bench marks in the field of industrial application

of label printers.

Based on years of experience with the HFP-printer-line a new

generation of printers was created. Above all the printing speed as well

as the printing quality have been improved considerably.

In addition many more possibilities for comfort and operation are now at

the customers disposal.

The ECO 200 can be handled simply and easily by means of a LCD-

display and 6 keys. Nevertheless, you should take the time to read this

user manual, in order to be able to use all the possibilities of this printer

to an optimum.

At the beginning you will learn how to initialise this printer. After you are

familiar with the operation of the printer, this manual will render a good

service to you for quick reference. Please keep this manual safe.

User Manual ECO 200

Initial Start Up

F+D Feinwerk- und Drucktechnik GmbH

Kirchenstraße 38, D-69239 Neckarsteinach

Tel.: 06229 7000, Fax: 06229 70067

E-Mail: [email protected], Internet: http://www.fuddruck.de

5

2. Initial Start Up

2.1 Preparation of Location

Location of installation must be even and stable. Please allow sufficient room

•to connect the cables, and

•to operate the printer.

The printer has to be used according to the conditions of operation for which the printer was conceived.

2.2 Security Advice

•The housing or the interior of the printer are not allowed to come into contact with liquids.

•Before operating the printer, please make sure that your mains supply is operated at 230V~, 50 Hz or

115V~, 60 Hz.

•In order to avoid the risk of an electric shock, do not remove the cover. The interior of the ECO 200 does

not contain any parts to be serviced by the operator.

•Maintenance work can only be effected by qualified service personnel.

•In case the printer is not used for a while, remove the mains plug from socket. Always remove on the

plug, never pull at the cable.

•Interrupt operation immediately, if liquids or parts enter the interior of the ECO 200. Shut off at the mains

plug and inform qualified service personnel.

•Before transporting the printer, all paper- and transfer ribbon rolls must be removed.

•To drive the printer via centronic interface, the enclosed delivered cable or an equivalent printer cable

according to the IEEE 1284 specification (the single conductors are twisted two by two and twice

shielded) must be used.

•Attention! This is a class A device. In a residential area it can cause radio interference. In this case the

responsible person can be obliged to take the adequate measures to prevent the interferences.

2.3 Unpacking

After unpacking the printer, please check contents of the box.

•Printer ECO 200

•Mains Cable (DIN-Standard)

•Centronics Cable (IEEE 1284 - specification)

•Sample Reel of Thermal Paper

•User Manual and Softwaremanual

•Printer Driver with Description

2.4 Connection of Mains Cable

At the rear of the printer the connector for mains cable and the mains switch are located.

•Switch off ECO 200 ("0" must be depressed on mains switch).

•Connect mains cable (consider firm connection). Use earthed socket only.

•Switch on ECO 200 („1“ must be depressed on mains switch).

6User Manual ECO 200

Initial Start Up

F+D Feinwerk- und Drucktechnik GmbH

Kirchenstraße 38, D-69239 Neckarsteinach

Tel.: 06229 7000, Fax: 06229 70067

E-Mail: [email protected], Internet: http://www.fuddruck.de

2.5 Insertion of Paper and Transfer Ribbon

Insertion of Paper

The label printer is suited to print onto thermal paper. Normal paper, plastic foil and metal foil can only be

printed by using the option transfer device. These materials are available on reels or adhesive labels.

1. Open the cover and remove the white paper guide disk.

2. Push reel onto wind off spindle.

3. Push paper guide disk back.

4. Unwind some label material or paper respectively and load the material into the right and left paper guide

while print head device is opened.

5. Adjust paper guide width by the black knurled screw. The label material should not be depressed down

by this action (leave approx. 0.5 mm play).

Notice: It is important that the distance between the paper and the mounting plate on the paper guide is

equal to that on the label reel. The reel can be moved easily. The paper guide disks should only press lightly

against the reels. Uneven wound or misaligned label reels lead to printing errors and paper jam.

The maximum diameter of the paper reels on the internal rewinder lies at 90 mm.

