– 5 –

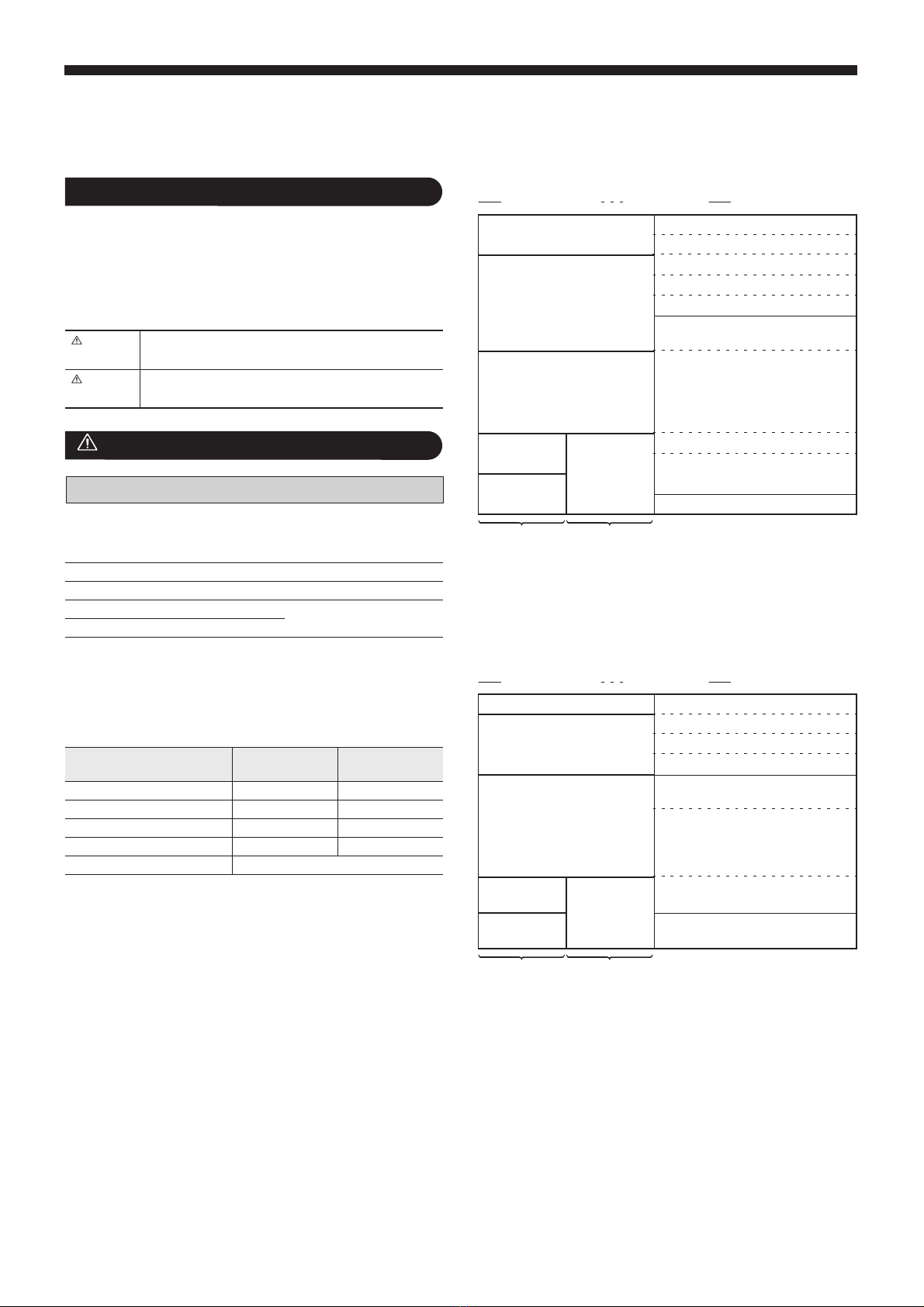

PV start................................................................................ 61

Setting PV Start ............................................................... 61

Continue mode .................................................................... 61

