6Rittal cooling unit assembly and operating instructions

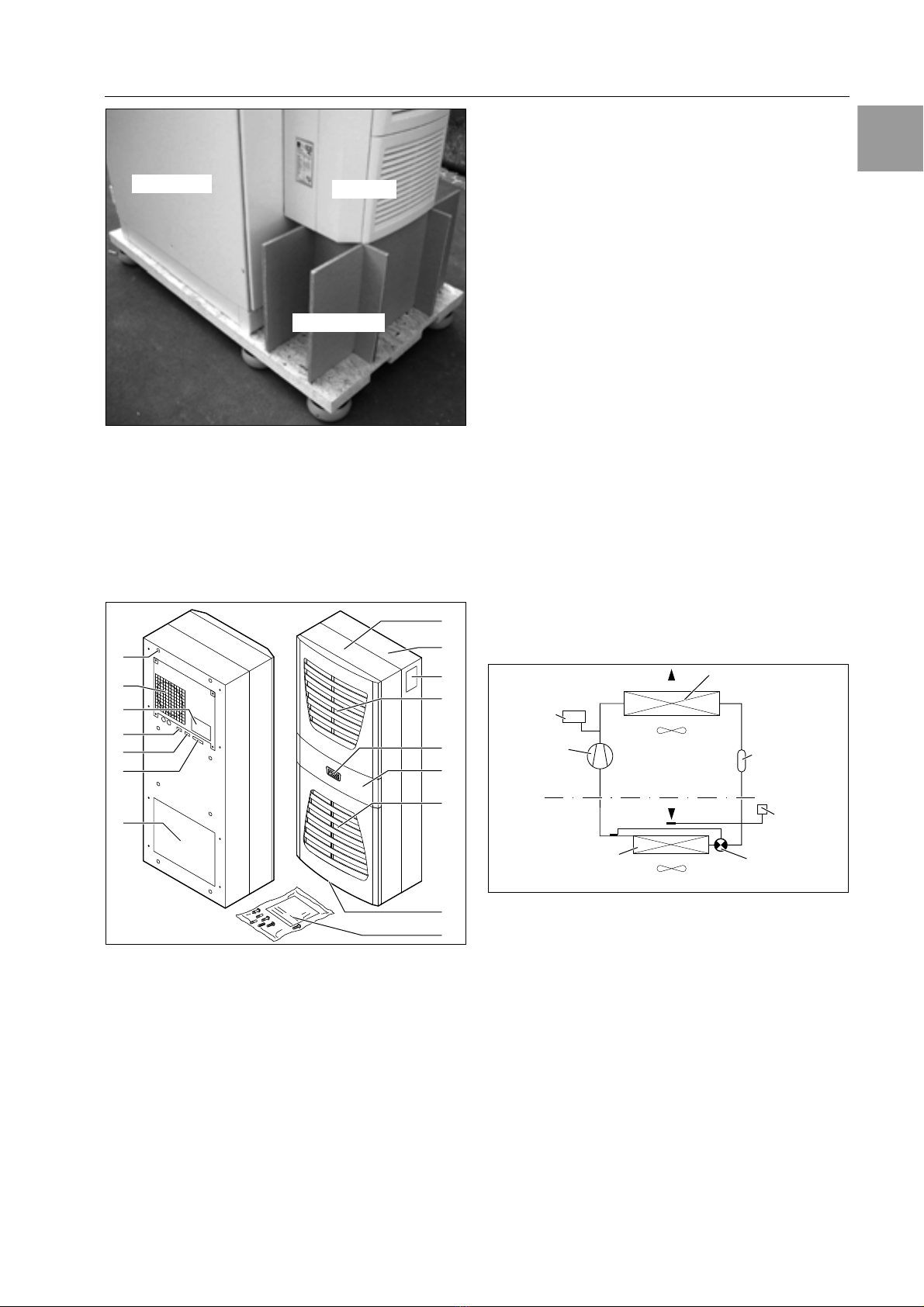

3 Device descriptiKJ

energy from the enclosure air in the evaporator coil.

The whole cycle begins again.

