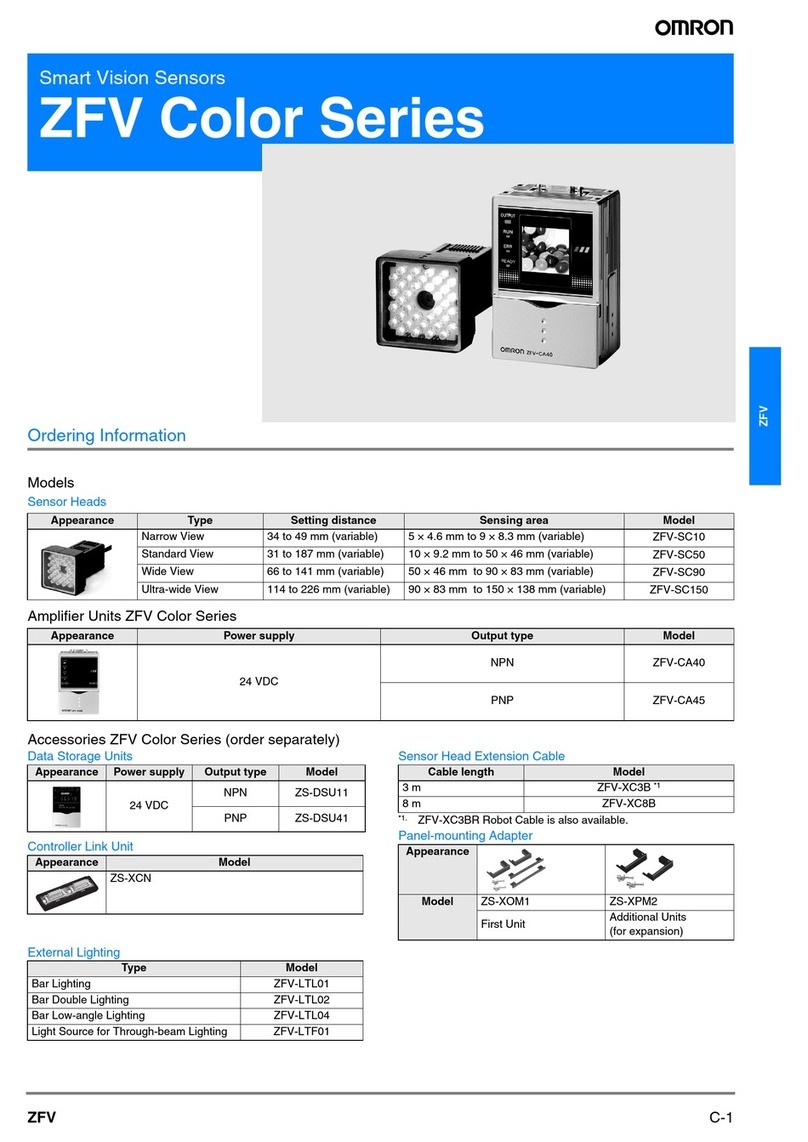

A-183F3C-AL

F3C-AL

Precautions

Safety Precaution

Laser beam!

Laser protection class 2

Do not look into the laser beam.

Pay attention to the accident prevention regulations and the

laser protection class.

Visible laser emission!

Avoid any indirect or direct radiation of

reflected or emitted laser light!

Laser safety

The laser safeguards have been stipulated for laser equip-

ment in and outside Japan. The following gives brief descrip-

tion for use in Japan.

The JIS C6802 Standard stipulates safety preventives that

must be taken by the user according to the laser product

class. (The outline is given in the following table.)

User's Requirements

* 5 mW or less in the visible range

Classification of F3C

Handle laser equipment in accordance with the following pre-

cautions.

• Do not look into the beam.

• Do not disassemble the product. Doing so will release the

laser beam to wander around.

Please obtain or prepare the "Laser product safety standards"

on your own responsibility.

