nCalibration ( OL compensation)

Every extra plug and additional piece of

cable influences the impedance measure-

ment of the test object. This unwanted in-

fluence can be completely compensated

for by the Short Open Load method (short-

ened to SOL method).

First of all, instead of the test object, three

reference elements are measured; Short

represents a short circuit, Open, an open

cable end, and Load, a resistance in the

magnitude of the system impedance (in

our case 50 Ohms.) These reference mea-

surements can be easily obtained with ac-

ceptable accuracy using three 50 Ohms

BNC co ax plugs.

In the case of the Short element the inner

connector and the plug housing are short

circuited, for the Open element the inner

pin remains unconnected, for the Load el-

ement there is a small 50 Ohm metal film

resistor between the inner connector and

the housing. If the materials aren’t to hand

further information on the reference ele-

ments (shown in Fig.10) is available at [2].

After calibration has been completed the

calculated values are automatically stored

in the analyzer so that the correct im pe -

dance is determined when the test object

is measured.

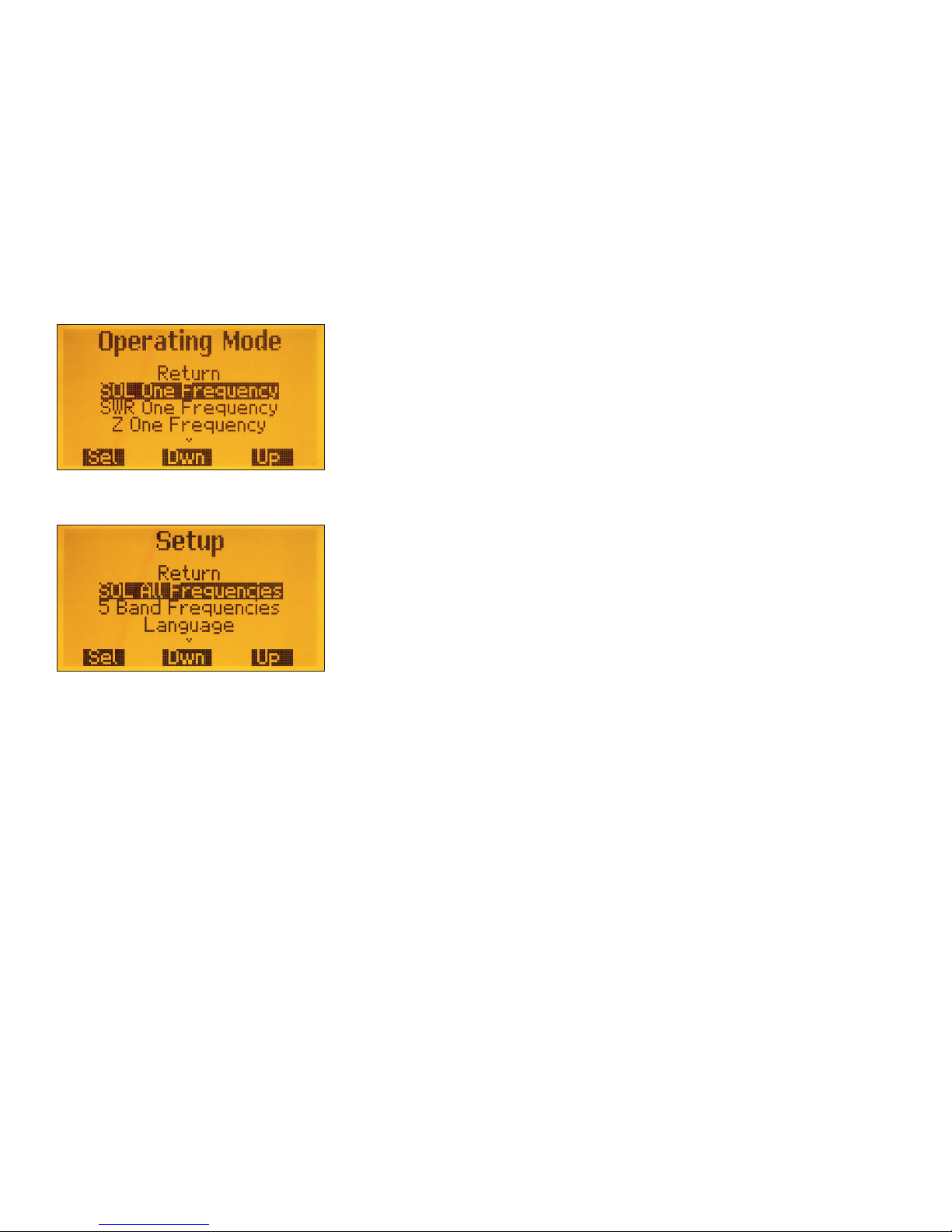

The analyzer knows two different modes

of SOL compensation.

SOL for a frequencies

It is possible to permanently save SOL ref-

erence values for the entire measuring

range. In this case, with the Short refer-

ence element connected, the analyzer runs

through the entire frequency range and

stores the determined measured values.

The same procedure is to be carried out

for connected Open and Load elements. It

is recommended to carry out this compen-

sation routine once, after commissioning,

for the built in plug, any permanently at-

tached cable or measuring device and in

between times as required. Thereafter the

measurement of a test object is possible at

any time without further compensation.

The analyzer then uses these reference

values as a standard (master compensa-

tion), in particular for multi frequency

measurements. This function can be ac-

cessed via the Operatin Mode ÆSetup

ÆSOL All Frequencies (Fig. 12).

Please note: the entire process takes sev-

eral minutes but may be cancelled, in this

case however the resulting measurements

will be inaccurate and the calibration pro-

cedure should be recommenced at the first

opportunity.

8 • BX-240 © Box 73 Amateurfunkservice GmbH 2017

Fig. 10: The optional kit for the reference

elements BX-240- OL [2] contains a 50 Ohm

termination resistor (middle) along with two

BNC co ax plugs for the Short and Open refer-

ence elements.