6. Hinge print head device down and secure.

Lock

Printer Device Upper Paper Guide Disk

Printer Device Lower Knurl Screw Paper Guide

Label Reel

* Rewinder Device for

Label Base Material * Optional

Label

Colour Layer

*Rewinder Device for

Transfer Ribbon

Tensioner

User Manual ECO 200

Initial Start Up

F+D Feinwerk- und Drucktechnik GmbH

Kirchenstraße 38, D-69239 Neckarsteinach

Tel.: 06229 7000, Fax: 06229 70067

E-Mail: [email protected], Internet: http://www.fuddruck.de

7

Insertion of Transfer Ribbon

Printers equipped with the option „Transfer Device“, feature a wind off / wind on mechanism positioned

above the printer upper section (see diagram on previous page).

1. Push transfer ribbon reel onto winding device below operator panel.

2. Centre reel to print head.

3. Guide ribbon according to diagram on previous page below the opened printer device upper.

4. Wind transfer ribbon round rewinding device.

5. Insert clamp strap into the groove and hole.

6. Turn the rewinding device one full circle clockwise and thus tension the transfer ribbon.

7. Hinge printer device down and secure again.

Notice: The shiny side of the ribbon must point towards the thermal print head. The somewhat more dull

side is the colour layer, which must point towards the paper.

Synchronization

Recognition of label start is effected via scan-through light barrier and

requests synchronization marks between the labels. The synchronous

light barrier has a clearance A = 5 mm from the edge of the paper.

Therefore the depth (D) of the synchronization mark should be at least

6 mm from the left paper edge in order to have an edge radius (R) of

less than 3 mm. The width (W) has to be at least 1.5 mm. Label

distances or printed synchronization marks could also be recognized if

the sensor had been adjusted accordingly.

2.6 Printout of a Test Label

1. Switch printer on.

2. Put paper into the printer.

3. Go to menu Printer Infos / Labels

4. Depress the l- button in order to chose the label Firmenadresse.

5. Confirm your choice by depressing the SAVE - key.

The menu will be exited and the label will be printed, at the same time a black shape appears on the

LCD left of the "1" (in accordance to the set macro).

6. Press again PRINT-button and the test label will be printed.

Notice: Please check in advance

•Is thermal print head inserted?

•Is printer device upper closed?

•Is paper reel (and transfer ribbon) inserted?

2.7 Parallel Interface

In order to connect the parallel cable, align the wider side of the plug to the wider side of the printer

connector. Afterwards fasten the plug with the two existing clamps in order to produce a stable electrical

contact.

Then connect the cable to the computer (corresponding parallel interface).

Notice: Before connecting the cable, the printer and the PC have to be switched off.

D

ECO 200 ok -> g1

#0000

8User Manual ECO 200

Initial Start Up

F+D Feinwerk- und Drucktechnik GmbH

Kirchenstraße 38, D-69239 Neckarsteinach

Tel.: 06229 7000, Fax: 06229 70067

E-Mail: [email protected], Internet: http://www.fuddruck.de

2.8 Serial Interface

In order to connect the serial cable, align the wider side of the plug to the wider side of the printer connector.

Afterwards fasten the plug with the two existing screws in order to produce a stable electrical contact.

Then connect the cable to the computer (corresponding serial interface).

The serial interface also serves for communication with the PC, but it is slower than the parallel interface. By

using the keyboard you can set

Baud rate: 4800, 9600, 19200, 38400

Data bits: 7, 8

Stop bit: 1, 2 and

Parity: without, with (even, odd)

Protocol: without XON / XOFF, with XON / XOFF

Standard settings are printed in bold.

Notice: Before connecting the cable, the printer and the PC had to be switched off.

2.9 Transporting the Printer

1. Switch printer off.

2. Unplug carefully the mains cable and the interface cable (serial and/or Centronics-cable).

3. Use original packing material for transportation, where possible.

Notice: Before transporting the printer, all paper- and transfer ribbon rolls must be removed.