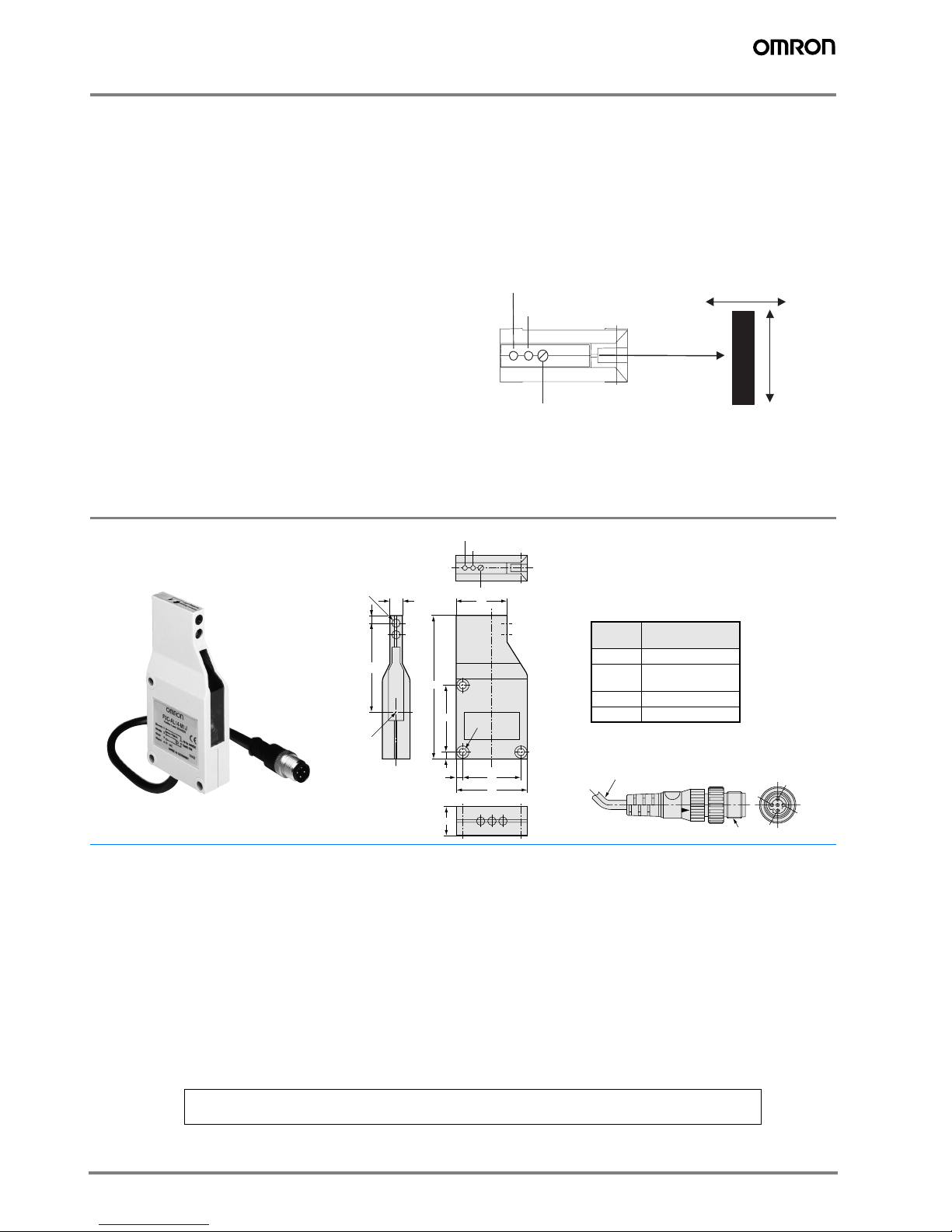

Labels related to laser

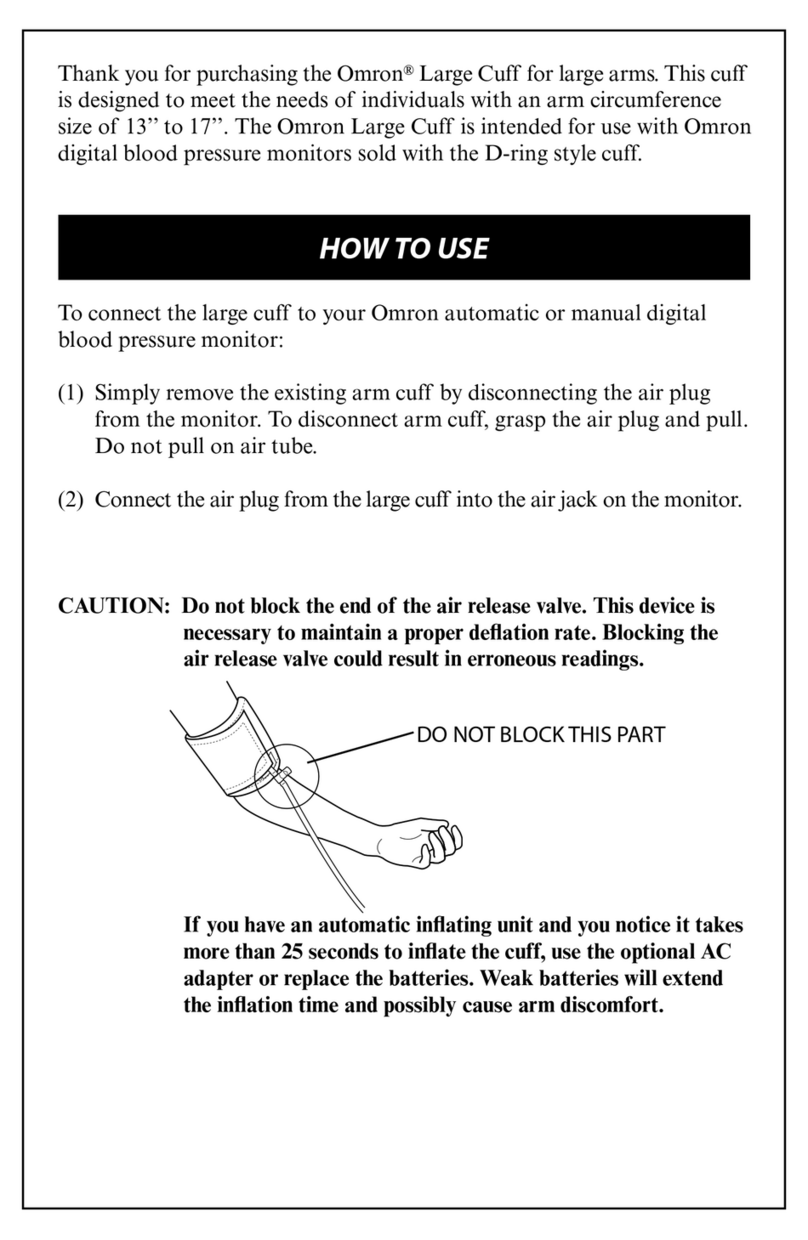

The following warning label is applied to the side face of the

photoelectric sensor.

For use in Japan, change the above label for the one that

meets the JIS Standards.

Handling Instructions

F3C radiates a visible-light laser. Do not look into it directly.

Use F3C so that the light path of the laser beam is terminated.

If there is a mirror-smooth reflector in the light path, confine

