SpectraPure

®

SpectraPure

®

Inc.

480.894.5437 Call us toll-free 1.800.685.2783

2167 East Fifth St, Tempe, Arizona 85281 3

PREINSTALLATION CHECK LIST FOR CARBON OR WATER SOFTENER:

1.

WATER PRESSURE:

A minimum of 25 lbs of water pressure is required for regeneration valve to operate effectively

.

2.

ELECTRICAL:

An uninterrupted alternating current (A/C) supply is required. Please make sure voltage

supply is compatible with unit before installation. Make certain the electrical outlet is grounded

by having it checked by an electrician or by using a UL Listed Circuit analyzer. Units are

furnished with 3-prong grounded plugs to protect you against the possibility of electrical shock.

The outlet must be within reach of the power cord. Do not use an extension cord. Extension cords that are too

long or too light do not deliver sufficient voltage to the unit and could present a safety hazard if the insulation were

to become damaged. The receptacle should be located four (4) feet above the basement floor to guard against the

possibility of immersion.

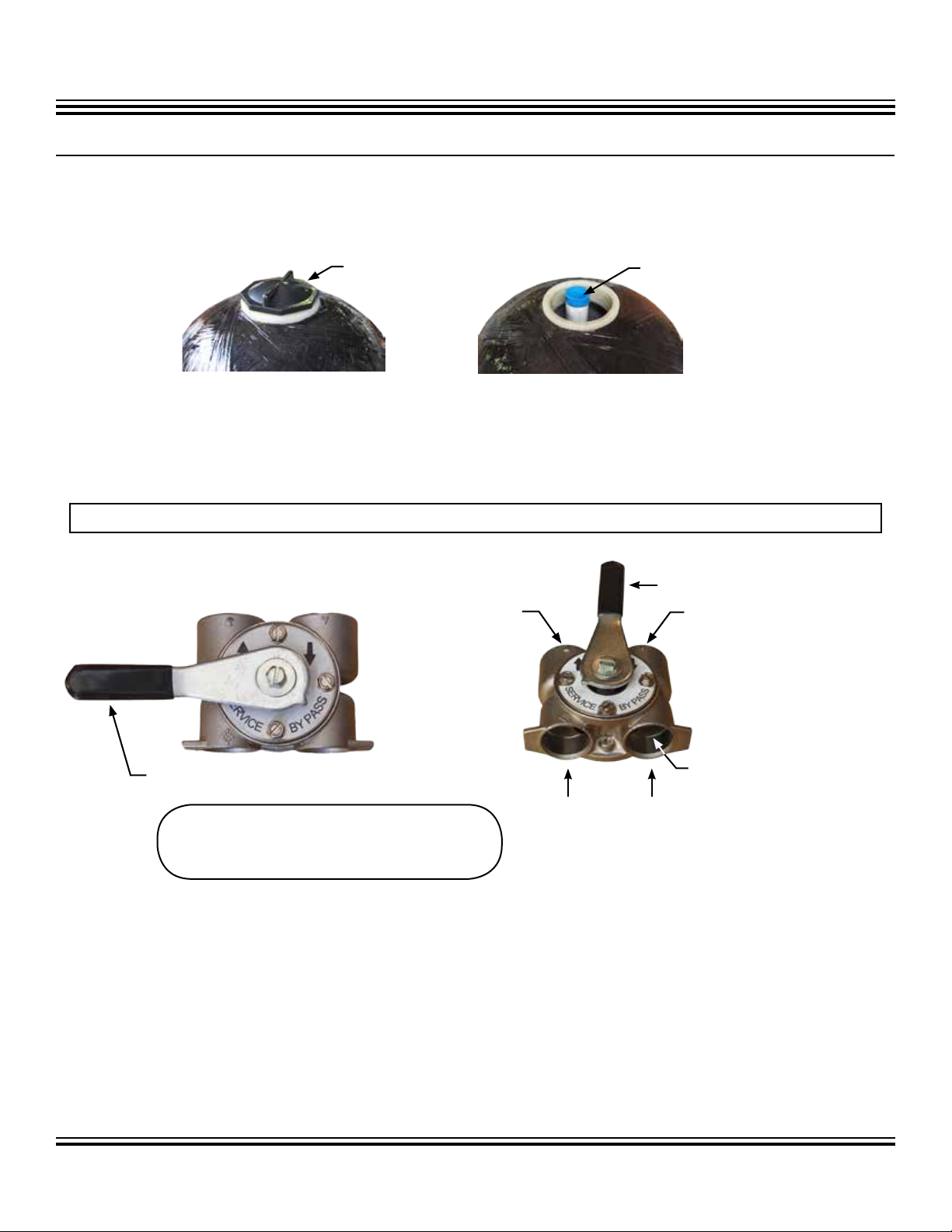

3. PLUMBING: Condition of existing plumbing should be free from lime and iron buildup. Replace piping that has

heavy lime and/or iron build-up. If piping is clogged with iron, install a separate iron filter unit ahead of the water

softener.