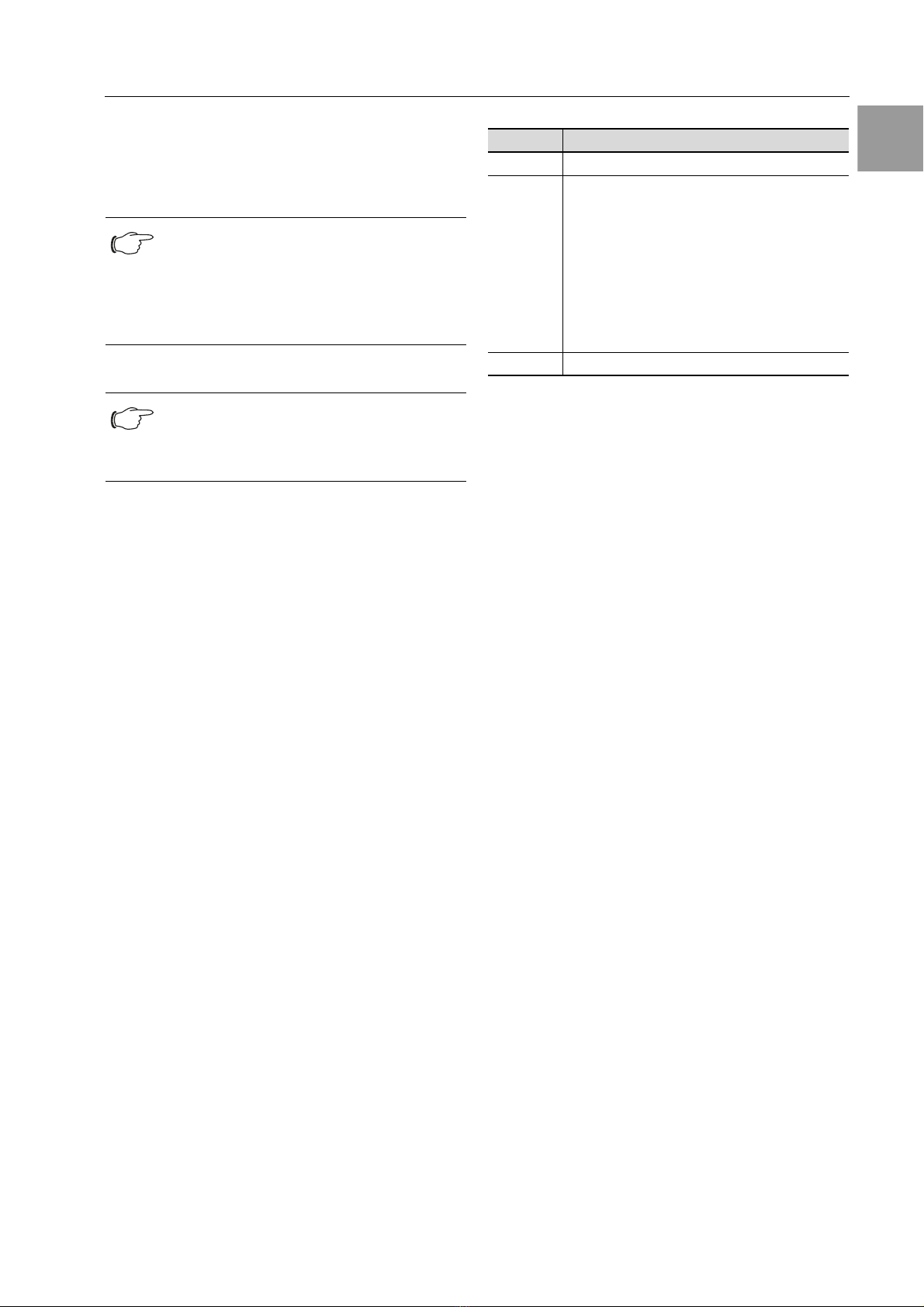

322CKJtrKH

Rittal enclosure cooling units are fitted with a control-

ler for setting the functions of the cooling unit.

Depending on the design, this is either a Basic

controller (operating status display via LED) or an

e-Comfort controller (display plus extended func-

tions, see chapter “6 Operation”, page 21).

