3

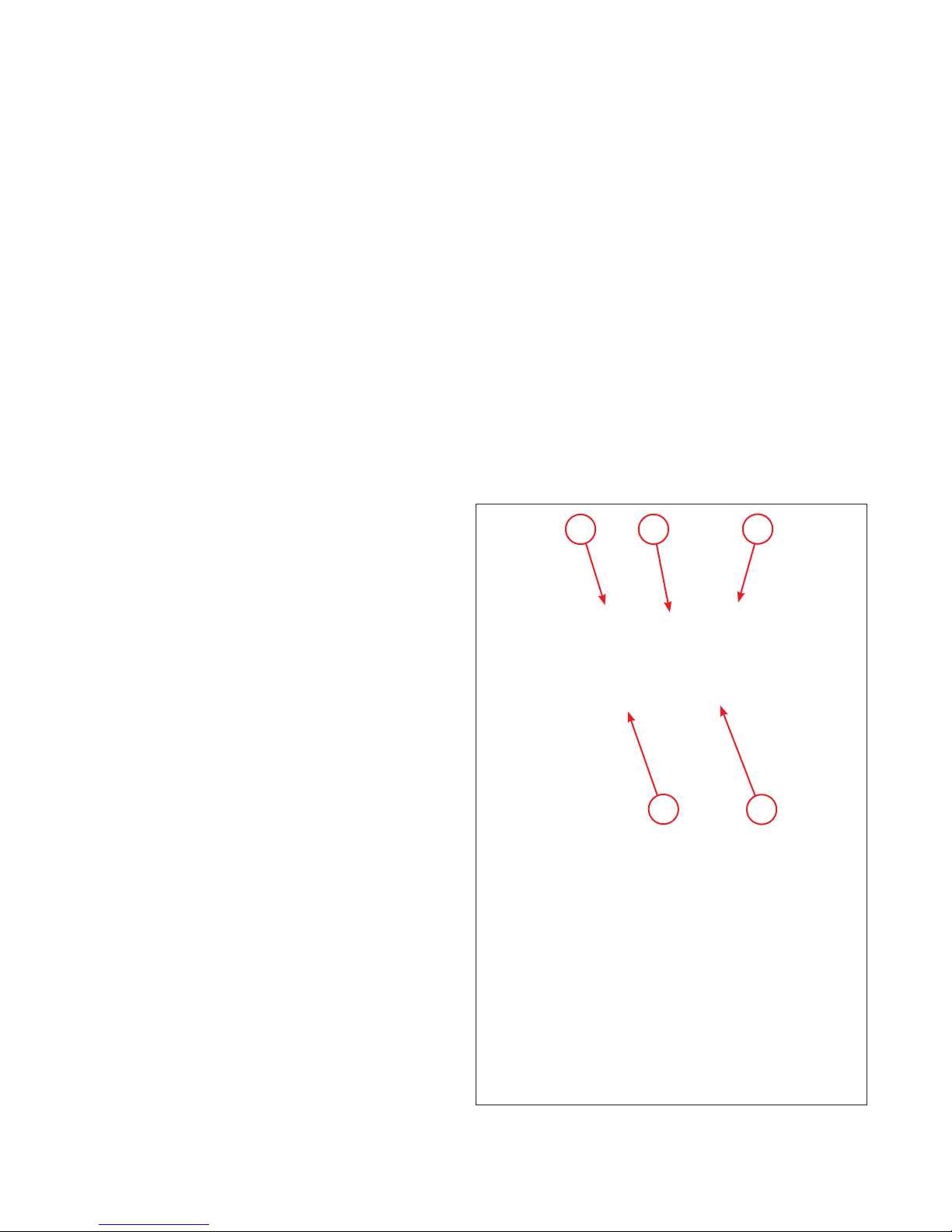

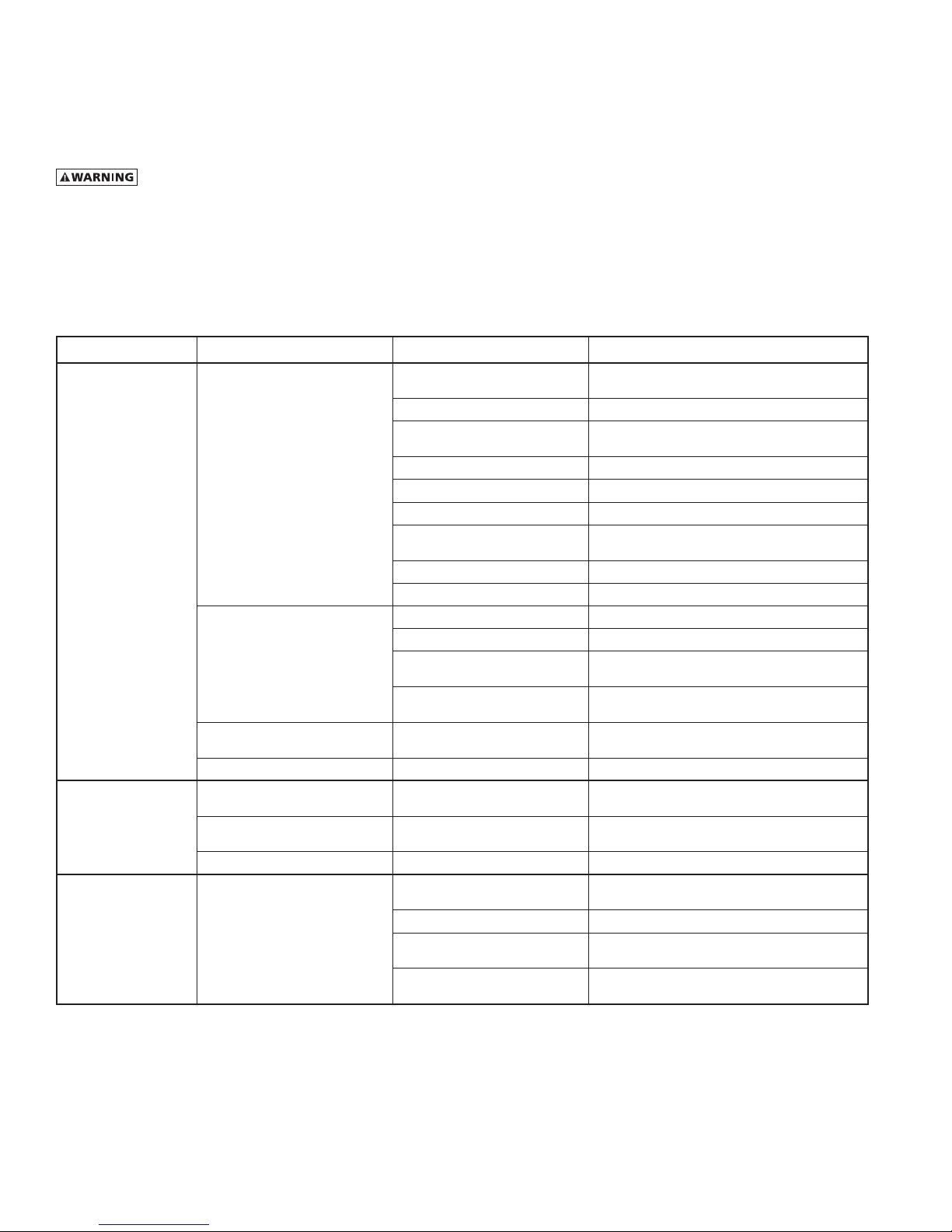

Compressor

Oil Removal

Filter

Aftercooler Automatic Drain

Dryer

Separator Receiver

TYPICAL COMPRESSED AIR SYSTEM

INSTALLATION

Ambient Air Temperature

Locatethedryerindoorswheretheambientairtemperature

willbebetween45°Fand110°F.Intermittentoperationat

ambient temperatures up to 113°F will not damage the dryer

but may result in a higher dew point or dryer shutdown

duetohighrefrigerantdischargepressure(seeFieldService

Guide).

Donotoperateair-cooleddryersatambientairtemperatures

below40°F.Suchoperationmayresultinlowsuction

pressure,causingfreeze-up.

Location and Clearance

Mountthedryeronalevelbase.Ifthebasevibrates,bolt

theunitdownusingvibrationdampeners.Ifthedryeris

air-cooled,installitinaclean,well-ventilatedareatoreduce

foulingofthecondensercoilswithdirtanddust.Allowat

least24inchesclearanceonthesidesandthefrontofthe

dryerforcoolingairowandforserviceaccess.

System Arrangement

Liquidwaterintheinletairwilladverselyaffectthe

performanceofthedryer.Installthedryerdownstreamofan

