1

Thank you for purchasing this Furrion® product. Before operating your new product, please read these instructions carefully.

This will ensure safe use and reduce the risk of injury. This instruction manual contains information for installation, operation,

maintenance of the product and safe use.

Please keep this instruction manual in a safe place for future reference. Be sure to pass on this manual to any new owners of

this product.

The manufacturer does not accept responsibility for any damages due to not observing these instructions.

WARNING: If the information in these instructions is not followed exactly, a fire or explosion

may result causing property damage, personal injury or death.

−Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any

other appliance.

−WHAT TO DO IF YOU SMELL GAS

●Evacuate all persons from vehicle.

●Shut off gas supply at gas container or source.

●DO NOT touch any electrical switch, or use any phone or radio in vehicle.

●DO NOT start vehicle’s engine or electric generator.

●Contact nearest gas supplier or qualified service technician for repairs.

●If you cannot reach a gas supplier or qualified service technician, contact the nearest fire

department.

●DO NOT turn on gas supply until gas leak(s) has been repaired.

−Installation and service must be performed by a qualified installer, service agency or the gas

supplier.

Table of Contents

Table of Contents................................................................................................................................................................................... 1

Explanation of Symbols ........................................................................................................................................................................ 2

Important Safety Instructions.............................................................................................................................................................. 2

Ensuring a Safe Operating Environment ...................................................................................................................................................................................2

Responsibilities of the Operator....................................................................................................................................................................................................2

About Your Product ............................................................................................................................................................................... 3

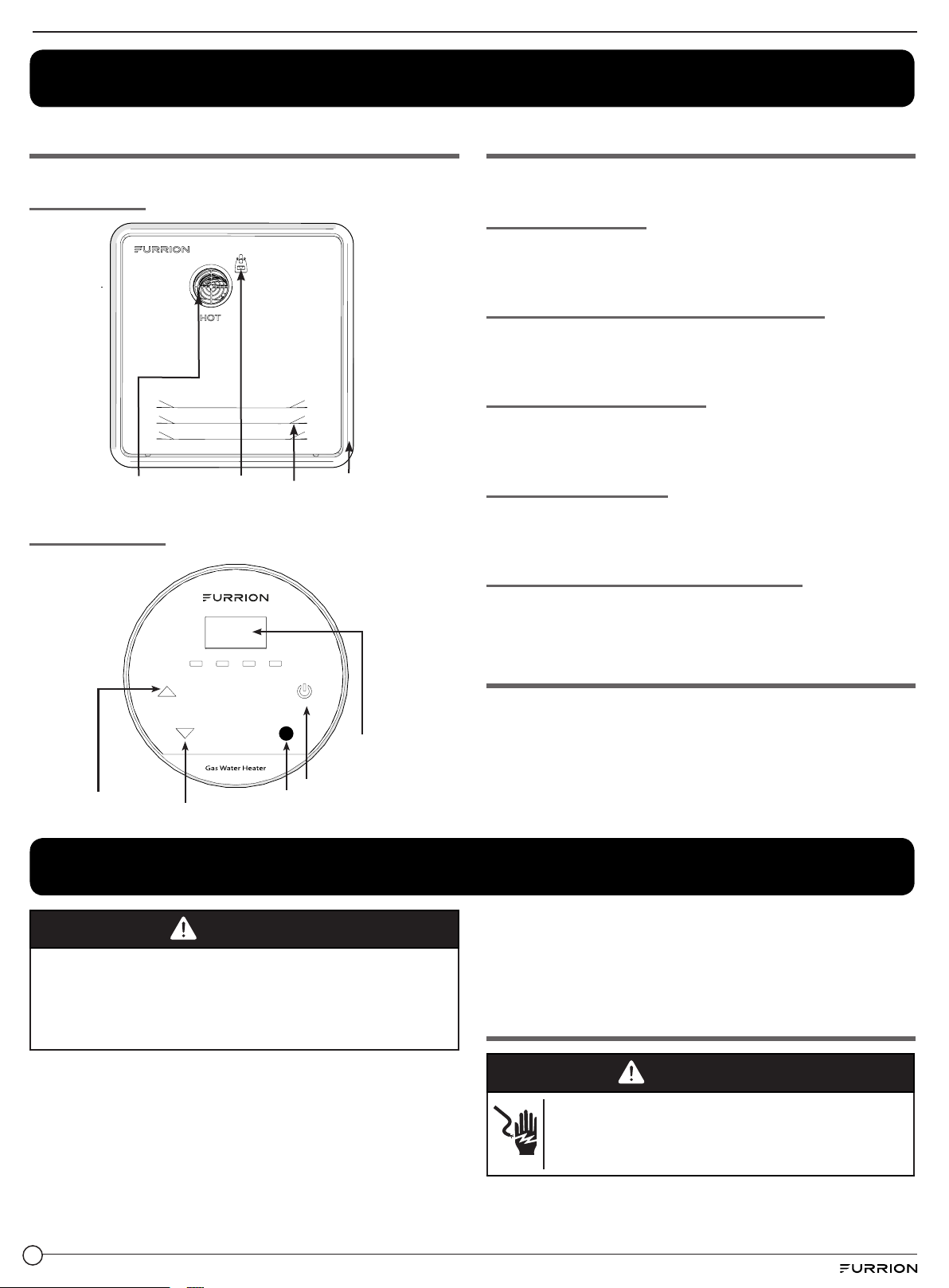

Product Overview ................................................................................................................................................................................................................................3

