4

2.0 OPERATION

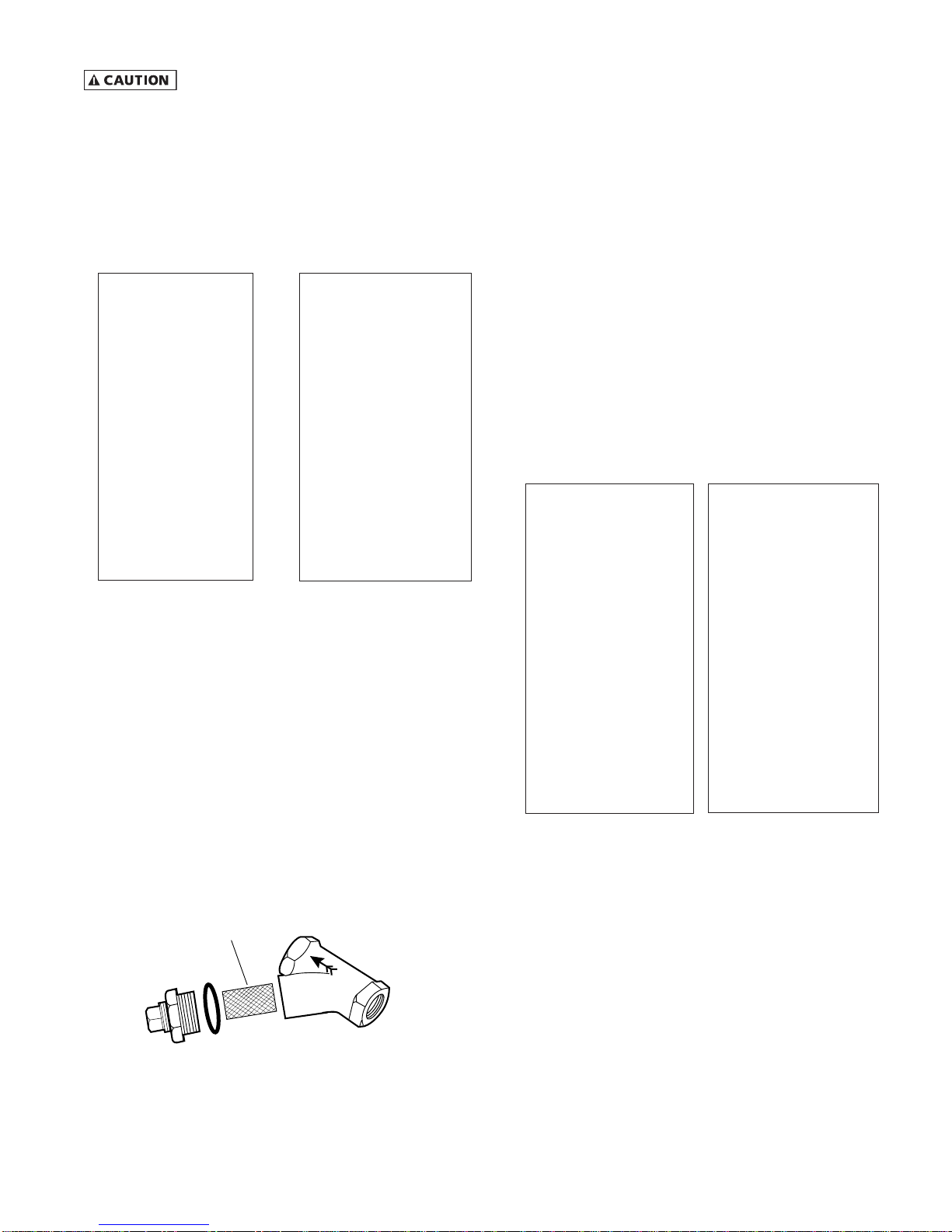

NOTE:Installationsabove6000feet,1825meters

Unitisadjustedtooperateinaltitudesupto6000feet,

1825meters.Ifunitisinstalledinanaltitudeabovethis,

andhasnotbeenpresetatthefactoryforthisaltitude,

contactManufacturer’sServiceDepartment.