Setting the Continue Mode............................................... 61

Setting the Max Pattern Selection,

Setting the Min Pattern Selection ........................................ 62

Selecting a Maximum/Minimum Number of Patterns ....... 62

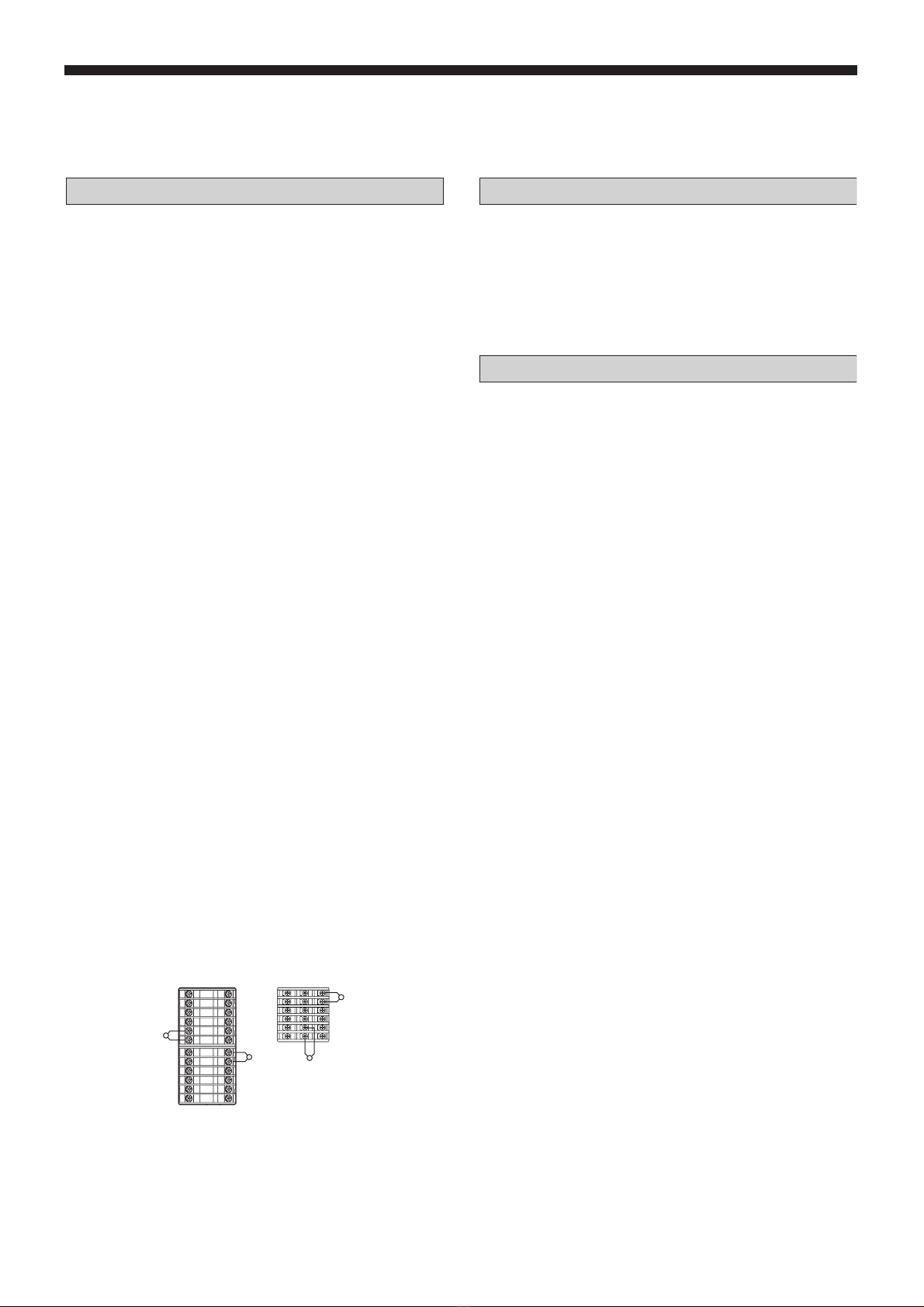

7. Monitor Parameters (Ch5)

Overview of Monitor Parameters (Ch5) ............................... 64

Ramp/Soak Operation Display ............................................ 65

Checking the State of Ramp/Soak................................... 65

Control Output Display ........................................................ 65

