2

Important Safety Messages

FE Petro equipment is designed to be installed in association with volatile hydrocarbon liquids such as gasoline and

diesel fuel. Installing or working on this equipment means working in an environment in which these highly flammable

liquids may be present. Working in such a hazardous environment presents a risk of severe injury or death if these

instructions and standard industry practices are not followed. Read and follow all instructions thoroughly before

installing or working on this, or any other related equipment.

As you read this guide, please be aware of the following symbols and their meanings:

Follow all applicable codes governing the installation and servicing of this product and the entire

system. Always lock out and tag electrical circuit breakers while installing or servicing this

equipment and related equipment. A potentially lethal electrical shock hazard and the possibility

of an explosion or fire from a spark can result if the electrical circuit breakers are accidentally

turned on during installation or servicing. Do not smoke while working on or near this equipment,

and use only non-sparking tools.

Before entering a containment sump, check for the presence of hydrocarbon vapors. If these

vapors are inhaled they could cause dizziness or unconsciousness, and, if ignited, hydrocarbon

vapors could explode causing serious injury or death. Electronic and electrical petroleum

monitoring equipment is often housed in containment sumps designed to trap hazardous liquid

spills and prevent contamination of the environment, and, as a consequence, containment sumps

can trap dangerous amounts of hydrocarbon vapors. If these vapor levels reach unsafe amounts,

ventilate the sump with fresh air. While working in the sump, periodically check the atmosphere

in the sump, if vapors reach unsafe levels, exit the sump and ventilate it before continuing work.

Always have a second person standing by for assistance when working in, or around, a

containment sump.

Follow all federal, state, and local laws governing the installation of this product and its

associated systems. When no other regulations apply, follow NFPA codes 30, 30A, and 70 from

the National Fire Protection Association. Failure to follow these codes could result in severe

injury, death, serious property damage, and/or environmental contamination.

Always secure the work area from moving vehicles. The equipment in this manual is usually

mounted underground, so reduced visibility puts service personnel working on this equipment in

danger from moving vehicles entering the work area. To help eliminate these unsafe conditions,

secure the area by using a service truck to block access to the work environment, or by using any

other reasonable means available to ensure the safety of service personnel.

FE Petro’s PMAs are designed for use with motor fuels and are UL listed for blend concentrations of:

Standard Models AG (Alcohol/Gasoline) Models

0% - 10% ethanol with gasoline 0% - 85% ethanol with gasoline

20% MTBE with 80% gasoline 20% MTBE with 80% gasoline

20% ETBE with 80% gasoline 20% ETBE with 80% gasoline

17% TAME with 83% gasoline 17% TAME with 83% gasoline

100% Diesel 0-20% Biodiesel Blend or 100% Biodiesel

Other motor fuels that may be used with the PMA are diesel, fuel oil, avgas, jet fuel, or kerosene.

The maximum liquid viscosity for a product is 70 S.S.U. at 60° F.

Using our PMA in liquids other than those mentioned above has not been tested. The reaction of

other liquids with seals and wetted surfaces of the pump is unknown. A hazardous situation may

result from using other liquids with our pump.

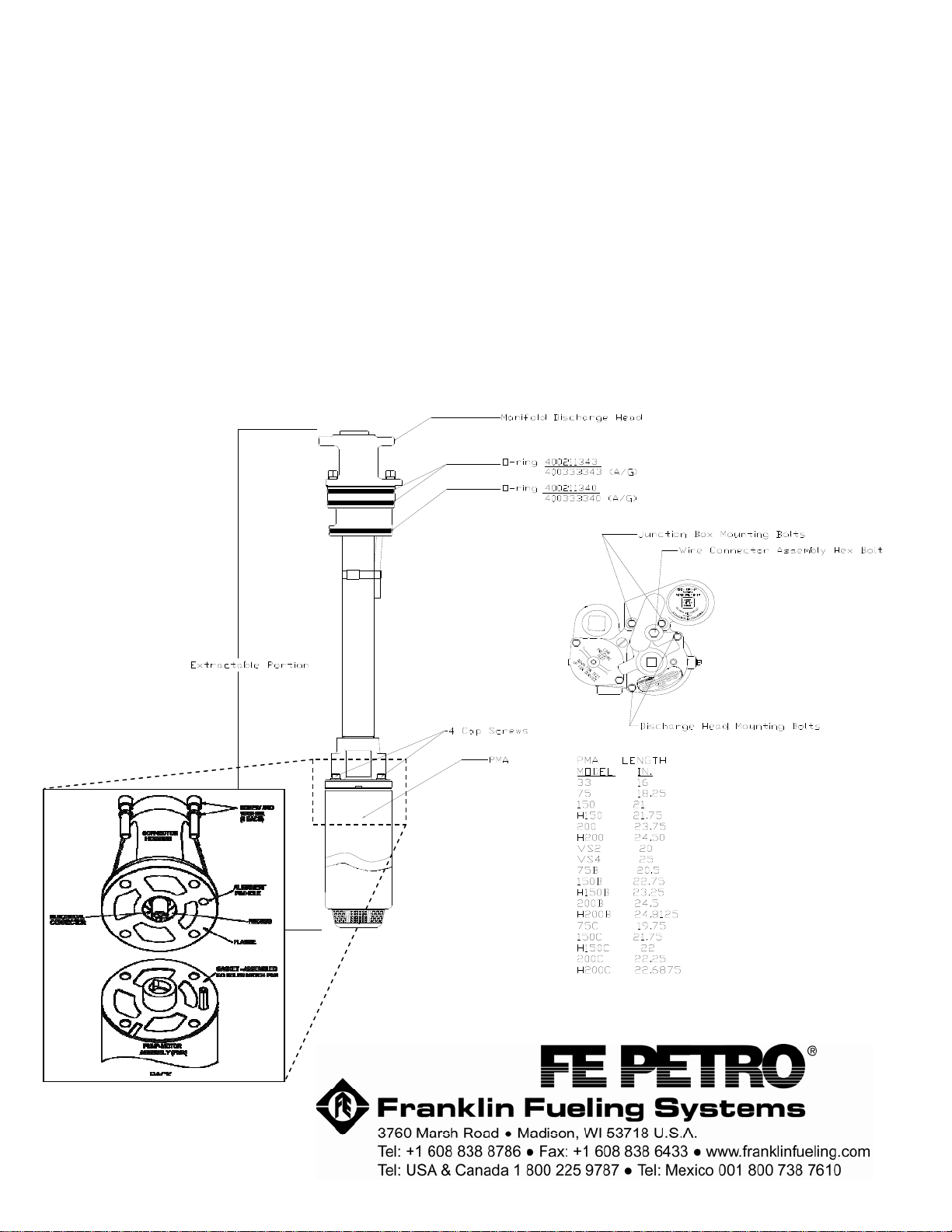

Note: Schedule 40 riser pipe will not work with our MagShell™ PMAs because of an enlarged outside diameter

(4.050"). Our standard shell PMAs have a maximum outside diameter of 4.014" (3.922" for AG models).

This symbol identifies a warning. A warning sign will appear in the text of this document when a

potentially hazardous situation may arise if the instructions that follow are not adhered to closely.

potentially hazardous situation may involve the possibility of severe bodily harm or even death.

This is a caution symbol. A caution sign will appear in the text of this document when a potentially

hazardous environmental situation may arise if the instructions that follow are not adhered to closely.

potentially hazardous environmental situation may involve the leakage of fuel from equipment that

could severel

harm the environment.

Warning

Warning

Warning

Warning

Caution

Warning

Warning