Hayes Endeavor 81770 User manual

Electronic Brake Controller

Hayes Brake Controller Company P/N 81770

INSTALLATION MANUAL

For trailers with 2-8 electric brakes and vehicles with 12 volt negative ground systems only.

READ AND SAVE THESE INSTRUCTIONS

•Before beginning installation, read and become familiar with these instructions.

•Leave in tow vehicle for future reference.

•IMPROPER INSTALLATION AND OPERATION COULD CAUSE PERSONAL INJURY

AND/OR EQUIPMENT AND PROPERTY DAMAGE.

•Questions on installation, adjustment, trouble shooting, or operation of brake controllers

•Call 800-892-2676 Monday through Friday between 8:00 a.m. and 5 p.m. Eastern Time.

SAFETY INFORMATION

!

!

WARNING: Indicates a potentially hazardous situation that,

if not avoided, could result in death or serious, personal injury.

CAUTION: Indicates a potentially hazardous situation that,

if not avoided, could result in damage to product or property.

TIP: Contains helpful information to facilitate installation.

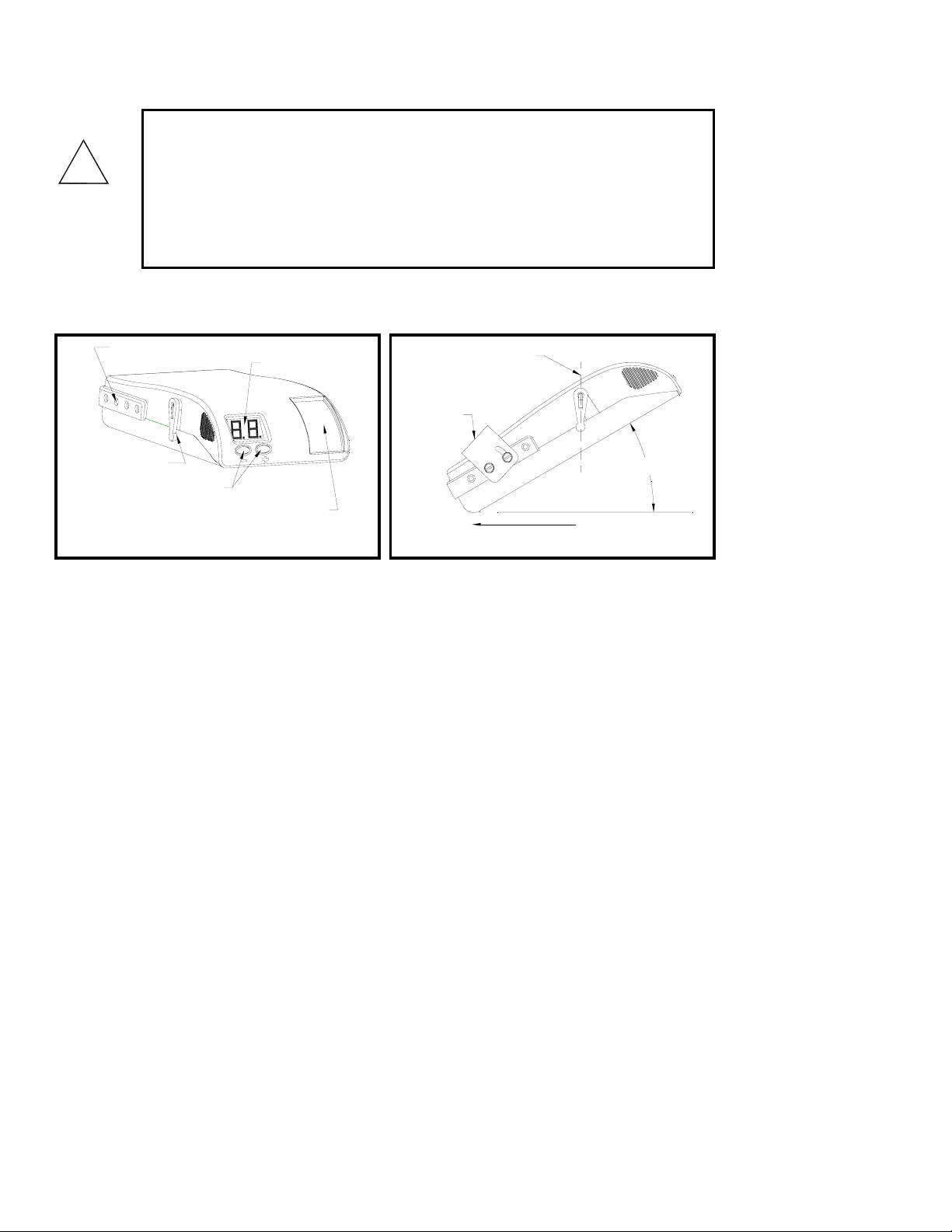

Installation

-35° to 90°

MOUNTING

BRACKET

PENDULUM ARM

STRAIGHT DOWN

FRONT OF VEHICLE

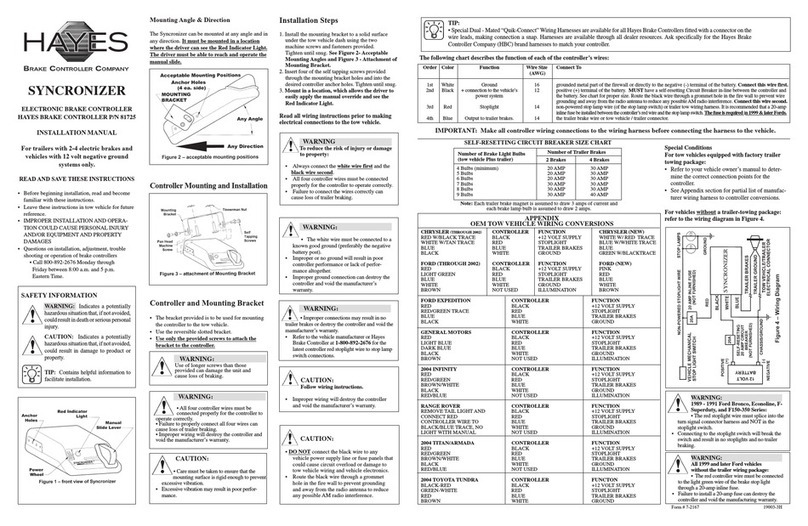

Figure 2 –

Acceptable Mounting Angles

SETUP / ADJUSTMENT

BUTTONS MANUAL OVERRIDE

SLIDE LEVER

DIGITAL

DISPLAY

ANCHOR HOLES

FOR MOUNTING

PENDULUM

LEVEL

ADJUSTMENT ARM

Fi

g

ure 1 – Front view of Endeavor

CAUTION:

•In the automatic mode and minimum power setting at 10, noticeable braking

is applied only when the sensor detects deceleration.

•With the vehicle at rest and the brake pedal depressed, there should be only

a slight output to the trailer brakes (when minimum power is set to 10).

•Higher at rest outputs and reverse braking can be obtained by increasing the

minimum power setting.

!

- 3 -

Mounting Angle

Mounting angles between –35 and + 90 degrees can be accommodated by the controller. THE UNIT

MUST, HOWEVER, BE INSTALLED SO THAT IT IS PARALLEL WITH THE TRAVEL OF THE TOW

VEHICLE AND TRAILER.

