FSA100 Rev1206

2

CONTENTS Table of Contents

CONTENTS ............................................................................................................... 2

INTRODUCTION...................................................................................................... 3

Overview ................................................................................................................ 3

Features.................................................................................................................. 4

Specifications......................................................................................................... 4

GENERAL DESCRIPTION....................................................................................... 6

Components .......................................................................................................... 6

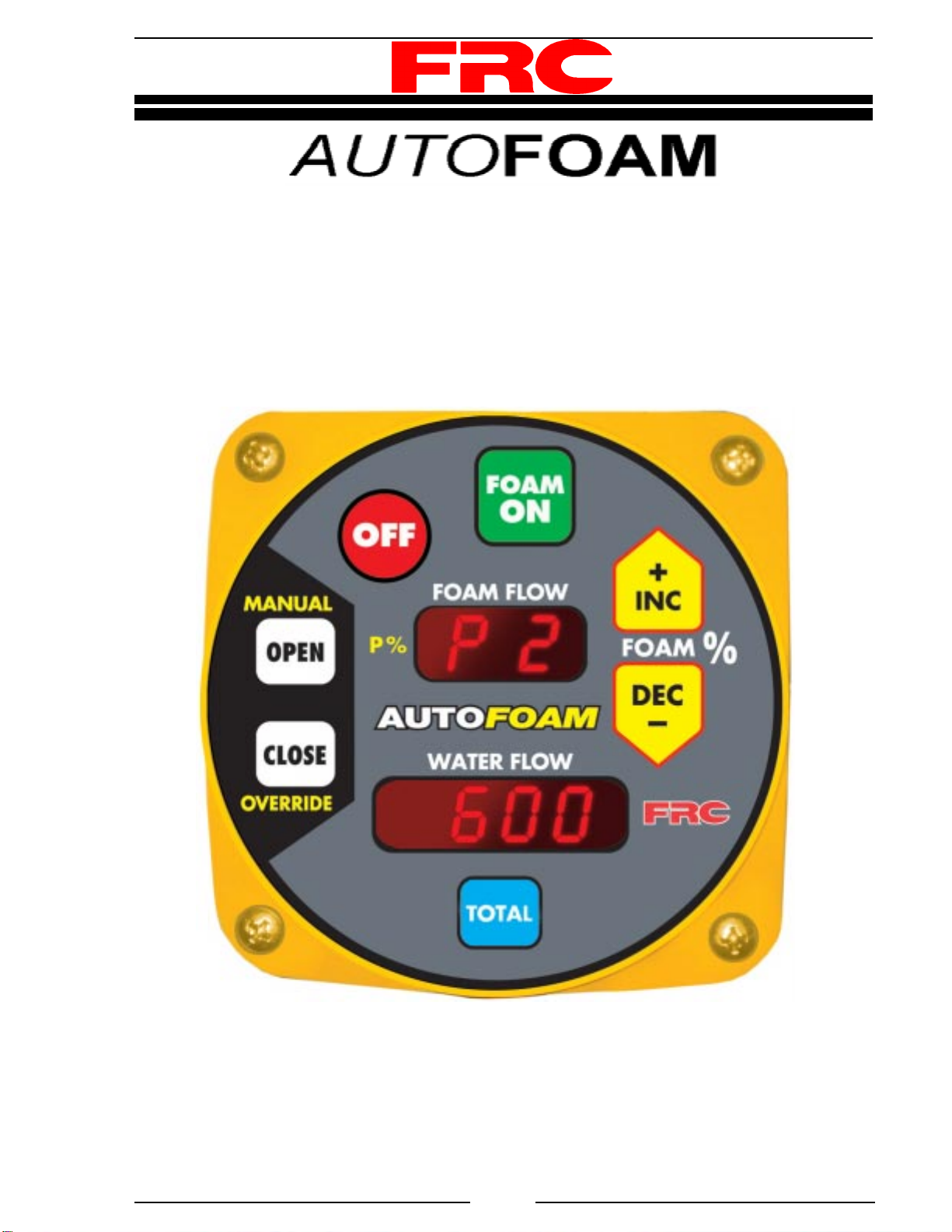

Controls and Indicators ......................................................................................... 8

INSTALLATION ...................................................................................................... 10

Install Control Module ......................................................................................... 10

Install Metering ValveAssembly and Eductor ..................................................... 10

Install Flow Sensor(s).......................................................................................... 12

InstallSummingDevice........................................................................................ 18

Install Cables........................................................................................................ 18

Figure 8. Cables ....................................................................................................... 19

THEORY OF OPERATION .................................................................................... 20

OPERATION............................................................................................................ 22

Static Operational Check ..................................................................................... 22

Pump Intake and Discharge Pressure Requirements ........................................... 23

Operational Check ............................................................................................... 24

CALIBRATION........................................................................................................ 28

TROUBLESHOOTING TIPS ................................................................................. 30

MAINTENANCE ..................................................................................................... 31

Flushing the System ............................................................................................. 31

Cleaning the Paddlewheel Sensors....................................................................... 31

DRAWINGS ............................................................................................................. 32

List of Figures/Tables

Figure 1. Plumbing Schematic ................................................................................... 7

Figure 2. Controls and Indicators .............................................................................. 9

Figure 3. Control Module Dimensions..................................................................... 11

Figure 4. Metering ValveAssembly and Eductor Installation................................... 11

Figure 5. Flow Sensor Location Guidelines............................................................. 13

Figure 6. Saddle Clamp Installation ......................................................................... 15

Figure 7. Weldment Installation................................................................................ 17

Figure 8. Cables ....................................................................................................... 19

Table 1. Pump Pressure Requirements.................................................................. 23

Figure 9. Sample Displays ....................................................................................... 25

Figure 10. Summing Device ...................................................................................... 29

Figure 11. Eductor Drawing ...................................................................................... 32