200.108-IOM (FEB 2018)

Page 5

RTF ROOFTOP FREEZER SYSTEMS

INSTALLATION

PREINSTALLATION REQUIREMENTS

TRAINING & SAFETY CONSIDERATIONS

The Johnson Controls – Frick RTF evaporator design utilizes

the •nest materials and corrosion protection to deliver de-

pendable and consistent cooling for coolers and freezers.

This manual provides the information needed for safe instal-

lation, operation, and maintenance. Close attention to the

instructions and guidelines provided will ensure the longest

possible system life and dependable, consistent performance.

CAUTION

JCI-Frick recommends that only experienced industrial

refrigeration contractors, operators, and maintenance

technicians be used to install, operate and maintain the

RTF unit. Before working on the RTF unit, it is further

recommended that they be provided formal training on

the RTF’s design and features that incorporates reading

and understanding this manual.

Installation, operation, and maintenance of the Frick RTF unit

involves rotating machinery operating at high speed and high

voltage. Normal operations and maintenance procedures may

require working at elevations, entry into enclosed spaces,

and the use of hand and power tools. Taking these consid-

erations into account, it is clear that safety should always

be the top priority.

We recommend that every site installing an RTF unit analyze

and develop an installation-speci•c safety regime that takes

into account such variables as speci•c site and unit features,

personnel quali•cations, hazard identi•cation, etc.

NOTICE

Configure all power switches and controls to provide an

open, safe circuit before and during maintenance pro-

cedures, until the system is cleared by management for

normal on-line operations. For extended shutdowns, it

is recommended that a qualified technician remove fuses

from “fused-disconnect panels” or otherwise open the

circuit in an accepted, secure manner.

JCI-Frick recommends that the following elements related

to operational safety be incorporated into every client's RTF

safety requirements and safety program.

Fans – All fan covers, guards, and shaft retainers (if any)

must be in place before applying power to an RTF unit. Al-

ways disengage and lock out power before allowing interior

inspections. To prevent foreign objects from being sucked

into rotating fan blades, never allow operation with the

doors open.

Enclosed space inspections – Inspections of coils, drain

pans, guards, etc., require machinery lockout and the use

of a “lookout buddy” at a minimum – consult your internal

safety policy and OSHA requirements for additional recom-

mended safety procedures.

Vibration and noise – Discontinue or stop machinery that

emits unusual vibration and noise. The source of the distur-

bance must be investigated, identi•ed, and corrected before

testing or placing the system back in operation.

Wet Surface Precautions – Poorly maintained and wetted

machinery requires care to avoid electrical shocks from in-

adequate or loose •eld wiring and connections. All personnel

must lock out and tag machinery before working on the unit.

Proper safety precautions such as the use of insulating soles

and gloves and a trained “lookout buddy” are indispensable.

Ice formation in cold weather can present slip and fall haz-

ards around a rooftop penthouse unit. Ice related safety

procedures should be mandatory when the daily ambient

temperature falls below 40°F.

RTF units typically operate in a continuous-duty capacity and

must be properly located, installed, and connected in the

•eld (by others). It is imperative that the electrical power and

control wiring, refrigerant lines and air duct be adequately

sized and properly installed. The engineering plans, piping

layouts, etc. for all peripheral “•eld” work should be detailed

in accordance with local and governing codes and the best

industry standards and practices.

If you have any comments or questions regarding this manual

or the RTF unit, you are urged to call your installing contrac-

tor and/or the local Frick sales representative.