4. LOCATION OF SOFTENER AND DRAIN: Locate the softener close to a clean working drain and connect

according to local plumbing codes.

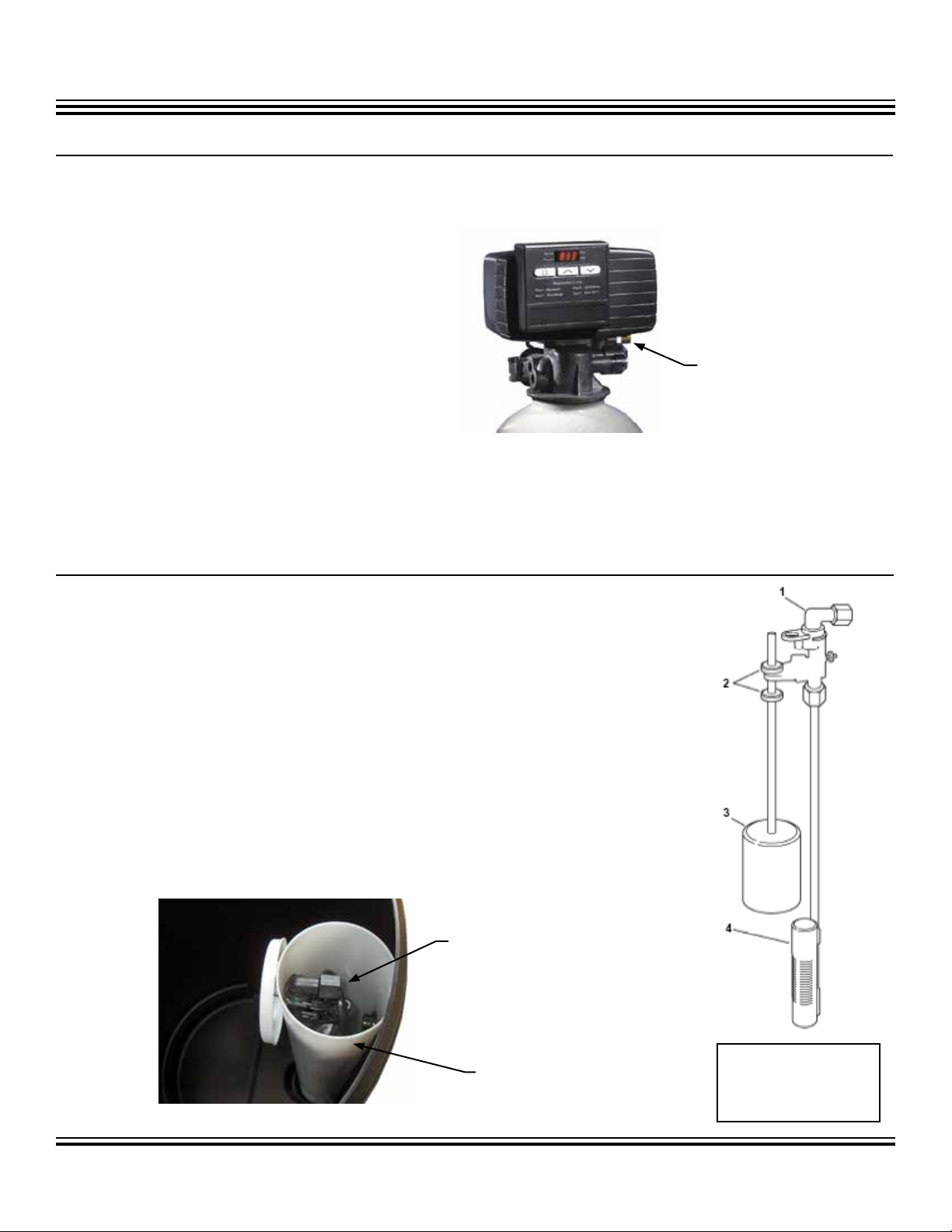

Place the softener tank where you want to install the unit. If you have a carbon tank, you will install it in front of

the water softener. Both the water softener and carbon tank will need a drain line.

NOTE: Be sure the tank(s) are level and on a firm base.

CAUTION: DO NOT exceed 120 psi water pressure. DO NOT exceed 110° F water temperature. (Keep system

away from extreme hot and cold temperatures.) DO NOT subject unit to freezing conditions.

SAFETY INFORMATION

1. Read instructions carefully and learn the specific detail regarding installation and use. Failure to do so

could cause serious bodily injury and/or property damage.