323BusIKde (eCKIfKrt cKJtrKHHer KJHy)

The serial unit interface X2 allows you to create a bus

connection with up to ten cooling units using the

master-slave cable (shielded, four-wire cable, Model

No. 3124.100). This allows you to implement the fol-

lowing functions:

– Parallel unit control (the cooling units in the network

can be switched on and off simultaneously)

– Parallel door status message (“door open”)

– Parallel collective fault message

Data is exchanged via the master-slave connection.

During commissioning, assign an address to each

unit that also includes the identifier “master” or

“slave”.

324 Safety devices

– In the cooling cycle, the cooling units (with the ex-

ception of type 3302.xxx) have a tested pressure

switch to EN 12 263 which is set to maximum PS

(permissible pressure); this operates via an auto-

matic reset device whenever the pressure drops

again

– Temperature monitoring prevents the evaporator

coil from icing over. If there is a risk of icing, the

compressor switches itself off and automatically

switches itself back on again at higher tempera-

tures

– The refrigerant compressor and the fans are

equipped with thermal winding shields to protect

against excess current and excess temperatures

– In order to allow a reduction of pressure inside the

compressor and hence a safe restart, once it has

been switched off (e.g. upon reaching the set tem-

perature via the door limit switch function or via de-

energising), the device will switch back on with a

delay of 180 seconds

– The device has floating contacts on the connection

pins (terminals 3 – 5), via which system messages

from the device may be polled, e.g. using a PLC

(1 x change-over contact Basic controller, 2 x nor-

mally open contacts e-Comfort controller)

325CKJdeJsatiKJ

At high levels of humidity and low temperatures in-

side the enclosure, condensation may form on the

evaporator coil.

The cooling units (except 3302.xxx, 3303.xxx and

3361.xxx) have automatic, electric condensate

evaporation. The thermal component used for this

purpose is based on self-regulating PTC technology.

Condensate arising on the evaporator coil is collect-

ed in a tank in the external circuit of the cooling unit,

and partially evaporated via the airflow. When the

water level rises, the water enters the PTC thermal

component and is evaporated (through-flow heater

principle). The water vapour streams out of the cool-

ing unit with the airflow from the external fan.

The PTC thermal component is permanently con-

nected and has no switchpoint. It is protected

against short-circuits with miniature fuses (F1.1,

F1.2). If the fuse has tripped, any condensation is

drained off via the safety overflow.

For unit types 3302.xxx, 3303.xxx and 3361.xxx, the

condensate is routed downwards out of the unit via a

drain pipe on the evaporator coil divider panel. For

this purpose, a hose must be connected to the con-

densate nozzle (see “4.4 Connecting the conden-

sate discharge”, page 12). External condensate

evaporators are available as accessories for these

unit types (refer also to the accessories in the Rittal

Catalogue).

326FiHter Iats

The entire cooling unit condenser is covered with a

dirt-repelling, easy-to-clean RiNano coating. In many

applications, therefore, the use of filter media is

unnecessary, particularly with dry dusts.

For dry, coarse dust and lint in the ambient air, we

recommend installing an additional PU foam filter

mat (available as an accessory) in the cooling unit.

Depending on the incidence of dust, you will need to

replace the filter mat from time to time.

For air containing oil condensate, we recommend

the use of metal filters (also available as an accesso-

ry). These may be cleaned with suitable detergents

and reused.

Function of the filter mat monitor (with e-Comfort con-

troller only):

Dirt on the filter mat is automatically determined by

measuring the temperature difference in the external

circuit of the cooling unit. As the level of filter mat soil-

ing increases, the temperature difference will in-

crease. The setpoint value of the temperature differ-

ence in the external circuit adapts automatically to

the relevant operating points in the performance

diagrams. Hence there is no need to readjust the

setpoint value for different unit operating points.

327DKKr HiIit switch

The cooling unit may be operated with a floating door

limit switch connected. The door limit switch is not in-

cluded with the supply (available as an accessory,

Model No. 4127.010).

The door limit switch function causes the fans and

the compressor in the cooling unit to be switched off

after approximately 15 seconds when the enclosure

door is opened (contacts 1 and 2 closed). This pre-

vents the formation of condensation inside the enclo-

sure while the enclosure door is open. In order to