PRELIMINARY SITE LAYOUT CONSIDERATIONS

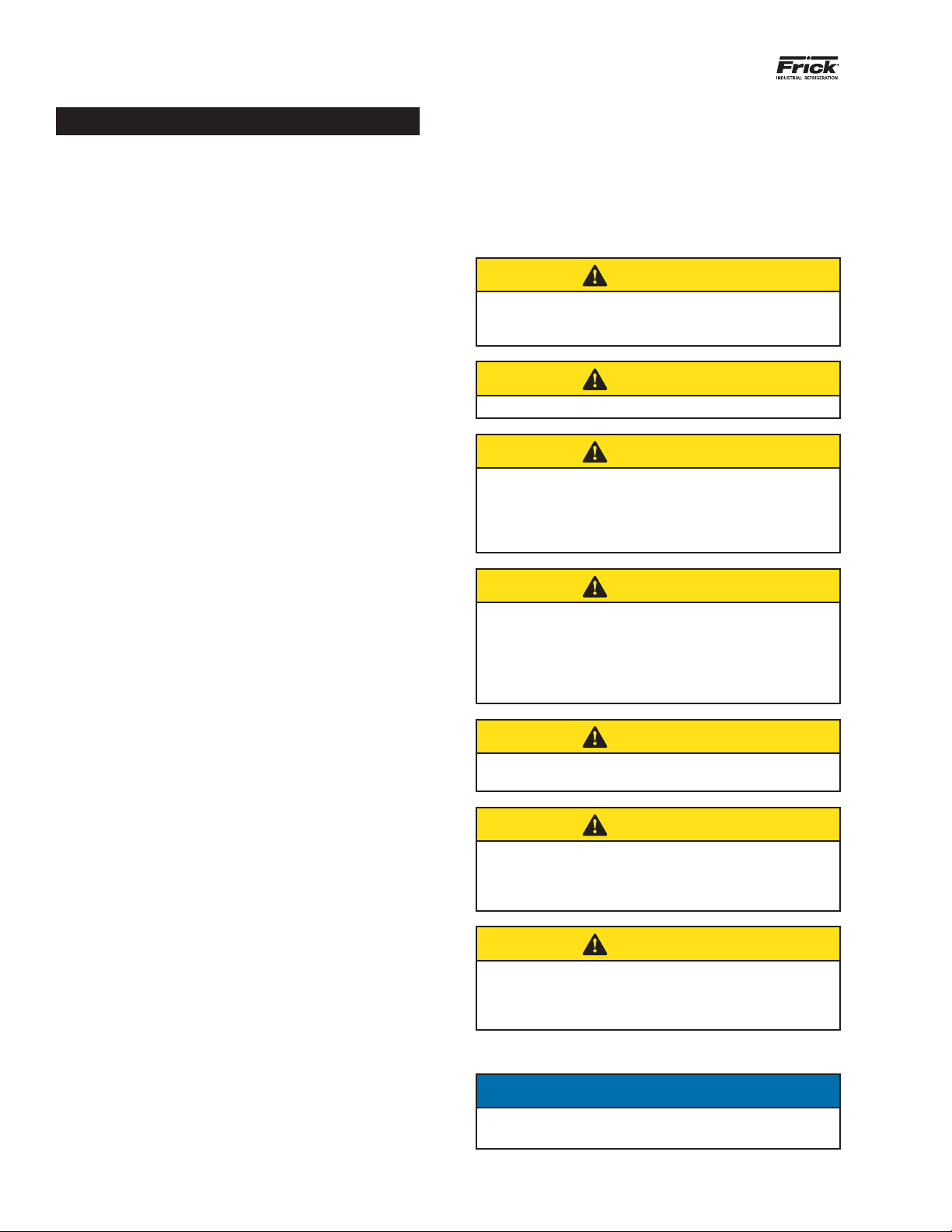

All Frick RTF units must be located for accessibility on the

roof and air !ow in and out of the cold space. The Frick RTF

enclosure has two access doors, one on either side of the

unit. Provision must be made for service and maintenance

access to both of these locations.

