CROMAR

Page 53

5.5.3 Filter Blocked Alarm

(Not applicable to Media Free System)

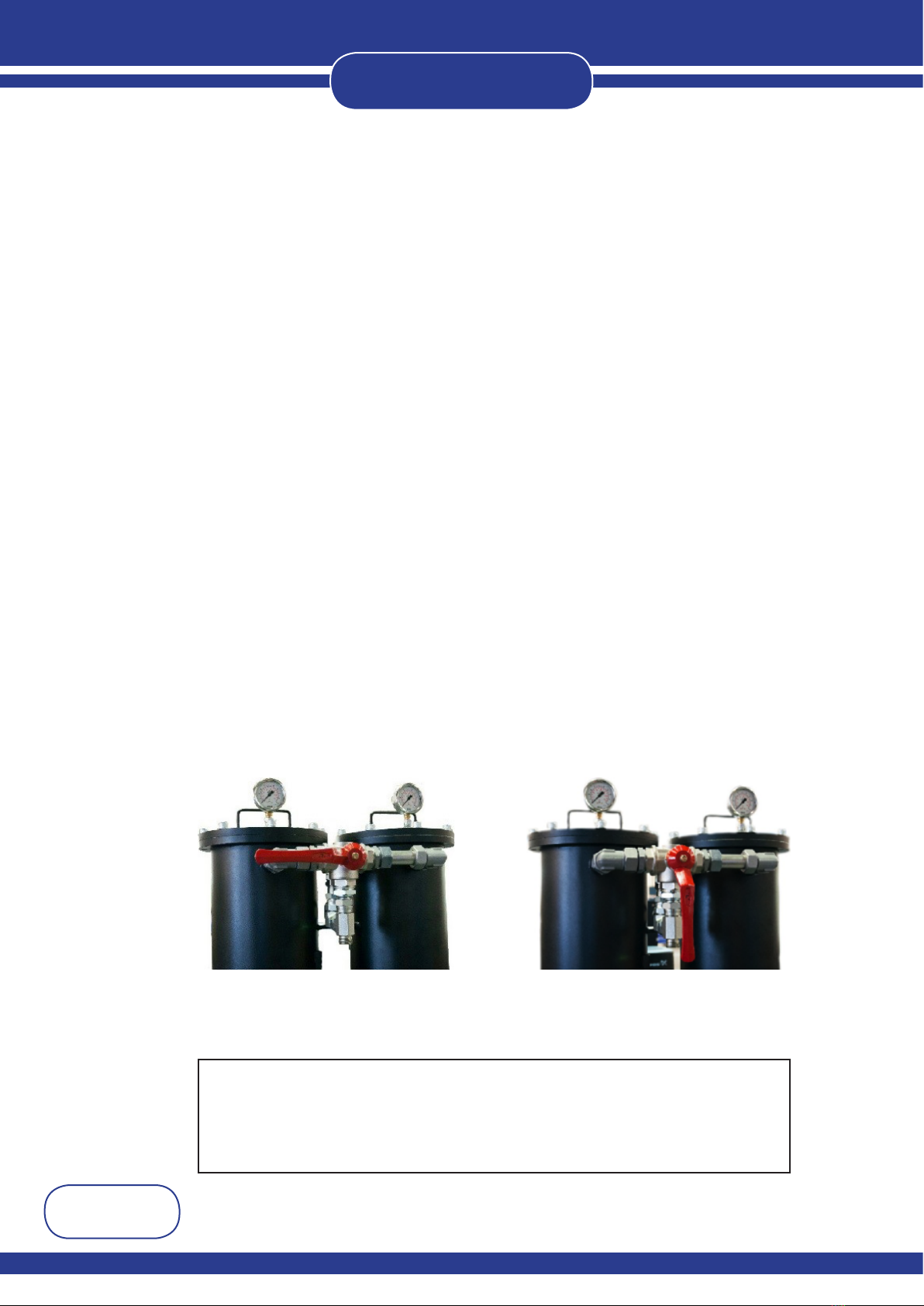

A pressure switch monitors the ow of coolant entering the HP tank through the lter

unit and has been preset to activate when the back pressure rises to a certain setting.

If the switch activates then the lter blocked alarm will appear on the screen and a

signal will be sent to the machine controller as a ’Pressure alarm’.

The panel beacon will also ash.

Please be aware that the reason may be a blocked lter or may be due to lack of

coolant in the main machine tank which would also result in a low ow of coolant

passing through the lter.

This condition should be investigated and the appropriate action taken.

Refer to the enclosed procedure for switching over the lter and for changing the lter bag.

5.5.4 Pressure Switch Error Alarm

(Not applicable to Media Free System)

If the pressure switch shows a coolant pressure when the transfer pump is not running

then the pressure switch error alarm will appear on the screen.

The panel beacon will also ash.

This indicates there is a fault with the ow switch which should be investigated and

may require replacement of the switch unit.

5.5.5 Alarm Reset Procedure

The four alarms already mentioned are of the latched on type.

If any alarm is activated, the alarm message and the signal back to the machine

controller will remain on, even if the condition clears itself.

To clear an alarm from the system, rst ensure the cause of the alarm has been

rectied, then follow the instruction from the main screen -

Press ‘Menu Page’

Press ‘Alarm Page’ - to show the active alarm which will be ashing red

Press ‘Ack’ - the alarm will turn to green (unless the condition still exists)

Press ‘Exit’ - to return to the Menu Page

Press ‘System Reset’ - to return the system back to normal operation

Press ‘Exit’ - to return to the title screen

Any alarms still active will remain even after pressing the reset.

5.5.6 Coolant System Alarm

If the thermal protection breaker on the 24V DC supply for the high pressure coolant

unit trips out, an alarm signal will be issued to the machine controller using the

‘Coolant system Alarm’.

The condition should then be investigated and rectied.