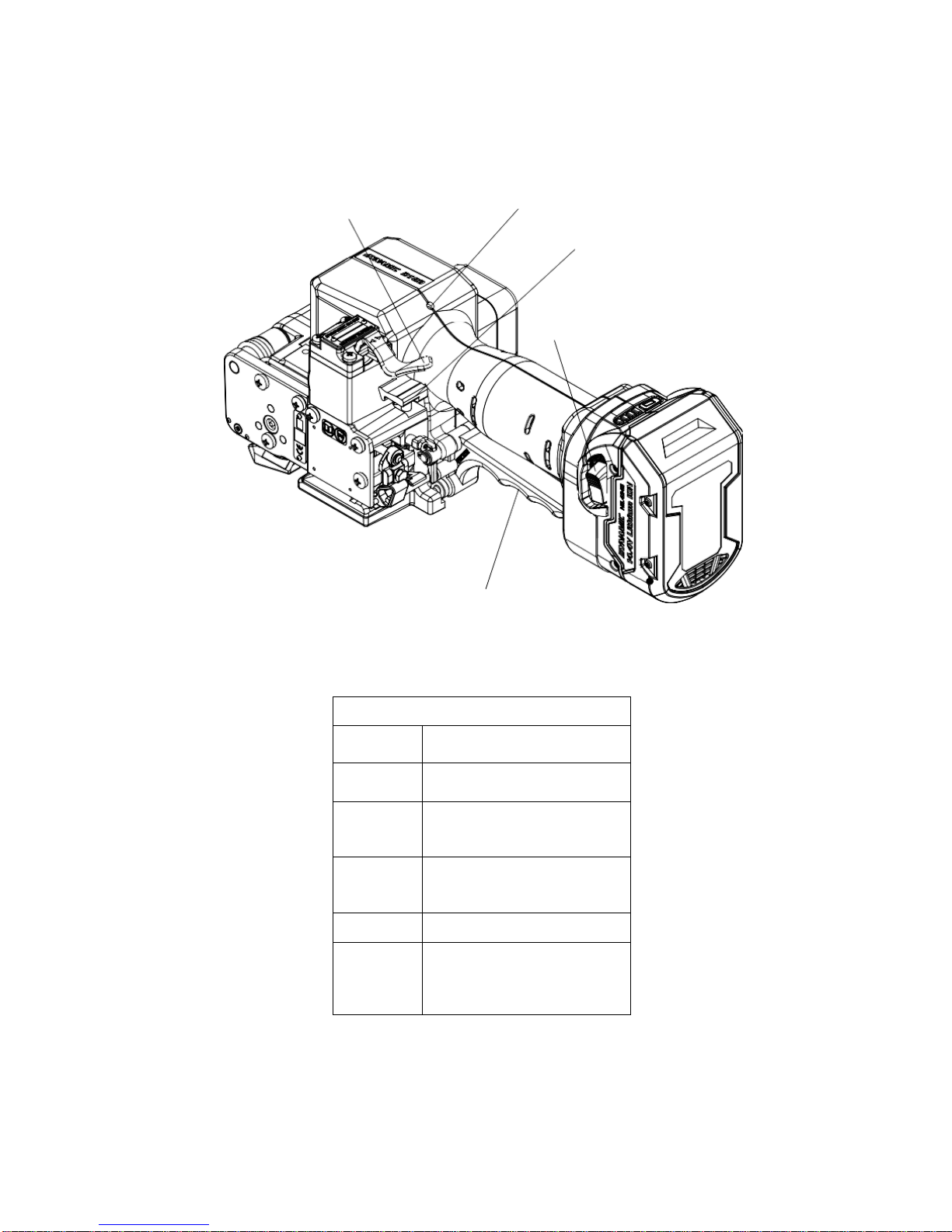

Dynamic 2100 Battery Strapping Tool Operation Manual | FPA001 | Apr 2018 | Page 6

