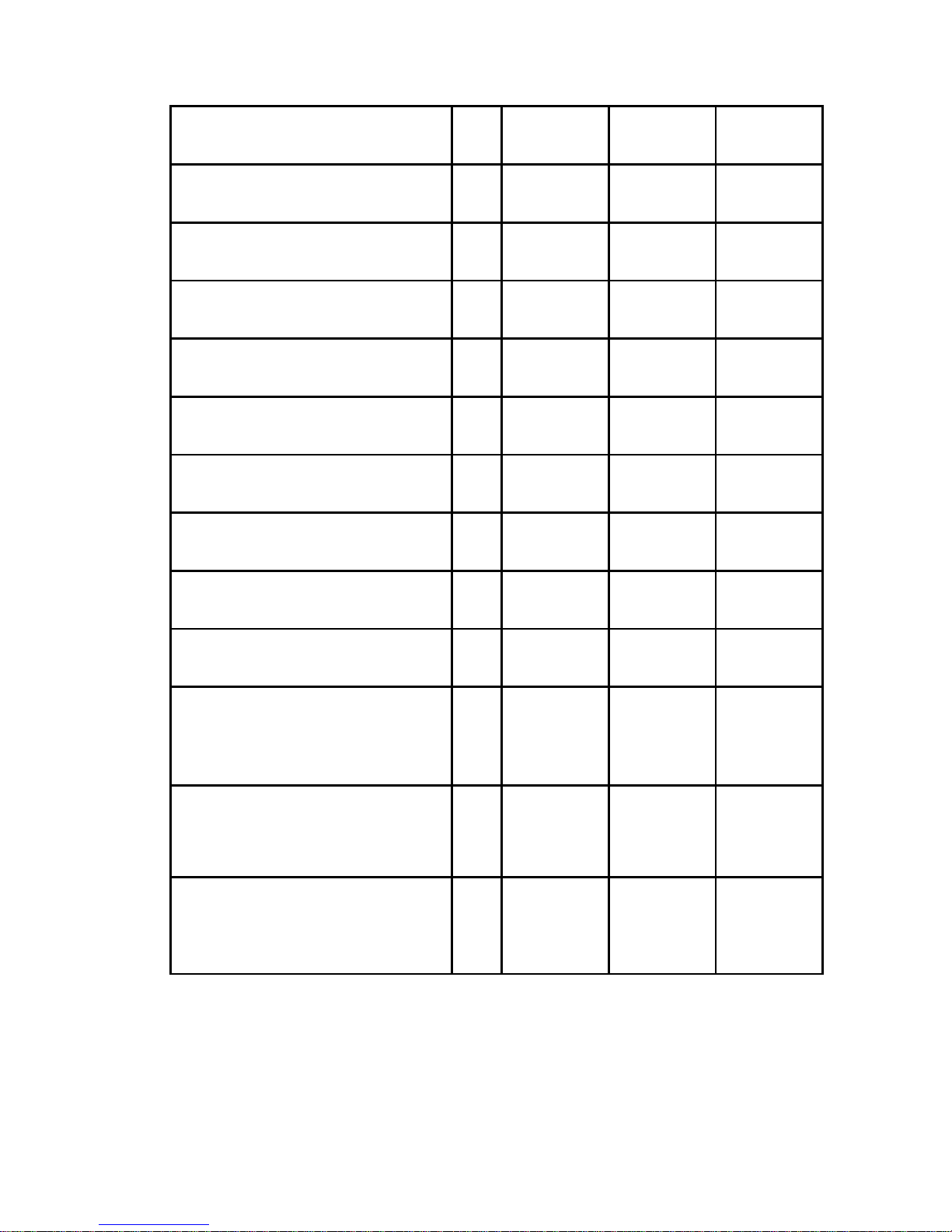

Recovery tank

污水箱容量 l 55 55 55

Wheel diameter

驱动轮直径 mm 200 200 200

Net weight without batteries

净重(不含电瓶) Kg 86 93.5 109.5

Number of batteries

电瓶数量 n° 2 2 /

Series battery voltage

电瓶电压 V 24 24 /

Single battery capacity

单个电瓶最大容量(仅供参考)

Ah (5h)

Ah (20h)

110

140

110

140

/

/

Single battery weight

单个电瓶重量(仅供参考) Kg 30 30 /

Power supply cable length

电源线长度 mm / / 500

Power supply voltage

工作电压 V 24 DC 24 DC 220/240 AC

Power supply frequency

交流电频率 Hz / / 50

Battery compartment size (length, width,

height)

