147220126, No Rev Sheet 8 of 14

Due to variations of depth between various fuel tanks, the draw tube included in this kit (item 14) will have to be cut

to the correct length. If too much length is cut from the draw tube, then the vehicle will prematurely “run out of fuel”

while significant fuel still remains in tank. If the draw tube is too long, then the tube can be crushed upon

installation of the fuel tank.

To derive the correct length to cut from the end of the Draw Tube Kit (item 14), loosen and remove the locking nut

and washer from the Draw Tube Kit (item 14). The remaining rubber grommet and rubber washer should remain

on the Draw Tube Kit. Insert the draw tube into the fuel tank module, until it hits the bottom of the fuel tank module.

SPECIAL NOTE: Some fuel tank modules are spring loaded when inserted in the tank. Fuel tank modules such

as these that can change length, when inserted in the tank. Fuel tank modules in this configuration must

first be dry-fitted into the fuel tank prior to continuing, to ensure that the proper length of the draw tube is

determined. In cases such as this, it is important to remove the fuel from the tank, and support the fuel

tank along the outside of tank (or along straps) during this measurement procedure. This is done so that

the tank’s center is not pushed up during measurement (for higher accuracy).

Once the tube hits the bottom of the fuel tank module, a gap will form between the top of the fuel tank module and

the bottom of the rubber grommet of the Draw Tube Kit. Measure this gap and write it down. Add 1/4” to 3/8” to

this earlier measurement. Cut this calculated length of tube from the plastic tube portion of the Draw Tube Kit (item

14). This cut should be performed at an angle, to prevent the bottom of the fuel tank module from closing off fuel

flow, should the measurement be off, or fuel tank is later dented or tank shape is changed after tank installation.