Product Features..................................................................................................................................................................................................................................3

Basic Function .......................................................................................................................................................................................................................................3

Installation .............................................................................................................................................................................................. 3

General Installation Safety...............................................................................................................................................................................................................3

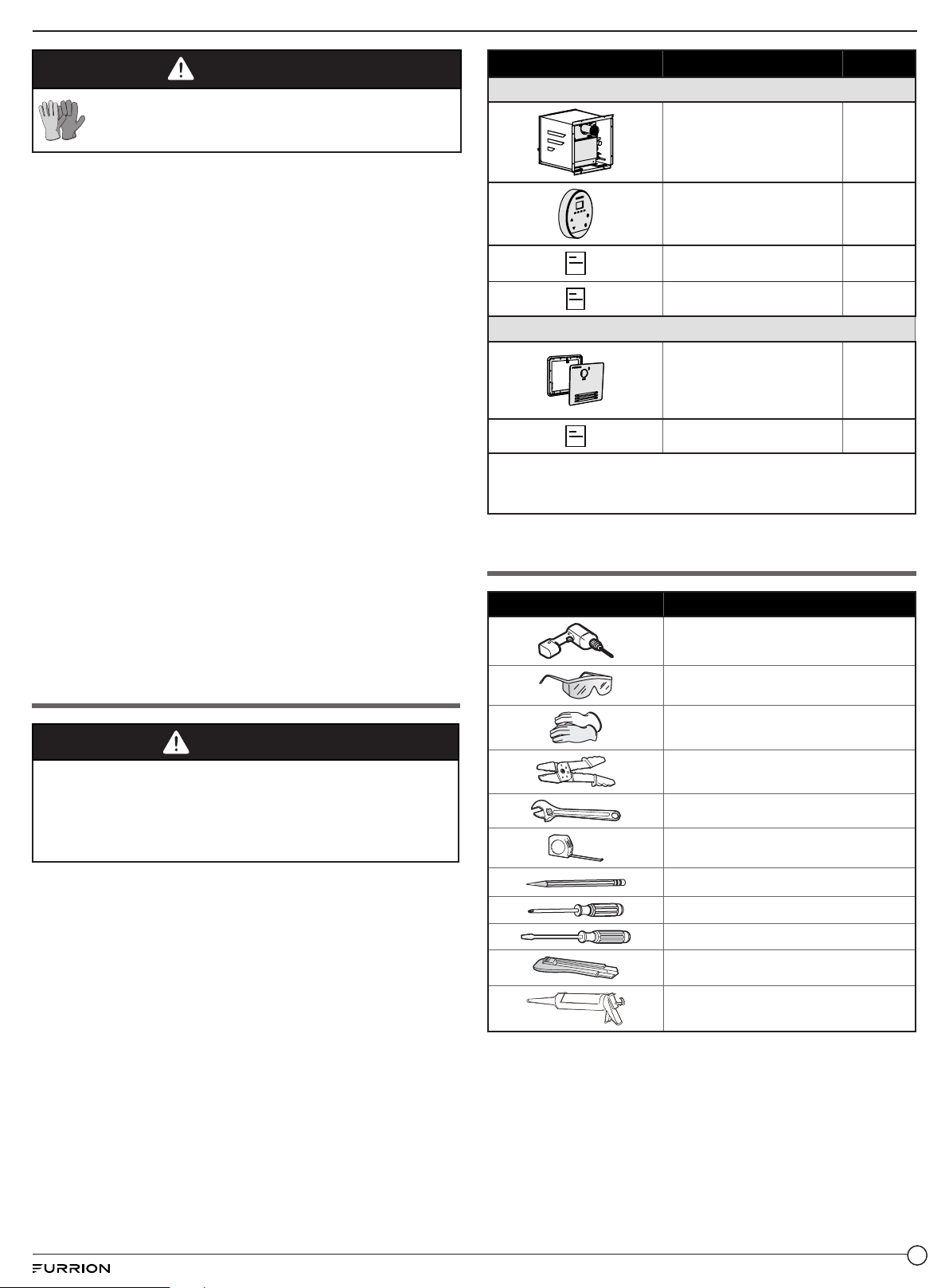

What’s in the Box ..................................................................................................................................................................................................................................4

Tools Required (Not Provided).......................................................................................................................................................................................................4

