5

4. The assembly

Preparation

First put all the parts on your workbench and check them for completeness. If

anything is missing, please contact us.

We suggest to group the parts along the building blocks (wing/fuselage/rudder

& elevator)

Wings

The 5 main wing parts are CNC milled and we

therefore recommend to give them a light

sanding with a 240 grit sandpaper. The

dihedral at the joints is already set and mustn't

be altered.

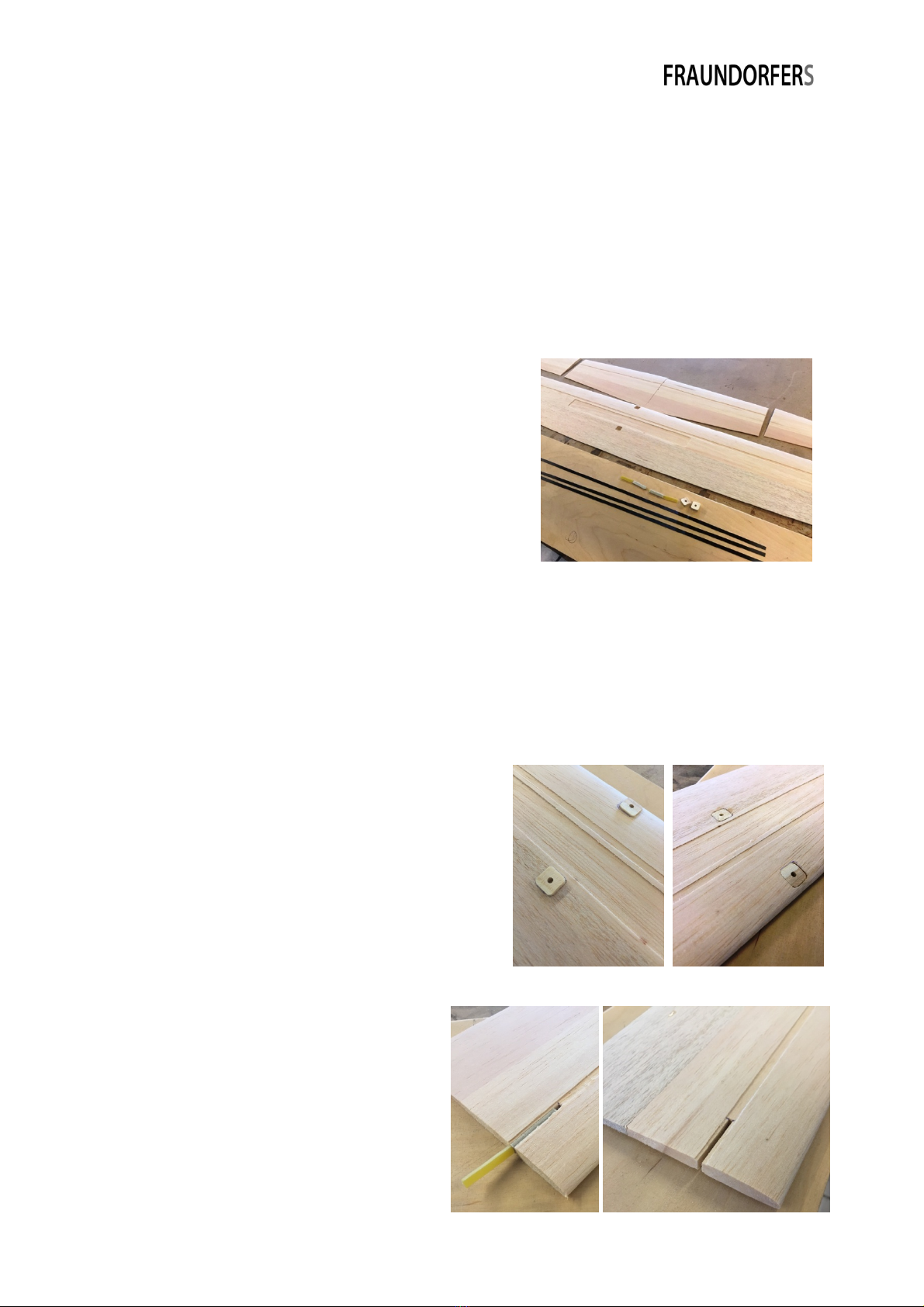

First cut the 3 carbon strips (5.8 x 0.6) to the correct length (2 for the main

wing panel and 2 for each inner tip). The strips must fit exactly into slots of the

3 wing panels and should not overlap them!