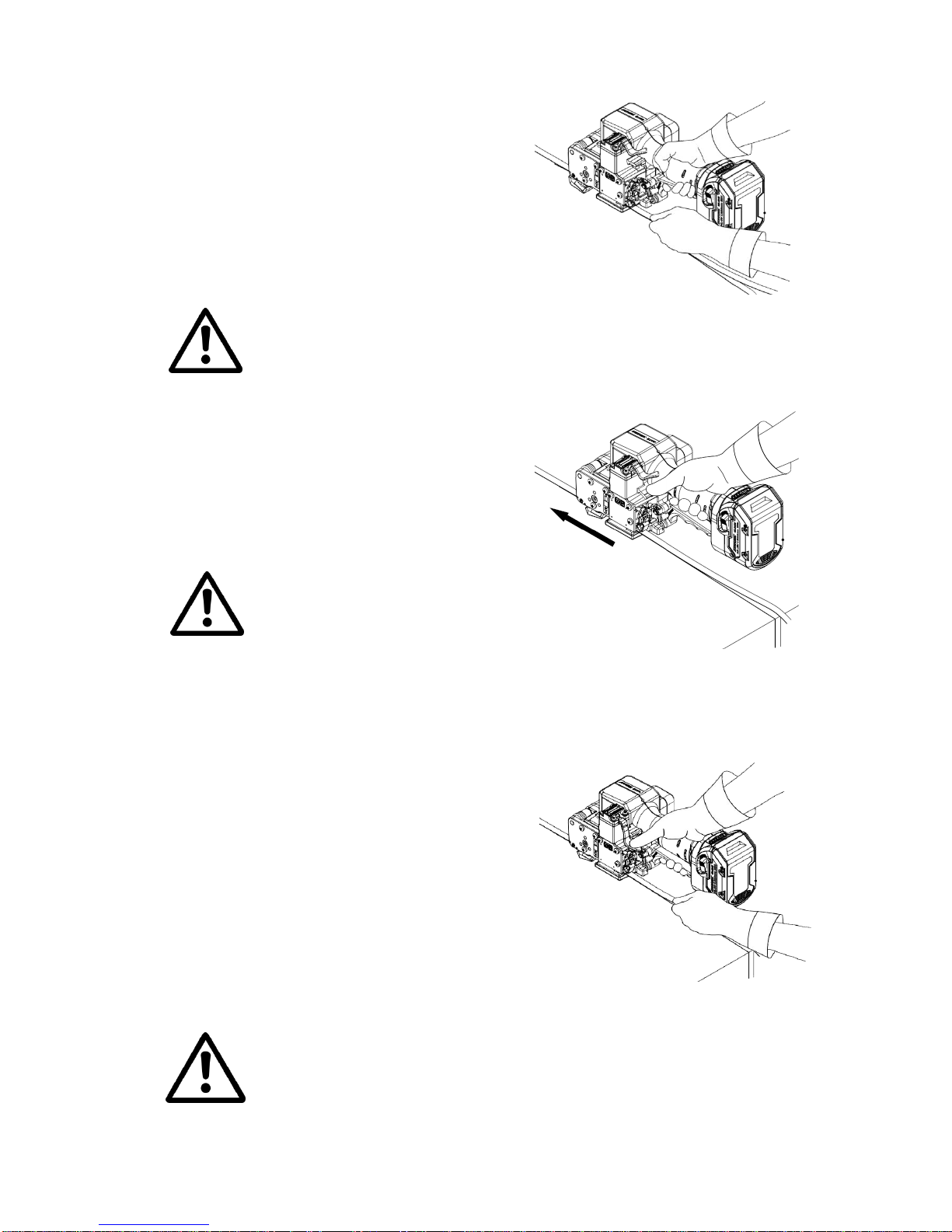

3.4 Inserting the Strap

Pull up the handle lever firmly with your

right hand.

Insert the two straps well aligned on each

other into the strap guide using your left

hand. The lower strap end must slightly

protrude the end of the base plate.

Release the handle lever.

After welding of the strapping it is neither permitted to tension again nor to weld

again. After welding and cooling the tool has to be removed from the strapping

before a new strapping cycle is started. Disregard of this instruction can cause

severe malfunction and damage to the tool.