aftercoolerorseparatorsothatthetemperatureofthedryer

inletairdoesnotexceed120°Fandtheinletairdoesnot

contain any liquid water.

Ifthecompressedairowisrelativelyconstantanddoesnot

exceedthedryerowrating,itisrecommendedthatthe

dryerbelocateddownstreamofthereceivertank.Ifthe

natureoftheapplicationissuchthattheairdemandregularly

exceedsthedryerowrating,itisrecommendedthatthe

dryerbelocatedupstreamofthereceiver.

Forsafetyandconvenience,installinletandoutletshutoff

valvesanddepressurizationvalves.Thesevalvesallowthe

dryertobeisolatedanddepressurizedforservicing.Bypass

pipingmaybeinstalledaroundthedryerforuninterrupted

airowwhenthedryerisserviced.Ifthecompressedair

operationcannottolerateundriedairforshortperiods,install

a second dryer in the bypass line.

Compressedairsystemscommonlyrequirelterstoremove

compressoroils,particulates,condensedliquidsandother

contaminants.Whenanoil-removallterisused,itshould

beinstalleddownstreamoftherefrigerateddryer.At

thislocation,thelifeofthereplaceablelterelementis

prolongedsincesomeoftheentrainedoilisremovedbythe

dryer and drained through the separator.

