2.2.1 Pressure Equalisation

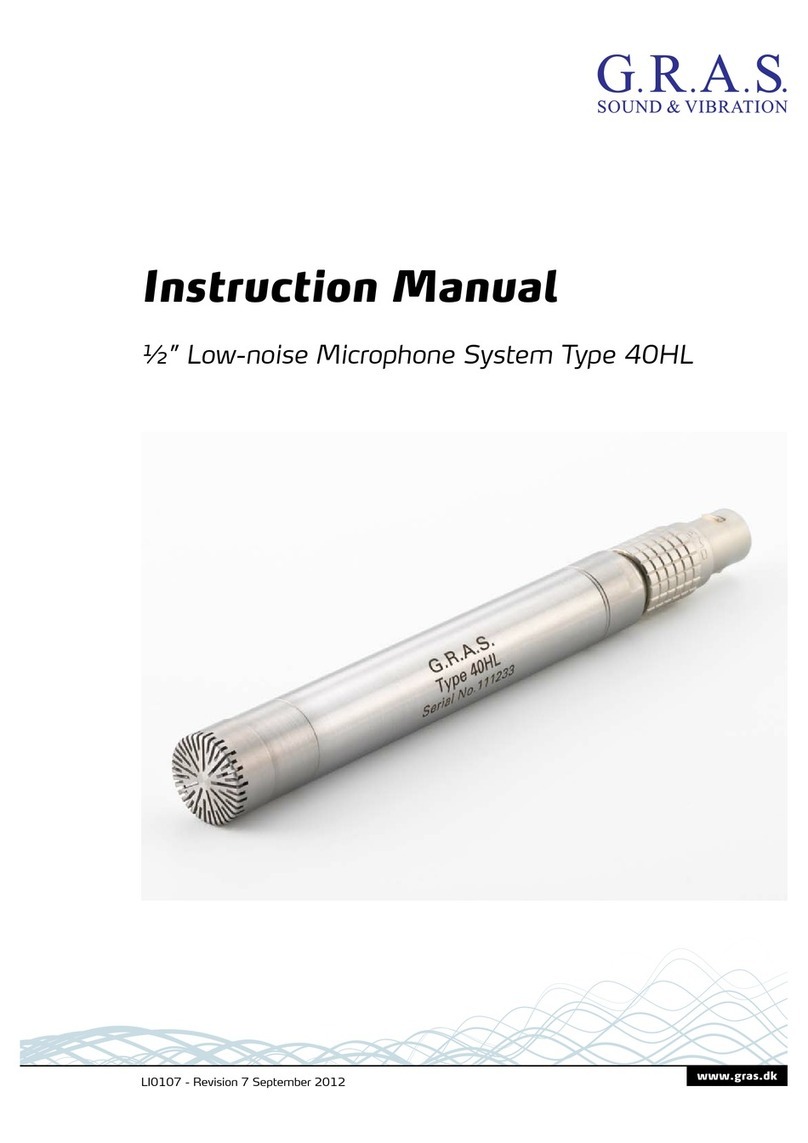

The pressure equalisation system, which ensures that the air-pressure within the cartridge of

the condenser microphone is kept equal to the ambient atmospheric pressure, allows sufciently

rapid pressure equalisation while keeping to a minimum the exchange of air between the interior

and exterior. This also extends the working life of the dehumidier.

Pressure equalisation takes place via the 1.5 mm diameter stainless-steel tube visible on the

side of the upper cylindrical section (see Fig. 2.4). This tube is also a conduit for the signal wire

connecting the calibration oscillator with the electrostatic actuator.

2.2.2 Electrostatic Actuator

The position of the actuator relative to the microphone is maintained by a calibration ring posi-

tioned under the Teon sleeve. The calibration ring ensures the correct spacing between the

actuator and the diaphragm of the microphone.

For inspection purposes, access to the signal wire in the pressure-equalisation tube is gained

after removing the rain-protection cap (see section 2.2.4) which is held in place by a left-hand

thread mushroom-head screw. In the case of the Type 41CN, the small black plastic cone

mounted on top of the screw has to be removed rst.

2.2.3 Microphone

If the electrostatic actuator, Teon sleeve and calibration ring are removed, the microphone

can be unscrewed (see section 2.2.4). The microphone is mounted on a galvanically isolated

assembly, together with a thick-lm, high-impedance input preamplier which is miniature,

ceramic-based, and robust.

Fig. 2.4 Showing microphone assembly - note the difference between

the two rain-protection caps

Rain-protection cap and actuator

Teon sleeve

Pressure-equalisation tube

Dehumidier inspection window

Transport tube

Type 41AM

Type 41CN

Add silicone grease to this thread