1 Overview

1.1 overview

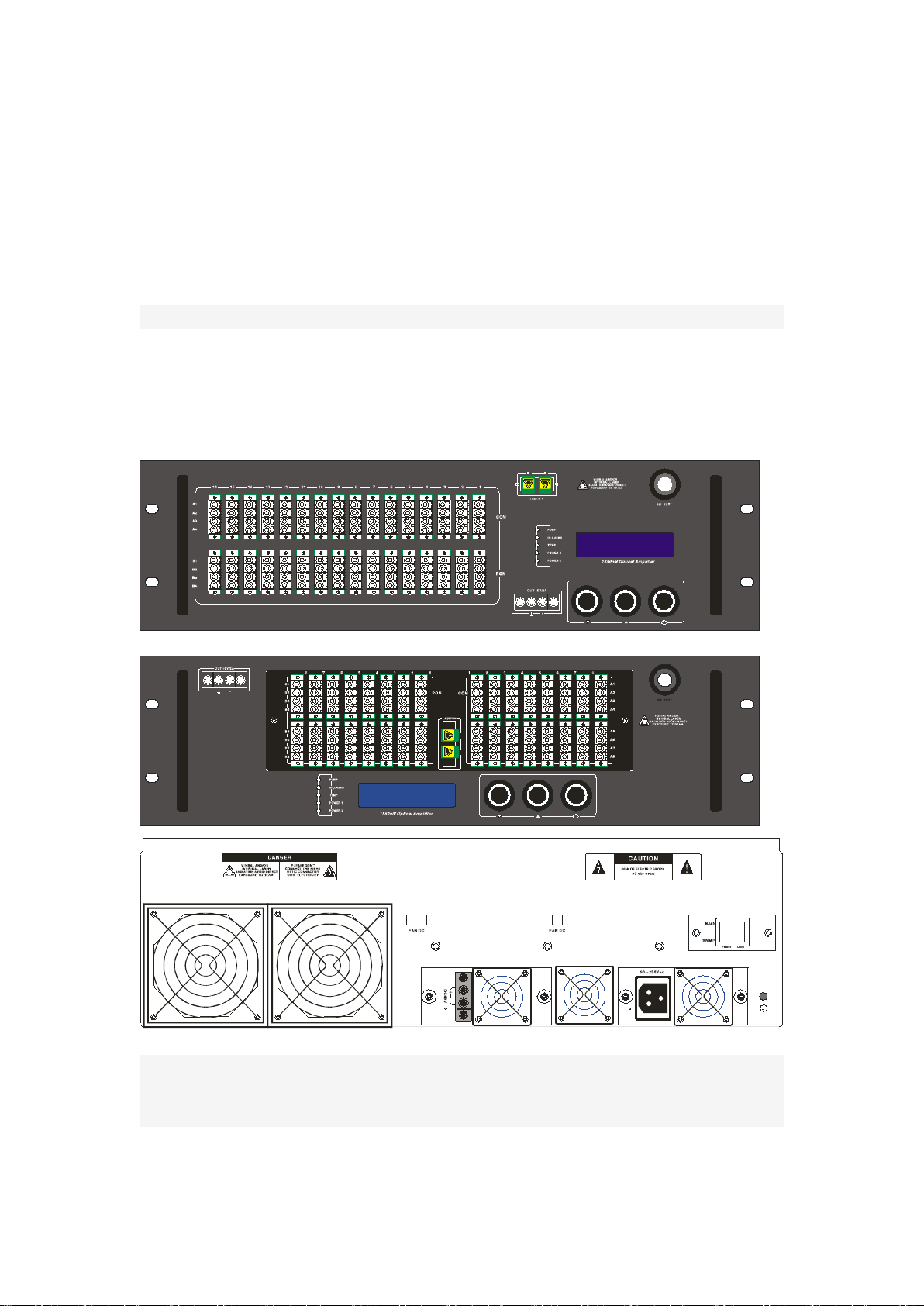

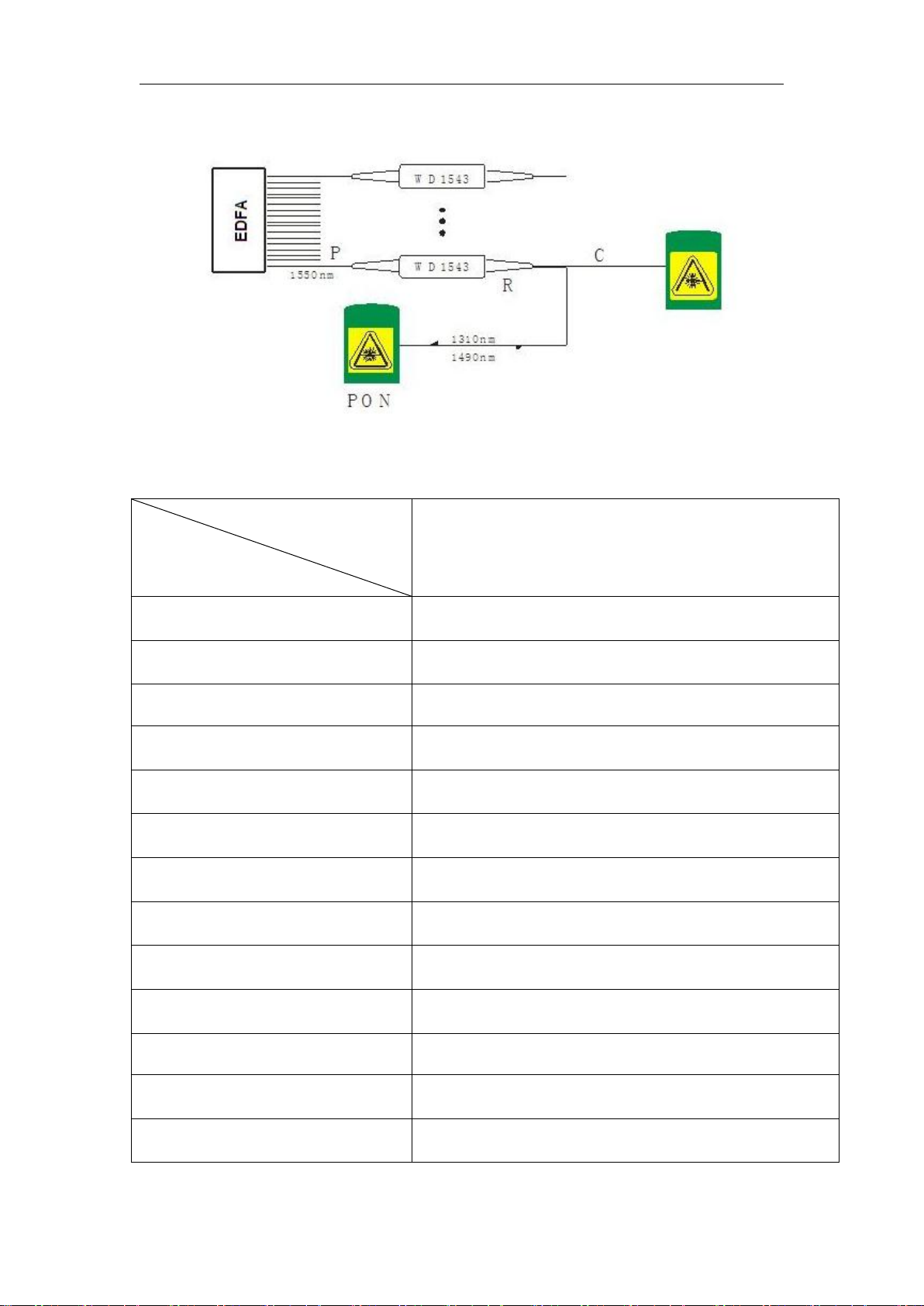

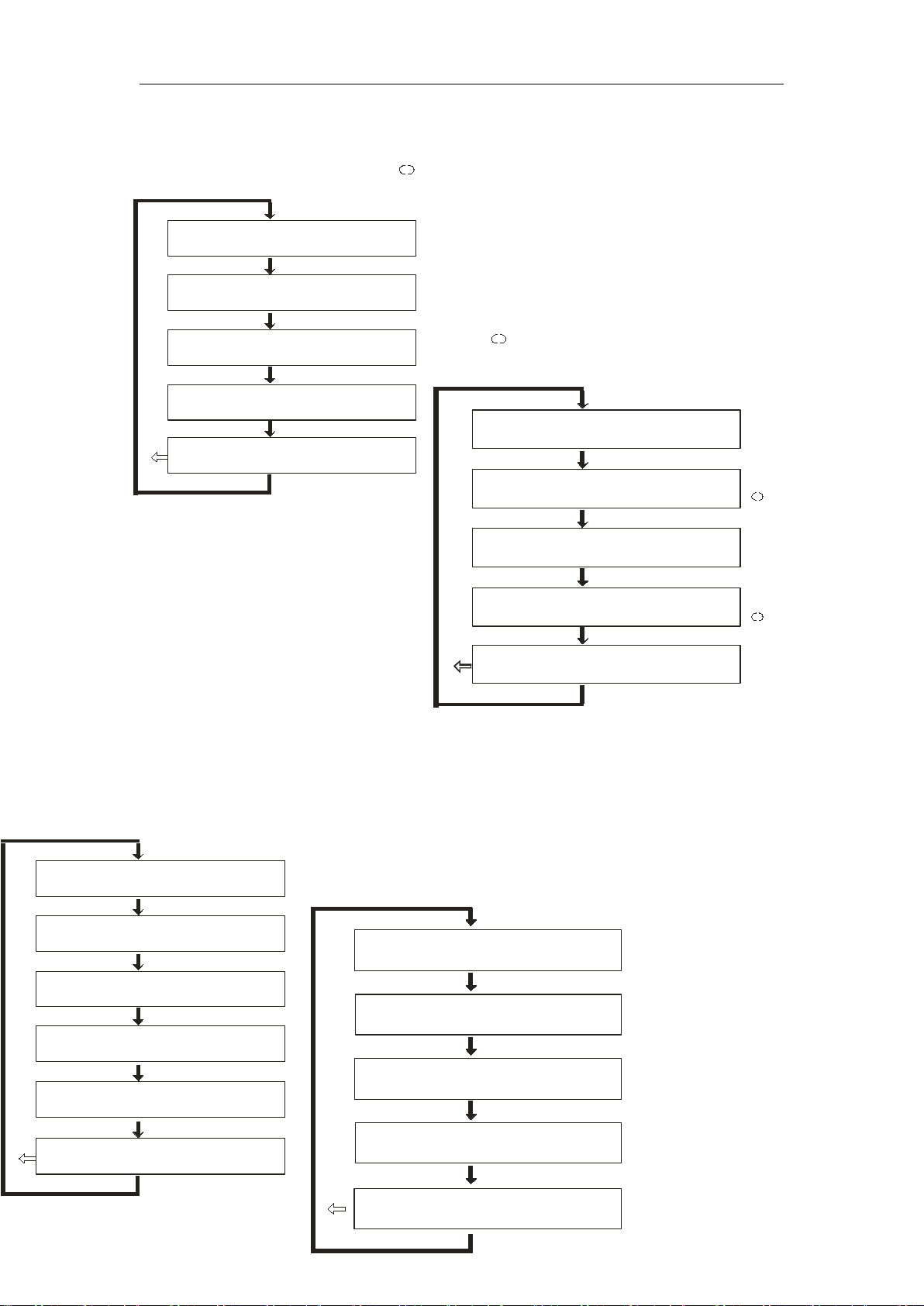

EDFA 16 pons Series WDM EDFA Combiner, High power Erbium Doped Fiber Amplifier, it is the core

equipment of three of one net in optical transmitter system, input 8 ports PON+1port CATV and output

8 ports combined 1550/1490/1310nm. The combined optical output power: 15dBm. plug-in dual power

supply, achieved the function of OLT and CATV 1550nm optical single combined and amplify, having

high cost performance value.(Erbium Doped Fiber Amplifier)is a representative one in the optical

amplifier.As the EDFA’s wavelength is 1550nm, it is in line with the low-loss band of fiber and its

technology has been relatively mature, so widely used. Erbium-doped fiber is the core components of the

