0 – 1

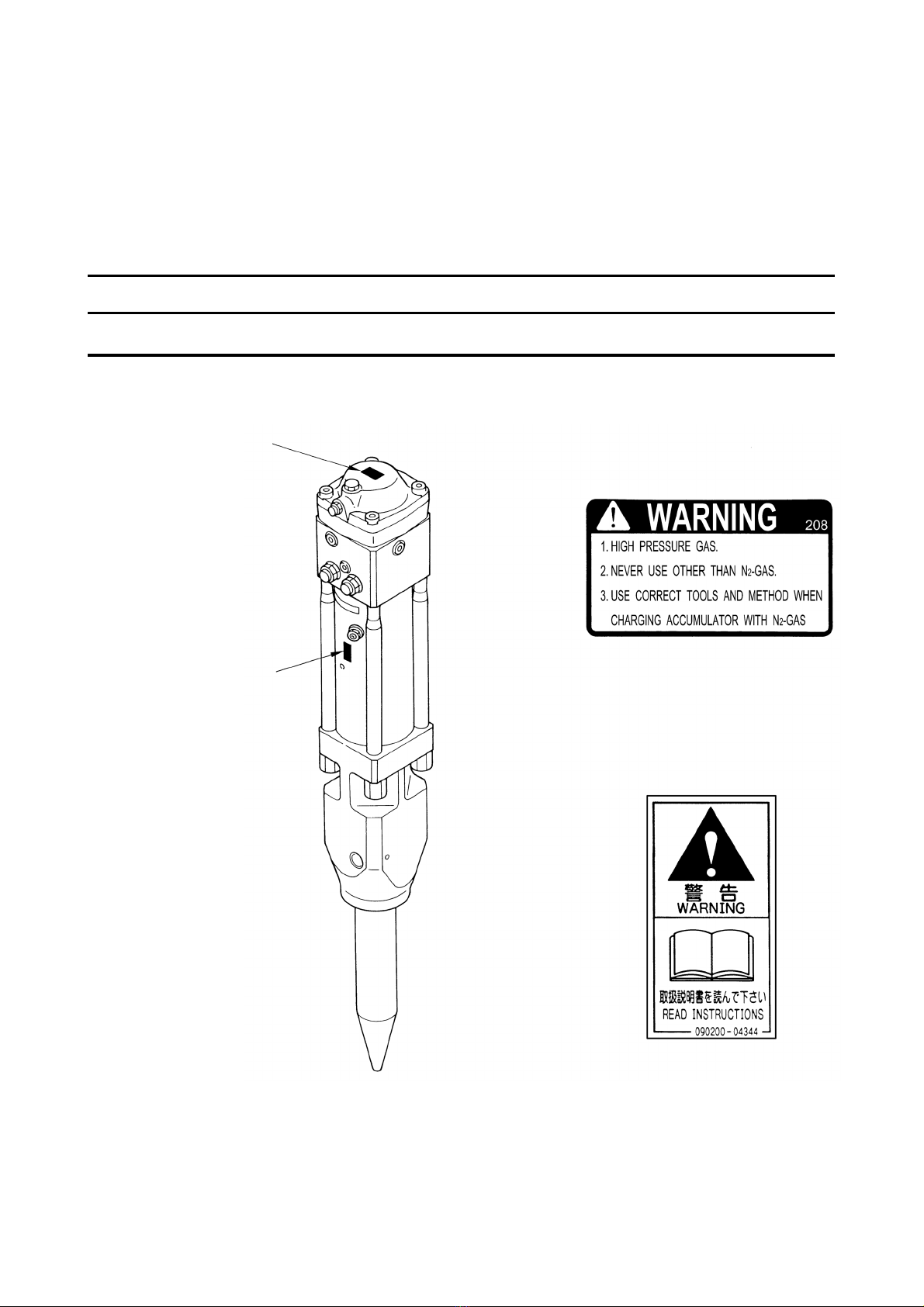

Warning for prevention of danger

DANGER

Indicates an imminently hazardous situation which, if not avoided, will result in serious

injury or death. This signal word is to be limited to the extreme situations. (Risk of

serious injury or death)

WARNING

Indicates a potentially hazardous situation which, if not avoided, could result in serious

injury or death. (Possibility of serious injury or death)

CAUTION

Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury. It may also be used to alert against unsafe practices. (Minor or

moderate injury)

NOTICE

Signs used to indicate a statement of company policy directly or indirectly related to the

safety of personnel or protection of property.

Most accidents are caused by disregarding the basic rules of operation, inspection, or repair, or by

neglecting the inspection before operation. Many accidents can often be avoided by recognizing

potentially hazardous situations before they occur. Before operating, inspecting, or repairing this

breaker, be sure to read and fully understand the preventive methods and WARNINGS described on

the breaker or in this manual. Thoroughly understand the contents of this manual before operation,

inspection, or repair of the breaker.

Safety labels and messages are classified as follows so that users can understand the warnings on the

breaker or in this manual.

The safety messages include the preventive measures to avoid danger.

For safety, common items are described in "SAFETY PRECAUTIONS," and others are mentioned in

the succeeding pages.

FURUKAWA Rock Drill cannot anticipate every possible circumstances that might involve a potential

hazard on operation, inspection, or repair. Therefore, the WARNINGS in this manual are not all

inclusive. If an operation, inspection, or repair not described in this manual is conducted, you must

assume responsibility for safety.