User Manual ECO 200

Operating

F+D Feinwerk- und Drucktechnik GmbH

Kirchenstraße 38, D-69239 Neckarsteinach

Tel.: 06229 7000, Fax: 06229 70067

E-Mail: [email protected], Internet: http://www.fuddruck.de

9

3. Operating

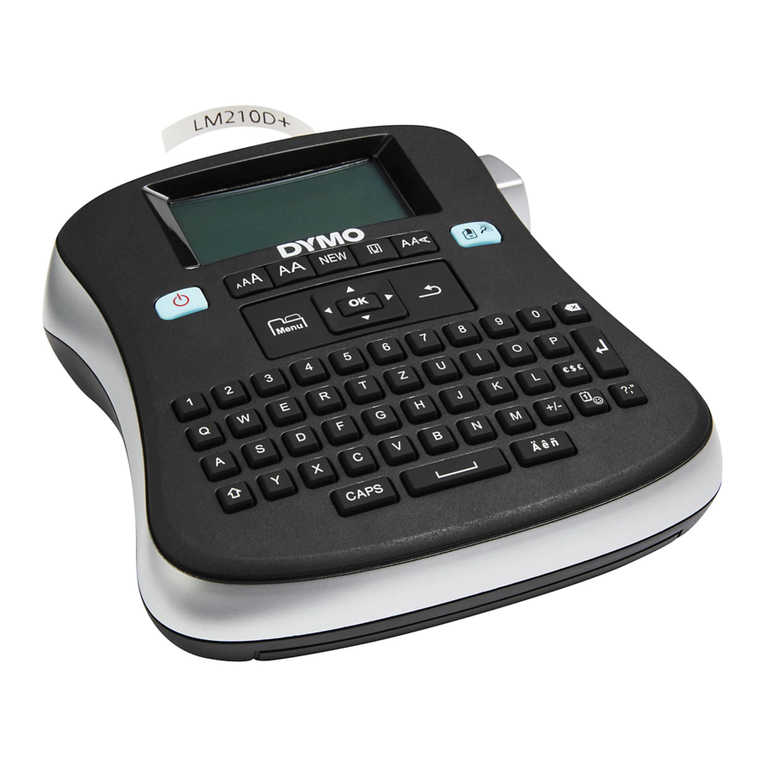

3.1 Control Panel

The control panel consists of

•LCD- Screen (2x16 digits)

•2 LEDs (Power and Error)

•6 keys:

PRINT- key

FF / SAVE - key

MENU- key

STATUS / - key

CUT / - key

CLEAR / l- key

3.1.1 LCD-Display

The information shown on the display depends on present operating mode of the printer. In total, 4 different

sub-screens can be opened.

Standard Screen: This mode displays the actual short-status of the printer, which is of

interest during the printing process. This screen (see picture opposite)

should always be displayed when printer is switched on.

Meaning of the status symbols:

-> XON- status

| XOFF- status

no label set edited

nlabel set edited

1 Macro 1 active

# Number of labels, which still have to be printed by the actual label set.

Menu-Screen:

Will be opened, when MENU-key is depressed. Inside the menu structure, the upper line shows the main

menu and the lower line shows the sub-menu.

Error-Screen:

Is displayed by the printer in case an error incurred.

Status-Screen:

Will be displayed when STATUS-key is depressed. By depressing the key again, the second part of the

status-window will be displayed. By depressing the key anew, the standard-screen will be displayed or in

case of an error the error listing is displayed. (see Software Manual: Status Message)

1. Status-Screen 2. Status-Screen

ECO 200 ok -> 1

#0000

DEVICE # 1008

31-10-2001 D ECP

ECO 200 S02/V2.02

=00#0000*0131072

10 User Manual ECO 200

Operating

F+D Feinwerk- und Drucktechnik GmbH

Kirchenstraße 38, D-69239 Neckarsteinach

Tel.: 06229 7000, Fax: 06229 70067

E-Mail: [email protected], Internet: http://www.fuddruck.de

3.1.2 Power- and Error-Display

Power-Display:

This display is green and lights up in case the mains switch of the printer is switched on.

Error-Display

This display is red and lights up or blinks in those cases the error-screen is active.

3.1.3 Keys

PRINT key

Of the actual label set one label will be printed.

FF key

Transports the paper through the printer without printing and synchronizes to print start.

MENU key

The menu-screen will be displayed. This gives the user the possibility to check the set printer functions or

change them respectively. The menu will be exited by depressing the same key again.

By depressing this key for a longer time period, that particular part of the menu can be skipped to, where the

last skip back took place.

During a print job, this can be stopped by depressing the key for a while, and depressing the key again

enables finishing the print job.

