3

2014 Fueltec 950AW & 955SS Manual

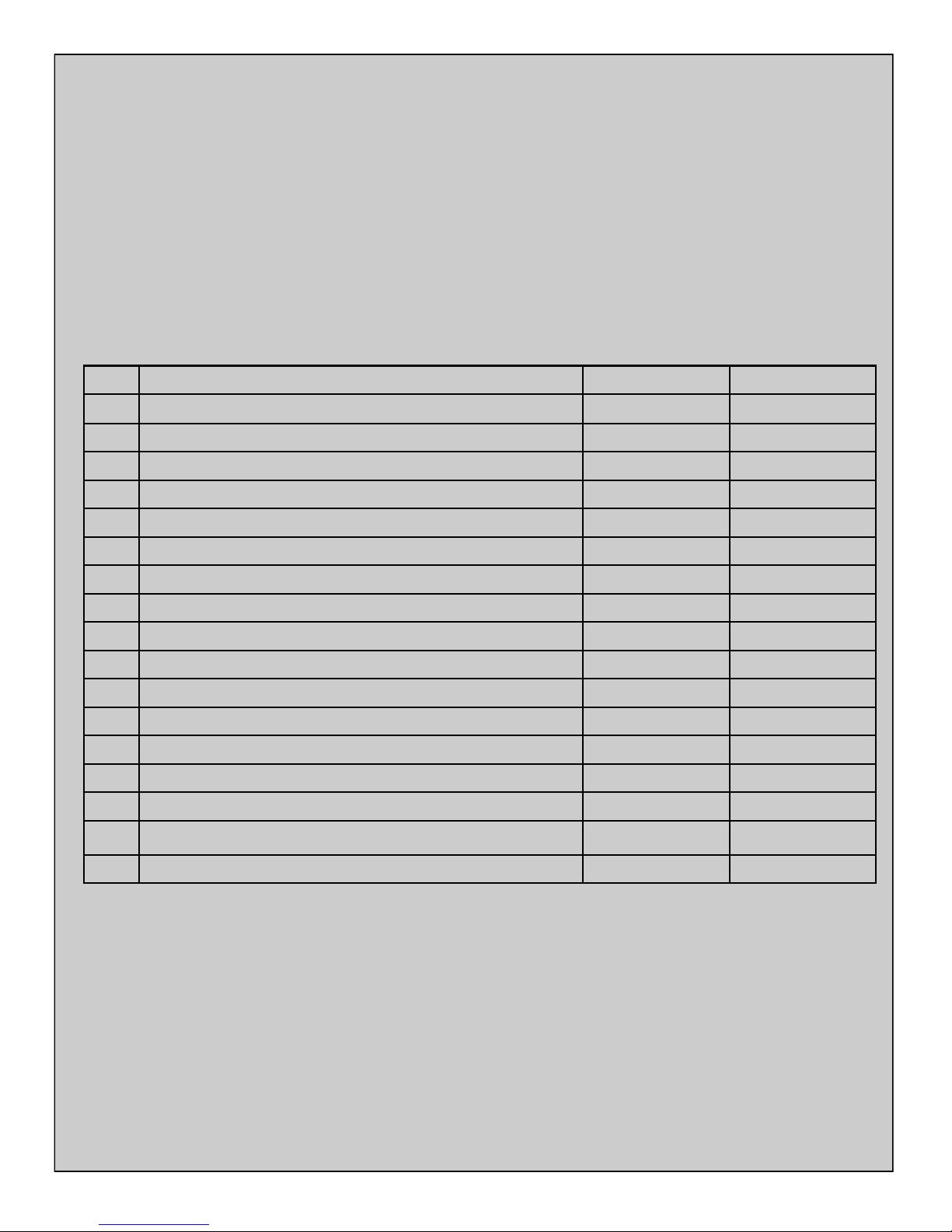

Item SPECIFICATIONS Model 950AW Model 955SS

1Chassis Steel and Aluminum Brite Tread Standard Standard

2Air Diaphragm Fuel Pump flow rate* 0– 720 GPH 0– 2100 GPH

3Compressed Air Required at 40 PSI 10-16 CFM 20-25 CFM

4Maximum Lift wet 22 feet 22 feet

5Primary Stainless Steel Filter Housing 24 inch bag 24 inch bag

6Fuel Pressure Working Max. 40 PSI 40 PSI

7Separated Water Trap Capacity 2 gallons 2 gallons

8Filter/ Coalescer Micro-glass (Mil Type) CF-10 inch CF-20 inch

9Water Separator Teflon coated Stainless Steel S-11 inch S-22 inch

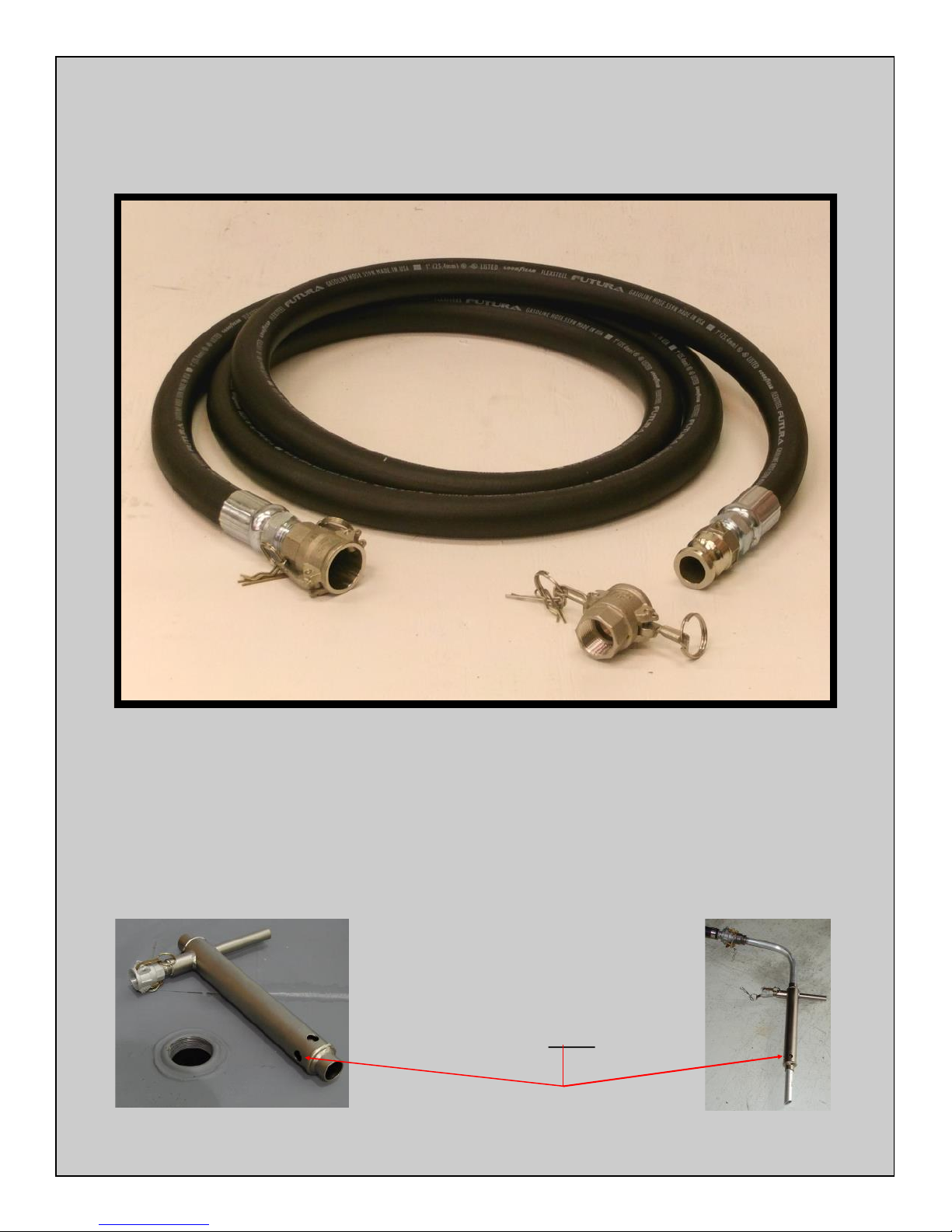

10 Supply & Return Fuel Hose with cam-lock connectors 1 inch X 12 foot 1 inch X 12 foot

11 Separated Water Sight Gauge Standard Standard

12 Swing Bolt Housing Cover for Quick Filter Change Standard Standard

13 Separated Water Drain while System is Running Standard Standard

14 Filter Condition Vacuum Gauge Standard Standard

15 Coalescer Pressure Gauge Standard Standard

16 Air Regulator and Pressure Relief Valve Standard Standard

17 Width X Length X Height.. Lbs. 32x47x60..250lbs. 32x47x61.. 325 lbs.

WARNING: Read carefully and understand all

INSTRUCTIONS before operating. Failure to follow the safety

rules and other basic safety precautions may result in serious

personal injury, or death.

It is important that you read the entire manual to

become familiar with this product before you begin using it.

This machine is designed for certain applications only. FuelTec Systems cannot be

responsible for issues arising from modification. We strongly recommend this machine is not modified and/or used

for any application other than that for which it was designed. If you have any questions relative to a particular appli-

cation, DO NOT use the machine until you have first contacted FuelTec Systems to determine if it can or should be

performed on the product.

* Flow rates may vary with compressed air supply, filter type and condition, length and size of hoses, and

size and shape of fluid pickup and return tubes.

General Safety Regulations

WARNING: Maximum air pressure setting not to exceed forty (40) psi.

WARNING: The warnings, cautions, and instructions discussed in this instruction

manual cannot cover all possible conditions or situations that could occur. It must be

understood by the operator that common sense and caution are factors which cannot be built into this product,

but must be supplied by the operator.