2.1 Start-up

Startrefrigerationsystembypushingtheon/offswitch

totheONposition(depressrockerswitchonsidemarked

“I”).

NOTE:Thefaultlightmayilluminatewhenunitisener-

gized.Lightshouldgooutapproximately5minutesafter

start-up.Iflightremainslitafter30minutesorillumi-

natesaftergoingout,refertoTroubleshootingGuide.

2.2 Operating check points

Checkthefollowingonaperiodicbasis:

A. RockerswitchisintheONposition.

B. Amberfaultlightisout.

C. Condensateisbeingregularlydischarged.

2.3 Minimum/maximum operating conditions

A. Minimum/Maximumairpressure:20/250psig,

1.4/17.6kgf/cm2

B. Maximuminletairtemperature:180°F,82°C

C. Minimum/Maximumambienttemperature:

40/110°F,4/43°C

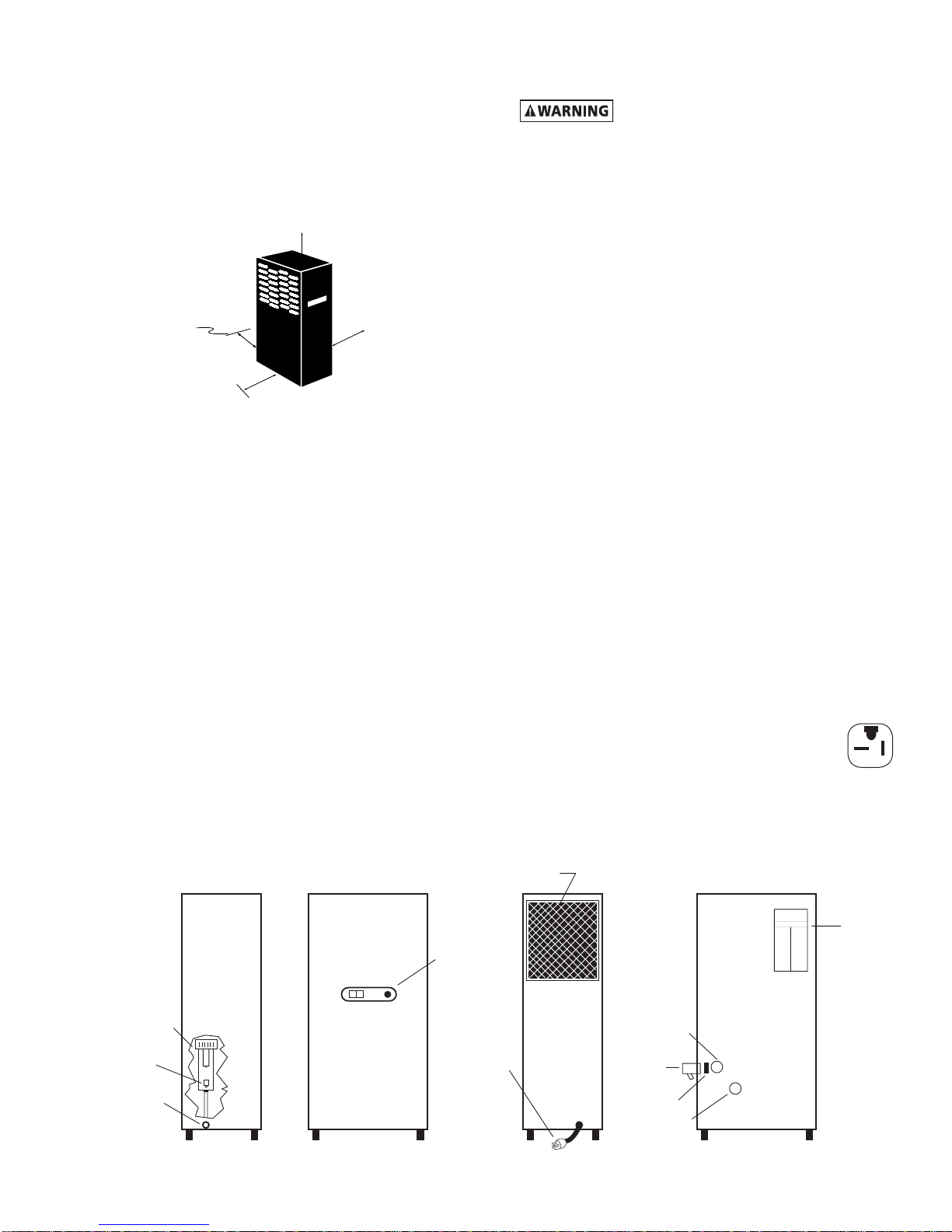

ControlPanel

2. Fordryerswithanaftercoolerinstalledupstream

Flowcapacityinscfm(m3/min)@100°F,38°Cinlet

temperature,100°F,38°Cinletpressuredewpoint,

100°F,38°Cambienttemperature,50°F,10°Coutlet

pressuredewpoint,andlessthan10psi,0.7kgf/cm2

pressure drop.

D. Maximumowcapacity

1. Fordryerswithoutanaftercoolerinstalledupstream.

Flowcapacityinscfm(m3/min)@180°F,82°Cinlet

temperature,160°F,71°Cinletpressuredewpoint,

95°F,35°Cambienttemperature,50°F,10°Coutlet

pressuredewpoint,andlessthan5psi,0.35kgf/cm2

pressure drop.