STATUS key

The status-screen will be displayed. In case of an error, this key (depress key 2x) displays the 2nd status-

screen with up to 8 error codes. The menu will be exited by depressing the same key again.

CUT key

Should a cutting device be available, this can be activated by depressing the Cut-key.

CLEAR key

Functions only when error-screen is opened. By means of CLEAR-key the displayed warning-message can

be erased. In case several errors are indicated at the same time, only the warning-message with the highest

priority at that time will be displayed. The CLEAR-key can only be depressed for that amount of time until all

warning-messages are displayed or erased respectively.

ERROR- and HARDWARE- messages cannot be erased.

User Manual ECO 200

Operating

F+D Feinwerk- und Drucktechnik GmbH

Kirchenstraße 38, D-69239 Neckarsteinach

Tel.: 06229 7000, Fax: 06229 70067

E-Mail: [email protected], Internet: http://www.fuddruck.de

11

3.2 Main Menu Mode

This menu is called-up by depressing the MENU-key. Depressing the

key for only a short time, skips to the start of the menu. Depressing the

key longer, skips directly to that option of this menu where it has been

exited from last time.

The menu is exited by depressing the MENU-key.

After call-up of the menu, the menu display is shown and the functions

of the keys are different. The first line of the LCD-screen displays the

first main menu.

Scrolling the main menu is effected with the -key. Main menus are

always displayed in the first LCD-line and also in capital letters.

In this example the main menu PRINTER SPECS. is indicated.

The menu can be exited by depressing the MENU-key.

3.3 Sub-Menu Mode

General

With the -key the displayed main menu can be skipped. In order to display the various sub-menus of the

chosen main menu, continue to depress the -key.

Sub-menus, as long as they are not chosen, are displayed in the 2nd LCD-line in capital- as well as small

letters.

For this example the main menu LABEL DATA has been chosen and the sub-menu 'Number of Labels'. The

menu can be exited by depressing the MENU-key.

By depressing the key lthe displayed sub-menu is chosen. In order to display the various options of a sub-

menu, the key lis depressed furthermore. Current active settings are marked with a hook (√) and most of

the time also displayed as first option.

For this example the main menu LABEL DATA has been chosen and the sub-menu 'Number of Labels'.

The menu can be exited afterwards via -key and then by depressing the MENU-key.

SAVE key

When an option is chosen, it can be saved by depressing the key SAVE and stored in the current macro. A

confirmation will be displayed for about 2 seconds on the screen:

After storage this menu option will automatically be exited.

In case the stored value should be checked afterwards, this can be effected by depressing the 2-key.

The menu can then be exited by depressing the -key and then the MENU-key.

PRINTER SPECS.

LABEL DATA

Copies

-------------------------

-------------------------

--

MACRO NAVIGATER

LABEL DATA

PRINT PARAMETERS

CHARACTER / LCD

PRINTER SPECS.

PRINTER INFOS

12 User Manual ECO 200

Operating

F+D Feinwerk- und Drucktechnik GmbH

Kirchenstraße 38, D-69239 Neckarsteinach

Tel.: 06229 7000, Fax: 06229 70067

E-Mail: [email protected], Internet: http://www.fuddruck.de

Input of numerical values

A menu option can also mean a further choice of different options. Alternatively at this point a numerical

value could be expected to be input according to the actual menu. The ECO 200 places a simple editor at

your disposal.

Example:

Change the number of labels from 10 to 60!

Input: Key lto call-up editor

Input: key lfor first numerical position

Input: key lfor next numerical position

Input: key lfor next numerical position

Input: key for actual digit depress key 6x

Input: key lfor next numerical position

Input: key lto exit editor

In case the number is incorrect, the editor can be called again by depressing the l-key once again. The

option is exited either by depressing the - key or the SAVE-key.

