Identification

These instructions have been made to support

the users of the cable blowing machine

PowerFlow. The machine type can be identified

by the type plate on the machine. The type

plate provides information about serial

number, year of production and name and

address of the manufacturer.

It is recommended to read this instruction

carefully and become familiar with the

functionality and maintenance of the cable

blowing machine before use.

Application

The cable blowing machine PowerFlow is

constructed for blowing fiber optic cables into

ducts. An example might be a 12 mm cable

into a 40 mm duct.

Always use format parts designed for the

actual diameter of cable and duct.

It is very important to use the correct format

parts. If the format parts do not fit the duct,

dangerous situations may occur.

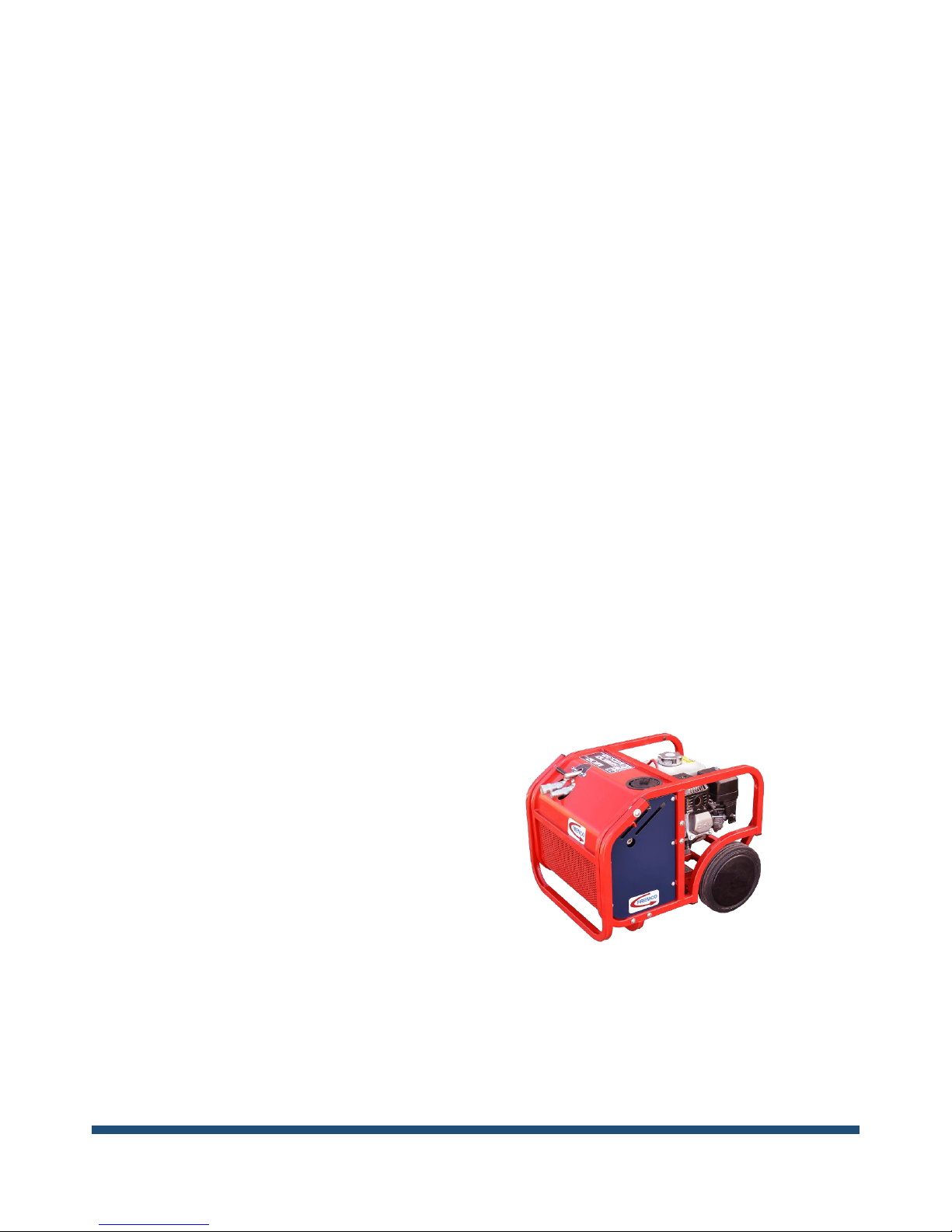

Mounting

Depending on the facilities, mount the air

compressor or water pump and the hydraulic

MultiPower Pack in inserting direction in front

of the manhole. Check oil and fuel, and test-

run equipment.

Arrange the PowerFlow in front of the manhole

and guide the duct out of the hole and into the

Powerflow. If the duct cannot reach the

PowerFlow, extend the length with an extra

piece of duct and a connector. Connect the

hydraulic MultiPower Pack to the hydraulic

control unit.

Make sure to place the Powerflow machine on

a stable foundation and to fasten it to

withstand the forces, which occur during use.

These push/pull forces can be up to 125 kg.

Be careful to avoid any dirt on the surfaces

when mounting the duct into the blowing

junction block. Tighten the four screws equally

so that the two halves are pressed completely

together.

The cable seals in the black nylon part of the

blowing junction block must fit tightly around

the cable –the hole in the cable seal should be

no more than 0.5 mm larger than the diameter

of the cable. Use one to three cable seals

depending on the expected pressure. New

cable seals should always be installed after

each cable blowing to secure maximum

sealing.

The hydraulic control unit controls the direction

(forward/back), speed and push/pull force.

Use the joystick on the hydraulic control unit to

control start/stop and direction.

Speed can be adjusted by turning the screw

marked “Speed”. By turning the screw to the

left, pressure is reduced.

With the screw marked “Force”you can adjust

the maximum force to be transferred to the

cable. The pressure, and with it the force, is

increased when the screw is turned to the right.

Use the manometer to read the pressure and

thereby the push/pull force.

CAUTION: Do not use excessive

force, as this can damage the fiber

cable.