7

SECTION

FITTING THE COVER INTO

POSITION

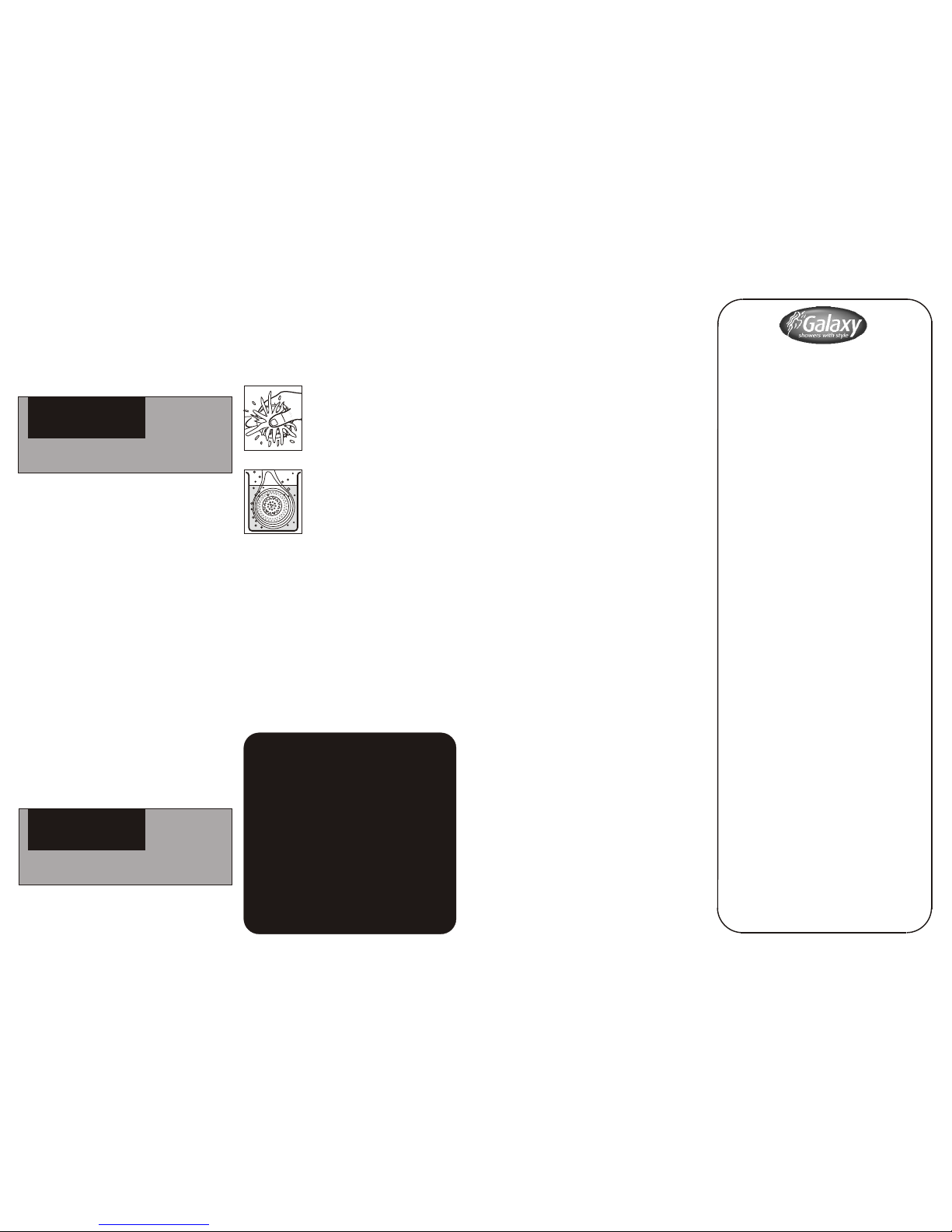

1. Turn the flow control knob spindle anti-

clockwise until the valve is fully open,

before switching on the unit (See Fig 1).

This will ensure a fast fill up of the unit

when the shower is first switched ‘ON’.