Air is drawn into the RTF unit along one side, entering up-

ward through the bottom of the unit. Colder air is discharged

downward along the opposite side of the unit. Adequate

free !ow area must be available for returning air to enter

the bottom of the RTF unit. Excessive restriction will reduce

the air !ow and thus the cooling capacity of the RTF unit

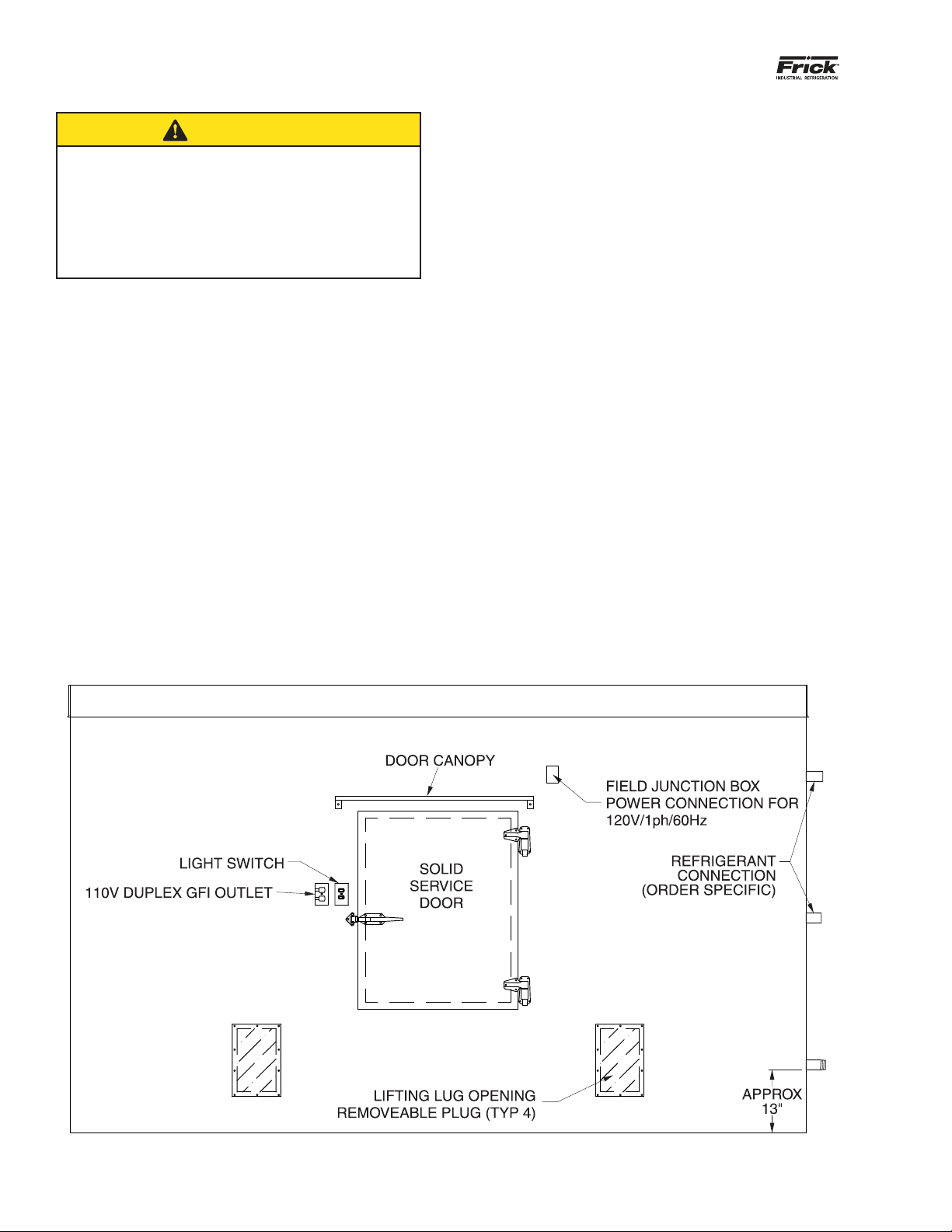

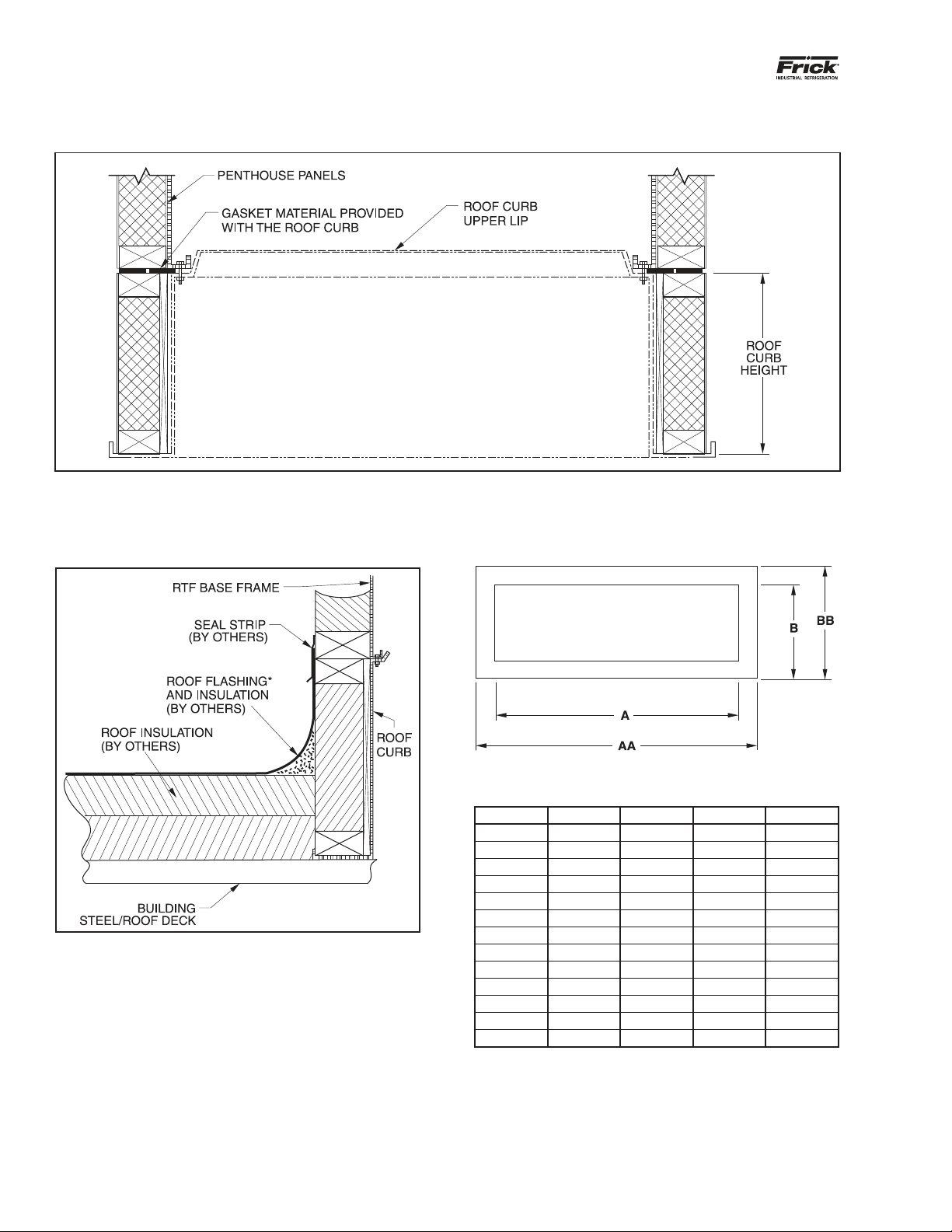

It is the owner’s responsibility to properly locate the RTF

unit in consultation with a quali•ed engineer before laying

out structural supports and installing the penthouse unit.

In general, Frick RTF units must be uniformly supported

around the perimeter either by roof curb or building structural

steel under roof decking.

PRELIMINARY FIELD PIPING

DESIGN CONSIDERATIONS

Before •nalizing the refrigerant piping plans for the new

RTF unit, it is recommended that related plans for potential

expansion of the refrigeration system and building be dis-

cussed with your refrigeration system designer and Johnson

Controls-Frick®sales representative. Incorporating appropri-

ate pipe and opening sizes now (in light of existing and future

needs) is often the most economical long term strategy.

CAUTION

Avoid hydraulic lockup caused by trapped liquid. When

there is an increase in ambient temperature and liquid

refrigerant confined in rooftop piping, the resulting

expansion pressure has the potential to cause

refrigerant lines to burst.