Safety Warning:

Looking for financing or eager to buy, contact Sales:

Need help, visit us at our Help Center or contact Support:

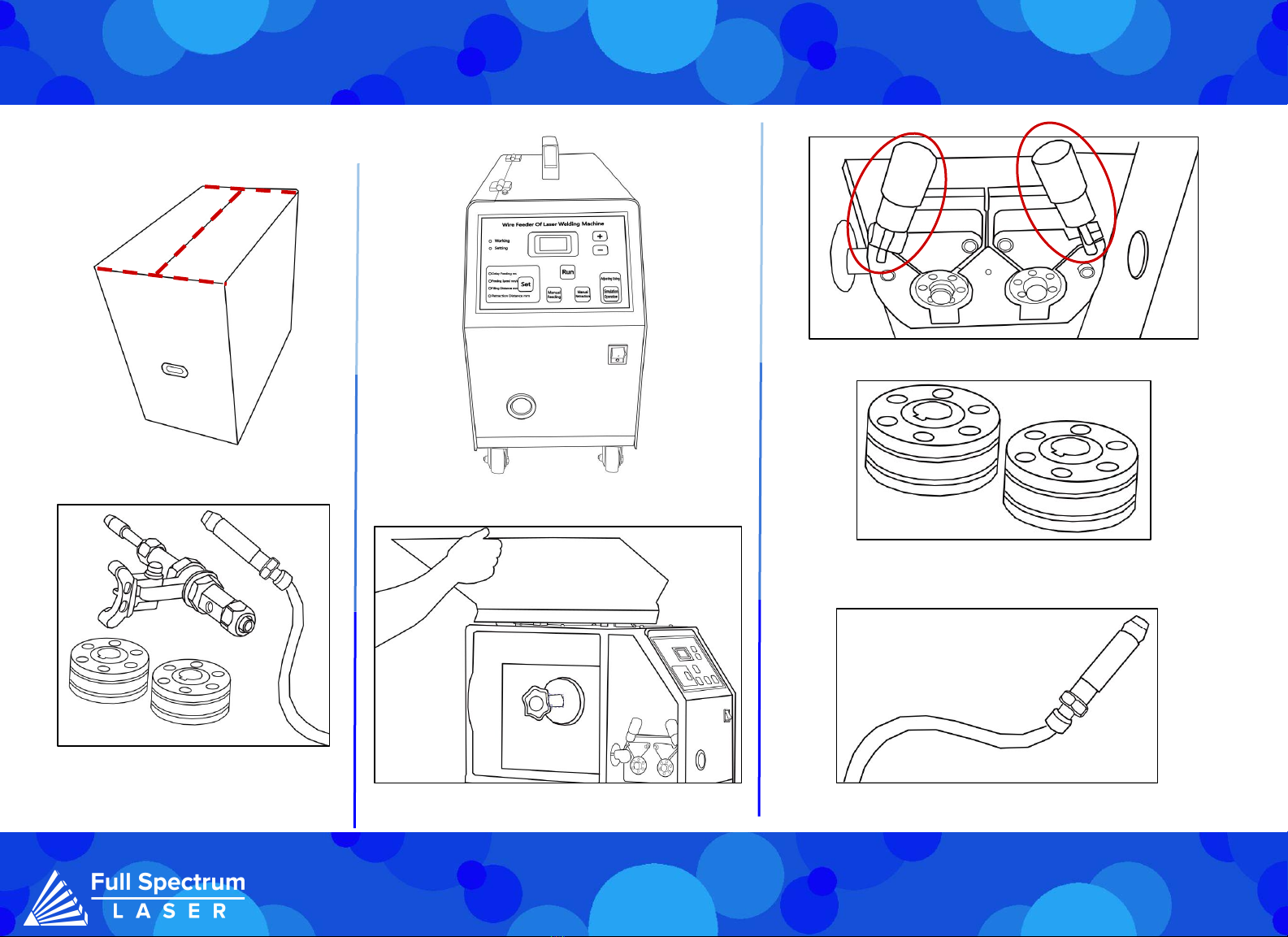

Do not leave your machine unattended.

Avoid using materials made of carbon or that contain carbon

components.

Have a fume extractor ready to catch any fumes or vapors

that may be created during the welding process

Do not store the laser machine or its accessories near eye

level. Never stare directly into the laser when running a

project. Always wear the provided safety goggles.

