Franke TF LO User manual

Other Franke Garbage Disposal manuals

Franke

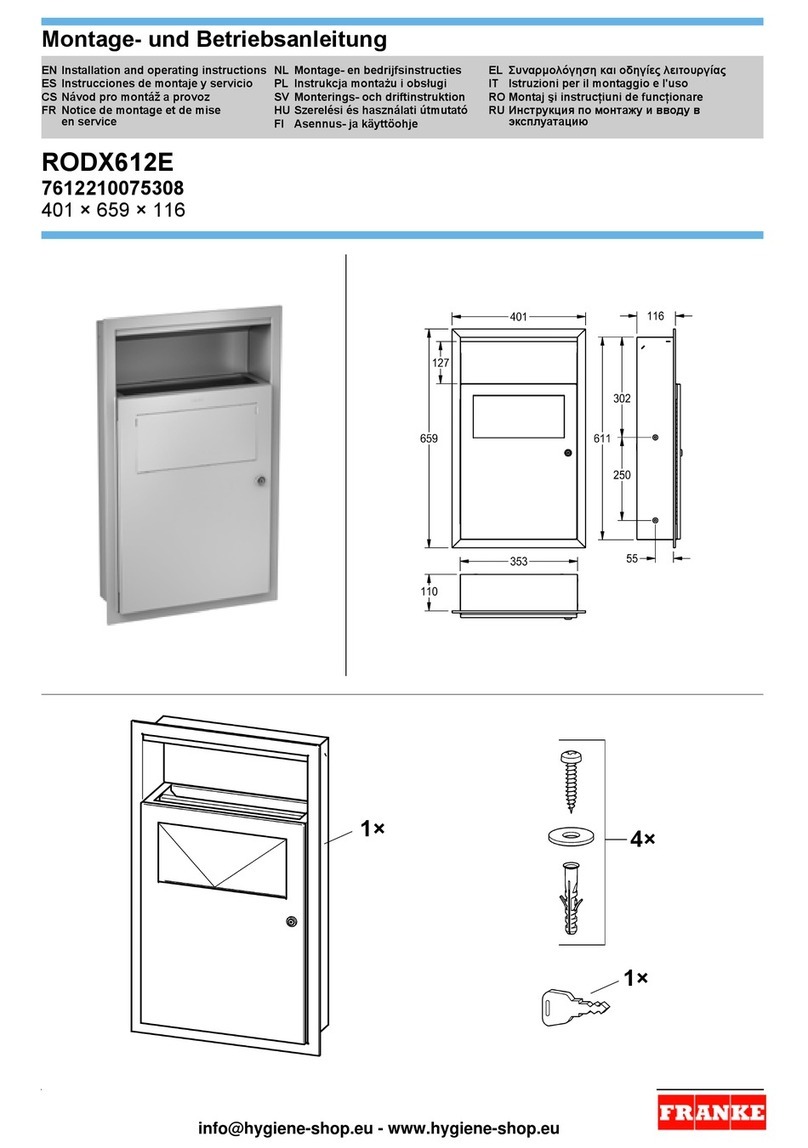

Franke RODX612E User manual

Franke

Franke RODX605E User manual

Franke

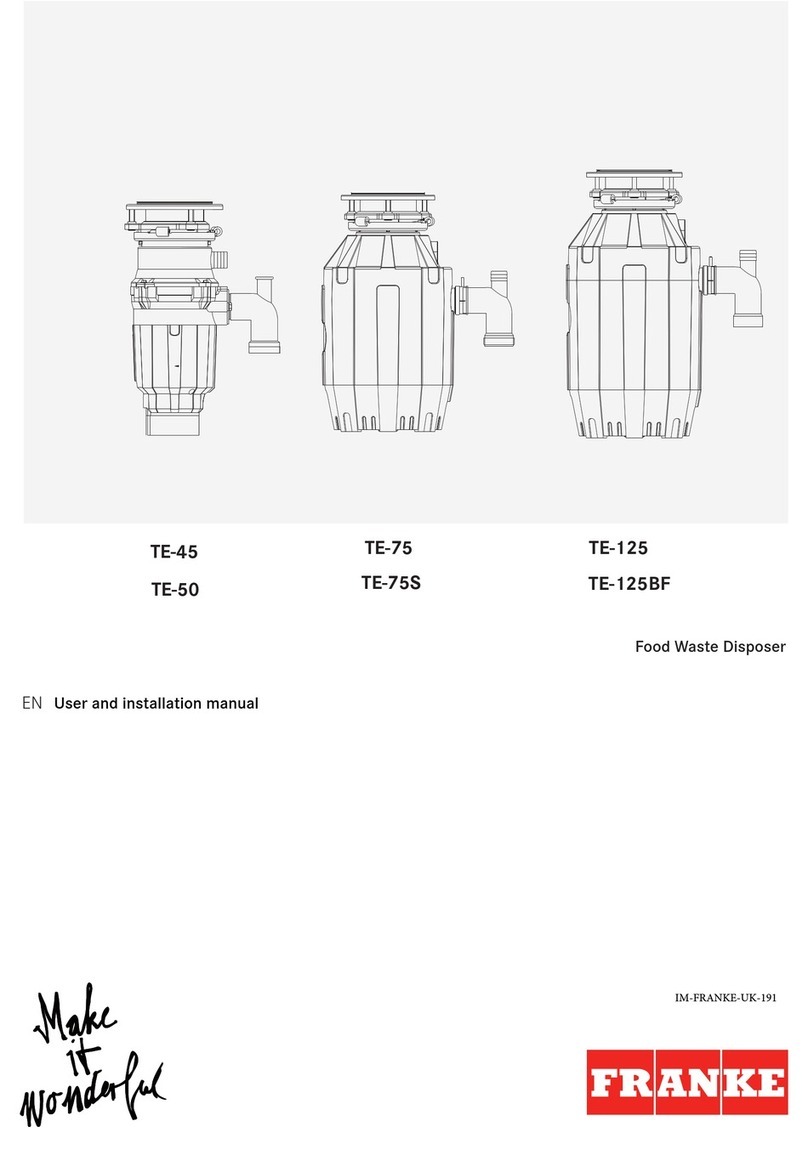

Franke TE-50 Operating manual

Franke

Franke RODX602E User manual

Franke

Franke TE-50 Operating manual

Franke

Franke EXOS611X User manual

Franke

Franke TURBO PLUS User manual

Franke

Franke CE-50 Operating manual