the beam away from the reflected light path. If F3C must be

used with the light path open, avoid placing the light path on

the eye level.

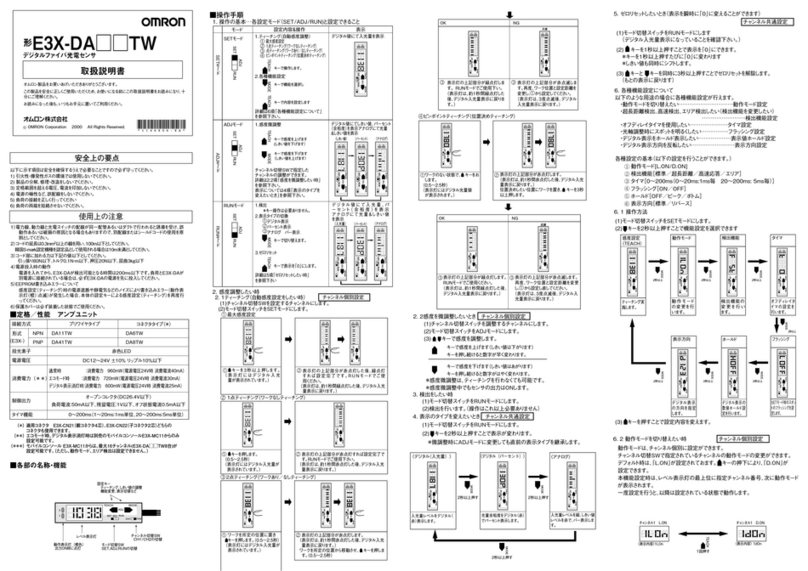

Design

Power Reset Time

The Photoelectric Sensor is ready to sense an object in 300

ms after power-on. Therefore, use it 300 ms after power-on. If

the load and Sensor are connected to different power sup-

plies, always switch on power for the Sensor first.