Piping and Connections

Pipingmustbefurnishedbytheuserunlessotherwise

specied.Connectionsandttingsmustberatedforthe

maximumoperatingpressuregivenonthedryerdataplate

andmustbeinaccordancewithapplicablecodes.Support

allpiping;donotallowtheweightofanypipingtostressthe

dryerorlterconnections.Inletandoutletshutoffvalvesand

avalvedbypassvalvearerecommended.Pipingshouldbeat

leastthesizeoftheinletandoutletconnectionstominimize

pressuredropintheairsystem.SeeEngineeringDatasection

fordryerinletandoutletconnections.

Removing Condensate

Condensatemustbedrainedfromthedryertopreventre-

entrainment. The dryers are equipped with automatic drain

valves and internal drain hoses up to the drain connections

on the dryer cabinets. The user must install a separate

dischargelineatthedrainconnectiontocarryoffcondensate

to an environmentally approved condensate collection/

disposalsystem.Pipingorcoppertubing1/2inchorlarger

isrecommendedforcondensatedischargelines.Installthe

drain lines so that condensate can be seen as it drains.

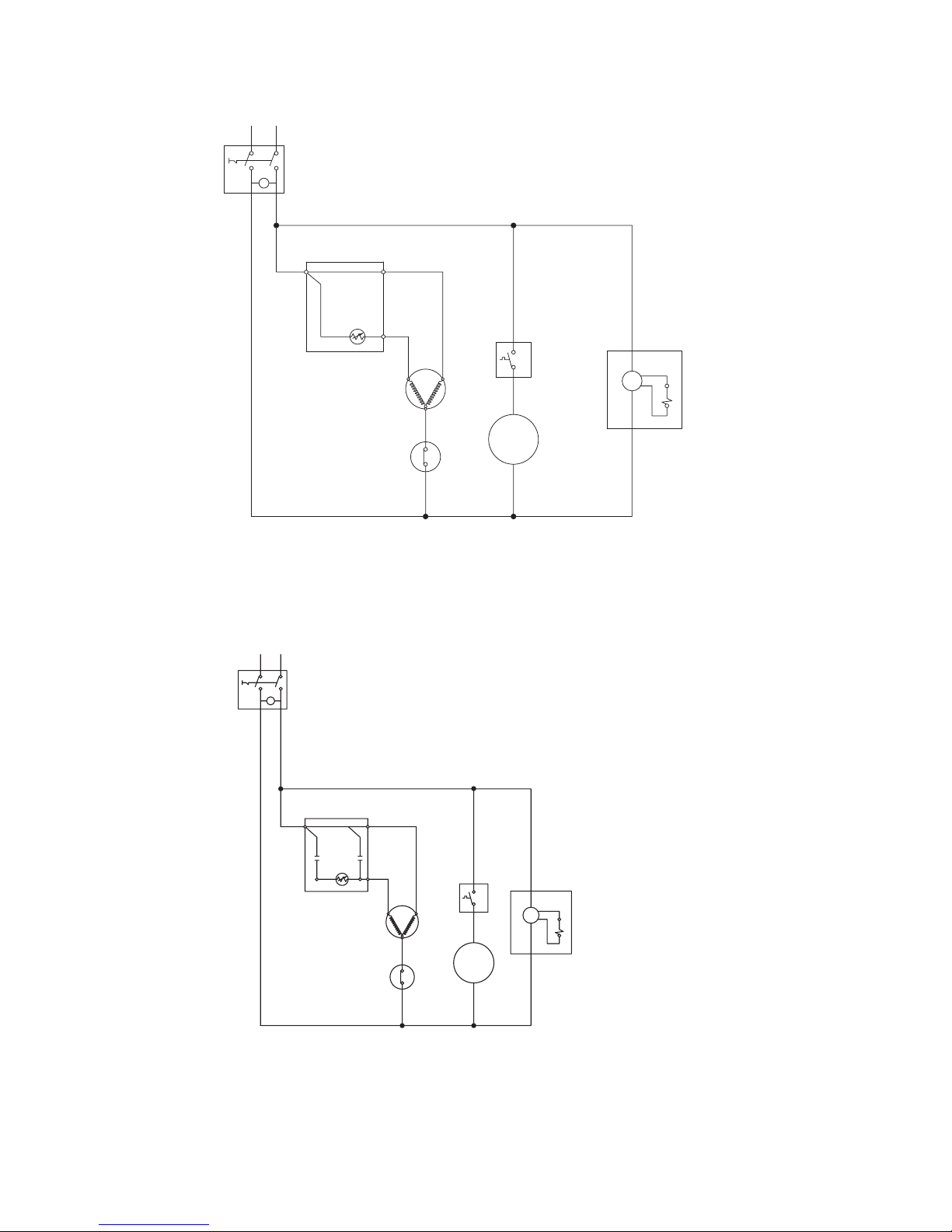

Electrical Connections

ThedryersareconstructedaccordingtoNEMAType1

electrical standards. Field wiring must comply with local and

nationalre,safetyandelectricalcodes.Installationmust

beinaccordancewiththeNationalElectricalCode.Conrm

that your line voltage is the same as the voltage listed on the

dryerdataplate.RefertoFigure1forelectricalschematics.

Operation of dryers with improper line

voltage constitutes abuse and could affect the dryer

warranty.