EDFA, it makes quartz optical fiber as matrix material, and incorporate a certain proportion of rare earth

element erbium ions(Er3 +)in the core of a fiber.When certain amount of pump light is injected into the

erbium-doped fiber, Er3 + have been excited from the low-energy level to the high energy level, due to

Er3 + has a very short lifespan on the high energy level, and soon transit to a higher level by the form of

a non-radiative, and form the population inversion distribution between this energy level and

low-energy-level. Because the energy between these two energy levels is exactly equal to the photon

energy of 1550nm, stimulated emission of 1550nm light can only occur, we can only enlarge 1550nm

optical signal.

EDFA 16 PONS Series WDM EDFA Combiner , adopt 980nm or 1480nm high linearity, optical

isolation, the DFB, thermoelectric cooling DFB laser produced by JDSU, Fujitsu, Nortel, Lucent, Fitel

and other world-renowned semiconductor companies as the pumping source. In the interior of the

machine is equipped with the light power export stable circuit and laser thermoelectric cooling device

Temperature stability control circuit to ensure optimal machine performance and long-life laser

stability.The microprocessor software monitor the lasers’working state, the Digital Panel(VFD)displays

the operating parameters.Once the laser operating parameters deviate from the permissible range set by

the software, micro-processing will automatically turn off laser power, red light goes on to warn, digital

panel prompts cause of troubles., a detailed report of the device parameters please read"instructions.