Copies

0010

Copies

< 0 . . . >

Copies

< 0 0 . . >

Copies

< 0 0 0 . >

Copies

< 0 0 6 . >

Copies

< 0 0 6 0 >

Copies

0 0 6 0

3.3.1 Menu and Parameters

PRINTER INFOS

ECO 200 ok

press MENU

warnings

insert data

l

acknowledge

ldisplay only

lignore

l#70 ignore

byteam.:XXXXH

logos

print - status

l

FDLogo

fonts

l

COURI06F -

COURI14F

lARIAL08F-

ARIAL22F

barcodes

labels

l

EAN 8/13

lC_2o5_I

lC_39

lC_128

lEAN128

lPDF417

l

Firmenadresse

LABEL DATA

copies

image width

l

0000

l

0800 dot 100 mm

image height

image abort.

l

0478 dot 60 mm

l

000 dot 002 mm

dispersing pos.

l

060 dot 8 mm

paper end at..

paper jam at..

l

80 dot 10 mm

l

4000 dot 500 mm

TOF-offset

l

50 dot - 50

PRINT PARAMETERS

heating time tph

l

+30% to –30%

printing speed.

synchronisation

l

75 mm/s -

200 mm/s l

no(with FF)

lno(no FF)

lyes (with FF)

lyes (no FF)

lyes (AUTO FF)

Queue process

l

no

lyes

PRINTER SPECS.

printer - mode

l

no print key

lwith print key

aut.papersensor

l

start?

man.papersens

or

l

Value: 22 LED -

CHARACTER / LCD

schedule

country

l

ANSI

lASCII

lmultilingual

l

USA

lEngland

lGermany

lDenmark

lFrance

lSweden

lItaly

lSpain

lNorway

lNetherlands

Update FlashDa

l

Send Data

keys- and character explanation

-key: leaf through the main menu

-key: leaf through the sub menu

l-key: select option

ldefault

boot-macro 0-3

init macro

l

Macro 1

lMacro 2

lMacro 3

lMacro 0

l

macro 0->1

lmacro 0->2

lmacro 0->3

copy macro

l

macro 1->2 |1->3

lmacro 2->3 |2->1

lmacro 3->1 |3->2

MACRO NAVIGATER

cutting pos..

l

158 dot 20 mm

RS232

l

4800 Baud

l9600 Baud

l19200 Baud

l38400 Baud

l7 data bits

l8 data bits

l1 stop bit

l2 stop bits

lno parity

leven parity

lodd parity

lno XON/XOFF

lwith XON/XOFF

dispersing ...

l

no

lwith print key

llabel taken

cutter

l

no

lyes

lyes, always

transfer

l

not present

lpresent

language

l

English

lFrench

lGerman

scrolling

l

no

lyes

14 User Manual ECO 200

Operating

F+D Feinwerk- und Drucktechnik GmbH

Kirchenstraße 38, D-69239 Neckarsteinach

Tel.: 06229 7000, Fax: 06229 70067

E-Mail: [email protected], Internet: http://www.fuddruck.de

3.3.2 Printer Infos

Print - Status:

Print out of all parameter to be set. Image width and image height must

be set to ≥54 mm (648 dots) each. You can print the print-status by

using the l- key.

Labels:

All label sets stored in the printer will be displayed here. You can print

the select label by using the SAVE-key.

Barcodes:

All barcodes stored in the printer will be displayed here. You can print

the select barcode by using the SAVE-key.

Fonts:

All fonts stored in the printer will be displayed here. You can print the

select font by using the SAVE-key.

Logos:

All logos stored in the printer will be displayed here. You can print the

select logo by using the SAVE-key.

Insert data:

Amount of data submitted to the ECO 200. The amount is displayed in a

hexadecimal number.

Warnings:

Details of warnings including confirmation possibilities

Print-out stored label set

Barcodes, fonts, logos and labels stored in the printer can be printed

out easily and is described below:

4. Go to menu Printer Infos / Labels

5. Depress the l- button in order to chose the desired label.

6. Confirm your choice by depressing the SAVE - key.

The menu will be exited and the label will be printed, at the same time a black shape appears on the

LCD left of the "1" (in accordance to the set macro).

7. Depress the PRINT - key again for a short time in order to print a further label.

ECO 200 ok -> g1

#0000

PRINTER INFOS

warnings

PRINTER INFOS

insert data

PRINTER INFOS

barcodes

PRINTER INFOS

fonts

PRINTER INFOS

labels

logos

PRINTER INFOS

PRINTER INFOS

print-status

User Manual ECO 200

Operating

F+D Feinwerk- und Drucktechnik GmbH

Kirchenstraße 38, D-69239 Neckarsteinach

Tel.: 06229 7000, Fax: 06229 70067

E-Mail: [email protected], Internet: http://www.fuddruck.de

15

3.3.3 Macro Navigater

What is a macro?

