2

1.Safety requirements: Warning

1.1 The maximum permissible ambient and air temperature at the intake is + 40°c.

1.2 All the works of transportation, installation, maintenance and trouble shooting must

be executed by a responsible, qualified personnel.

1.3 This device must be set up according to this instruction manual.

1.4 The grounding wire must be connected well accordingly.

1.5 The lead wires as a conductor to the power supply should be properly sized and have

strain relief to the wires at the connection terminals. If this is failed , electric shock and

fire will be possible.

1.6 While rotating , human body must be kept away from the rotating portions such as

the cooling fan and do not reach into the device through the intake or outlet.

1.7 Once the power electricity was interrupted , the power switch must be turned Off

immediately .

1.8 If the device does not reach its rated speed in 6 seconds from the power switch

turned on , please turn off the power immediately and check it carefully.

1.9 The power supply must be turned off before moving, maintaining , or repairing this

device. Please note that , due to rotating inertia, the device may continue running

several minutes after power turned off .

1.10 These devices are only used to handle or convey dust-free air, non-combustible,

non-corrosive and non-explosive gases, vapors.

1.11 The intake must be properly sited and covered so that no dirt or solid particles can

be sucked in .

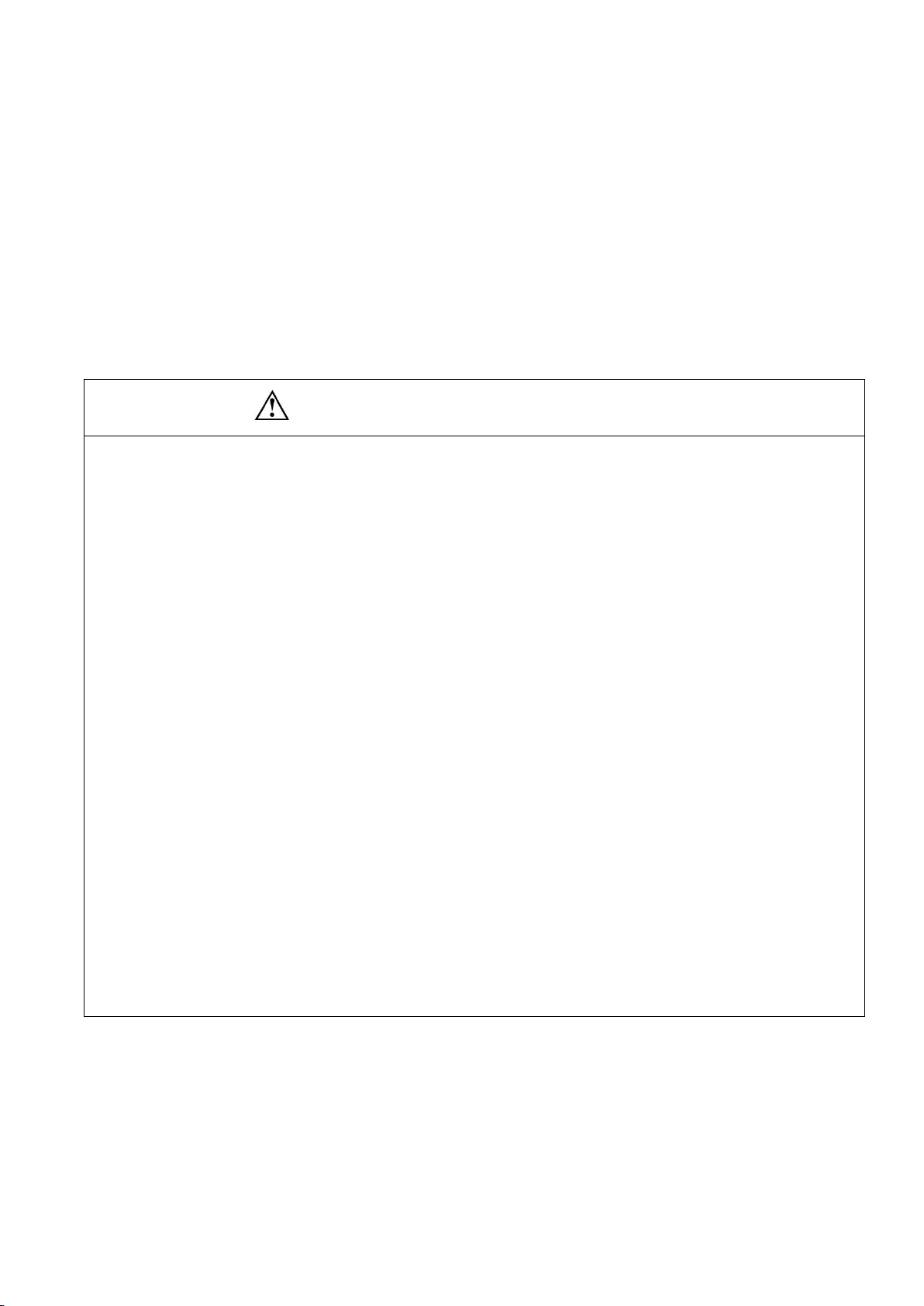

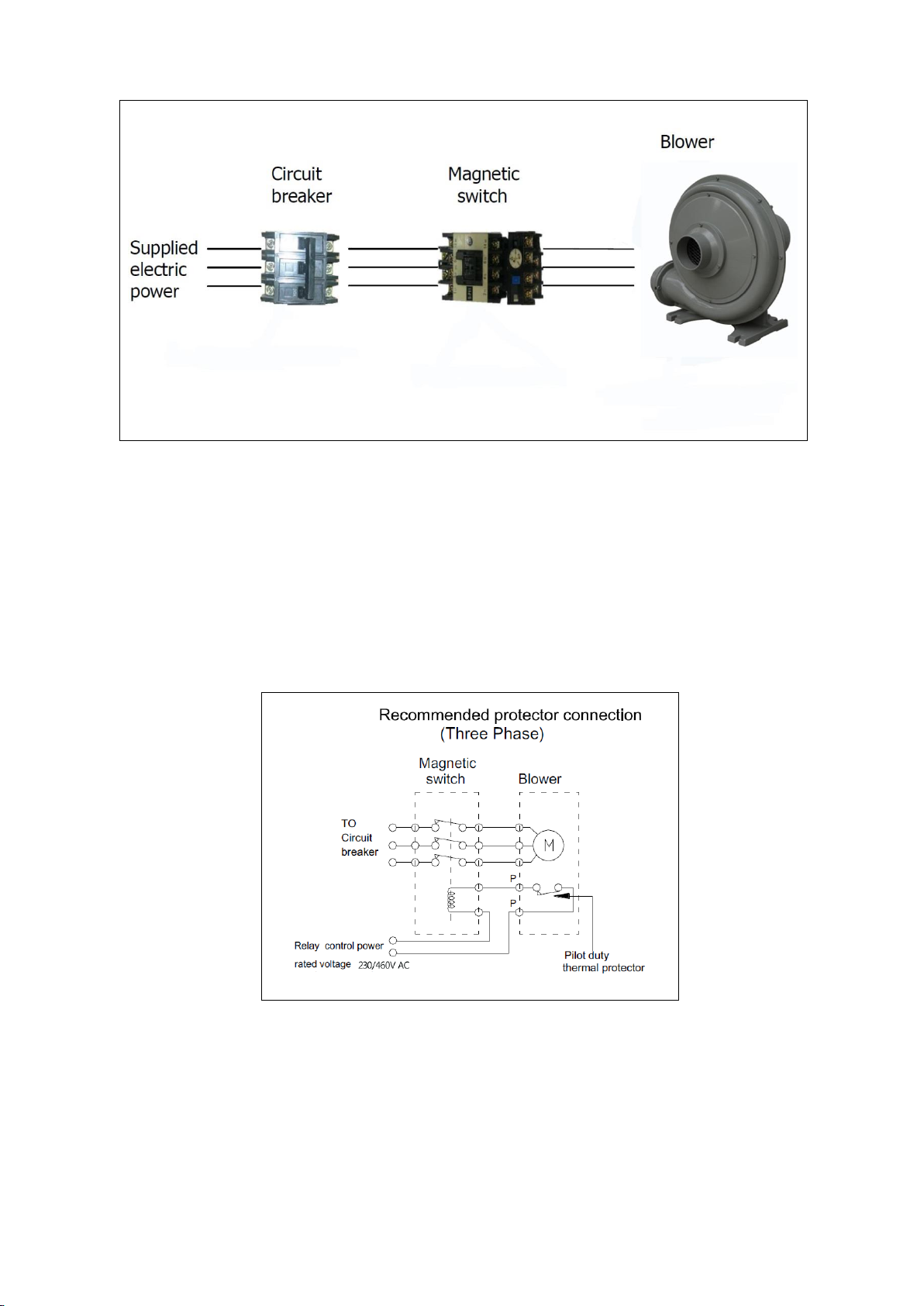

1.12 Pilot type of thermal protector is provided. This protector should be externally

connected with a magnetic switch which is used to control the power imput ON/OFF.

1.13 This device is designed for continuous operation , in case of non-continuous

running or high ambient temperature, checking suitability(maximum permissible

temperature)with the representatives of manufacturer.