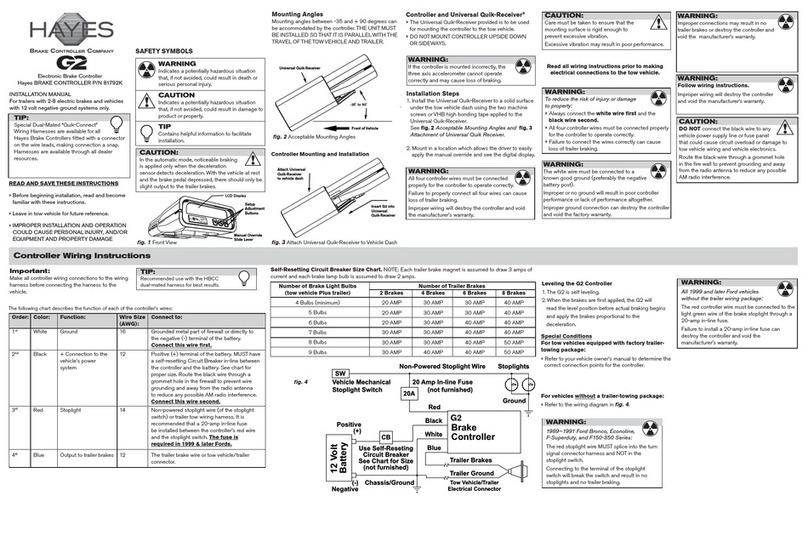

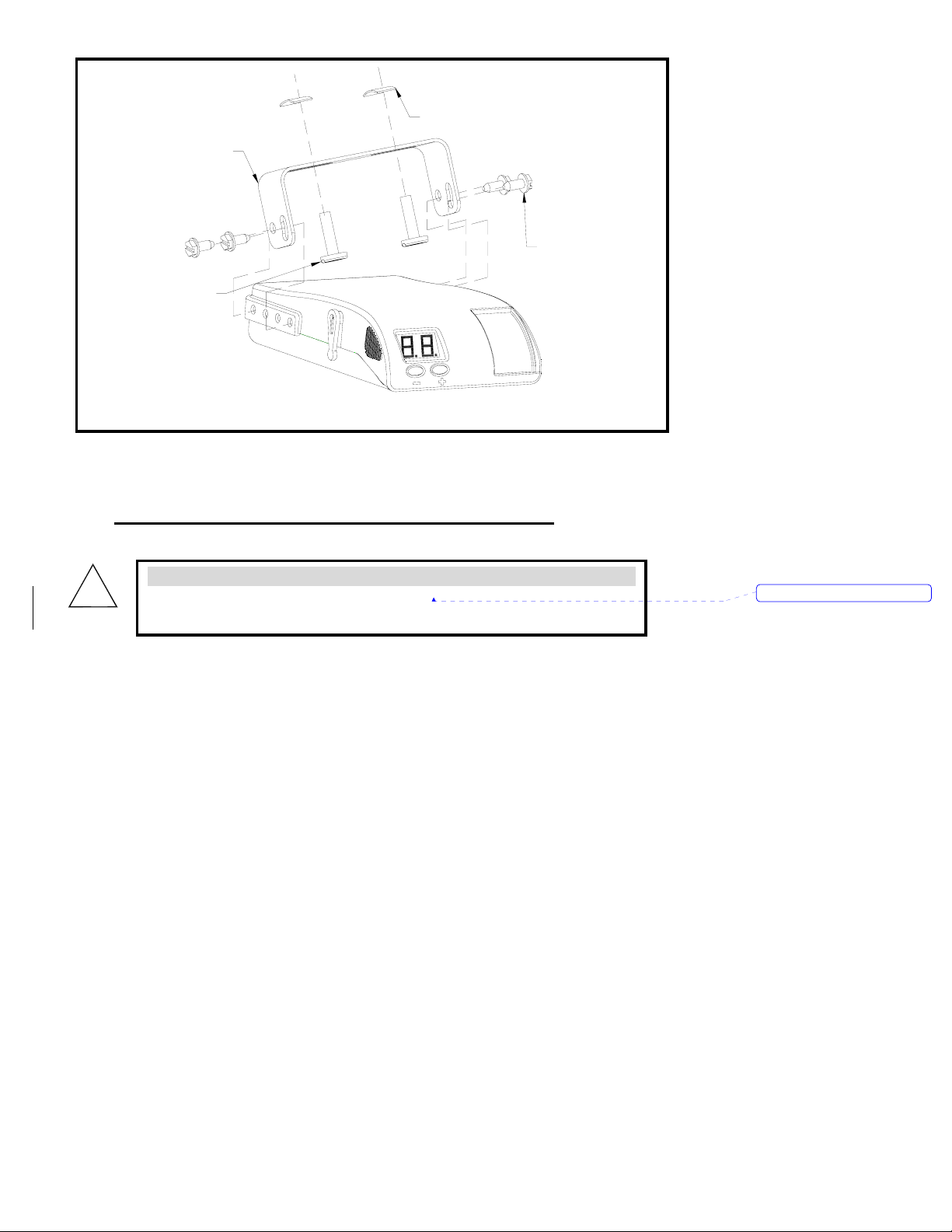

Controller Mounting & Installation

Controller and Bracket Mounting

•The bracket provided is to be used for mounting the controller to the tow vehicle.

•Use the reversible slotted bracket.

•DO NOT MOUNT CONTROLLER UPSIDE DOWN OR SIDEWAYS.

Mounting

Bracket

Pan Head

Machine Screw

Tinnerman

Nut

Self Tapping

Screws

Figure 3 – Attachment of Mounting Bracket

WARNING:

•If the controller is mounted incorrectly, the pendulum cannot operate

correctly and may cause loss of braking.

!Formatted: Font: (Default) Arial

Installation Steps

1. Install the mounting bracket to a solid surface under the tow vehicle dash using the two

machine screws and fasteners provided. Tighten until snug. See Figure 3 – Attachment

of Mounting Bracket.

