Safety instructions

Caution:

The following safety rules must be observed for adequate protection against electric

shocks, injuries or fire hazards:

• The blind riveting tool should be used exclusively to set blind rivets!

• Do not overload the tool; work within the prescribed work capacity.

• Never use the blind riveting tool in a humid or wet environment or close to inflammable

substances or gases. Risk of explosion!

• Ensure that the battery is properly secured in the grip.

• Remove the battery when the blind riveting tool is not in use and for repair/servicing

operations.

• Do not use the blind riveting tool as a hammer.

• When not in use, keep the blind riveting tool in a dry, closed room and out of the reach

of children.

• When working with the tool, always wear protective goggles. Personal protection like

clothes, gloves, safety helmet, non-slip shoes, ear protection and anti-fall protection are

highly recommended.

• The air inlets for the motor should not be obstructed. Do not introduce anything into

them.

• When setting the blind riveting tool down, make sure that it cannot fall.

• Use only genuine spare parts for repair.

• Repair work must be carried out by skilled workers. In case of doubt, always send the

blind riveting tool back to the manufacturer.

• Do not use the tool outside of riveting holes! The blind rivet could be ejected from the

tool! Never turn the tool towards yourself or towards another person!

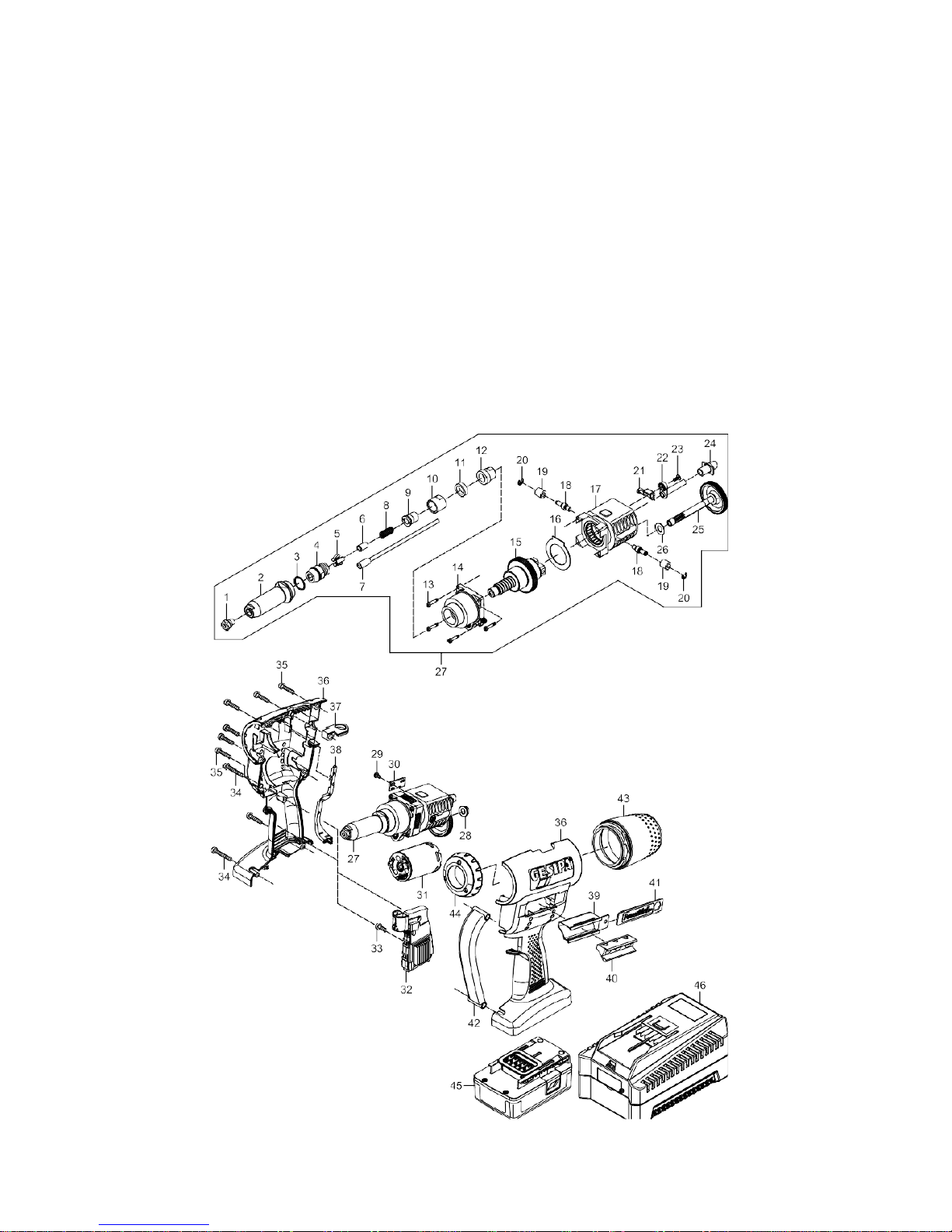

• The mandrel container (n° 39) must be mounted on the blind riveting tool during operation.

Starting procedure

• Insert fully charged battery in correct position into housing.

• Select correct nosepiece according to table 1.4.

• To screw in the nosepiece, activate the switch and proceed until the stop position has

been reached at the back.

• Then remove the battery. Screw in the nosepiece and tighten it using the wrench

provided. Put the battery back in and activate the switch.

Mode of operation

The blind riveting tool features optimized operating speed. After inserting the blind rivet, the

blind riveting tool can be operated in two different modes:

a. Pressing and holding the switch:

Press and hold the switch to start riveting. The pulling process stops automatically when the

rivet reaches the rear end position. The tool automatically assumes the front starting position

when the switch is released.

b. Tapping the switch:

Riveting is triggered by briefly tapping and immediately releasing the switch. As soon as