4

surface, and a plumb upward laser and a down point, it has a vertical

surface and horizontal beam.

2. It can speed adjusting, stop rotating, move left or right step

by step, or directional scanning and slope setting.

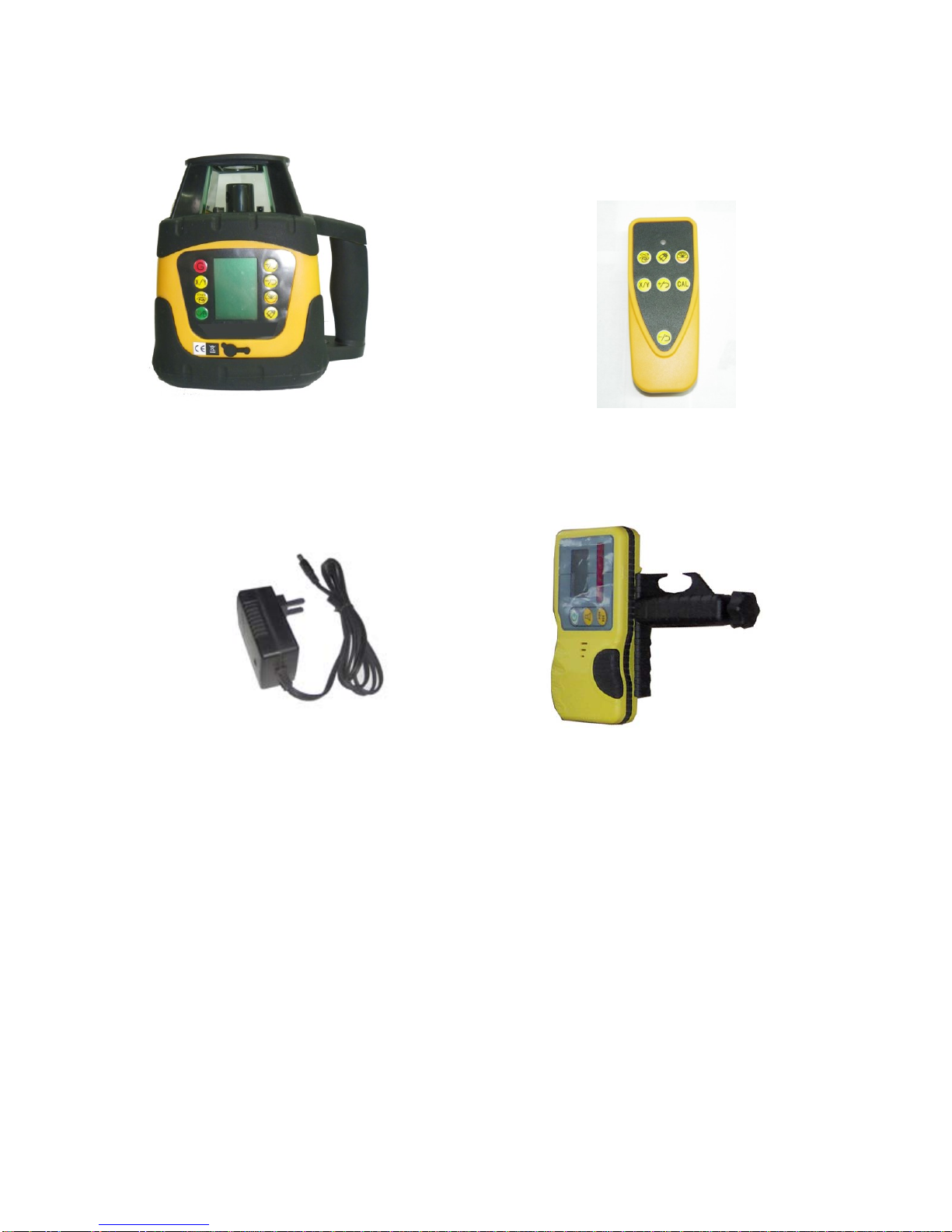

3. It can match with detector FRD100, and get the position of laser

beam from the indict line of the detector.