Checking the Control Output Display ............................... 65

PFB Input Value Display ......................................................66

Checking the PFB Input Value Display............................. 66

Remote SV (RSV) Input Display.......................................... 66

Checking the Remote SV Input Value .............................. 66

Heater Current Display ........................................................ 67

Checking the value for Heater current.............................. 67

Leak current Display............................................................67

Checking the value for Leak current................................ 67

Remaining Time on Timer ................................................... 68

Checking the Time Remaining on Timer .......................... 68

Error Source Display ........................................................... 68

Checking the Error Source............................................... 68

Current palette No. .............................................................. 69

Checking the Palette No................................................... 69

Current pattern No............................................................... 69

Checking the Pattern No. ................................................. 69

8. Setup Parameters (Ch6)

Overview of Setup Parameters (Ch6).................................. 72

PV Input Types..................................................................... 74

Setting the PV Input Type................................................. 74

PV Input Lower Limit, PV Input Upper Limit ........................ 75

Setting PV Input Upper/Lower Limits ............................... 75

Decimal Place ..................................................................... 75

Setting the Decimal Place................................................ 75

PV Input Shift ...................................................................... 76

Setting PV Input Shift....................................................... 76

SV Offset ............................................................................. 76

Setting SV Shift................................................................ 76

PV Input Filter...................................................................... 77

Setting the PV Input Filter ................................................ 77

PV Display Zero Adjustment,

PV Display Span Adjustment............................................... 78

Setting PV Display Zero/Span.......................................... 78

Cold Junction Compensation............................................... 79

Setting Cold Junction Compensation............................... 79

Remote SV Zero Adjustment,

Remote SV Span Adjustment.............................................. 80

Adjusting Remote SV Zero/Span......................................80

Remote SV Input Range......................................................81

Setting the Remote SV Input Range ................................81

Remote SV Input Filter.........................................................82

Setting the Remote SV Filter ............................................82

OUT1 Range, OUT2 Range.................................................83

Setting the OUT1/OUT2 Range........................................83

FALT OUT1 Value, FALT OUT2 Value ..................................83

Setting FALT OUT1/OUT2 ................................................83

Soft Start OUT1 Output, Soft Start Time .............................84

Setting Soft Start OUT1 Output/OUT1 Time ....................84

Standby OUT1 Output, Standby OUT2 Output....................85

Setting Standby Mode OUT1/OUT2 Output .....................85

Standby Mode Settings........................................................85

Setting Standby Mode Output ..........................................85

AO Output Type....................................................................86

Setting AO Output Type ....................................................86

AO Lower Limit Scaling, AO Upper Limit Scaling ................87

Setting AO Upper/Lower Limit Scaling .............................87

9. System Parameters (Ch7)

Overview of System Parameters (Ch7)................................90

USER Key Assignments ......................................................93

Setting USER Key Assignments.......................................93

DI Function Select................................................................94

Selecting DI Function .......................................................94

DO Event Type .....................................................................96

Setting DO Option Functions............................................97

DO Option Functions ...........................................................98

Setting DO Option Functions............................................98

Ramp SV ON/OFF, Ramp SV decline, Ramp SV incline,

Ramp SV slope time unit .....................................................99

Setting Ramp SV..............................................................99

SV Display Mode ...............................................................100

Setting the SV Display Mode..........................................100

Control Method ..................................................................101

ON/OFF (2 setting) control .............................................101

Reverse Operation (Heating) ......................................101

Normal Operation (Cooling) ........................................101

PID Control .....................................................................102

Setting PID Control .....................................................102

Fuzzy PID Control ..........................................................102

Changing to Fuzzy PID Control...................................102

Self-tuning Control..........................................................103

Conditions where self-tuning can be used ..................103

Conditions where self-tuning cannot be used .............103

Conditions to halt self-tuning.......................................103

Setting Self-Tuning ......................................................104

About Self-Tuning Methods.........................................104

PID2 Control ...................................................................106

Changing to PID2 Control ...........................................106

Auto-tuning .....................................................................107