- 2 -

OPERATION MANUAL AND WARRANTY CARD

"Galmet Sp. z o.o.”

Table of contents

1. Use and operation...................................................................................................................3

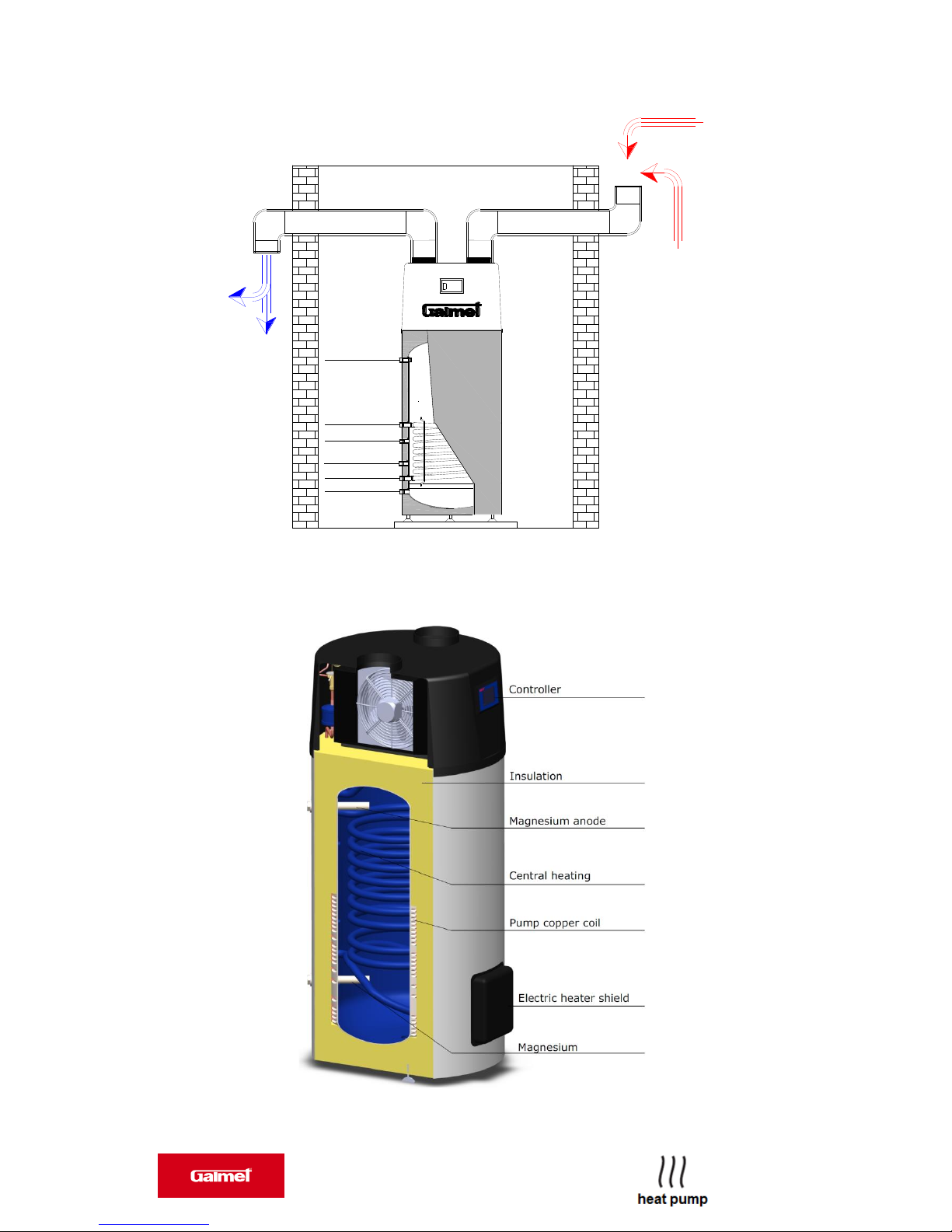

2. Device description..................................................................................................................3

3. Proper operation.....................................................................................................................4

4. Improper operation.................................................................................................................4

5. Operating principle.................................................................................................................4

6. Heat pump specifications.......................................................................................................5

7. Maintenance:..........................................................................................................................5

8. Checking and moving the device...........................................................................................5

9. Schematic diagrams of the heat pump....................................................................................6

9.1. General dimensions........................................................................................................... 6

9.2. Transport method..............................................................................................................7