I

O

On/Off Switch Fault Light

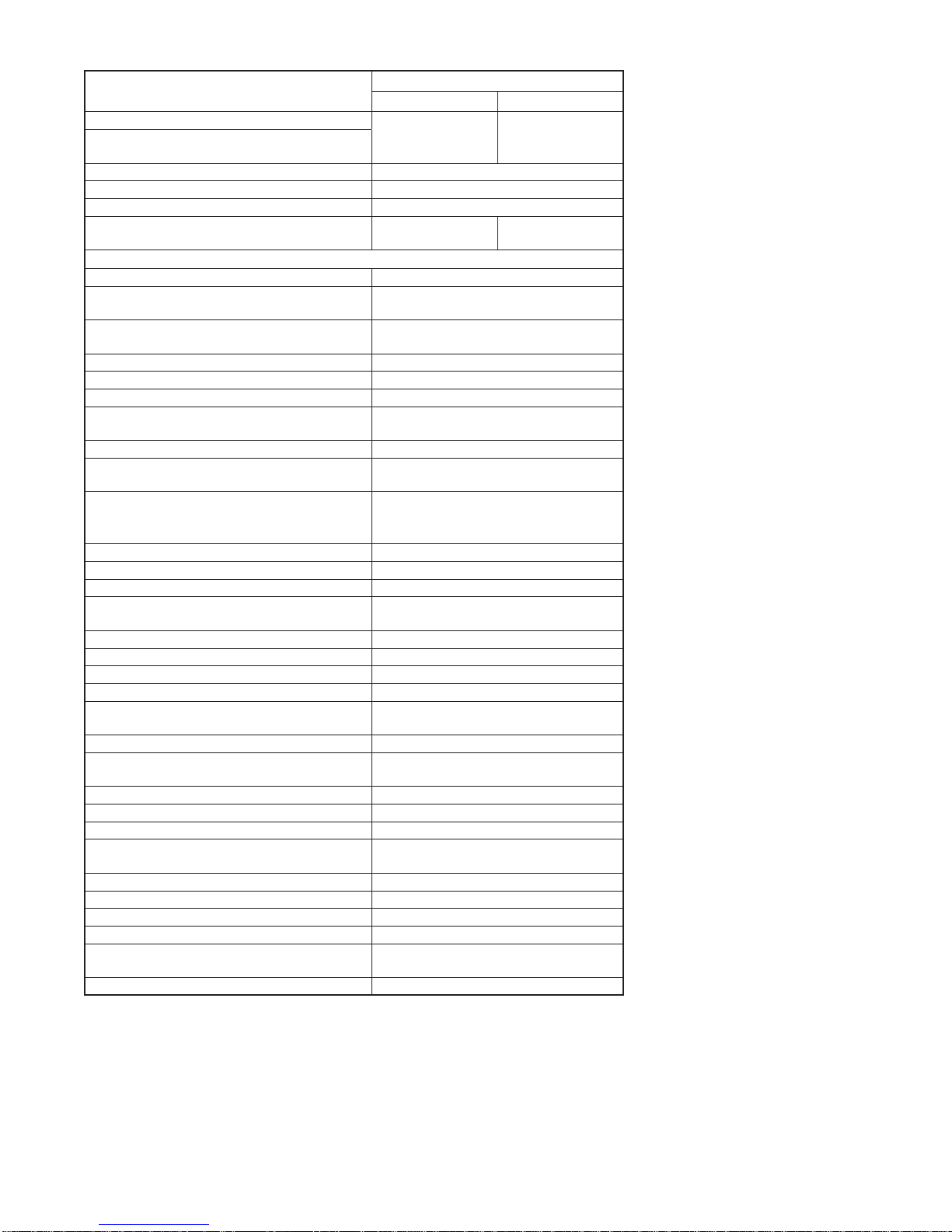

60 HZ

Inlet Pressure

psig (kgf/cm2)175 (12.3) 150 (10.6) 125 (8.8) 100 (7.0)

Model

20 23 (0.65) 22 (0.62) 20 (0.57) 18 (0.51)

25 29 (0.82) 27 (0.76) 25 (0.71) 23 (0.65)

35 41 (1.16) 38 (1.08) 35 (0.99) 32 (0.91)

50 58 (1.64) 54 (1.53) 50 (1.42) 45 (1.27)

75 87 (2.46) 81 (2.29) 75 (2.12) 68 (1.93)

100 116 (3.29) 108 (3.06) 100 (2.83) 91 (2.58)

125 145 (4.12) 135 (3.82) 125 (3.54) 114 (3.23)

50 HZ

Inlet Pressure

psig (kgf/cm2)175 (12.3) 150 (10.6) 125 (8.8) 100 (7.0)

Model

20 20 (0.57) 18 (0.51) 17 (0.48) 15 (0.42)

25 24 (0.68) 23 (0.65) 21 (0.59) 19 (0.54)

35 31 (0.88) 29 (0.82) 27 (0.76) 24 (0.68)

50 58 (1.64) 54 (1.53) 50 (1.42) 45 (1.27)

75 71 (2.01) 66 (1.87) 61 (1.73) 55 (1.56)

100 97 (2.75) 90 (2.55) 83 (2.35) 76 (2.15)

