FPQ41 Superminor Issue 1 3

Contents

1Introduction.................................................................................................................. 4

1.1 About this manual......................................................................................................... 4

1.2 EC Declaration of Conformity........................................................................................ 5

2Safety............................................................................................................................ 6

2.1 Warnings ....................................................................................................................... 6

2.2 Residual risks................................................................................................................. 7

3Description ................................................................................................................... 8

3.1 Operational overview.................................................................................................... 8

4Operation ..................................................................................................................... 9

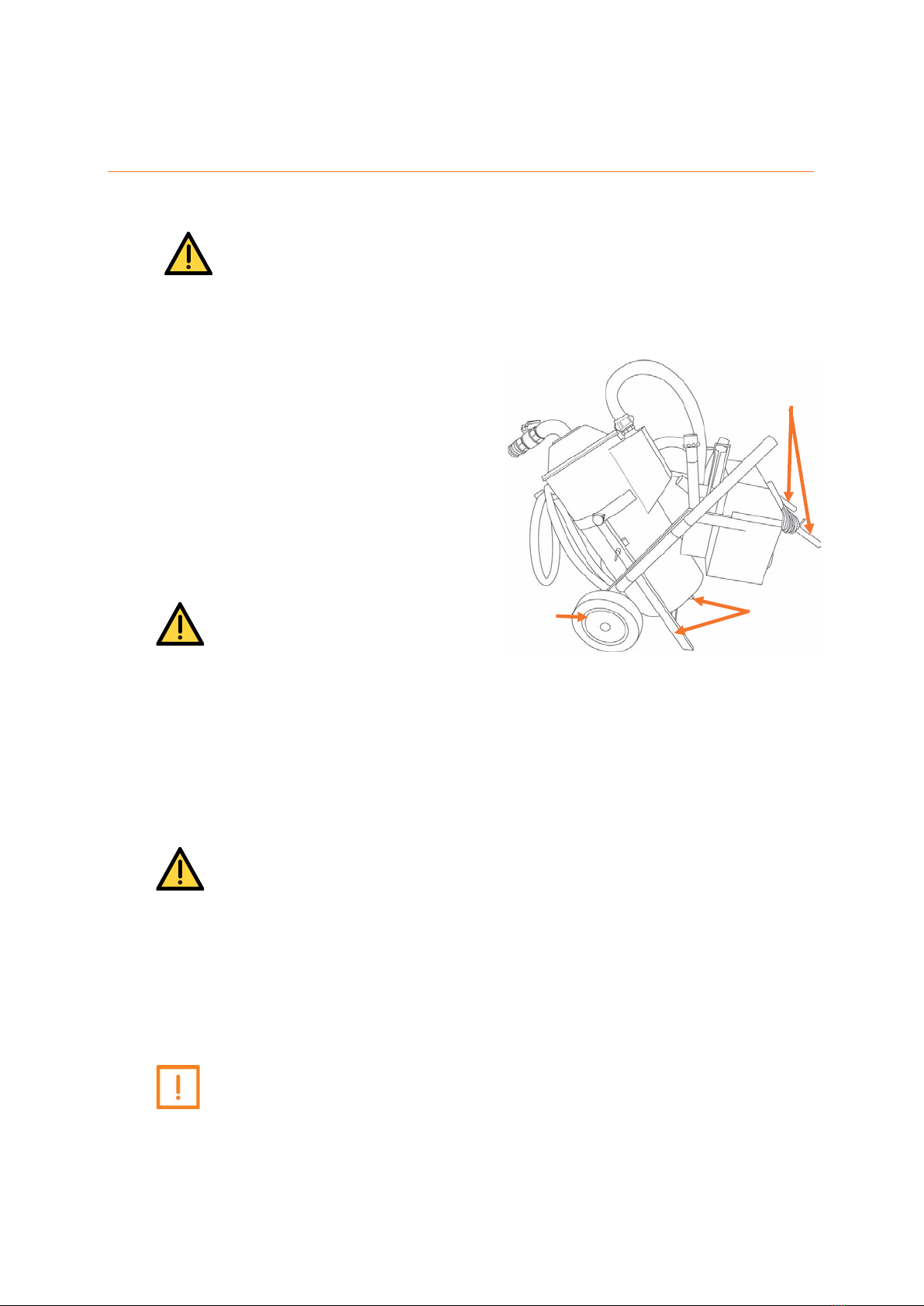

4.1 Moving the Superminor ................................................................................................ 9

4.2 Changing the filter......................................................................................................... 9

4.3 Fit the suction hose ..................................................................................................... 12

4.4 Fit the tools ................................................................................................................. 13

4.5 Switching on and off.................................................................................................... 15

4.6 Selecting suction or discharge..................................................................................... 16

4.7 Tank operations .......................................................................................................... 17

4.8 Vacuum ....................................................................................................................... 18

4.9 Discharge..................................................................................................................... 20

4.10 Changing the tank ....................................................................................................... 23

4.11 Storage ........................................................................................................................ 24

5Technical specification .................................................................................................25

5.1 Superminor +............................................................................................................... 25

5.2 Superminor + compact................................................................................................ 26

5.3 Operating conditions................................................................................................... 27

5.4 Storage conditions ...................................................................................................... 27

6Cleaning and maintenance ...........................................................................................28

6.1 Regular checks............................................................................................................. 28

6.2 Cleaning....................................................................................................................... 29

7Troubleshooting...........................................................................................................31

8Spares list ....................................................................................................................33

9Circuit diagrams ...........................................................................................................34

10 Warranty .....................................................................................................................37

11 End of life.....................................................................................................................37

12 Index............................................................................................................................38