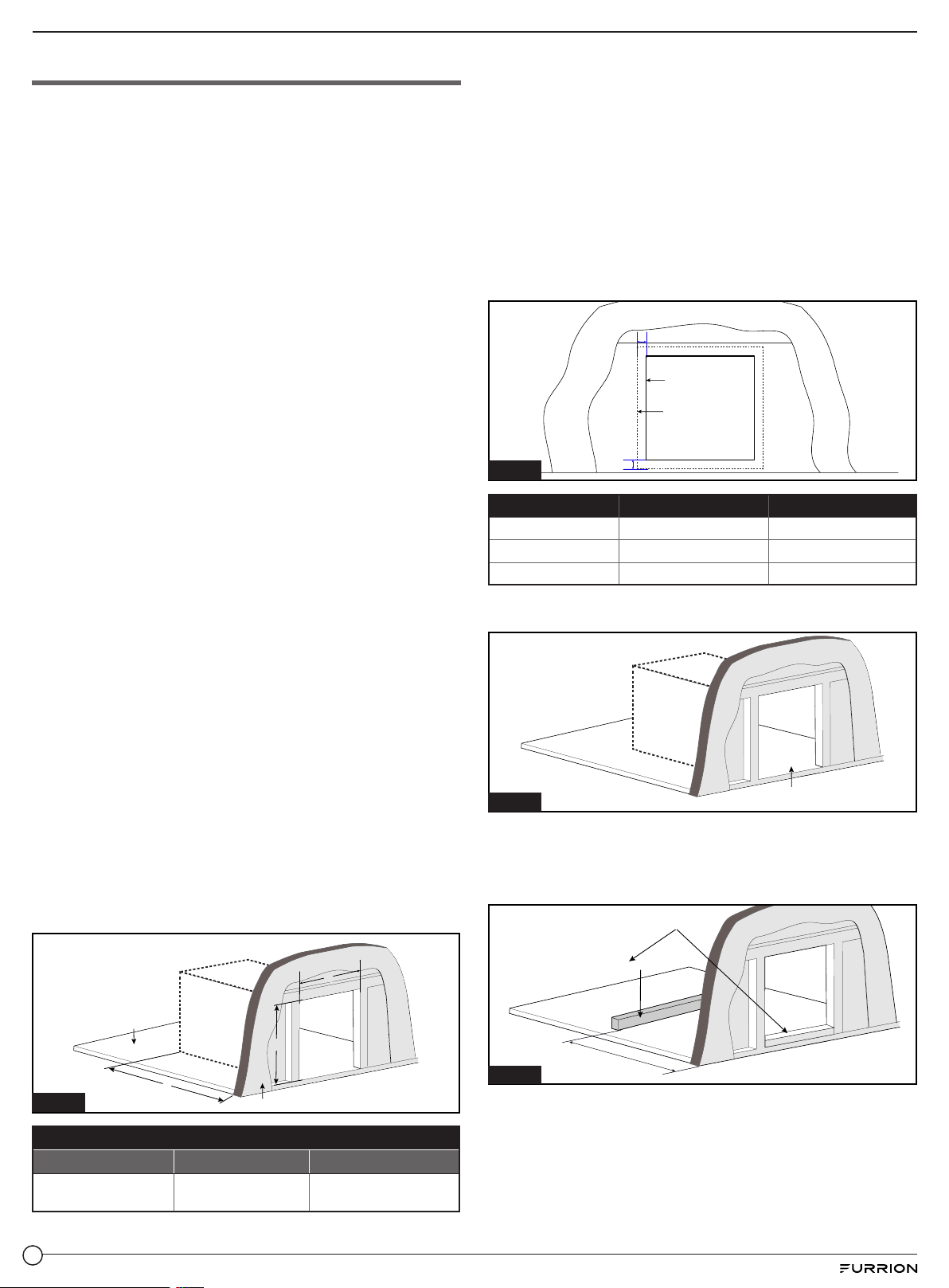

Prepare Cutout Opening...................................................................................................................................................................................................................5

Prepare Utilities.....................................................................................................................................................................................................................................6

Prepare Wall Control...........................................................................................................................................................................................................................7

Prepare Water Heater.........................................................................................................................................................................................................................8

Prepare Water Heater Door.............................................................................................................................................................................................................8

Water Heater Installation .................................................................................................................................................................................................................8

Leak Check ............................................................................................................................................................................................................................................10

Functional Test ......................................................................................................................................................................................................................................11

Operation................................................................................................................................................................................................. 11

Controller Operation...........................................................................................................................................................................................................................11

Safe Operation ......................................................................................................................................................................................................................................11

Water Control Valve.............................................................................................................................................................................................................................12

High Altitude Use .................................................................................................................................................................................................................................12

Cleaning and Maintenance ................................................................................................................................................................... 12

Storage and Transit.............................................................................................................................................................................................................................12

Winterizing Water Heater..................................................................................................................................................................................................................12

Routine Inspection...............................................................................................................................................................................................................................13

Filter Cleaning........................................................................................................................................................................................................................................14

Pressure Safety Valve Maintenance............................................................................................................................................................................................14

Hard Water and Decalcification.....................................................................................................................................................................................................14

Error Code............................................................................................................................................................................................... 15

Troubleshooting ..................................................................................................................................................................................... 16

Wiring Diagram ....................................................................................................................................................................................... 17

Specifications......................................................................................................................................................................................... 17