buttons. Press and hold the DOWN arrow button then press the UP arrow

button. The display will switch to FAN SPD and display HIGH. As soon as the

display reverts to normal operation the fan speed will change to HIGH. To

switch back to LOW fan speed press and hold the UP button and then press

the DOWN arrow the display will switch to FAN SPD LOW and as soon as the

display reverts to normal operation the fan will switch back to the LOW speed.

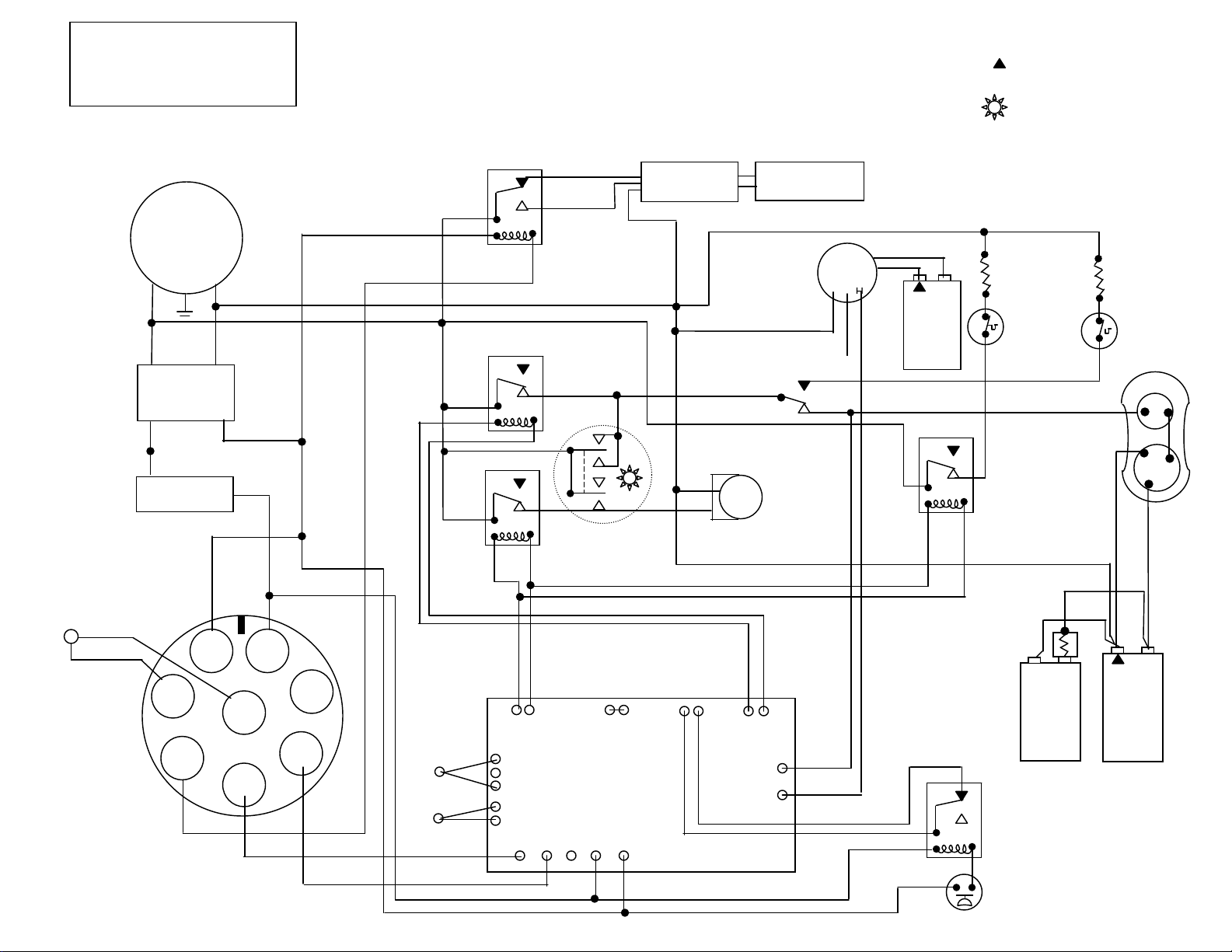

Basic operation of the ECU

Initially pressing the on/off key on the controller, the ECU will start heating

with resistance heat or cooling 5 minutes after power is applied to it and the

asterisk appearing on the display.

On subsequent restarts there is a (5) five-minute delay built into the operating

program to allow the unit to equalize refrigerant pressures before it restarts

again. This is normal operation. This is not adjustable and is a mandatory

period required between cycles to insure that the internal pressures can

equalize before the ECU attempts to start.

The ECU will cycle on and off to maintain the set temperature. During startup

in a warm humid condition it may require a significant amount of time for the

ECU to reach the desired temperature. The ECU will dehumidify the space

first, and then lower the temperature second.

The ECU during it’s heating mode at certain outside temperatures will

develop frost and ice on the outside coils. In order to maintain the optimum

conditions for heating the ECU will automatically go into a defrost mode to

clear the coils. The resistance heater will continue to operate during the

defrost mode. Although the heatpump will not be supplying heat for a short

time and the return air will feel cool to the inside occupants, this is normal and

will only last a short time. Dependant on outside temperatures and conditions

the defrost control is automatically controlled by the freeze sensor located on

the condenser coils and no user intervention is required. This is normal

operation and immediately upon the defrost of the condenser coils the unit will

again go back to normal heating mode and start to supply heat pump heat to

the shelter.

Heating options for ECU Switch position

Normal Operation Cold Weather

AC & Heating R Heat Only

In extreme cold conditions the heatpump will become ineffective in heating

the shelter, the user should then select the cold weather R heat only setting.