will vary from season to season on any

one setting of the temperature control, e.g.

if you have chosen 'Medium' power for

your preferred shower temperature in the

Summer, you may have to increase that

to 'Full' power during the Winter Months.

C. If for any reason there is a sudden rise

in water temperature, the Aqua 9000 XP

has thermal cut-out devices built-in.

D. Switch off immediately at the isolating

switch if water ceases to flow. Contact

Galaxy Customer Service for advice. If

ever the water becomes too hot and you

cannot obtain cooler water, first check that

the sprayplate in the sprayhead is not

blocked.

DO NOT place items such as soap or

Shampoo bottles on top of the unit. Liquid

could seep through the joint between the

cover and backplate, and possibly

damage the sealing rubber.

Replacement parts can be ordered from

Galaxy Customer Service..

Due to continuous improvement and

Updating, specification may be altered

Without prior notice.

5

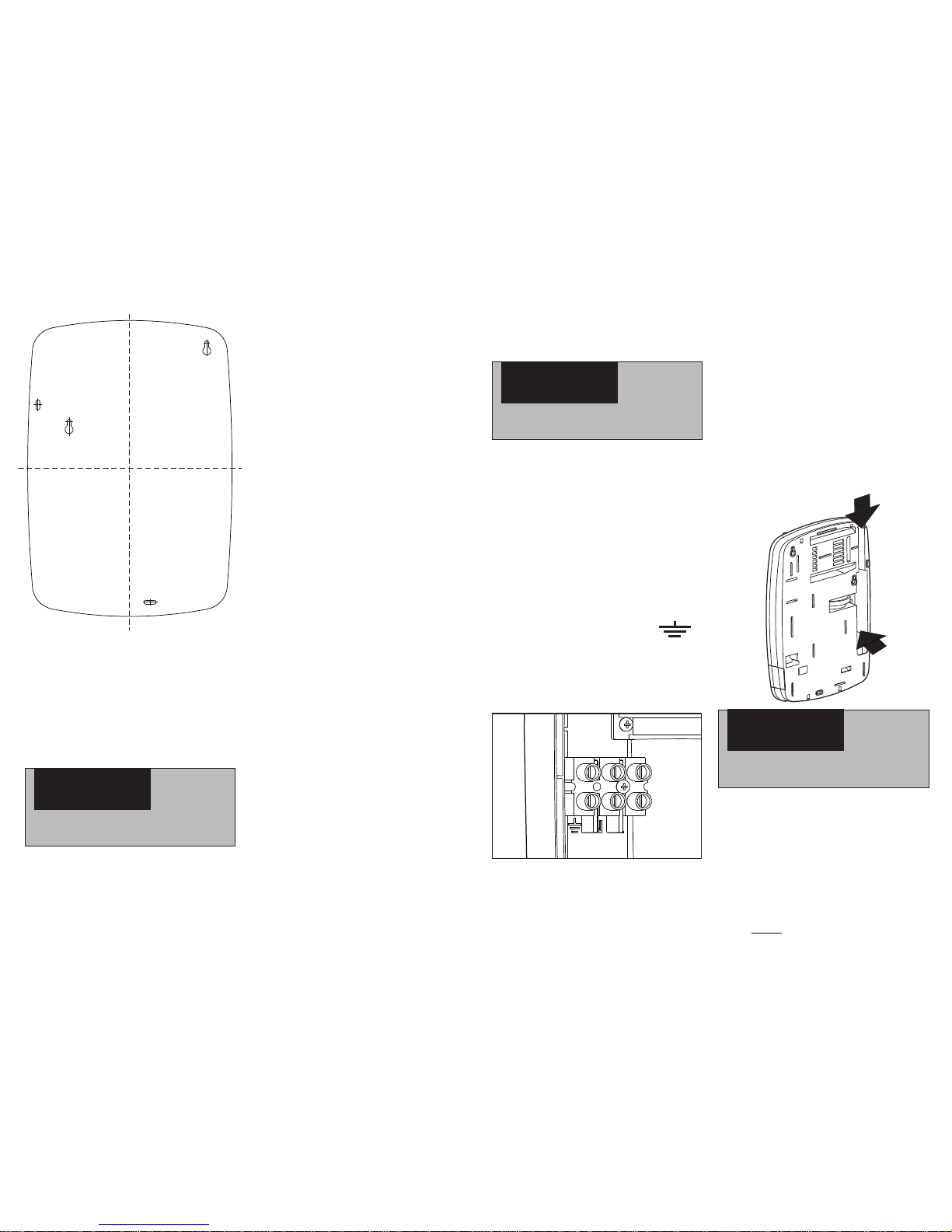

SECTION

ELECTRICAL

REQUIREMENTS

WARNING

THIS APPLIANCE MUST BE

EARTHED

The installation, supply cable and

circuit protection must conform with

IEE wiring regulations and be

sufficient for the amperage required.

2. If you are installing a shower with a

kilowatt rating above 9kW, it is

advisable to contact the local

electricity supply company.

3. The electrical rating of the shower is

shown on the rating label (Fig.1)

within the unit.

4. Before making any sort of electrical

connection within the installation,

ensure that no terminal is live. If in

any doubt, switch off the whole

installation at the consumer unit.

5. The shower must be connected to its

own independent electrical circuit.

IT MUST NOT be connected to a ring

main, spur, socket outlet, lighting

circuit or cooker circuit.

6. The electrical supply must be

adequate for the loading of the unit

and existing circuits.

7. Check your consumer unit (main fuse

box) has a main switch rating of 80A

or above and that it has a spare fuse

way which will take the fuse or mcb

necessary for the shower.

8. If your consumer unit has a rating

below 80A or if there is no spare fuse

way, then the installation will not be

straight forward and may require a

New consumer unit serving the house

or just the shower.

9. You will need to contact the local

electricity company.They will check

the circuit and carry out what is

necessary. They will also check the

main bonding.