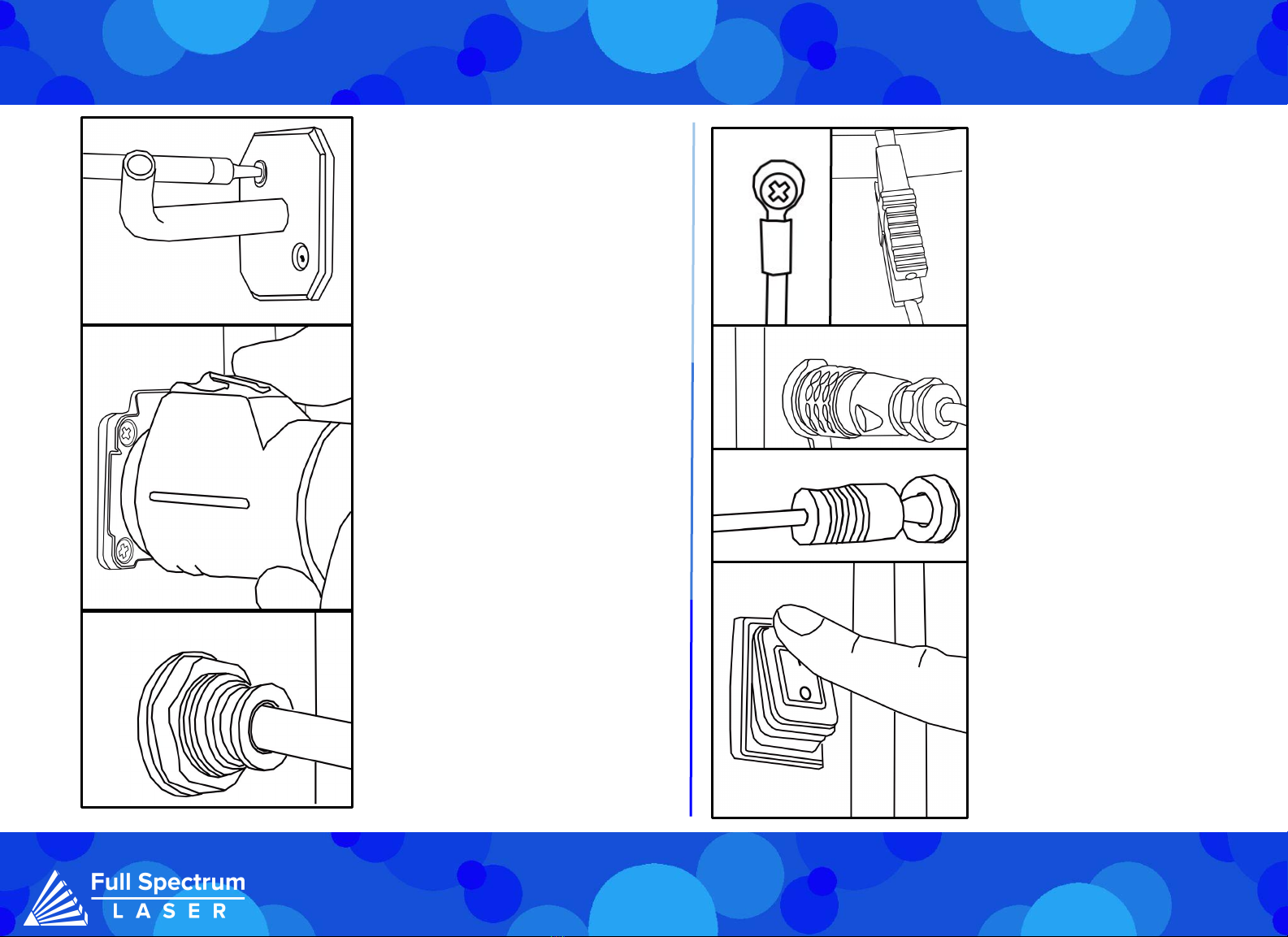

Do not run your machine is any cables or connection are

loose or damaged in any way.

Inspect your machine before each use. Do not use if the

machine or its accessories are damaged in any way.

Always maintain a clean work area.