2. Insert four of the self tapping screws provided through the mounting bracket holes and into

the desired controller anchor holes. Tighten until snug.

3. Mount in a location which allows the driver to easily apply the manual override slide

lever and see the digital display.

WARNING:

•All four controller wires must be connected properly for the controller to

operate correctly.

•Failure to properly connect all four wires can cause loss of trailer braking.

•Improper wiring will destroy the controller and void the manufacturer’s

warranty.

WARNING:

•Use of longer screws than those provided can damage the unit and cause

loss of braking.

CAUTION:

•Care must be taken to ensure that the mounting surface is rigid enough to

prevent excessive vibration.

•Excessive vibration may result in poor performance.

!

!

!

Formatted: Font: (Default) Arial

Formatted: Font: (Default) Arial

Read ALL wiring instructions prior to making electrical connections to the tow

vehicle.

WARNING:

Follow wiring instructions.

•Improper wiring will destroy the controller and void the manufacturer’s warranty.

!

WARNING:

To reduce the risk of injury or damage to property:

•Always connect the white wire first and the black wire second.

•All four controller wires must be connected properly for the controller to operate

correctly.

•Failure to connect the wires correctly can cause loss of trailer braking.

!

WARNING:

•The white wire must be connected to a known good ground (preferably the negative

battery post).

•Improper or no ground will result in poor controller performance or lack of

performance altogether.

•Improper ground connection can destroy the controller and void the manufacturer’s

warranty.

!

WARNING:

•Improper connections may result in no trailer brakes or destroy the controller and

void the manufacturer’s warranty.

•Refer to the vehicle manufacturer or to Hayes Lemmerz (800-892-2676) for the

latest controller red stoplight wire to stop lamp switch connections.

!

CAUTION:

•DO NOT connect the black wire to any vehicle power supply line or fuse panel that

could cause circuit overload or damage to tow vehicle wiring and vehicle

electronics.

•Route the black wire through a grommet hole in the fire wall to prevent wire

grounding and away from the radio antenna to reduce any possible AM radio

interference.

!

Controller Wiring Instructions

The following chart describes the function of each of the controller’s wires:

IMPORTANT: Make all controller wiring connections to the wiring harness before connecting the

harness to the vehicle.

Order Color Function Wire

Size

(AWG)

Connect To

1st White Ground 16 grounded metal part of the firewall or directly to the

negative (-) terminal of the battery. Connect this

wire first.

2nd

Black + connection

to the

vehicle’s

power system

12 positive (+) terminal of the battery. MUST have a

self-resetting Circuit Breaker in-line between the

controller and the battery. See chart for proper size.

Route the black wire through a grommet hole in the

fire wall to prevent wire grounding and away from the

radio antenna to reduce any possible AM radio

interference. Connect this wire second.

3rd Red Stoplight 14 non-powered stop lamp wire (of the stop lamp switch)

or trailer tow wiring harness. It is recommended that

a 20-amp inline fuse be installed between the

controller’s red wire and the stop lamp switch. The

fuse is required in 1999 & later Fords.

4th Blue Output to

trailer brakes 12 the trailer brake wire or tow vehicle / trailer connector.

SELF-RESETTING CIRCUIT BREAKER

SIZE CHART

Number of Trailer Brakes

Number of Brake Light

Bulbs (tow vehicle Plus

trailer) 2 Brakes 4 Brakes 6 Brakes 8 Brakes

4 Bulbs (minimum) 20 AMP 30 AMP 30 AMP 40 AMP

5 Bulbs 20 AMP 30 AMP 30 AMP 40 AMP

6 Bulbs 20 AMP 30 AMP 40 AMP 40 AMP

7 Bulbs 30 AMP 30 AMP 40 AMP 40 AMP

8 Bulbs 30 AMP 30 AMP 40 AMP 50 AMP

9 Bulbs 30 AMP 40 AMP 40 AMP 50 AMP

Note: Each trailer brake magnet is assumed to draw 3 amps of current and

each brake lamp bulb is assumed to draw 2 amps.

TIP:

•Special Dual-Mated “Quik ConnectTM” Wiring Harnesses are available for all Hayes

Brake Controllers fitted with a connector on the wire leads, making connection a

snap. Harnesses are available through all dealer resources. Ask specifically for the

Ha

y

es Brake Controller Com

p

an

y

(

HBC

)

brand harnesses to match

y

our controller.

