3

User instrucons

General

The Fumex FB fan is a radial fan for the evacuaon of

gases, smoke and low weight parcles. The fan series

conforms to the protecon and safety regulaons in

the EU's Machinery Direcve. The fans boast high

levels of quality and operaonal reliability. ALL fans

undergo inspecon and test operaon before leaving

the factory. However, risks can arise with any fan if:

- it is not installed, used or maintained by trained

personnel.

- it is not used in the intended manner.

Please note that electronic equipment is always

suscepble to stac electricity, high humidity,

high temperatures and line failures. The

equipment is supplied with high voltage. Use the

isolang switch when carrying out service work

on the fan.

The fans are not intended for use in the

evacuaon of explosive gases.

Fan installaon

Installaon may only be performed by authorised

personnel with regard to these installaon

instrucons and applicable regulaons. Make sure

that all safety-related fan components sasfy their

funcon. The stability of the fan must always be

ensured during operaon. In order to achieve

opmum funcon, it is important for the fan's duct

connecons to be correctly executed. Incorrect

installaon can cause considerable deterioraon in

the fan's performance with regard to pressure drop

and sound levels.

In order to achieve opmum performance, we

recommend that the inlet connecon is a straight

duct that is 5 mes the diameter of the duct. If an

outlet duct is used, the same applies to this. If the

system requires a 90° bend in the outlet, it should

deviate in the impeller's direcon of rotaon (see

below).

There is always a risk of clothes or loose items

being sucked into a free-blowing fan. This can

cause personal injury or damage to property.

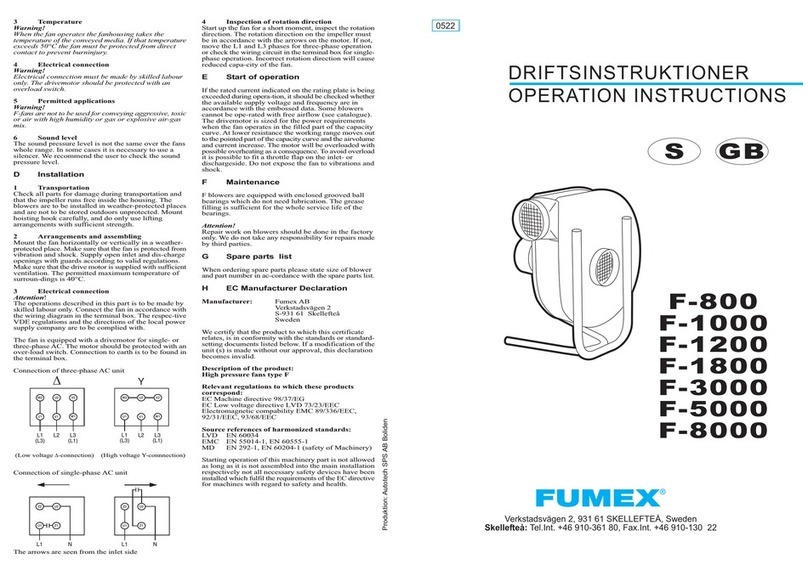

The fan is supplied with the outlet poinng as

illustrated on page 1. If an alternave outlet air

direcon is required, the fan housing can be set in 8

possible posions. If the direcon of outlet is changed,

thread locking must be applied to the screws. Take

great care to ensure that the impeller is not damaged

when reinstalling the fan housing.

In the event of outdoor installaon, a drainage hole

must be drilled at what becomes the lowest point in

the installed fan, according to the selected outlet

direcon.

In the case of professional installaon, too, fans

can produce harmful noise levels. It should also

be noted that specified noise data (see separate

product sheet) can be altered by the surroundings

or resonance in the operang locaon.

The fans are designed for installaon in systems

and therefore have no guard on the inlet. This

means that the fan must not be started unl it is

connected to a duct. The guard installed on the

outlet can be removed if you want to connect an

outlet duct (see accessories on page 8).

Maintenance

Fumex fans have been designed for connuous use for

an extended me with a high level of reliability. Like all

machines, regular servicing and maintenance are

required to achieve opmum funcon.

Fumex recommends the following maintenance

schedule:

Component Interval 6 months

Motor Check funcon. Replace motor if

necessary.

Impeller Check for any damage and clear

away foreign objects if necessary.

Replace impeller in the event of

damage.

Fan housing Check that connecons are secure

and clear away foreign objects.

Check the drainage hole and clear

if necessary.