125 121 (3.43) 112 (3.17) 104 (2.95) 95 (2.69)

60 HZ

Inlet Pressure

psig (kgf/cm2)175 (12.3) 150 (10.6) 125 (8.8) 100 (7.0)

Model

20 32 (0.91) 30 (0.85) 28 (0.79) 25 (0.71)

25 40 (1.13) 37 (1.05) 34 (0.96) 31 (0.88)

35 55 (1.56) 51 (1.44) 47 (1.33) 43 (1.22)

50 78 (2.21) 73 (2.07) 67 (1.90) 61 (1.73)

75 118 (3.34) 110 (3.12) 102 (2.89) 92 (2.61)

100 157 (4.45) 146 (4.14) 136 (3.85) 123 (3.48)

125 197 (5.58) 183 (5.18) 170 (4.82) 155 (4.39)

50 HZ

Inlet Pressure

psig (kgf/cm2)175 (12.3) 150 (10.6) 125 (8.8) 100 (7.0)

Model

20 27 (0.76) 25 (0.71) 23 (0.65) 21 (0.59)

25 33 (0.93) 31 (0.88) 29 (0.82) 26 (0.74)

35 43 (1.22) 40 (1.13) 37 (1.05) 33 (0.93)

50 78 (2.21) 73 (2.07) 67 (1.90) 61 (1.73)

75 96 (2.72) 90 (2.55) 83 (2.35) 75 (2.12)

100 131 (3.71) 122 (3.46) 113 (3.20) 102 (2.89)

125 164 (4.65) 152 (4.31) 142 (4.02) 129 (3.65)