With the printer a macro means a fixed set of printer characteristics, such as transfer printing, heating time,

cutting device, etc.

All parameter, which are changeable in the menu of the ECO 200 , can

be combined as a macro. Otherwise they will be lost when the printer is

switched off.

The ECO 200 contains 3 macros, numbered from 1 to 3. With these

macros the printer can chose between 3 different fixed configurations.

The macros are stored in the printer. The content of this memory will

remain, even if the printer is switched off.

As soon as the printer is switched on, that macro set in the boot macro

will automatically be loaded into the work area. Thus the printer knows

all printing options when it is switched on.

Macro 0 has been preset by the manufacturer as default macro. This

cannot be changed.

Macros 1,2, and 3 also contain preset values like macro 0, but these

can be changed by the user.

The loaded macro will be displayed in the standard display (1st LCD-line, 16th position).

Boot-Macro 0-3

The actual boot macro will be marked with a hook or displayed in the

standard display respectively. By depressing the l- button the desired

macro is selected and chosen by depressing the SAVE-key. With the

change of the boot-macro the printer is automatically restarted,

afterwards the new macro is active immediately.

Copy Macro

Around the content of the current macro in another macro to take over

you can copy a macro. For this select the respective menu option and

store it with the SAVE-key. Thus the macro is stored.

Init Macro

With it you put back the macro 1, 2 or 3 on the default values

of macro 0.

MACRO NAVIGATER

boot - macro 0-3

MACRO NAVIGATER

copy macro

MACRO NAVIGATER

init macro

boot - macro 0-3

√macro 1

copy macro

macro 1 -> 2

init macro

0 -> 1

16 User Manual ECO 200

Operating

F+D Feinwerk- und Drucktechnik GmbH

Kirchenstraße 38, D-69239 Neckarsteinach

Tel.: 06229 7000, Fax: 06229 70067

E-Mail: [email protected], Internet: http://www.fuddruck.de

3.3.4 Label Data

Copies

- 0000 - 9999

Number of labels to be printed

Image Width

- 0000 - 0896 dots

Image Width determines the width of the print area.

Parameter: d = image width * 8 / mm in number of dots

minimum width = 8 mm (d=64), maximum width = 108 mm (d=864)

The value for the image width can at any time be smaller than the real

label format. The resulting print area will thus be in image middle.

Image Height

- 0000 - 4000 steps

Image Height determines the height of the print area.

Parameter: d = image height * 8 / mm in number of motor steps

minimum height = 10 mm (d=80), maximum height = 500 mm (d=4000)

Image Abort

- 0002 – 6000 steps

The Image Abort forces an abort of the printing process. This is

sensible, if at the end of an image area there are only blanks. The

image abort encourages the image creation at high printing speeds.

Parameter: d = image abort * 8 / mm in number of motor steps

automatically image abort (d = 0000):

Display: 0000 dot 002

The Printer automatically find out the image abort to get the best

printing.

Paper End

- 000 – 999 steps

In case that within the set step no new label is recognized, the error

message Paper End will be displayed.

Parameter: d = paper end * 8 / mm in number of motor steps

Paper Jam

- 0000 – 4000 steps

In case that within the set step no paper end is recognized, the error

message Paper Jam will be displayed.

Parameter: d = paper jam * 8 / mm in number of motor steps

Without Label Synchronization:

There will be no check if paper jam incurred.

With Label Synchronization:

The input value must be larger than the label height (in dots), otherwise an unauthorized paper end - error

message will be given.

LABEL DATA

copies

LABEL DATA

image width

LABEL DATA

image hight

LABEL DATA

image abort

LABEL DATA

paper end at..

LABEL DATA

paper jam at..

LABEL DATAv

TOF-Offset

LABEL DATA

dispensing pos.

LABEL DATA

cutting pos.