1

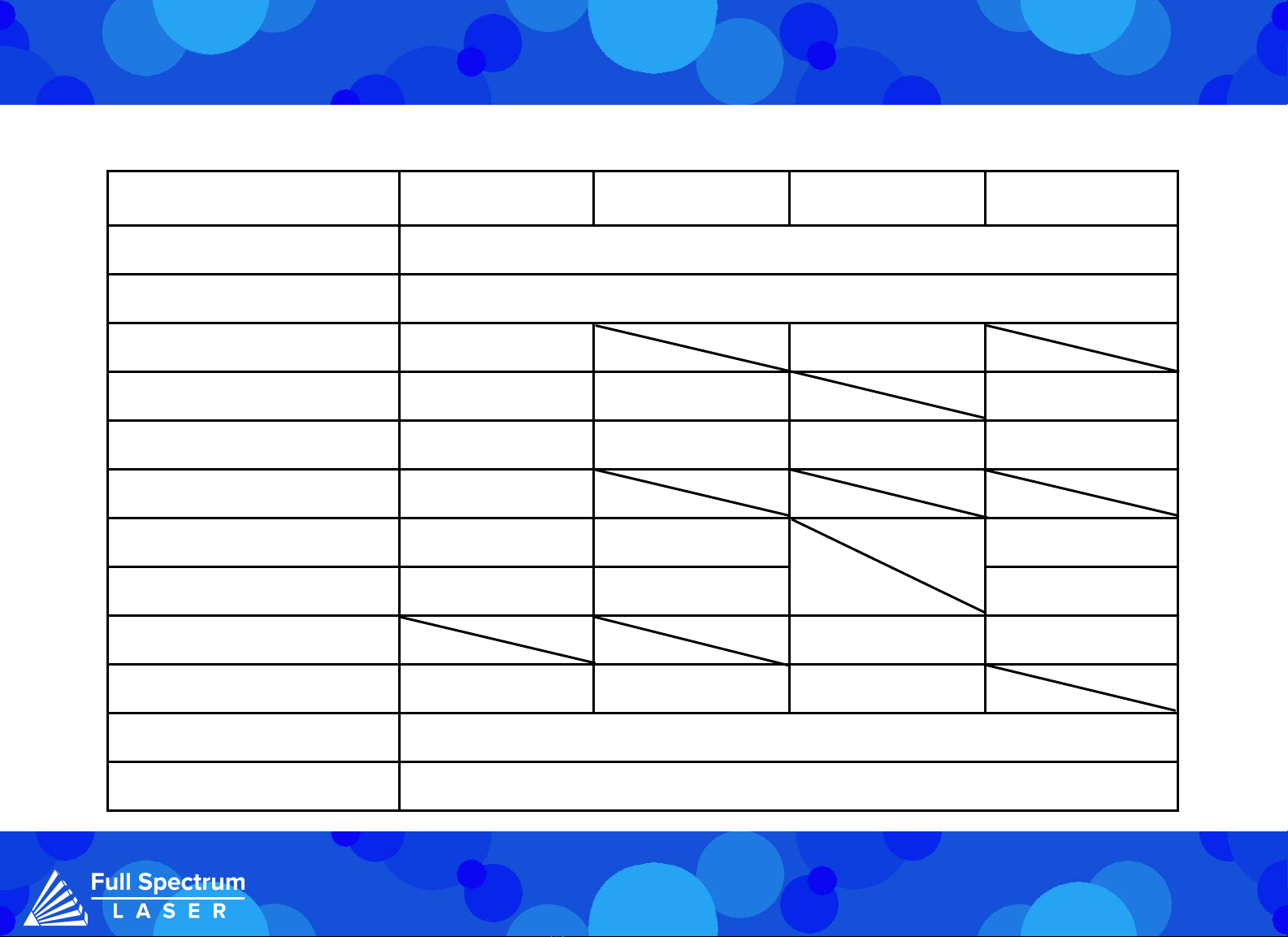

Specications:

Test Conditions

(if applicable)

Minimum Average Maximum

Operating Voltage 200V AC 220V AC 240V AC

Input Power 100 % Output 4.5 KW

Operating Ambient

Temperature

10 ℃40 ℃

Operating Ambient

Relative Humidity

10 % 85 %

Laser Cooling

Method

Air Cooled

Tip Cooling Method Nitrogen and Argon gas cooled

Storage Temperature -10 ℃60 ℃

Dimensions 667 X 276 X 542 mm

Weight < 38 kg