3

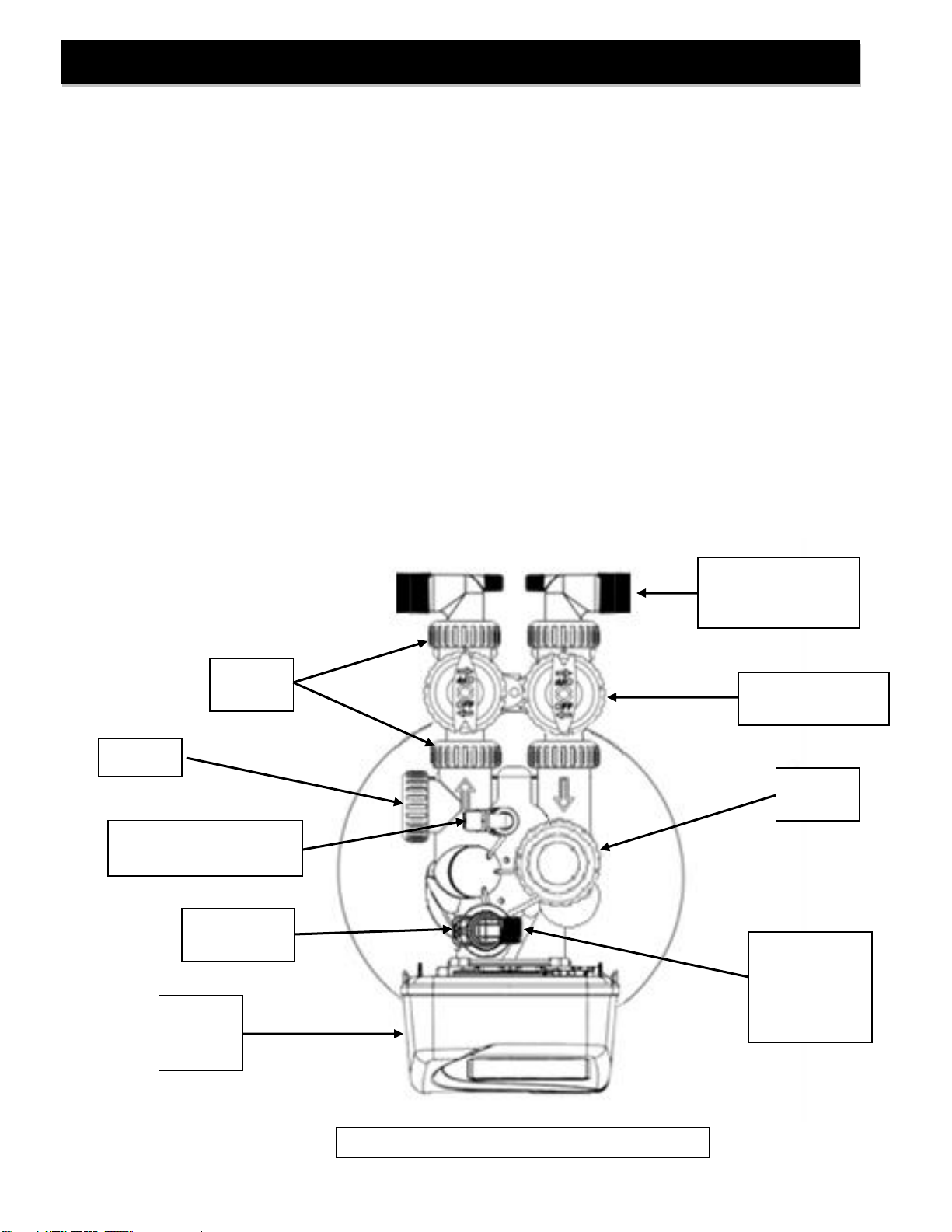

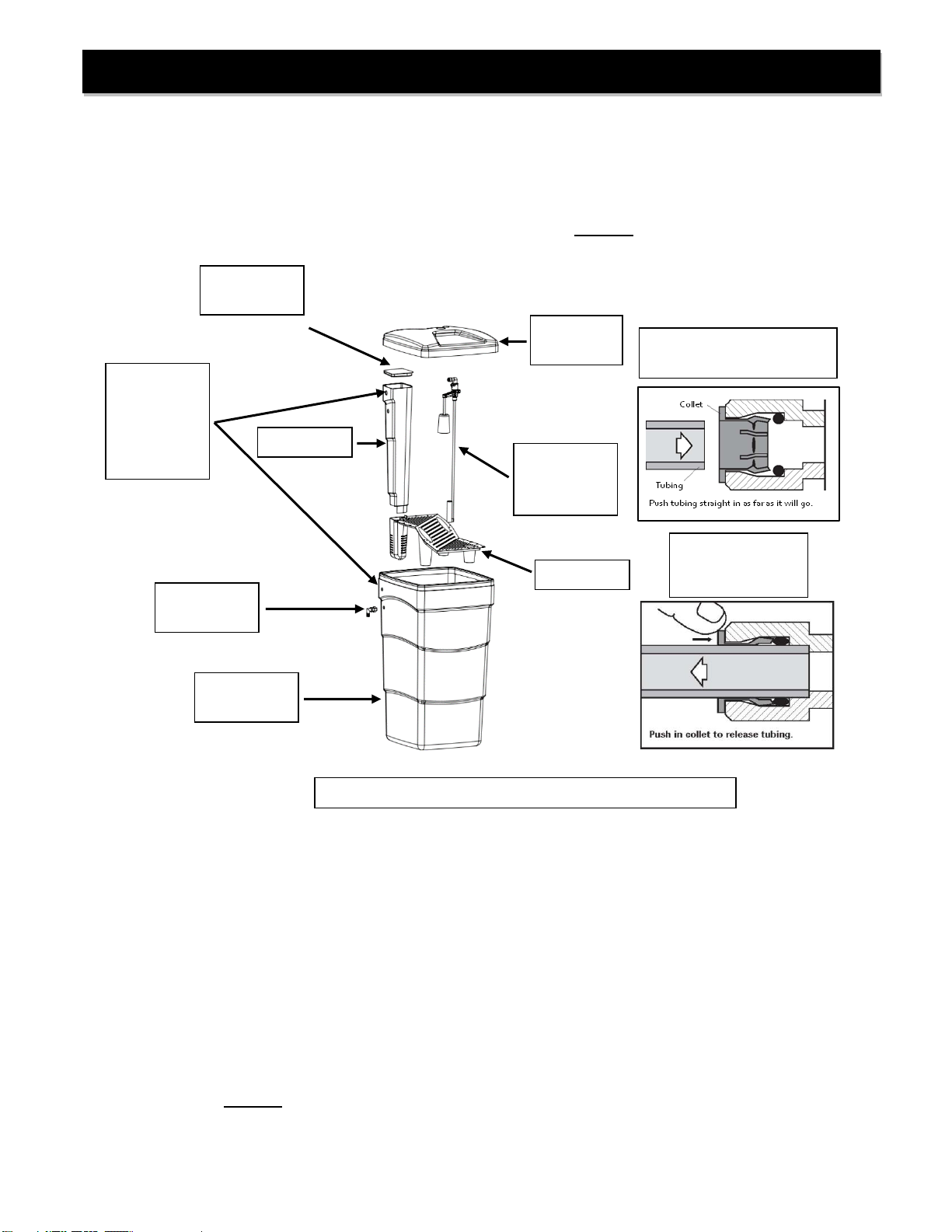

Description of the water softener system

This water softener system includes a brine (salt) tank and a resin (media) tank with a backwashing control

valve. Incoming water flows into the control valve and is directed down through the ion exchange softening

resin. This resin exchanges the hardness ions for softer ions. The softened water then returns to the control

valve where it is directed into the service lines.

Periodically the control valve will go through a regeneration cycle. The frequency of this regeneration process

will depend on the size of water softener, incoming water quality and amount of water used. This cycle is

factory preset to begin at 2:00 A.M. At this time the control valve will backwash, draw the brine solution out of

the salt tank and flush both the accumulated hardness and excess salt to the drain, followed by a rinse. Prior to

the next regeneration cycle the softener will put water back into the brine tank and allow it to dissolve salt for the

regeneration.

Water Quality

The water should be tested to determine the concentration, or levels of the items listed below:

Hardness - Hardness in drinking water is defined as those minerals that dissolve in water having a

positive electrical charge (cat ions). The primary components of hardness are calcium (Ca++) and

magnesium (Mg++) ions. But dissolved iron (Fe++) and manganese (Mn++) also contribute to total

“adjusted” hardness.Hardness produces scale, soap scum and white mineral deposits which shorten

the life of water using appliances, plumbing and fixtures. Water that has less than 1 grain of hardness is

considered “soft” water.

pH - A measurement of the acidity of the water. pH is reported on a scale from 0 to 14. Neutral water has a pH

of 7.0, lower values indicate acidic water. If your pH is below 6.8 you may consider installing an acid neutralizer