User Manual ECO 200

Operating

F+D Feinwerk- und Drucktechnik GmbH

Kirchenstraße 38, D-69239 Neckarsteinach

Tel.: 06229 7000, Fax: 06229 70067

E-Mail: [email protected], Internet: http://www.fuddruck.de

17

Dispensing Position

- 000 - 999 steps

To the position of the start of the label an additional forward feed is effected in order to remove the

previously printed label.

Parameter: d = dispensing position * 8 / mm in number of motor steps

After each dispensing operation and after the label has been removed, the next label will be re-positioned to

the start of the label.

The dispensing position will be ignored should the cutting device be logged-on.

Cutting Position

- 000 - 999 steps

To the position of the start of the label an additional forward feed is effected in order to cut the previously

printed label.

Parameter: d = cutting position * 8 / mm in number of motor steps

The cutting position describes the distance between the thermal print head and the cutting device. This

normally lies at 19.8 mm (d=158). By changing this value the cutting position can be moved.

After each cutting operation and before the next printing process, the label will be re-positioned to the start of

the label.

The cutting position will only be considered, should cutting device be logged-on.

TOF-Offset

- 00 - 99 steps – 50

Distance between start of printout to label edge.

d = number of input steps (motor steps)

image heigth

TEXT

TEXT

image abord

TOF-offset

paper end min.

image width

99

0

print direction

thermal print head with print

18 User Manual ECO 200

Operating

F+D Feinwerk- und Drucktechnik GmbH

Kirchenstraße 38, D-69239 Neckarsteinach

Tel.: 06229 7000, Fax: 06229 70067

E-Mail: [email protected], Internet: http://www.fuddruck.de

3.3.5 Print Parameters

Heating Time TPH

- from -30% to +30% in steps of 5%

By this the blackening intensity of the paper is set. The higher this value, the higher the intensity of black.

Notice: The higher this value, the higher the loading on the thermal print head.

Printing speed

Printing speed determines the transportation speed of the label paper

within the printing range.

- 75, 100, 125, 150, 175 or 200 mm/s

Synchronization

- no ( with FF)

This setting is required when using endless paper. No label

synchronization will be effected. FF causes a forwarding of the paper

according to the set image height. Paper end will be detected, paper

jam not. When switching the printer on, a forward feed of 1 label will be

effected.

- no (without FF)

As with the previous point, but when switching the printer on, no forward

feed will be effected.

- yes (with FF)

This setting is necessary for label paper with index marking. Each label

will be synchronized to the label start. FF will effect a forward feed to

the next label. Paper jam as well as paper end will be checked subject

to the input values. When switching the printer on, a forward feed will be

effected to the next possible label. With labels smaller than 60 mm,

more than 1 label will be forward fed.

- yes (without FF)

As with the previous setting, but when switching printer on, no labels will be lost, as no forward feed takes

place. The PRO 300 assumes that when the printer is switched on, the label paper is already positioned

correctly. If this is not the case, positioning can be effected by depressing the FF-key several times.

- yes (AUTO FF)

The printer autonomously determines image height, paper jam and paper end. Afterwards positioning to

label start (or dispensing position) will be effected. Labels up to a maximum length of 50 cm will be

supported whereas the space between the labels should not be wider than 10 cm. Larger distances between

the labels will cause a paper-error-message. Normally at least 2 labels have to be transported unprinted.

Queue Processing

- no

- yes

Normally the printer parameter can either be sent before or after the label set. Thus giving the possibility of

subsequent changes of the settings. In case there are more label sets in the input memory queue, no definite

allocation of the printer parameter between the 2 label sets is possible any more. Thus the printer parameter

of the following label set could, circumstances permitting, influence the actual label. In order to avoid this, the

following menu points must be observed:

Menu PRINT PARAMETERS / sub-menu Queue Processing chose option yes

By depressing the SAVE-button the option is saved and, if required, be stored in the macro.

With this setting printer parameter will only be processed before the label set. Only after the desired number

of labels is printed, the evaluation of the following printer parameter including the new set of labels takes

place.