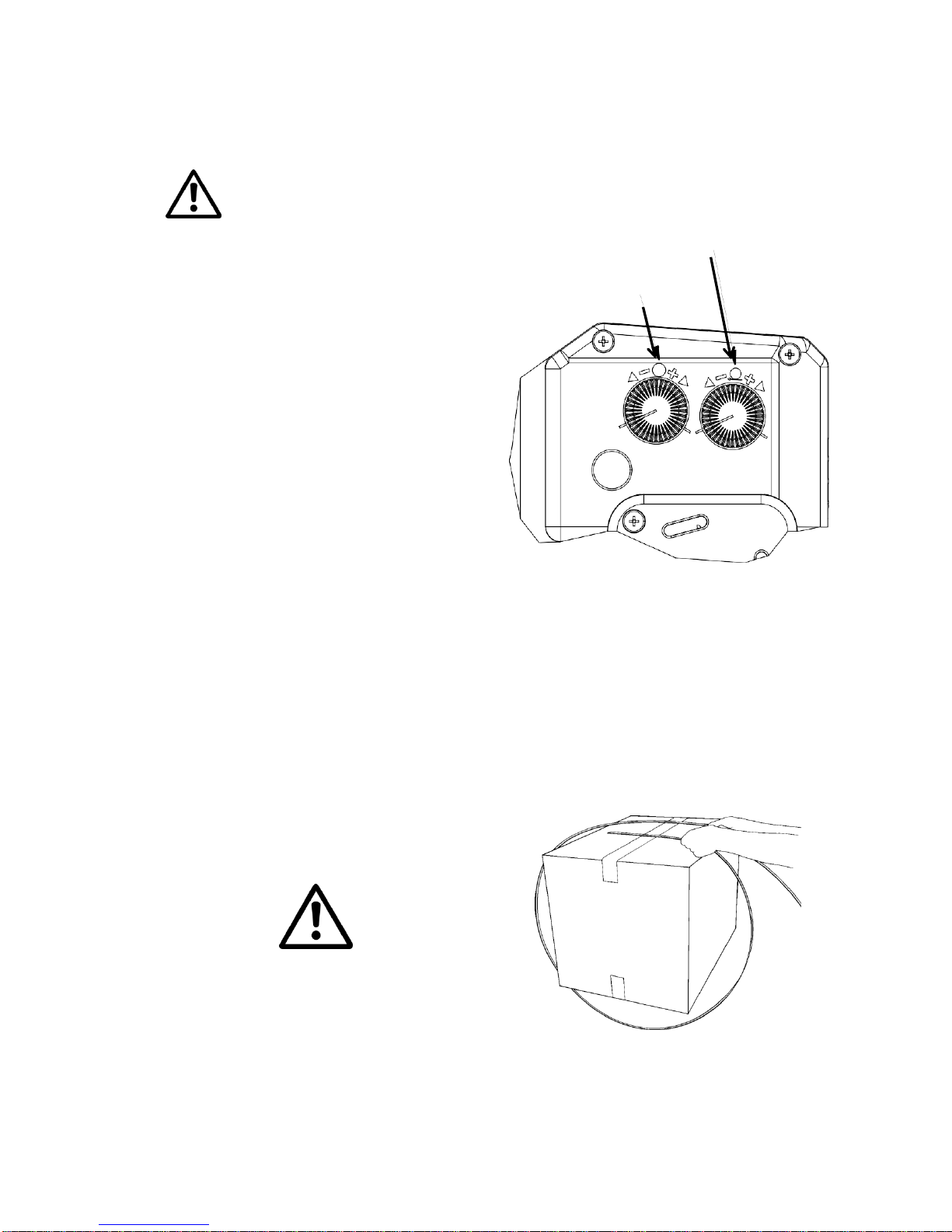

3.5 Tensioning the Strap

Press down the tension button and then

release it again after the desired strap

tension has been reached.

The tensioning operation can be interrupted

and restarted at any time.

During tensioning the LED lights green.

Do not press the switch rocker after

reaching the preselected tensioning.

Danger of strap breakage.

The tool must carry out a balance movement while

tensioning.

Therefore:

- Don’t hinder the tools movement in the signed direction.

Disregard:

- The feed wheel slips on the strap without tensioning it.

3.6 Sealing of the Joint

Press the sealing lever down and let it go

immediately.

The plastic strap is welded and cut off from the

rest of the strap. During the welding the LED

lights green.

After elapsing of the adjusted welding time (see

3.2.2) the cooling time begins (LED lights

yellow). During that time the tool must not be

removed from the strap. If the LED lights green again,

the sealing cycle is finished.

The tool must not be removed from the strap as long as the cooling time is not

finished. Disregard of this regulation is causing insufficient seal efficiencies,

which can cause severe injuries.