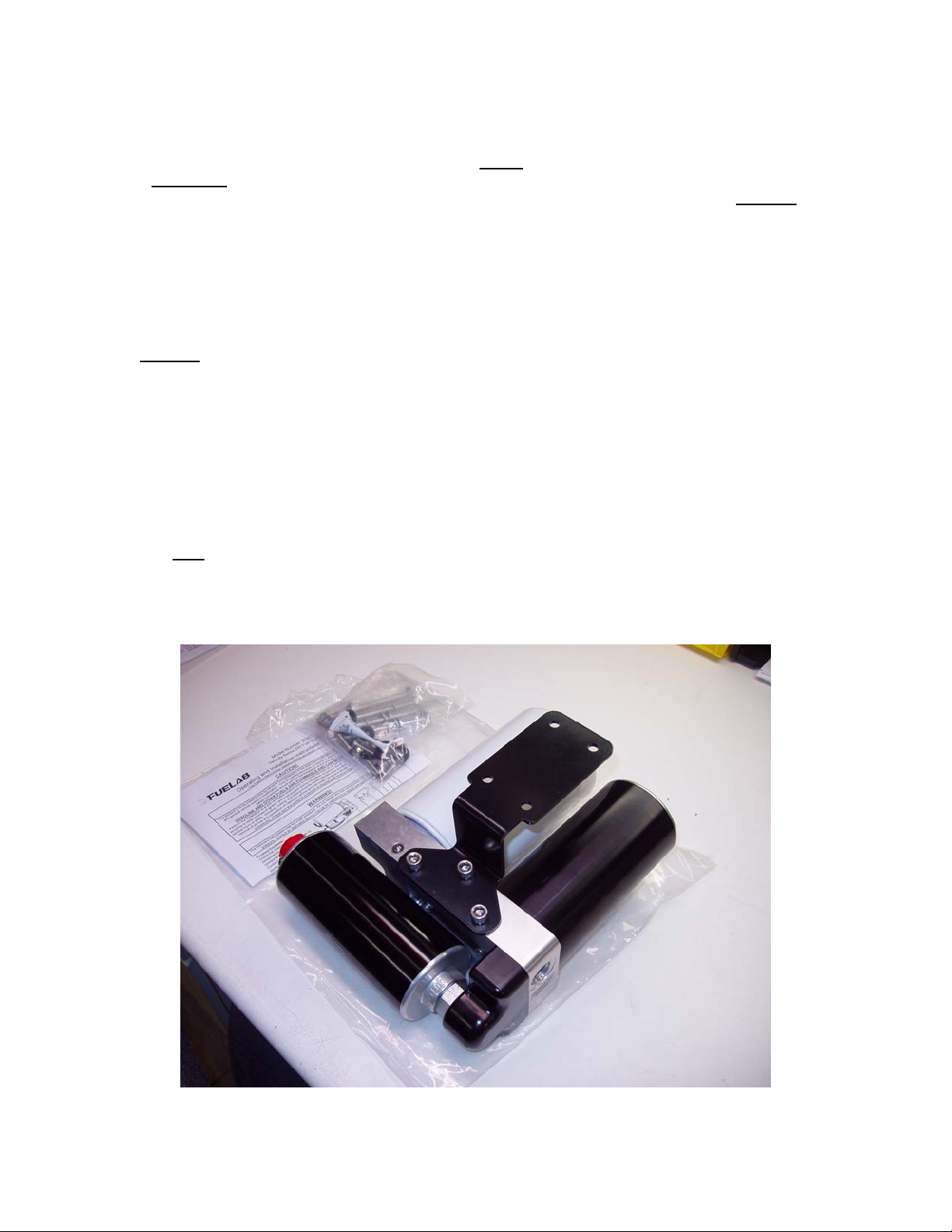

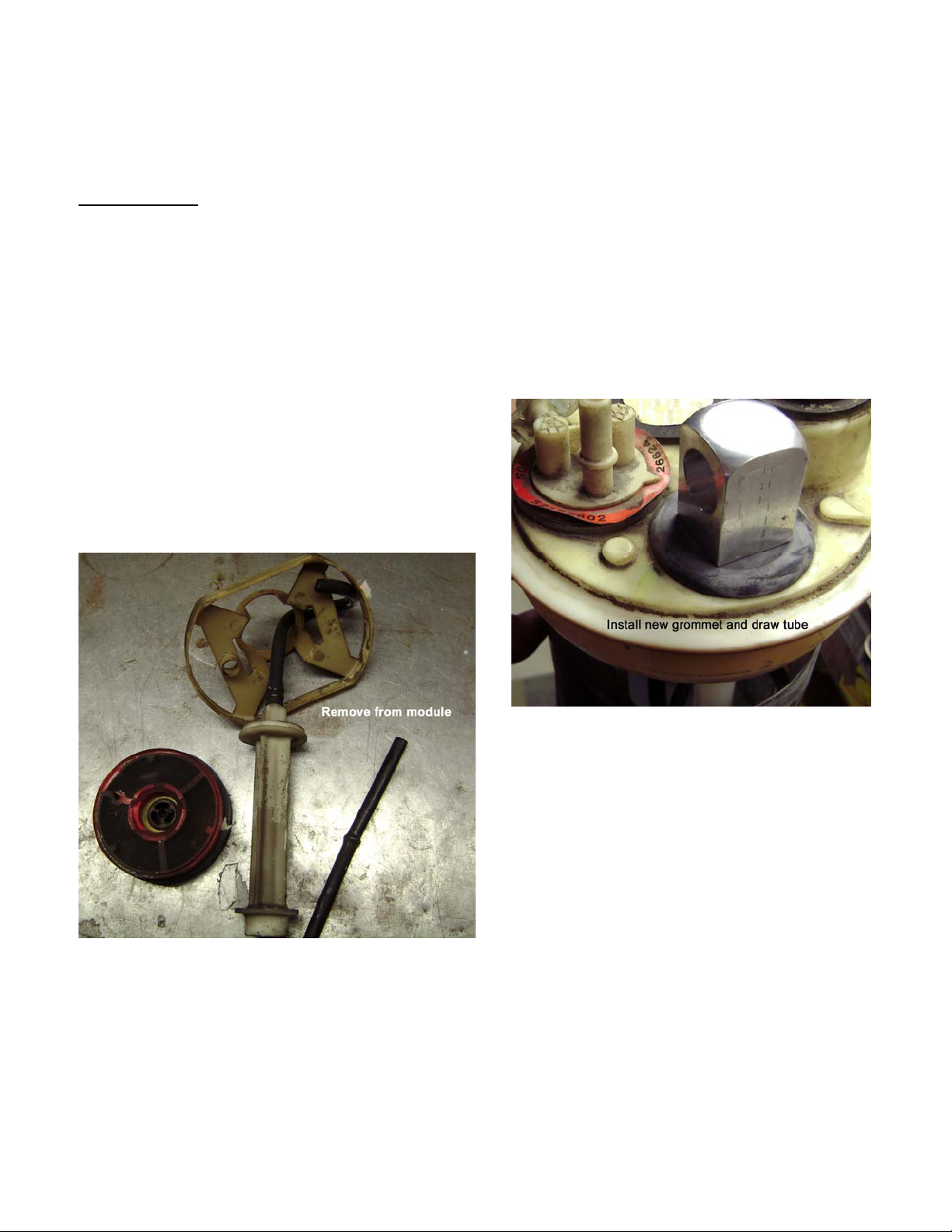

Remove fuel tank module from tank (if applicable) and

reinstall the modified Draw Tube Kit (item 14) back into the

fuel tank module. Re-install the kit washer and locking nut

back onto the threads of the Draw Tube Kit. Orientate the

outlet of the draw tube kit to point toward the same direction

as the original path of fuel lines. Tighten the nut until the

rubber grommet slightly compresses. See photo to right as

example (note: draw tube fitting is not pictured).

Remove and discard the original in-tank fuel pump from

the fuel tank module (if present), and wire tie any wiring

from pump, to secure (wiring of fuel pump is no longer

required, do not short wires together). Wiring is still

required for the fuel tank level sender. Remove other

unneeded components within the fuel tank module as

well including additional straining filters (such as shown

in the photo to the left).