PRINT PARAMETERS

heating time tph

PRINT PARAMETERS

printing speed

PRINT PARAMETERS

synchronisation

PRINT PARAMETERS

Queue process

User Manual ECO 200

Operating

F+D Feinwerk- und Drucktechnik GmbH

Kirchenstraße 38, D-69239 Neckarsteinach

Tel.: 06229 7000, Fax: 06229 70067

E-Mail: [email protected], Internet: http://www.fuddruck.de

19

3.3.6 Printer Specs.

Printer - Mode

- without Print key

- with print key

Printing is only possible by depressing the PRINT-key.

Automatic paper sensor

- start ?

When switching to another label paper there might incur problems with synchronization, should both paper

types be very different. In order to guarantee a reliable synchronization, it might be necessary to carry out

the following option.

Before starting the printout the paper sensor has to be positioned at a part of the label which has not yet

been printed. In the case of an incorrect measuring the notice ERROR appears on the screen. In order that

the printer retains the change made when subsequently switched on, the new information has to be

committed to memory. For that you have to select the option manual paper sensor and store it with the

SAVE-Key.

Manual paper sensor:

- 0 - 127 LED

For determination of the optimum sensor

adjustment.

STATUS-button - decrease sensor current

CLEAR-button - increase sensor current

Proceeding:

8. The label material has to be positioned with the

carrier in the area of the paper sensor.

9. The point of switching A determine: of - after *

10. The label has to be positioned in the area of the

paper sensor

11. Point of switching B determine: of * after –

12. The correct sensor value Z is the mean value of

the two measurements.

Dispensing

When dispensing labels, the label has to be transported after printing so far, so that it can be taken out

easily. Time of taking the label out will either be monitored by label-taken (option) or by means of operation

of the print-key. Dispensing position 0 corresponds to the positioning at the start of the label. In order to be

able to take the previous label, the value for the dispensing position has to be increased.

- no

- with print key

After the print job is finished the paper will be reset to the dispensing position for enabling the take- or tear-

off of the label. After pressing the print key it turns again back in the printing position and the next print order

can be carried out.

- with label taken

The label-taken-device can be installed as an option. The device ensures that the next label will only be

printed if the previous one has been taken out. A dispensing position > 0 always means, that the following

label has to be repositioned before printing takes place.

Logging-on of the label-taken-device is only possible – label taken without the cutting device. The dispensing

position will be ignored in case the cutting device is logged-on.

switching points

sensor current

-*

hysteresis hysteresis

-*

0 127

CL

C : carrier material

L : label

A : measuring point 1

B : measuring point 2

Z : ideal value

* : scan material

- : do not scan material

AZB

Z = (A+B) / 2

1st measuring 2nd measuring

20 User Manual ECO 200

Operating

F+D Feinwerk- und Drucktechnik GmbH

Kirchenstraße 38, D-69239 Neckarsteinach

Tel.: 06229 7000, Fax: 06229 70067

E-Mail: [email protected], Internet: http://www.fuddruck.de

Cutting Device

Separating labels by cutting, a cutting device (option) must be installed.

- no

Should a cutting device be connected, but not logged-on, the logging-on

will be effected automatically when switching the printer on.

- yes

The label will always be synchronized to the TOF-position. Thus, during

a print job no forward-/backward-positioning has to be effected. The

motor can run between 2 labels in brakeless mode.

By means of ESC-k-sequence a cutting operation at the end of the print

job can be activated.

Furthermore, the cutting device can also be triggered via the CUT-key.

The dispensing position will be ignored in case the cutting device is

logged-on.

Notice: When single labels should be cut off it is important that

each label has a minimim height of 25 mm.

- yes, always

Each label within a print job should be cut. After the printing of a label

the cutting position will be driven to, cut and only before the next

printout takes place the TOF-position will be re-positioned.

Transfer

Transfer can be applied in combination with all other components.

- not present

- present

In case transfer is logged-on, a monitoring of the transfer ribbon is

effected as well as the drive of the transfer ribbon rewinding device.

- automatically

In each case of forward feed as well as when switching the printer on,

the presence of the transfer ribbon is interrogated. In case the transfer

ribbon is available, the transfer is automatically logged-on, otherwise

the transfer is logged-off.

RS232

- 4800, 9600,19200, 38400 baud

- 7 data bits, 8 data bits

- 1 stop bit, 2 stop bits

- without parity, even parity, odd parity

- without XON/XOFF, with XON/XOFF

This manual suits for next models

1

Table of contents