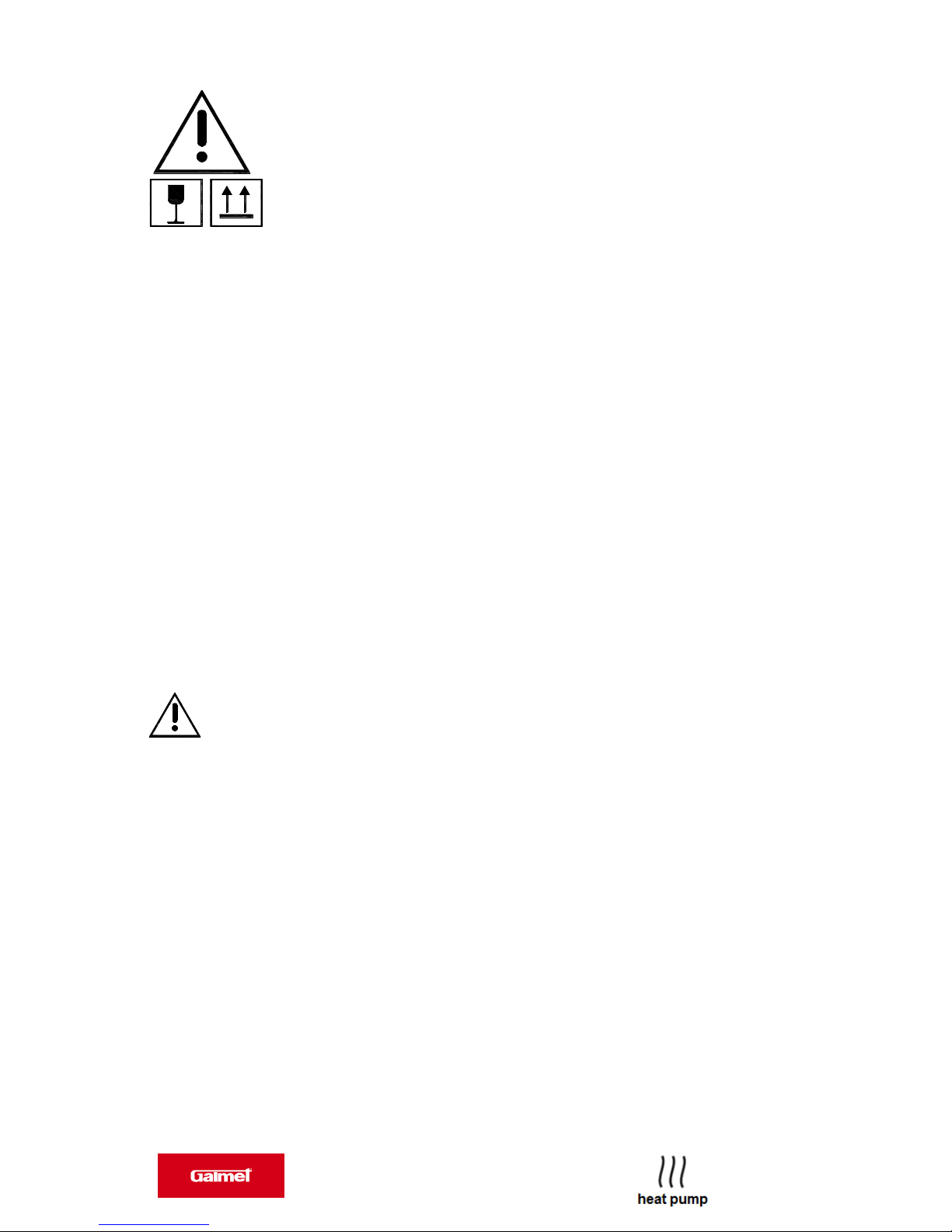

10. Connection diagram for heat pump air duct.........................................................................7

10.1. Installing the heat pump indoors.....................................................................................8

10.2. Heat pump positioning inside the boiler room................................................................8

10.3. Heat pump air supply from the outside and air discharge into another room.................9

10.4. Air pump supply from the boiler room and air discharge outdoors................................9

10.5. Supplying and discharging air from the heat pump outdoors.......................................10

11. Description of heat pump connections...............................................................................10

12. Schematic diagram of the heat pump hydraulic system.....................................................11

13. Connections........................................................................................................................11

14. Schematic diagram of the device hydraulic system...........................................................12

15. Schematic diagram of the device electrical wiring ............................................................13

16. Troubleshooting guide........................................................................................................15

17. Device inspection card .......................................................................................................15

18. Declaration of Conformity.................................................................................................15

19. Notes...................................................................................................................................17

20. Warranty Terms and Conditions........................................................................................18

21. Warranty card.....................................................................................................................19