Wiring Considerations

Load short-circuit protection

• The F3C-AL has load short-circuit protection. If a load short-

circuit or like has occurred, the output turns OFF. Therefore,

recheck the wiring and switch power on again. This resets

the short-circuit protection circuit. Load short-circuit protec-

tion is activated when a current of 1.8 times or more of the

rated load current flows. When using an L load, use the one

the inrush current of which is less than 1.8 times of the rated

load current.

• Do not use the input power exceeding the rated voltage.

Doing so can cause damage.

• Do not shorten the load with the open collector output. Oth-

erwise, damage might be caused.

• Run the wiring of F3C separately from the high voltage and

power cables.

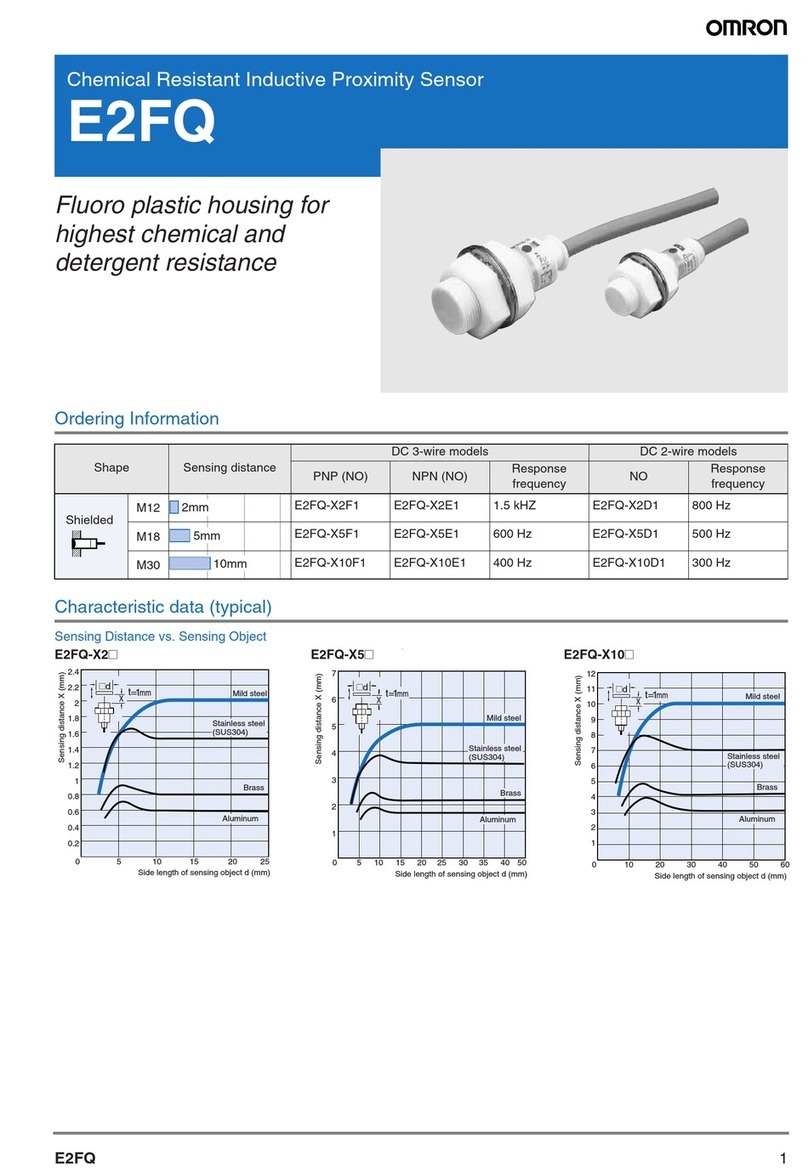

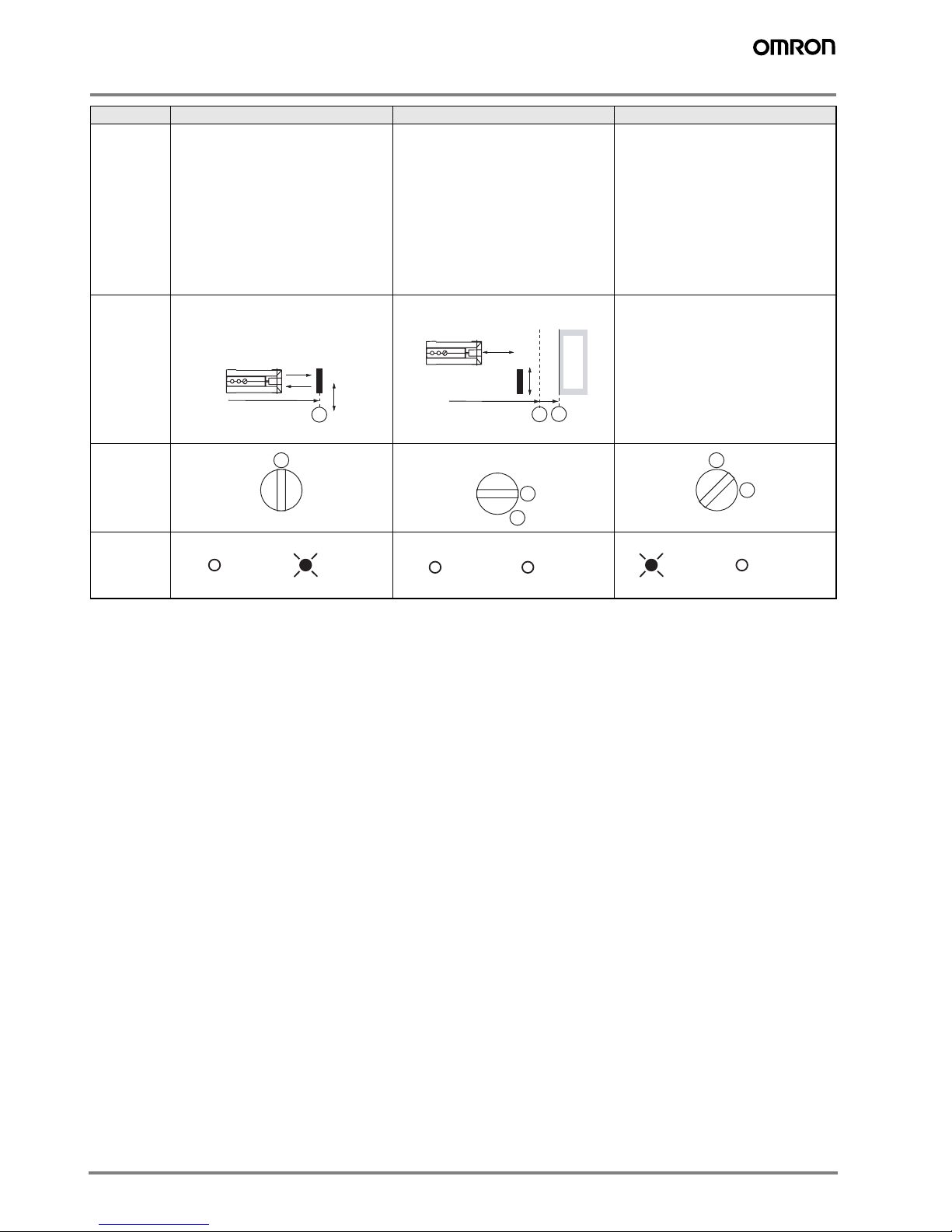

Class Class 1 Class 2 Class

3A

Class 3B Class 4

Item 3B* 3B

Using remote

interlock Not required

Connect the re-

mote interlock of

the laser beam to

the emergency

main interlock, the

interlock of the

room, or the inter-

lock of the door.

Key control Not required

Do not keep the

key in the lock

when the laser

beam is not used.

Beambreaker

or attenuator Not required

Used to protect

people from acci-

dental radiation by

the laser beam.

Warning sign Not required

Post a proper warning sign on

the door to the room where

laser beam equipment is in-

stalled.

Beam path Not re-

quired

The laser beam must be terminated and, as a rule,

must be enclosed. If the laser beam is exposed,

the vertical height of the beam must not be the

same as that of the eyes.

Mirror

reflection Not required

Appropriate optical elements

must be securely attached

and you must be able to con-

trol the optical elements dur-

ing laser radiation.

Eye protect Not required

Use eye protectors

except in special,

specified locations.

Protection

clothes Not required Wear protection clothes if exposure of

the skin to the laser beam may exceed

the MPE of the skin.

Training Not required The laser system must be operated by

only properly trained people.

Class 2

Correct Use

LASER LIGHT

DO NOT LOOK DIRECTLY INTO THE BEAM!

NOT EVEN THROUGH OPTICAL

INSTRUMENTS.

LASER PROTECTION CLASS 2

Pout < 1mW 670nm