The fuel tank module’s original supply line (from in-tank

pump) is now to be used as the overfill (return) line for

the new Lift Pump / Filtration System. Returning fuel

from the Lift Pump / Filtration System should be

returned below the fuel surface level. This prevents aeration of the fuel that can lead to excessive entrained air

within the fuel that can cause a loss of, or inconsistent fuel pressure.

Use a small section of fuel compatible hose and attach to the bottom of return tube if required. Replacement quick

connect, for the new return line, is included with this Kit (item 8) to attach to the fuel tank module, during fuel tank

re-installation.

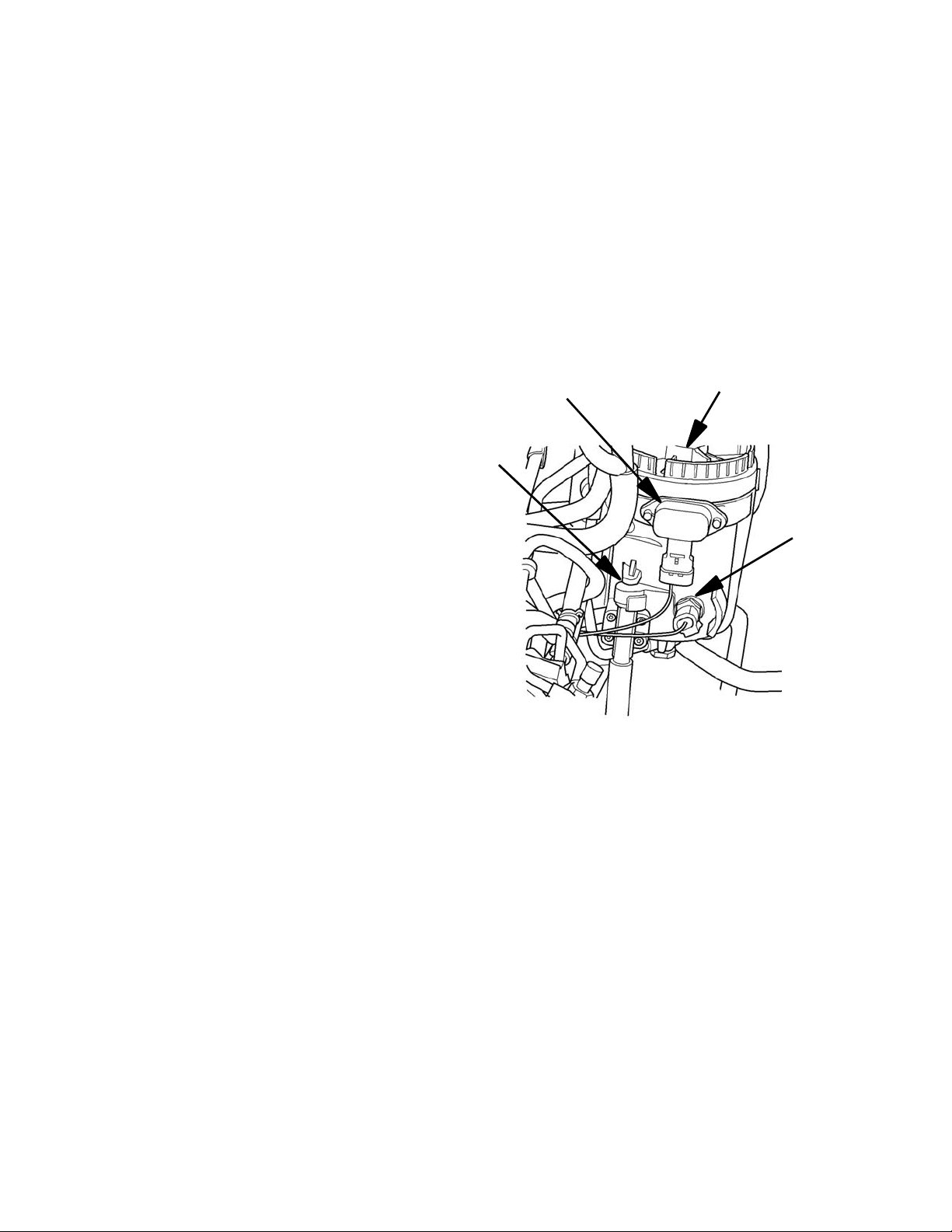

Drill a 1/2” hole in the side of the fuel tank module (as shown in picture). Drill an additional two holes approximately

3/4” in diameter at the bottom of the fuel tank module as shown as well. This step allows adequate fuel flow to

enter the fuel tank module. Deburr all holes drilled and use compressed air to blow out remaining plastic chips

(machining burrs) and loose debris. Take time to double check and clean or wipe the surface of the fuel tank

module that mate against the fuel tank / module seal.