3

Table of contents

1 Introduction............................................................. 5

1.1 Foreword................................................................... 5

1.2 Manufacturer........................................................... 5

1.3 Scope of Supply...................................................... 5

1.4 Pump Without Motor (Optional)...................... 5

1.5 Scope of Documentation.................................... 5

1.6 Display Conventions............................................. 5

2 Safety Instructions................................................. 6

2.1 Basic Safety Instructions...................................... 6

2.2 Intended Use ........................................................... 6

2.3 Improper Use........................................................... 6

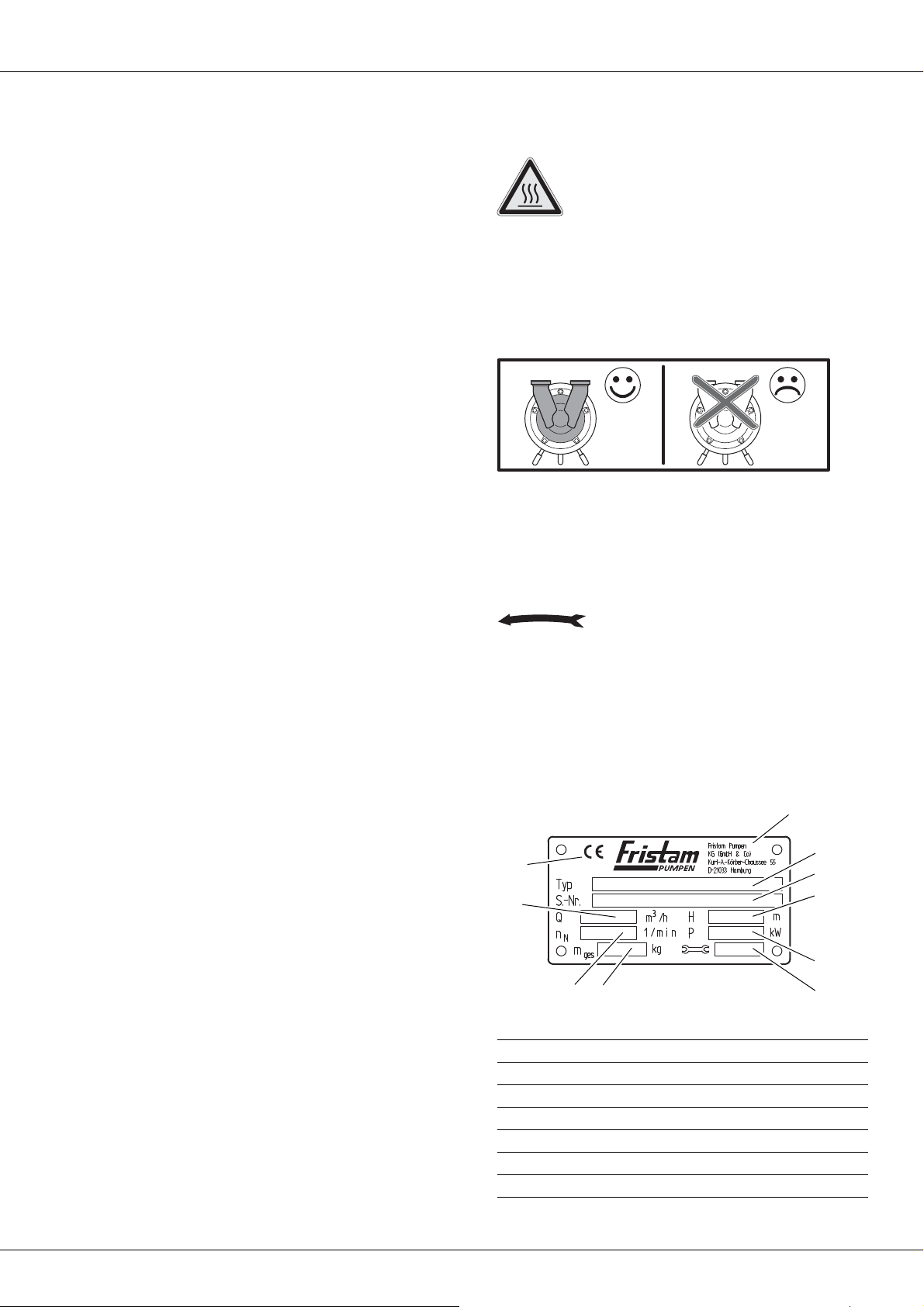

2.4 Warning and Instruction Labels........................ 6

2.5 Noise Emissions ...................................................... 7

2.6 Disposal ..................................................................... 7

3 Design and Function ............................................ 7

3.1 Principles of Design............................................... 7

3.2 Models ....................................................................... 8

3.3 Pump Key.................................................................. 9

3.4 Versions ..................................................................... 9

3.5 Pump Sizes ............................................................... 9

4 Transportation ........................................................ 10

4.1 Safety Instructions................................................. 10

4.2 Moving With Industrial Trucks .......................... 10

4.3 Moving With Crane ............................................... 10

5 Storage....................................................................... 11

5.1 Safety Instructions................................................. 11

5.2 Storage Conditions................................................ 11

5.3 Long-Term Storage ............................................... 11

5.4 Recommissioning .................................................. 11

6 Installation................................................................ 11

6.1 Safety Instructions................................................. 11

6.2 Installation Location ............................................. 11

6.3 Reduction of Noise and Vibration.................... 12

6.4 Pump Fixation ........................................................ 12

6.5 Electrical Connection........................................... 13

6.6 Connection of Sealing or Quenching

Liquid (Optional) ................................................... 13

6.7 Cleaning.................................................................... 13

7 Operation................................................................. 14

7.1 Safety Instructions ................................................ 14

7.2 Commencement of Operation......................... 14

7.3 Monitoring of Operation .................................... 14

7.4 Stopping of Operation ........................................ 14

7.5 Pump Decommissioning.................................... 14

7.6 Cleaning in Place ................................................... 15

8 Faults ......................................................................... 15

8.1 Safety Instructions ................................................ 15

9 Maintenance........................................................... 15

9.1 Safety Instructions ................................................ 15

9.2 Replacement Parts................................................ 15

9.3 Inspection of Sealing and Quenching

Liquid (Optional) ................................................... 16

9.4 Lubrication of Motor Bearings.......................... 16

9.5 Lubrication of Shaft Bearing ............................. 16

9.6 Motor Replacement ............................................. 17

9.7 Shaft Seal Replacement ...................................... 18

9.8 Pump Head Removal ........................................... 18

9.9 Checking of the Clearances............................... 20

9.10 Pump Head Attachment..................................... 20

9.11 Design FZ 27: Mounting and aligning the

pump shaft .............................................................. 29

9.12 Model L: Coupling Replacement ..................... 30

10 Appendix 1 .............................................................. 31

10.1 Specifications.......................................................... 31

10.2 Maintenance Intervals......................................... 31

10.3 Troubleshooting Table........................................ 32

10.4 Number Key ............................................................ 34

10.5 EC Declaration of Conformity........................... 35

10.6 EG Declaration of Incorporation...................... 35