Special Conditions

For tow vehicles equipped with factory trailer towing package;

•Refer to your vehicle’s owner’s manual or other information provided by the manufacturer in

determining the correct connection points for the controller.

•See Appendix section for partial list of manufacturer wiring harness to controller conversions.

For vehicles without a trailer-towing package: refer to the wiring diagram in Figure 4.

Figure 4 – Wiring Diagram

WARNING:

All 1999 and later Ford vehicles without the trailer wiring package:

•The red controller wire must be connected to the light green wire of the brake

stop lamp through a 20-amp inline fuse.

•Failure to install a 20-amp inline fuse can destroy the controller and void the

manufacturing warranty.

!

WARNING:

1989-1991 Ford Bronco, Econoline, F-Superduty, and F150-350 Series:

•The red stoplight wire MUST splice into the turn signal connector harness and

NOT to the stoplight switch.

•Connecting to the terminal of the stoplight switch will break the switch and result

in no stoplights and no trailer braking.

!

Appendix

OEM TOW VEHICLE WIRING CONVERSION

CHRYSLER (THROUGH 2002) CONTROLLER FUNCTION CHRYSLER (NEW)

RED W/BLACK TRACE BLACK +12 VOLT SUPPLY WHITE WITH RED TRACE

WHITE W/TAN TRACE RED STOPLIGHT BLUE WITH WHITE TRACE

BLUE BLUE TRAILER BRAKES BLUE

BLACK WHITE GROUND GREEN WITH BLACK TRACE

FORD (THROUGH 2002) CONTROLLER FUNCTION FORD (NEW)

RED BLACK +12 VOLT SUPPLY PINK

LIGHT GREEN RED STOPLIGHT RED

BLUE BLUE TRAILER BRAKES BLUE

WHITE WHITE GROUND WHITE

BROWN NOT USED ILLUMINATION BROWN

FORD EXPEDITION CONTROLLER FUNCTION

RED BLACK +12 VOLT SUPPLY

RED/GREEN TRACE RED STOPLIGHT

BLUE BLUE TRAILER BRAKES

BLACK WHITE GROUND

GENERAL MOTORS CONTROLLER FUNCTION

RED BLACK +12 VOLT SUPPLY

LIGHT BLUE RED STOPLIGHT

DARK BLUE BLUE TRAILER BRAKES

BLACK WHITE GROUND

BROWN NOT USED ILLUMINATION

2004 INFINITY CONTROLLER FUNCTION

RED BLACK +12 VOLT SUPPLY

RED/GREEN RED STOPLIGHT

BROWN/WHITE BLUE TRAILER BRAKES

BLACK WHITE GROUND

RED/BLUE NOT USED ILLUMINATION

RANGE ROVER CONTROLLER FUNCTION

REMOVE TAIL LIGHT & BLACK +12 VOLT SUPPLY

CONNECT RED RED STOPLIGHT

CONTROLLER WIRE TO BLUE TRAILER BRAKES

BLACK/BLUE TRACE, NO WHITE GROUND

LIGHT WITH MANUAL NOT USED ILLUMINATION

2004 TITAN/ARMADA CONTROLLER FUNCTION

RED BLACK +12 VOLT SUPPLY

RED/GREEN RED STOPLIGHT

BROWN/WHITE BLUE TRAILER BRAKES

BLACK WHITE GROUND

RED/BLUE NOT USED ILLUMINATION

2004 TOYOTA TUNDRA CONTROLLER FUNCTON

BLACK-RED BLACK +12 VOLT SUPPLY

GREEN-WHITE RED STOPLIGHT

RED BLUE TRAILER BRAKES

BROWN WHITE GROUND

Form7-2170 19083-3@B

Table of contents

Other Hayes Controllers manuals

Popular Controllers manuals by other brands

Kelly

Kelly KLS14801-8080N user manual

Siemens

Siemens LMV51 Series Basic documentation

HP

HP Compaq Presario,Presario 4400 Assembly Replacement Instructions

Smartgen

Smartgen HAT220A operating manual

Power Electronics

Power Electronics VS65 Series Hardware and installation manual

Bosch

Bosch BAT 250 Original instructions

Beckhoff

Beckhoff C6930 Installation and operating instructions

CKD

CKD AX1R Series instruction manual

Resol

Resol DeltaSol MX Manual for the specialised craftsman

Johnson Controls

Johnson Controls M9316-A Z Series installation instructions

Intiel

Intiel Dynamic Boiler Controller user manual

FUJIDENZO

FUJIDENZO FVR-2000SC Operation manual