Now completely open up the milled openings in the main wing panel for the

screw connection inlets, which is best done with a sharp carpet knife. Sand one

side of the prepared carbon strips (120 grit sandpaper ).

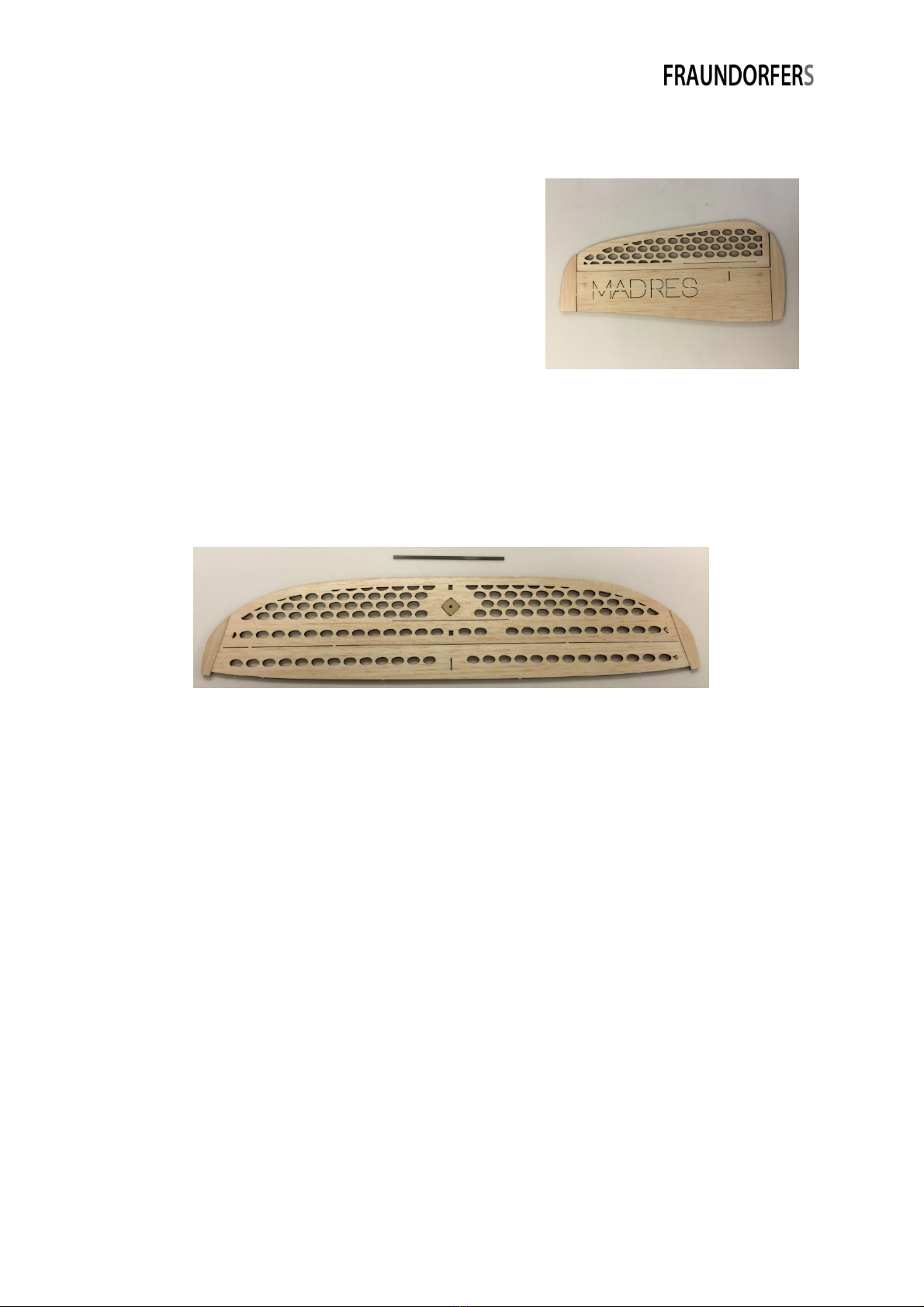

Try to fit the 2 plywood wing-inlets into the

milled recesses in the main wing panel. If

they don't fit in easily sand the edges until

you get a perfect fit. Now glue them into

the recesses with the glue of your choice

(epoxy/wood glue). It's important that the

glued in inlets flush with the wing surface!

Put the joiners (2 mm glass fiber)

into the joiner bags (they will be

later on glued into the wing panels

between the wing reinforcement

carbon strips) and cut out a recess in

the center of the milled channel of

the main wing panel (joiner bag) and

the tip (only for the joiner!). Make