3, Hagavish st. Israel 58817 Tel: 972 3 5595252, Fax: 972 3 5594529com.mrclab@mrc

Section 1

INTRODUCTION

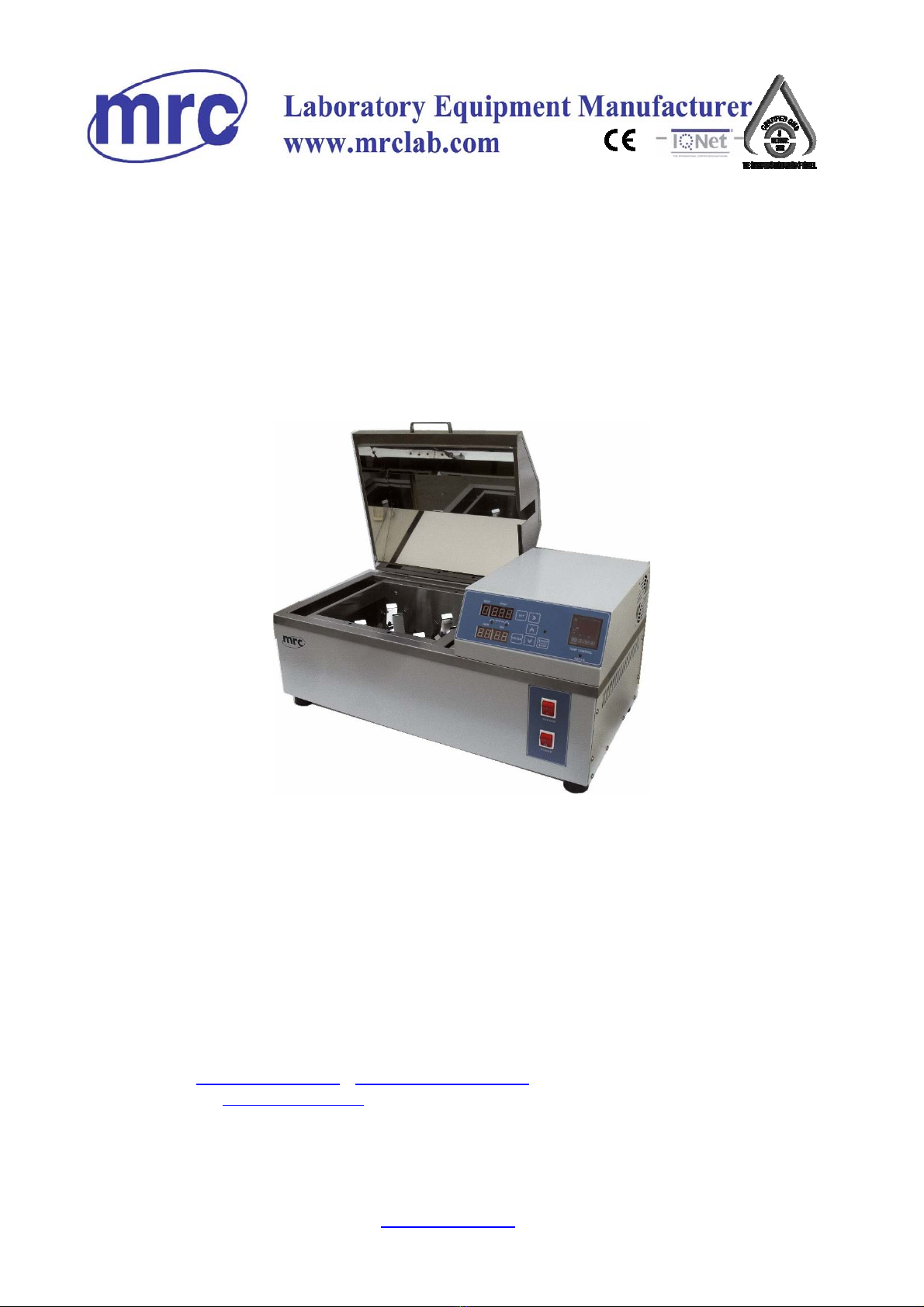

Thank you for choosing a water bath shaker. This unit is not intended for use

at hazardous or household locations. Before you use the unit, read this entire

manual carefully to understand how to install, operate, and maintain the unit in

a safe manner. Your satisfaction with the unit will be maximized as you read

about its safety and operational features.

Keep this manual on-hand so it can be used by all operators of the unit. Be

sure all operators of the unit are given appropriate training before you put the

unit in service.

Note: Use the unit only in the way described in this manual. Failure to follow

the guidelines and instructions in this manual may be dangerous and illegal.

General Safety Considerations

Your water bath shaker and its recommended accessories have been

designed and tested to meet strict safety requirements.

For continued safe operation of your water bath shaker, always follow basic

safety precautions including:

Read this entire manual before using the water bath.

Be sure you follow any city, county, or other ordinances in your area

regarding the use of this unit.

Use only approved accessories. Do not modify system components.

Any alterations or modifications to your water bath may be dangerous

and will void your warranty.

Always plug the unit’s power cord into a grounded electrical outlet that

conforms to national and local electrical codes. If the unit is not

grounded, parts such as knobs and controls may conduct electricity

and cause serious injury.

Do not connect the unit to a power source of any other voltage or

frequency beyond the range stated on the power rating overlay at the

rear of the unit.

Do not modify the power cord provided with the unit. If the plug does

not fit an outlet, have a proper outlet installed by a qualified electrician.

Avoid damaging the power cord. Do not bend it excessively, step on it,

place heavy objects on it. A damaged cord can easily become a shock

or fire hazard. Never use a power cord after it has become damaged.

Do not position equipment in a manner that prohibits access to power

cord.

Do not attempt to move the unit during operation or before the unit has

been allowed to cool.