before the water softener to elevate the pH.

Iron - A naturally occurring metallic element. Iron levels in excess of 0.3 milligrams/liter (mg/l) combine with

oxygen causing orange or red (rust) stains on plumbing fixtures. Iron exists in some water sources in clear

water (ferrous) state, red water (ferric) state or bacterial form. Iron levels that exceed 2.0 mg/l require special

ion exchange resin for reduction, or if bacterial or ferric (red water) iron is present or iron level exceeds 3.0 mg/l,

an iron filter should be installed ahead of this water softener.

Manganese - A naturally occurring metallic element. Manganese levels as low as 0.05 milligrams/liter (mg/l)

can combine with oxygen to cause dark brown or black staining on fixtures. Additionally, manganese can cause

an odor in the water similar to a “rotten egg” smell. This water softener may reduce manganese as well as iron;

however, an iron filter may be required in some cases.

Tannin - A naturally occurring humic acid. Tannin is caused by water passing through decaying vegetation.

Coffee and Tea are prime examples of tannin in water. Tannin levels as low as 0.5 milligrams per liter can

cause a yellow discoloration in water. Consult your dealer for a system designed to remove both tannin and

hardness.

Hydrogen Sulfide - A naturally occurring gas. Hydrogen sulfide, more commonly referred to as sulfur gas,

causes a distinct odor similar to “rotten eggs.” Due to its gaseous nature, hydrogen sulfide must be tested at the

well site within 1 minute of drawing the sample. If sulfur is present additional equipment will be required. Air

injection iron filters can typically treat up to 2 ppm of sulfur gas if regenerated daily. Specialized filter media may

reduce sulfur up to 6 ppm. Beyond 6 ppm and up to 10 ppm require chemical injection. Beyond 10 ppm may

be impractical to treat.