10. The earth continuity conductor of the

electrical installation must be

effectively connected electrically to all

exposed metal parts of other

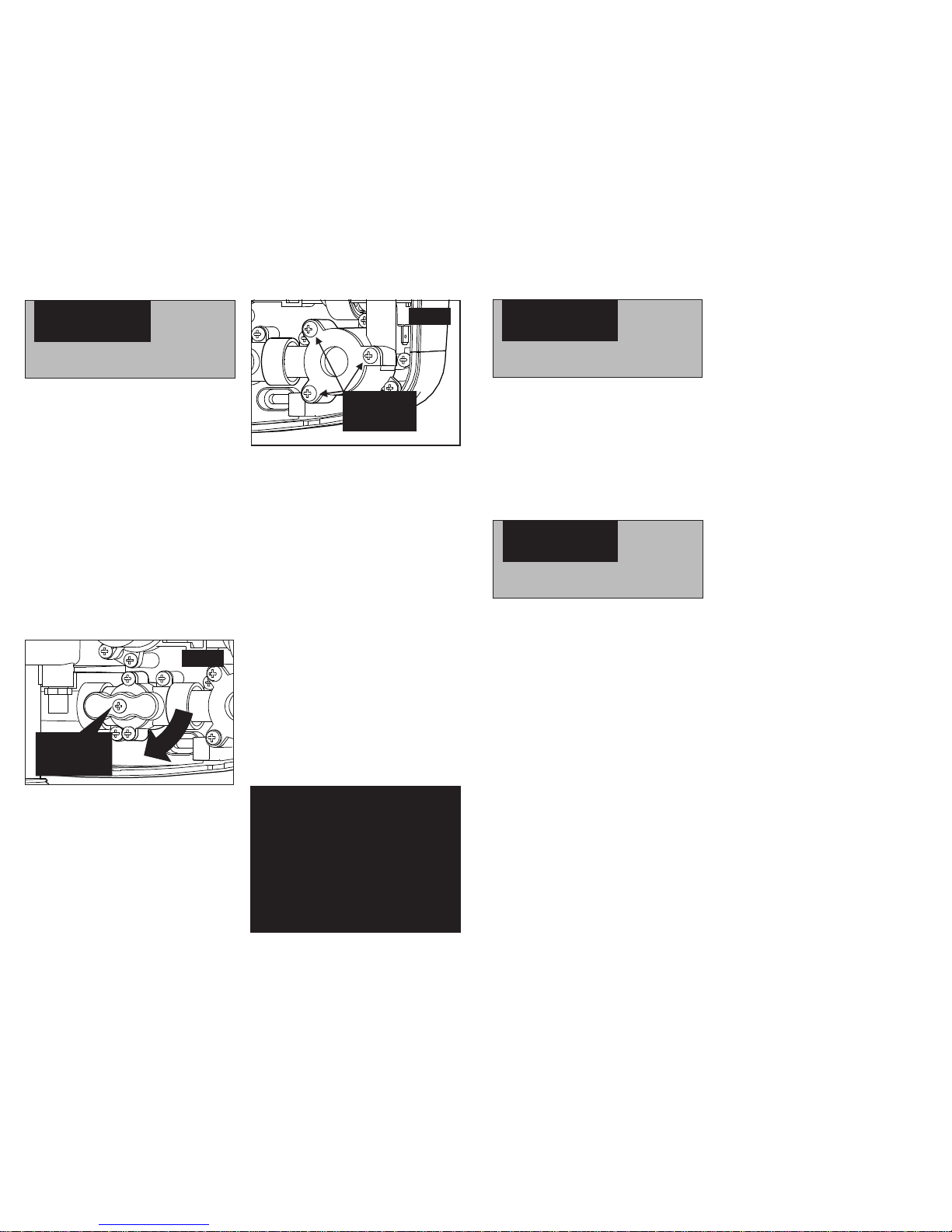

MAX SUPPLY HEAD 10 METRES

MIN SUPPLY HEAD 0.08 METRES

RATING 20 MINS ON/60MINS OFF

RATED PRESSURE 0.Pa

THIS SHOWER UNIT WILL NOT

EXCEED A FLOW RATEOF 20 LPM

GALAXY SHOWERS

COVENTRY UK

REGISTERED DESIGN

Model: AQUA 9000XP

8.5KW 240V IPX4

SERIAL No: A9XP70005

1 2 3 4 5 6 7 8 9 10 11 12

The following notes are for guidance only:

1. The shower must only be connected

to a 230-240V ac supply.

Fig.1

‘High’ setting (Double Solid Red Symbol):

Is maximum power setting which

Allows the highest flow achievable

for your preferred temperature.

Temperature adjustment at this

setting is via the temperature

control.

To adjust the shower temperature

The shower temperature is altered by

increasing or decreasing the flow rate of

the water through the shower via the

temperature control (Fig.19b).

After obtaining your preferred shower

temperature, the number can be

remembered as the normal setting and

should only need to be altered to

compensate for seasonal changes in

ambient water temperatures.

NOTE: To decrease the shower

temperature.

Turn the temperature control anti-

clockwise towards the

To increase the shower

temperature.

Turn the temperature control

clockwise towards the higher

numbers; this will decrease the

water flow.

CAUTION: Be certain the showering

temperature is satisfactory by testing

with your hand before stepping under

the sprayhead. There will always be a

time delay of ten to fifteen seconds

between selecting a flow rate and the

water reaching the stable temperature

for that flow rate.

It is recommended that persons who

may have difficulty understanding or

operating the shower controls should

not be left unattended whilst

showering. Special consideration

should be given to young children and

the less able bodied.

Power on indicator (Fig.20)

The Blue power neon will light when the

start/stop button is pressed. This indicates

that power is on to the pump and power

Selector.

15

SECTION

OPERATING FUNCTIONS

Low water pressure cut-out

Should the water pressure fall below the

minimum required to operate the shower,

power will be switched off to the heating

elements preventing any maintained

temperature rises.

Overheat cut-out

During normal operation if an overheat

temperature is sensed, power to the

elements will be reduced. Water will

continue to flow. When the temperature

has cooled sufficiently, power to

the elements will be automatically

restored to the previous setting at the time

of interruption.

Safety cut-out

The unit is fitted with a non re-settable

over-temperature safety device. In the

event of abnormal operation which could

cause unsafe temperatures within the unit,

the device will disconnect the heating

elements. It will require a visit from a

qualified engineer to determine the

nature of the fault and replace the safety

Fig.20

Blue Power

Neon