2

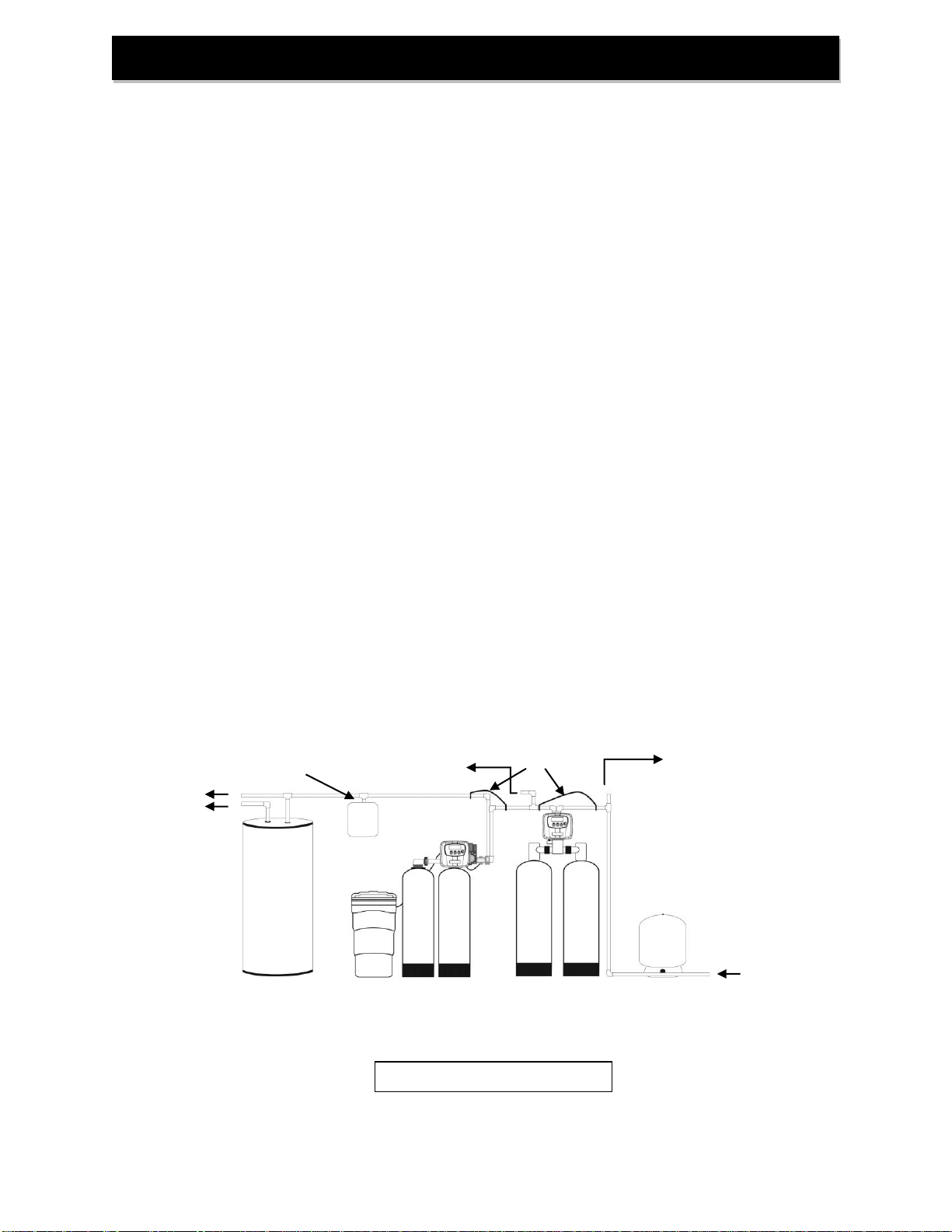

Description of the softener

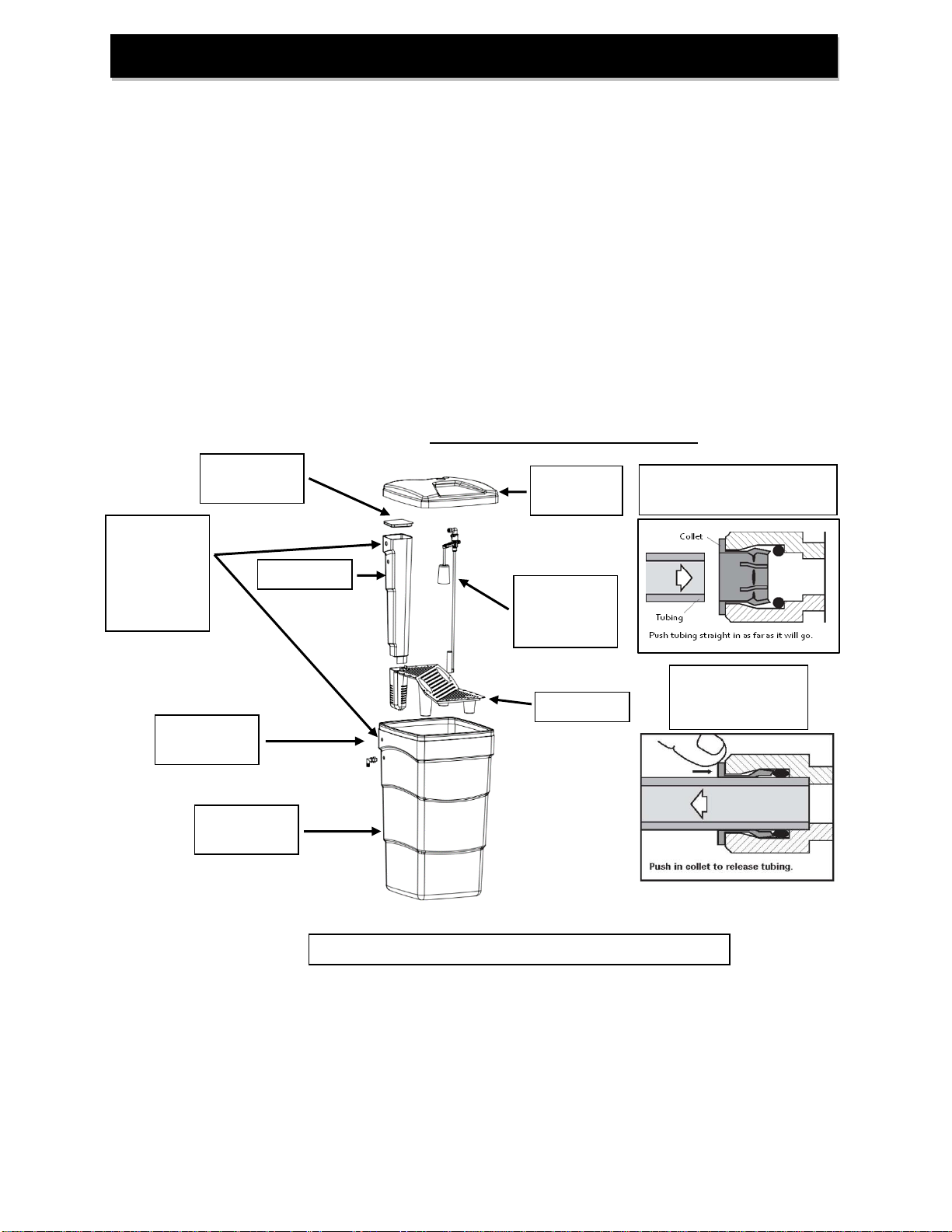

The softener system includes two mineral tanks (with gravel, distributor and softener resin), one brine tank (with

salt shelf {some models}, brine well, brine tank lid and safety brine valve), and a twin alternating, meter initiated,

digital, backwashing control valve with bypass and brine line.

Successful Application

Softeners are designed to remove hardness minerals (calcium and magnesium) from water by the process of

ion exchange. They may also remove small amounts of “clear water” iron (2 ppm or less). Softeners are not

designed to remove “red water” iron or bacterial iron. If greater levels of iron, “red water” or iron bacteria are

present, an iron filter must precede the softener. Softeners are not designed to remove particulates. If there is

any sediment or turbidity present in the water, a backwashing filter with appropriate media must precede the

softener. Only specialty tannin softeners are designed to remove tannins and the yellow to tea color from water.

Softeners will not reduce hydrogen sulfide (“rotten egg” odor).

Time of Regeneration

Periodically the control valve will go through regeneration. Regeneration is factory preset to 2:00 A.M. The time

of regeneration may be changed if needed (see programming procedures on page 7).

Location Considerations

The proper location to install the softener will ensure optimum performance and satisfactory water quality. The

following factors should be considered in selecting the location of this system.

1. The softener must be installed after the pressure tank (private well system only). Operating

pressure of the softener must be limited to within 25 –100 psi range.

2. The softener should be installed after any iron filter and/or other backwashing filter.

3. If chlorine is present in the supply water a whole house carbon filter (CS-1 or other backwashing

carbon filters or DF non-backwashing carbon filters.) should be installed before the softener.

4. The system must not be subject to freezing temperatures

5. Ensure that any in-line filter installed prior to the softener does not restrict the flow or pressure

required to backwash the softener.

6. The system should be installed as close as possible (preferably within 15’) to an adequate floor or

laundry drain capable of handling the backwash cycle volume and flow rate (refer to unit

specifications on pages 15-16). An air gap should be provided between the drain line and

plumbing drain.

7. All water conditioning equipment should be installed at least 10’ prior to the water heater. Water

temperatures exceeding 100°F can damage the internal components of the control valve and

mineral tank. An expansion tank may need to be installed in the line to the water heater to allow for

thermal expansion and comply with local plumbing codes.

8. Appliances requiring extended periods of continuous or high flow water use (i.e., geothermal heat

pumps, swimming pools, lawn irrigation, outside hose bibs, etc.) should bypass all water

conditioning equipment unless the equipment has been specifically designed for that purpose.