1.2 Features

1.2.1) High quality: adopt multimode large power pump laser, power is optimized reasonably by

software, and can most unlimited reduce NF of EDFA, it is comparable with EDFA. The feature can

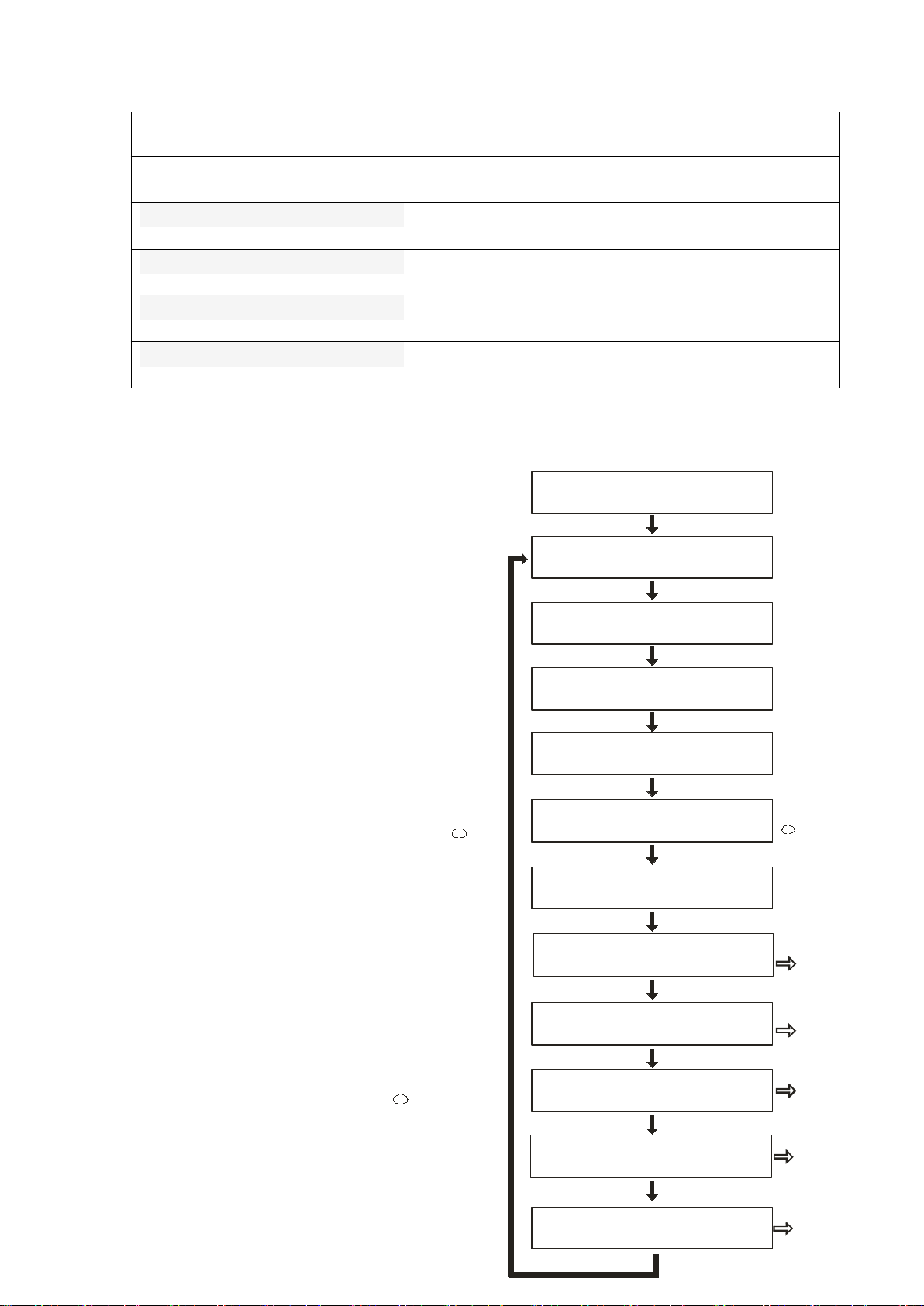

make system achieve excellent CNR. 1.2.2) Reliability: The 19 "2U rack, built-in high-performance

plug-in dual power supply, it can work at 85 ∽ 265Vac City Network Voltage, As well as an optional

DC48V power supply (reservations required);chassis cooling can be automatic control by temperature.

1.2.3) Intuition: The pump laser is the most expensive machine components, machine equipped with

microprocessor monitors the working state of the laser, the panel LCD window displays the operating

parameters. 1.2.4) Network type: Select All-piece status monitoring transponder guarantees to meet the