Franke

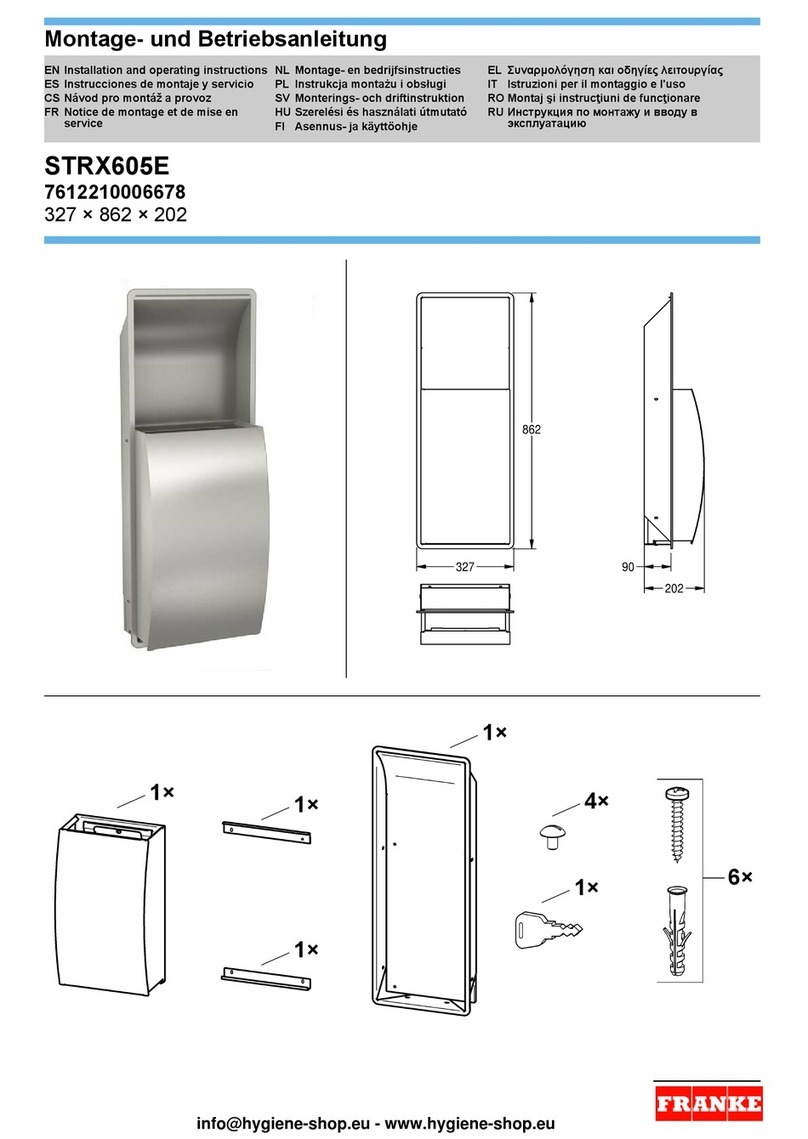

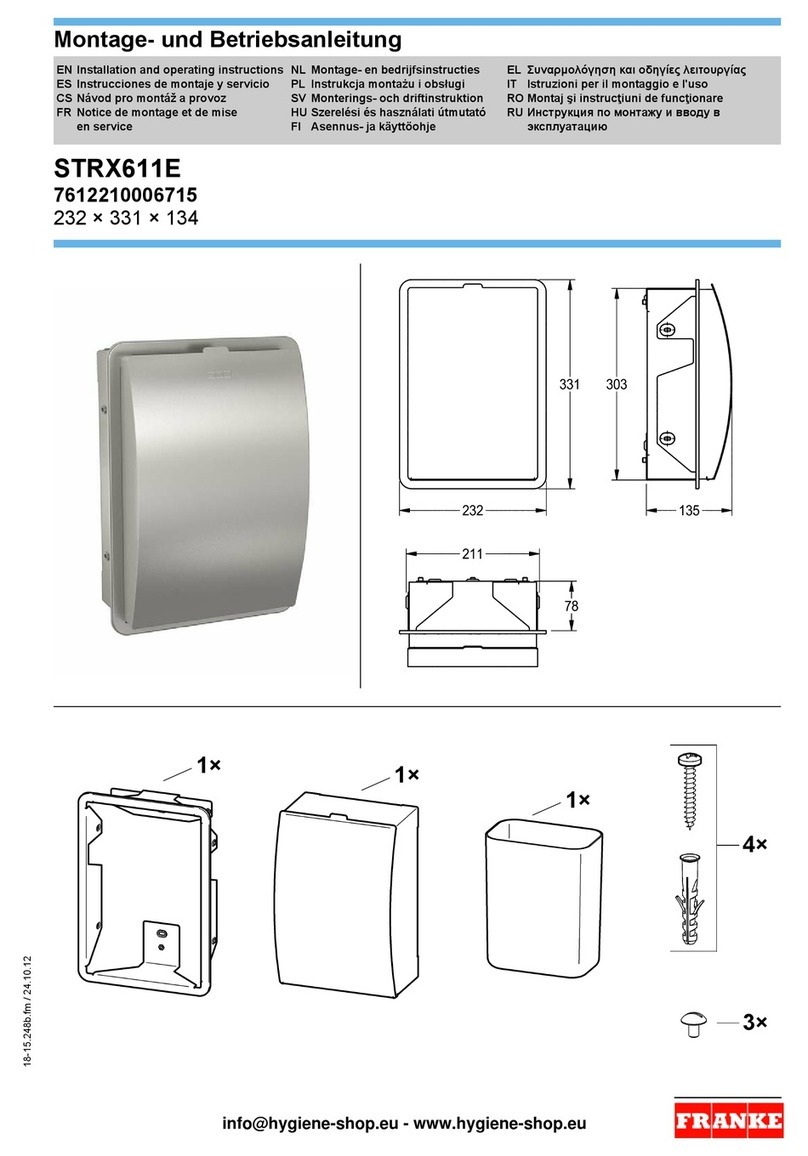

Franke STRX605 User manual

Franke

Franke FOOD WASTE DISPOSER User manual

Popular Garbage Disposal manuals by other brands

Weber mt

Weber mt CR 7 Operating and maintenance manual

THERMEx

THERMEx WASTEMINATOR II instruction manual

Weber mt

Weber mt CR 7-II Hd Operating and maintenance manual

ROBINHOOD

ROBINHOOD SE390 Service manual

Whirlpool

Whirlpool GC2000PE2 parts manual

Scheppach

Scheppach HP3000S Translation from the original instruction manual

Haigh

Haigh Quattro Vanguard Original manual

Maxmatic

Maxmatic 5000 OPERATING AND INSTALLATION Manual

InSinkErator

InSinkErator Model SS-100 Specifications

Toro

Toro FP-2200 Operator's manual

Elephants Foot

Elephants Foot eDiverter Photo step by step instruction booklet

Zanussi

Zanussi DU 4400 Instruction booklet