电瓶箱尺寸(长,宽,高) mm

380x

360x

300

380x

360x

300

/

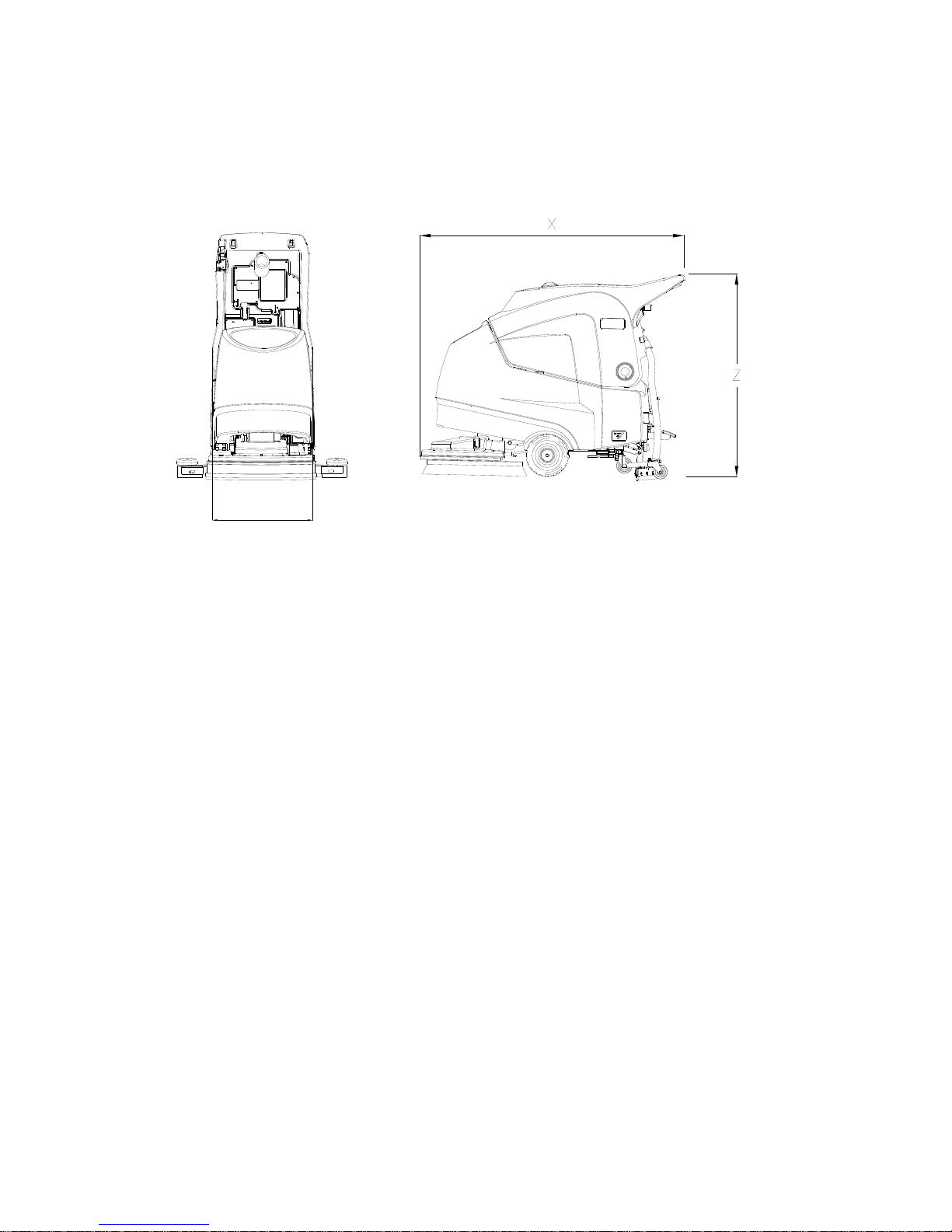

Machine size (length, width, height)

机器尺寸(长,宽,高) mm

X/Y/Z

1216x

502x

960

1216x

502x

960

1216x

502x

960

Dimensions of packing (length, width,

height)

包装尺寸(长,宽,高) mm

1268x

680x

1170

1268x

680x

1170

1268x

680x

1170

Data can be changed without notice.

以上数据制造厂商有更改的权利,无需事前通知