1.2 Panel function and utility

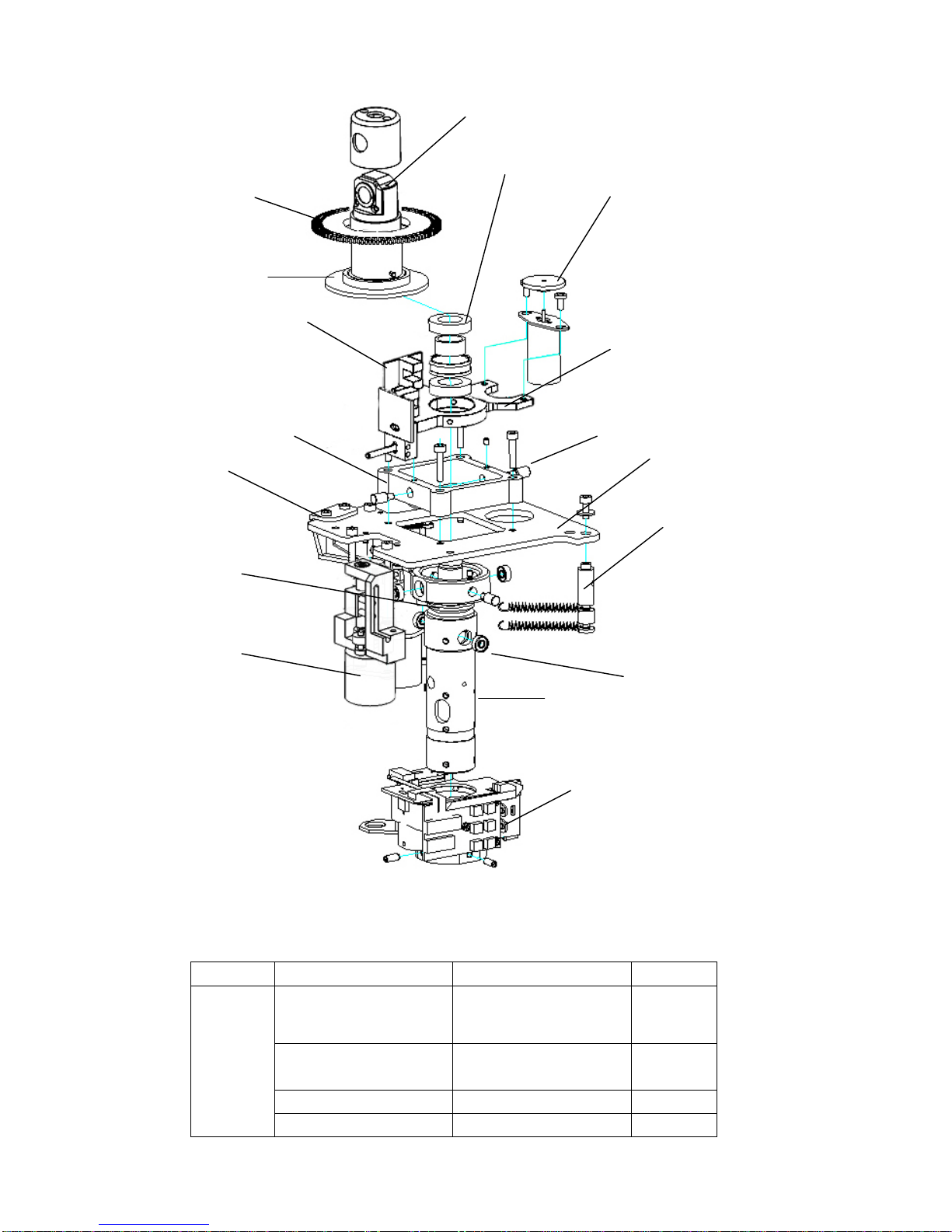

(1)ON/OFF/Manual: Control the state of ON/OFF, it will have display on

LCD about leveling and the power, press 3 seconds enter onto Manual

function; there will be a hand icon.

(2)Speed up: recyclable, it will display the on LED. It has 5 steps: 0

-60-120-300-600 r.p.m

(3)Direction scanning: recyclable, the angle will be display on LED,5

steps from 0-10°-45°-90°-180°

(4)Slope setting: Can switch the laser unit between manual mode and

self-leveling mode. There is a triangle icon on LED.

(5)+/left spining: It adjusts the slope when in slope setting mode and

it will be display on the LED. It can control the laser head move

anti-clockwise step by step when laser head is stopping or direction

scanning in self-leveling mode.

(6)-/right spinning: It adjust the slope when in slope setting mode, and

also display on the LED. It can control the laser head move clockwise

step by step when laser head is stopping or direction scanning in

self-leveling mode.