IMPORTANT!

THE SHOWER MUST BE FULL OF

WATER BEFORE HEAT SETTINGS ARE

USED.

Secure the cover with the two fixing

screws provided.

Switch on the power to the shower unit at

the consumer unit and the double pole

switch. At this stage the power selector

knob should be on the COLD position

(Solid Blue Symbol).

Remove the shower head from the flexible

hose and point to waste.

I

I

I

I

Connect the live cable to the terminal

marked L.

Connect the neutral cable to the terminal

marked N.

Connect the earth cable to the terminal

marked E on the back plate.

IMPORTANT

Ensure that the terminal block screws are

fully tightened and that no cable insulation

is trapped under screws,

Ensure the cable clamp is used to secure

the cable.

The earth continuity conductor of the

electrical installation must be effectively

connected to all exposed metal parts of

other appliances and services in the room

in which the shower unit is installed to

confirm with IEE regulations.

I

I

I

I

FLOW

SPINDLE

1

2

Start the shower unit by press the START/

STOP button. Let the water flow through

the shower unit to release any air which

may be in the system and fill the shower

unit with water.

2. It may be necessary to reposition the

flow control knob in the cover. This can

be done by turning the flow control knob

clockwise, on the full power setting until

you get a nice warm shower (See Fig 1).

Let the shower run for a short time then

switch the shower unit OFF by pressing

the START/STOP button. Also switch

OFF the power and pull cord switch.

Remove the cover and reposition the

flow control knob in the roughly an

8 o’clock position. Refit the cover.

I

HOT COLD

Fig 2

Fig 1

You should now be able to get a HOT

shower with the knob positioned at

about 11 o’clock and a COLD shower

with the knob positioned at about

1 o’clock by turning the flow control

knob anti-clockwise (See Fig 2).

Re-fit the shower head to the flexible hose.

Your shower is now ready to use. We

recommend that you allow your shower to

reach a stable temperature before you

commence showering.

I

I

8

SECTION

RISER RAIL & SOAP DISH

FITTING INSTRUCTIONS

TIPS

A piece of insulating or masking tape

applied to the wall before marking out the

fixing holes will help stop the drill from

wandering, particularly on tiled surfaces.

When working near a basin or bath, insert

the plug in the waste fitting so that small

parts cannot be lost. Take care not to drop

accessories or tools into basin or bath.

CAUTION

Check there are no hidden cables or pipes

before drilling holes for wall plugs. Exercise

great care when using power tools near

water. The use of a residual current device

(RCD) is recommended.

1. Establish position for the

riser rail, and mark the wall for

the lower mounting bracket.

Make allowances for the tallest

person likely to use the shower

regularly.

2. Use a No 10/5.5mm masonry

drill to make a hole 35mm deep,

and fit the wall plug. (NB some

wall constructions may require the

use of alternative types of wall

fixings).Screw the lower bracket

base to the wall.

4. The crimped end of the riser

rail. NOTE If it is necessary to

shorten the rail, use a junior

hacksaw to cut the excess material

from the plain end of the rail.

3. Locate the crimped end of

the riser rail (Figure 4) into the

mounting bracket, then fit the

upper bracket. Ensure the rail is

vertical, then mark the wall for

the fixing.

5. The three components that

comprise the Handset Height

Adjuster assembly are produced

with alphabetical ‘A’s and ‘B’s

moulded into the end section of

each part. Simply just match the

letter identification of each part with the central

piece i.e. ‘A’ to ‘A’ and ‘B’ to ‘B’ for correct

assembly.

6. With the showerhead height

adjuster lever set a 3 o’clock

and the showerhead holder in

the upright position, slide the

assembly onto the rail. Tighten

to the rail by turning the lever.

7. To lock the Handset Height

Adjuster at your chosen position

on the rail. Turn the lever up

right. This action is also used for

holding the showerhead at the

angle required.

8. Re-assemble the rail and

screw the upper mounting

bracket in place.

9. Slide the end cap onto the

mounting brackets.

10. Snap the soap dish onto the

rail below the holder assembly.