2. Check to be sure your power source is capable of handling the voltage requirements of the unit. Plug

into a dedicated grounded receptacle which contains a fuse or circuit breaker of 20 amps or less.

3. INSTALL WATER CONDITIONER IN AN AREA PROTECTED FROM FLOODING, RAIN, DIRECT SUNLIGHT,

DUST, SNOW AND FREEZING. THE WARRANTY DOES NOT COVER DAMAGE INCURRED AS A RESULT

OF EXPOSURE TO WEATHER.

* All water treatment installations must conform to local plumbing, electrical and sanitation codes. These

codes are established for your protection.

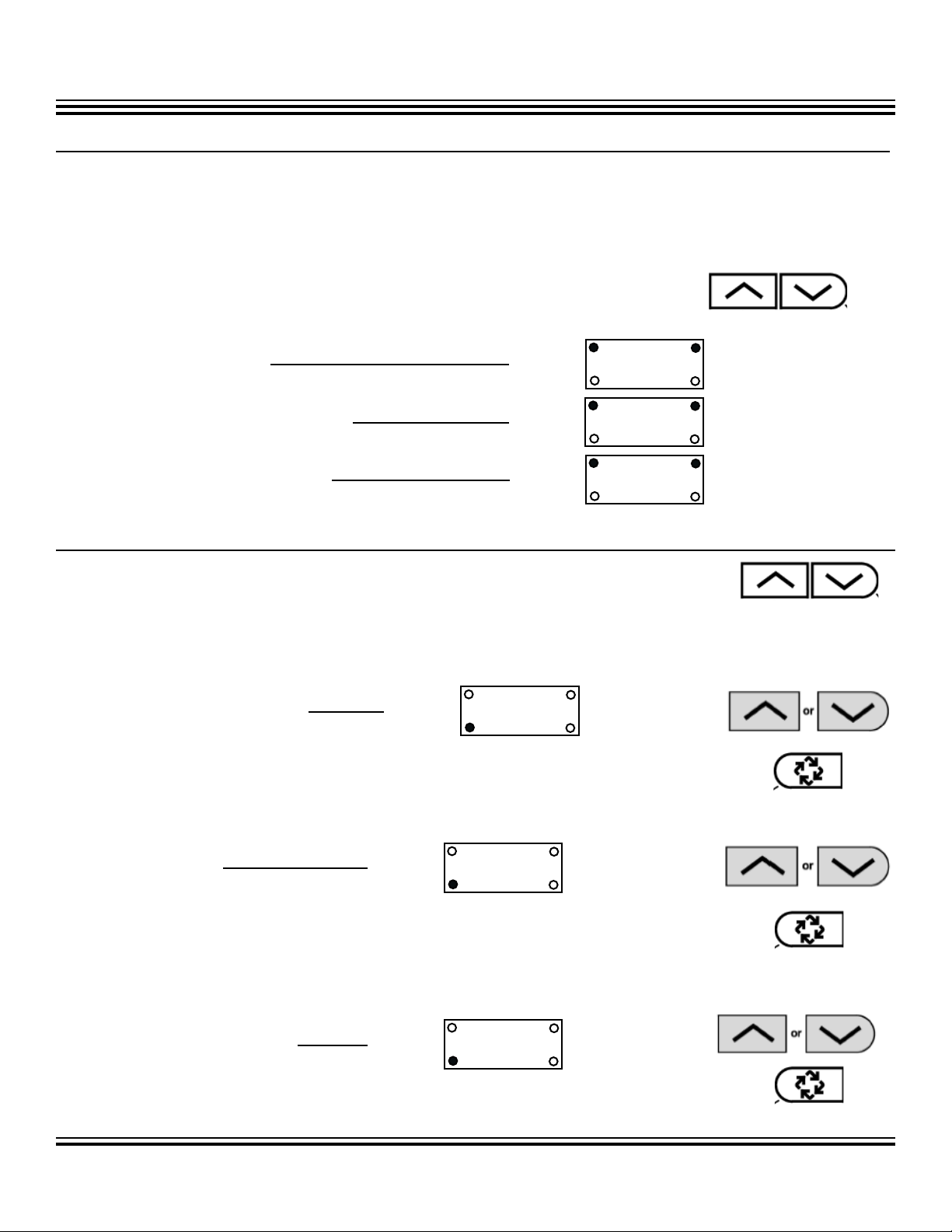

When scale buildup is this bad,

you must replace piping before

installation of a water softener

to prevent pipes from corrosion

and possible leakage.

Perform all plumbing according to local plumbing codes.

— Use a 1/2" minimum pipe size for the drain.

— Use a 3/4" drain line for backwash flow rates that

exceed 7 gpm or length that exceeds 20’ (6 m).

WARNING:

Do not under any circumstances remove ground prong and never splice or cut the electrical

cord.